Variable pressure absorption method for increasing absorption phase product yield

A technology of pressure swing adsorption and adsorption phase, which is applied in the field of pressure swing adsorption to achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This example is a pressure swing adsorption method for separating and recovering ethylene from catalytic cracking dry gas in an oil refinery, with a dry gas flow rate of 30,000 Nm 3 / h, its gas composition is shown in Table 1:

[0054] Table 1 Dry gas composition V%

[0055]

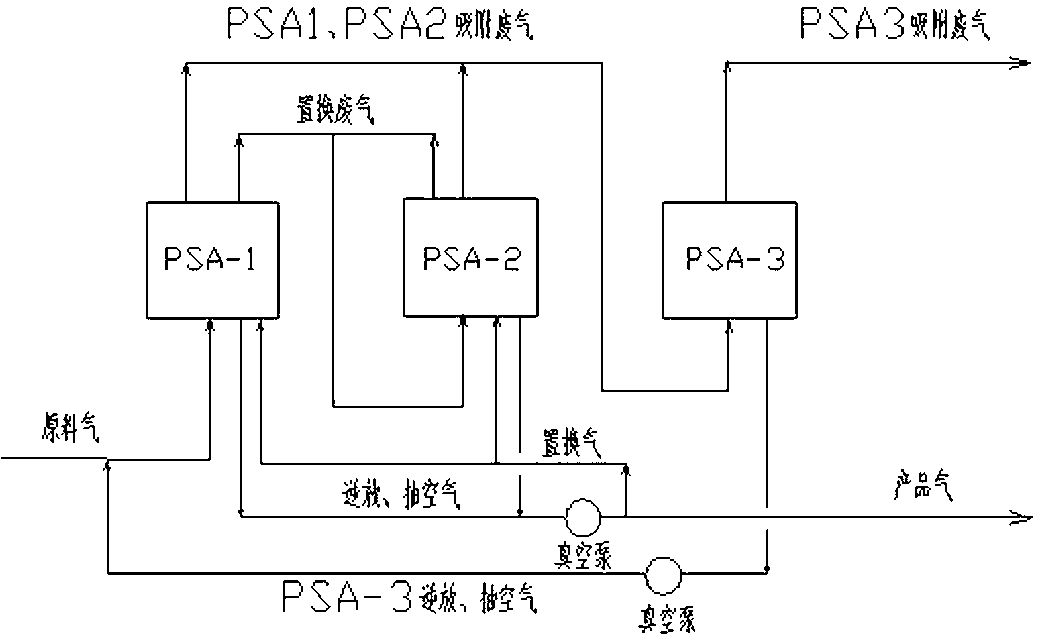

[0056] The PSA system in this embodiment is composed of PSA 1 stage PSA-1, PSA 2 stage PSA-2 and PSA 3 stage PSA-3. The feed gas enters the first stage of PSA, and the replacement exhaust gas of the first stage of PSA enters the second stage of PSA as the raw material gas of the second stage of PSA. Ethylene-rich product and displacement gas are obtained by pumping air, and the adsorption waste gas from PSA 1 and PSA 2 enters PSA 3 as raw material gas for PSA 3, reverse discharge and pumping in PSA 3 After the air is pressurized, it returns to the first stage of PSA and mixes with the raw material gas as the raw material gas for PSA, and the adsorption exhaust gas output device of the third s...

Embodiment 2

[0130] This embodiment is a pressure swing adsorption method for separating and recovering carbon dioxide from the converted gas of synthetic ammonia, and the flow rate of the mixed gas is about 15000Nm 3 / h, the adsorption pressure is about 0.75Mpa, and the temperature is about 30°C. The composition of the mixed gas to be processed is shown in Table 1:

[0131] Table 1 Composition of feed gas

[0132] .

[0133] The PSA system in this embodiment is composed of PSA 1 stage PSA-1, PSA 2 stage PSA-2 and PSA 3 stage PSA-3. The feed gas enters the first stage of PSA, and the replacement exhaust gas of the first stage of PSA enters the second stage of PSA as the raw material gas of the second stage of PSA. Air is pumped to obtain carbon dioxide product and replacement gas. The waste gas from PSA 1 and PSA 2 enters PSA 3 as raw material gas for PSA 3, reverse release and pumping air in PSA 3. After pressurization, return to PSA stage 1 to mix with raw material gas as raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com