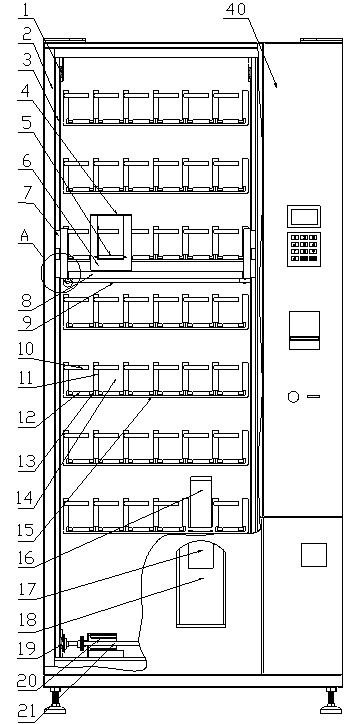

Vending machine shipment structure

A vending machine and shipping device technology, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. Avoid complication of cargo lane, avoid high failure rate and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

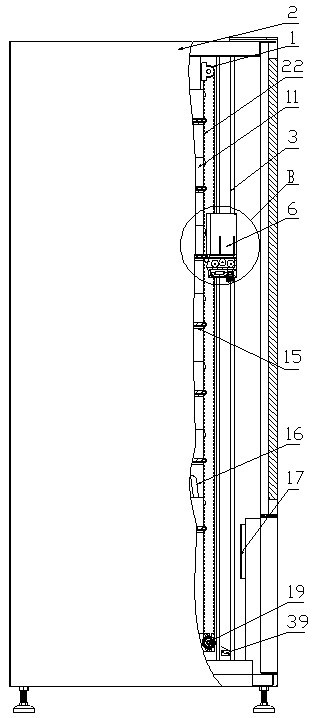

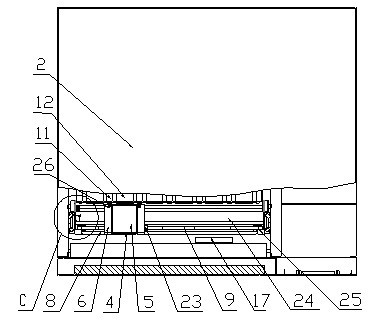

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] This automatic vending machine delivery structure is installed in the box body 2 of the automatic vending machine. Multiple rows of shelves 15 are installed in the box body. The shelf partitions 11 divide the shelves into a plurality of cargo lanes 14. Take the warehouse 18, and a baffle plate 16 is installed on a cargo lane in the bottom row of shelves. It is characterized in that: the lifting platform 8 installed horizontally in the box can move up and down along the guide rail 3 on the inner wall of the box body. The installed shelf 6 can move left and right along the horizontally installed guide rail 24 on the lifting platform. The conveyor belt 5 is installed at the bottom of the shelf, and the shelf driving lever 26 is installed on one side of the shelf. Driving wheel 27, driving wheel drives cargo lane delivery device 12, and cargo lane delivery device pushes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com