Low temp. red glaze for ceramics and mfg. method thereof

A manufacturing method and a low-temperature technology are applied to the low-temperature bright red glaze for ceramics and the field of manufacturing thereof, and can solve the problems of acid insufficiency, poor thermal stability and acid erosion resistance, and poor thermal stability of the bright red glaze.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Accurately weigh and mix the above-mentioned raw material components according to the specified ratio, melt at 1250°C, pour into water and quench into a frit; take 100 parts of the above-mentioned frit, add 6 parts of color base, 50 parts of water, and put it into a ball mill for ball milling After 72 hours, pass through a 250-mesh sieve to obtain a low-temperature bright red glaze at 760°C to 800°C.

[0021] According to the above process requirements, in 1124 # Glaze is applied on the milk cup. After testing, the product performance is as follows:

[0022] (1) Chromaticity value (chromaticity coordinate value): saturation (L) 36.31, redness value (a) 58.75, blueness value (b) 40.30.

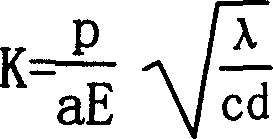

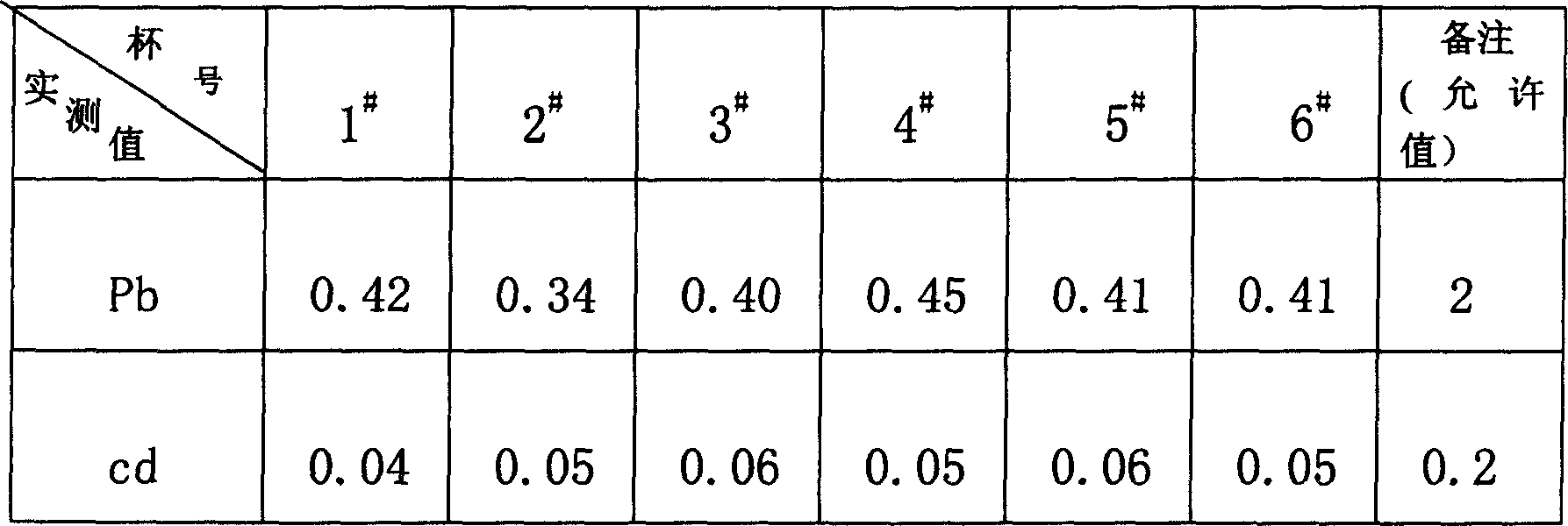

[0023] (2) Dissolution value of lead and cadmium: measured value (mg)

[0024]

[0025] It can be seen from the above that the product fully complies with international hygienic standards, and it is an ideal low-temperature bright red glaze for ceramics that meets internation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com