Flexible liquid crystal thin film and preparation method thereof

A flexible liquid crystal and thin film technology, applied in the field of liquid crystal, can solve the problems of time-consuming and laborious, difficult to control the thickness of the film, complicated printing and coating operation process, etc., and achieve the effect of full color of the film, lower control voltage and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

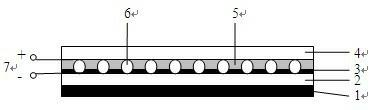

[0020] At 5×10cm 2 The square resistance is 200 / □Spin coating a layer of 15 on ITO-PET film m-thick positive photoresist, through the mask, with a wavelength of 220nm and an irradiation intensity of 1200μw / cm 2 The UV curing instrument is exposed for more than 15 minutes to polymerize the photoresist in the exposed part. Wash the polymerized photoresist with a developer solution and clean it with deionized water. Place the conductive film in an etching solution that is uniformly mixed with 10ml of 37% concentrated hydrochloric acid and 10ml of deionized water, and rinse the residual hydrochloric acid with deionized water. The ITO without photoresist protection is corroded to obtain The upper transparent electrode layer with display pattern.

[0021] The 0.1g particle size is 3 m SiO 2 The spacer was added to 4.9g of UV curing glue NOA65 solution, and stirred for 20 minutes under mechanical stirring at 500 rpm to obtain a coating solution with a spacer mass fract...

Embodiment 2

[0025] The difference from Example 1 is that 800 / □ ITO-PET film, the particle size of 0.1g is 6 m SiO 2 The spacer was added to 3.2g of UV-curable CBU226 solution to obtain a coating solution with a spacer mass fraction of 3%; the reuse specification was 6 The m screw is coated, the liquid crystal cell is cured at 60°C, and the liquid crystal cell is uniformly poured into the liquid crystal under a vacuum with a pressure of 3 MPa; the others are the same as in Example 1.

Embodiment 3

[0027] The difference from Example 1 is that 1500 / □ ITO-PET film, the particle size of 0.1g is 10 m SiO 2 The spacer was added to 2.4g of UV-curable CBU226 solution to obtain a coating solution with a spacer mass fraction of 4%; the reuse specification was 10 The m screw is coated, the liquid crystal cell is cured at 70°C, and the liquid crystal cell is uniformly poured into the liquid crystal under a vacuum with a pressure of 6 MPa; the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com