Production technology of super-flat high-crystal stone tile

A production process, the technology of high crystal stone, applied in the field of ceramic construction, can solve the problems of microcrystalline stone being bright and not wear-resistant, glazed tiles being wear-resistant and not bright, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with embodiment.

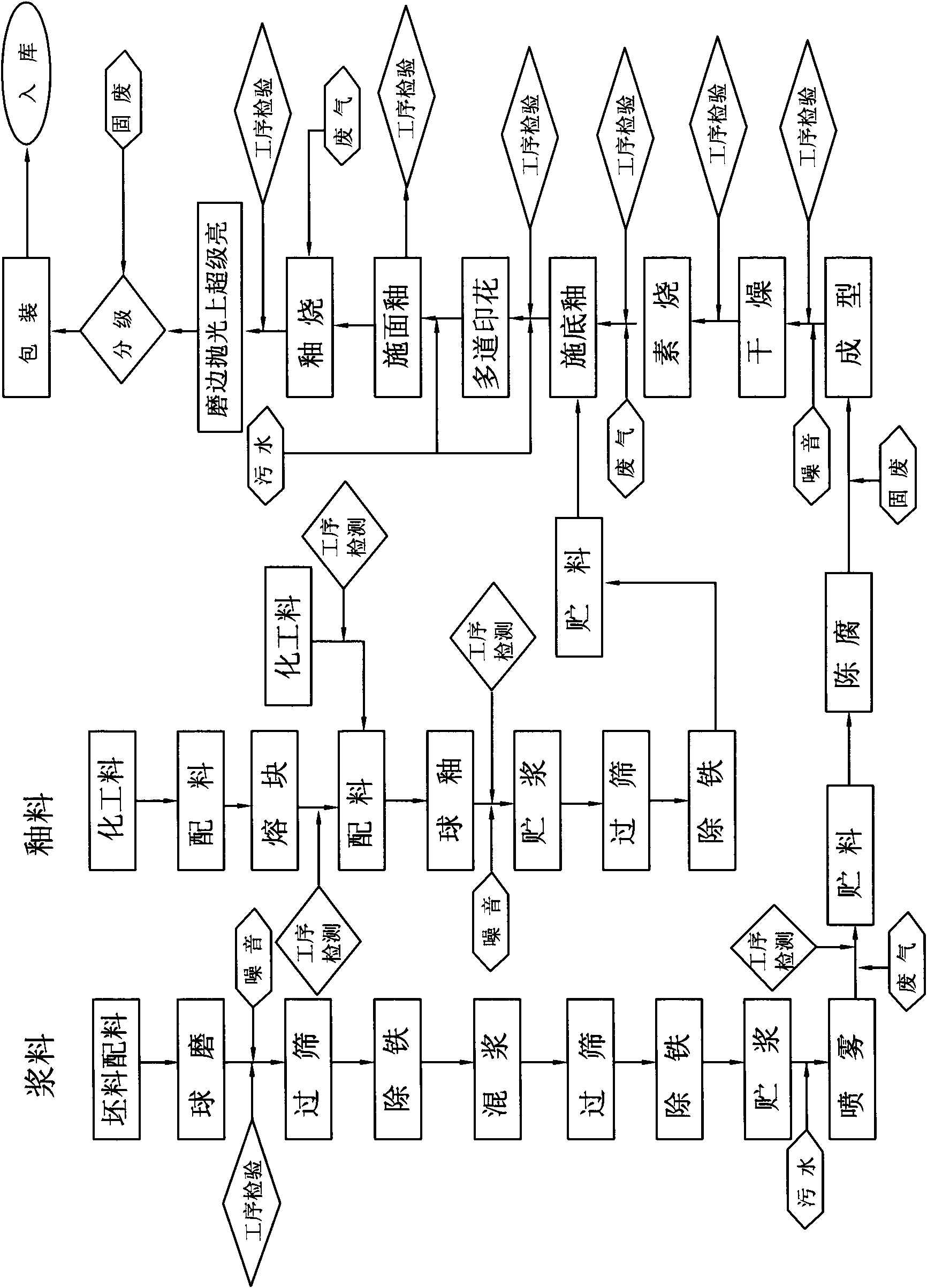

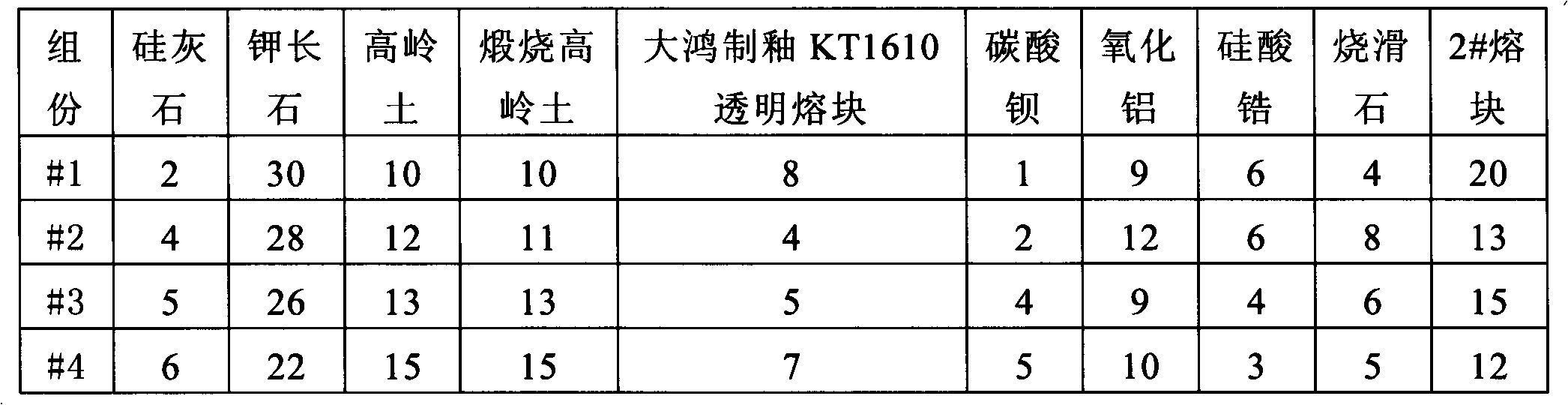

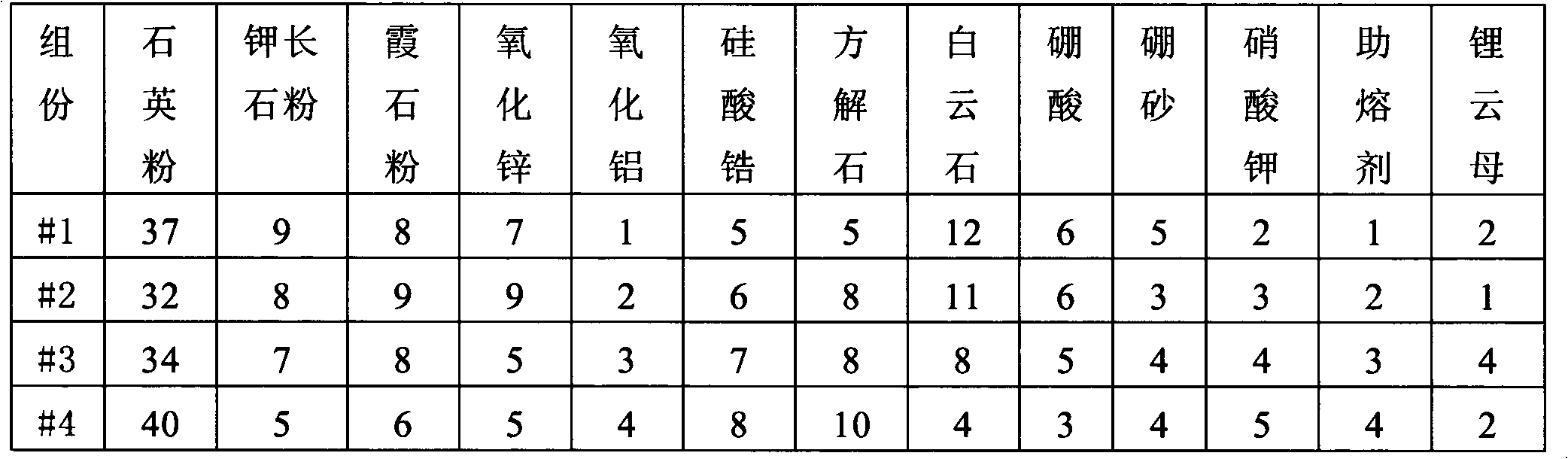

[0027] A production process of ultra-flat high-spar stone tiles, which includes: blank preparation, glaze preparation, blank press molding, low-temperature biscuit firing, dry blank underglaze application, printing, surface glaze application, high-temperature glaze firing, grinding Polishing super clean process on the side, the composition of the blank is shown in Table 1:

[0028] Table 1: Composition (parts by weight) of blank

[0029] Component

white talc

mung bean puree

white sand

High alumina ore

Jie brand white clay

Luocheng black mud

#1

1

2

16

20

23

9

9

15

5

#2

2

6

19

18

22

10

10

9

4

#3

2

3

18

22

22

6

10

11

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com