Preparation method of surface cladding type composite inorganic fire retardant

An inorganic flame retardant and coating technology, applied in the field of chemical engineering, can solve problems such as uneven dispersion and inability to fully exert the synergistic effect of flame retardants, and achieve the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

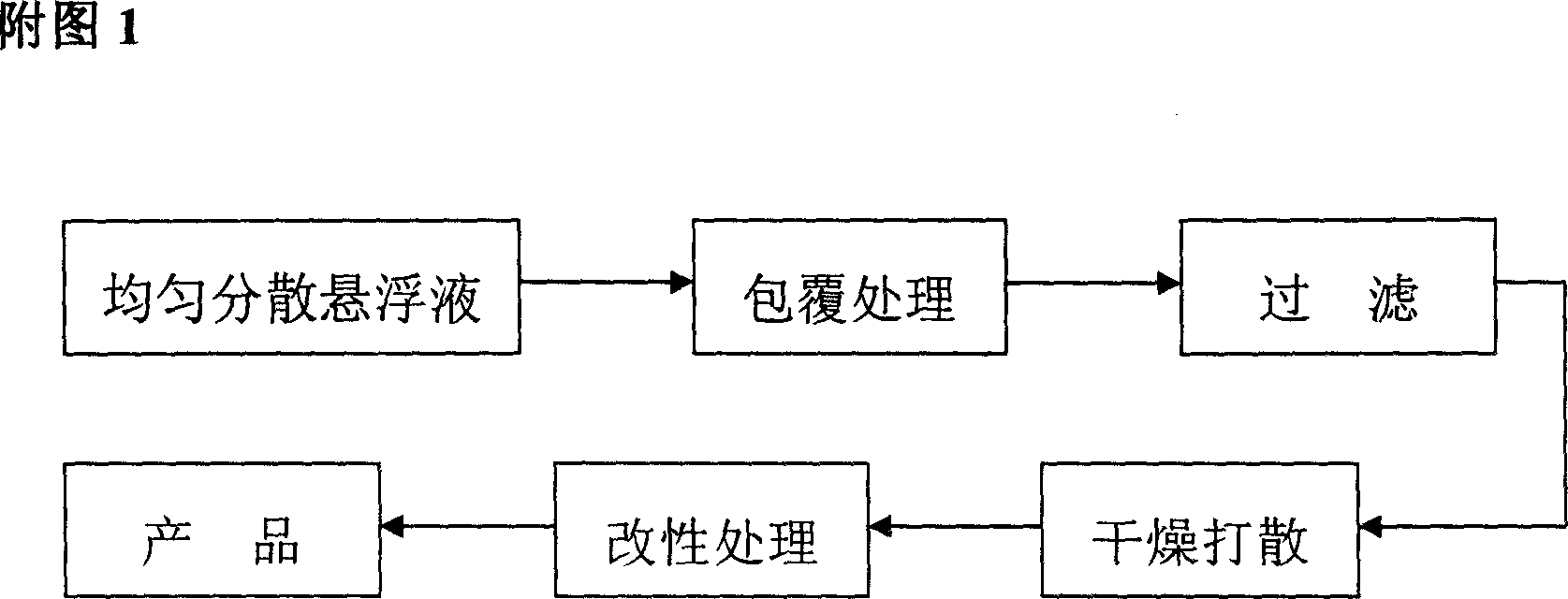

Image

Examples

Embodiment 1

[0019] Add 11.6kg ultrafine magnesium hydroxide (brucite) powder into 395L tap water and add 421g industrial grade sodium hexametaphosphate ((NaPO 3 ) 6 content is 95%), stirred at high speed for 20 minutes to form a uniformly dispersed suspension, and added a small amount of lye to control the pH between 10.5 and 11; 391 grams of industrial grade zinc sulfate (ZnSO 4 ·7H 2 O content is 98%) is dissolved in tap water and is made into 0.1mol / L solution, and 111 grams of industrial caustic soda (NaOH content is 96%) is dissolved in tap water and is made into 0.1mol / L solution; Then add magnesium hydroxide suspension Add zinc sulfate solution and alkali solution at the same time at the same flow rate of 1.8L / min. After the reaction was completed at room temperature, press-filtered and washed, the filter cake was dried and air-jet milled, and finally surface-modified with a silane coupling agent at 90°C to obtain product 1. The main technical indicators of this product and the ...

Embodiment 2

[0021] Add 46.8kg superfine aluminum hydroxide powder into 281L tap water and add 421g industrial grade sodium hexametaphosphate ((NaPO 3 ) 6 content of 95%), stirred at high speed for 20 minutes to form a uniformly dispersed suspension, and added a small amount of lye to control the pH between 9 and 9.5; 1.2kg of industrial grade zinc sulfate (ZnSO 4 ·7H 2 O content is 98%) is dissolved in tap water and is made into 0.1mol / L solution, and 333g industrial caustic soda (NaOH content is 96%) is dissolved in tap water and is made into 0.1mol / L solution; Then add aluminum hydroxide suspension simultaneously Add zinc sulfate solution at a flow rate of 4.6L / min, and add alkali solution at a flow rate of 9.13L / min. After the reaction was completed at room temperature, press-filtered and washed, the filter cake was dried, then jet-milled, and finally surface-modified with a silane coupling agent at 90°C to obtain product 2. The main technical indicators of this product and the main...

Embodiment 3

[0023] Add 13.9kg ultrafine magnesium hydroxide (brucite) powder into 394L tap water and add 465g industrial grade sodium hexametaphosphate ((NaPO 3 ) 6 content is 95%), stirred at high speed for 20 minutes to form a uniformly dispersed suspension, and added a small amount of lye to control the pH between 10.5 and 11; 469g of industrial grade zinc sulfate (ZnSO 4 ·7H 2 O content is 98%) tap water and is made into 0.1mol / L solution, and 133g industrial caustic soda (NaOH content is 96%) is dissolved in tap water and is made into 0.1mol / L solution; At the same flow rate of L / min, zinc sulfate solution and alkali solution are added at the same time. After the reaction was completed at room temperature, press-filtered and washed, the filter cake was dried and air-flow pulverized, and finally surface-modified with an aluminate coupling agent at 90°C to obtain product 3. The main technical indicators of this product and the application performance of filled EVA cable materials ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com