Preparation method of phosphorylated epimedium polysaccharide

A technology of Epimedium polysaccharide and phosphorylation, which can be applied in the direction of antitoxic agent, antiviral agent, drug combination, etc., can solve problems such as the blank of activity research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment one: the preparation of epimedium polysaccharide

[0010] Take 1000g of Epimedium herba that has been dried and crushed at 60°C, add enough 95% ethanol, heat and reflux for 3 times to degrease, take it out, dry, add 10 times the volume of the dregs to decoct twice, 3 hours each time, Filtrate, decoct the dregs with 8 times the volume of water once, decoct for 2 hours, filter, combine the filtrates for 3 times, concentrate to 1000mL, and centrifuge to remove impurities. Add 95% ethanol to the supernatant until the volume fraction of ethanol is 80%, let stand at 4°C for 12h, centrifuge at 3000rpm for 20min, collect the precipitate, dry it in vacuum, add water to redissolve, add 95% ethanol until the volume fraction of ethanol is 80%, and set aside at 4°C Let stand for 12 hours, centrifuge at 4000rpm for 15 minutes, collect the precipitate, and freeze-dry to obtain Epimedium crude polysaccharide. Accurately weigh the epimedium crude polysaccharide, add 10 times...

Embodiment 2

[0011] Example 2: Treatment of Phosphorylated Epimedium Polysaccharide and Determination of Phosphate Content

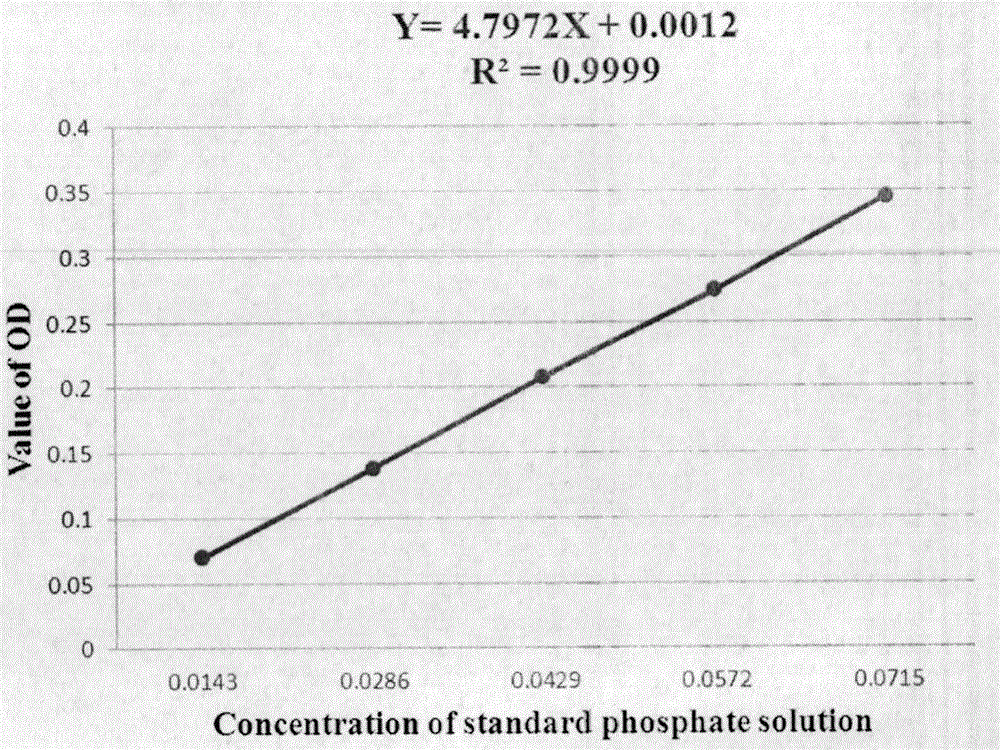

[0012] Drawing of phosphate standard curve:

[0013] Preparation of phosphate standard solution: Accurately weigh 3.6g tris and 120mgMgCl 2 ·6H 2 O was dissolved in distilled water, and diluted with water to 300ml, and finally adjusted to pH 7 with 1mol / L HCl, as a Tris buffer solution. Take equal volumes of 20% ascorbic acid aqueous solution (m / m), 3mol / L H 2 SO 4 Solution and 3% ammonium molybdate solution (m / m) mixture, as phosphorus determination reagent. Precisely weigh 0.7165g of potassium dihydrogen phosphate dried to constant weight and dissolve it in deionized water, transfer it into a 1000ml volumetric flask, add deionized water to make it up to the mark, and shake well. Draw 1mL of this solution, dilute it with deionized water in a 50mL volumetric flask and shake well, as a phosphate standard solution.

[0014] Preparation of Tris buffer solution: Ac...

Embodiment 3

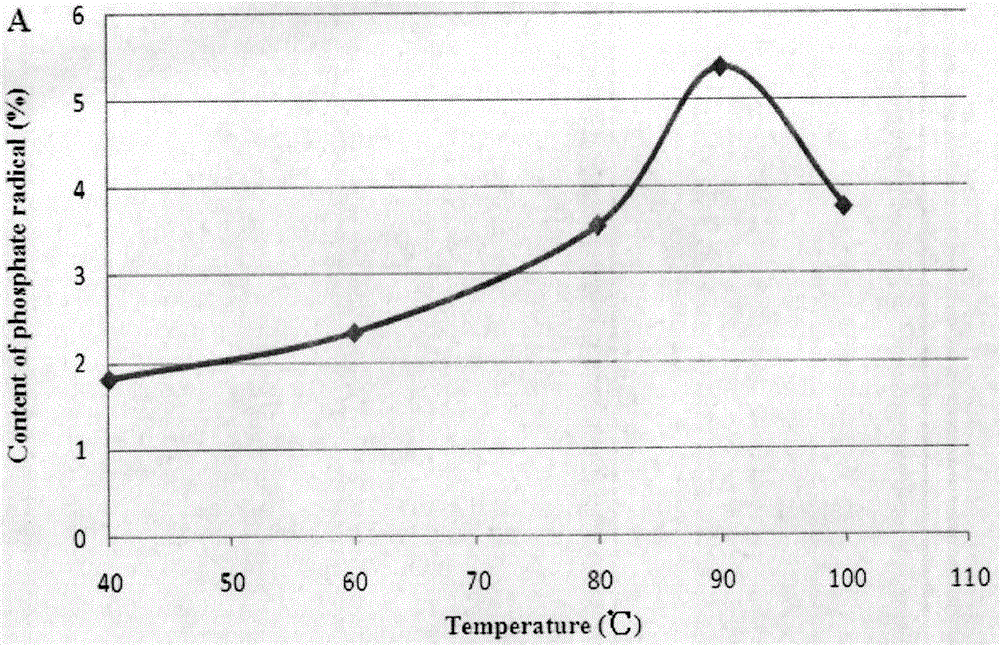

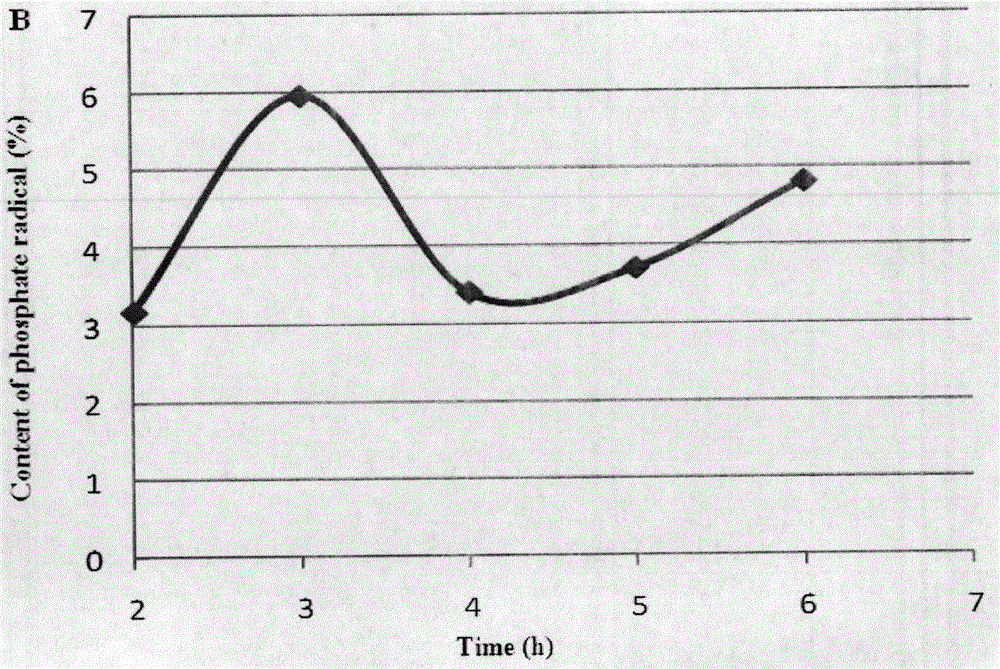

[0020] Example 3: Single Factor Test of Phosphorylated Epimedium Polysaccharide

[0021] Screening test of phosphorylation reagent: Accurately weigh the purified epimedium polysaccharide, and prepare a 10 mg / mL solution with deionized water. According to the proportions in Table 1, the mixed reagents of sodium tripolyphosphate and sodium trimetaphosphate in different mass ratios were used as phosphorylation reagents, and an equal mass of 5% Na 2 SO 4 , reacting for 2 hours under the conditions of reaction pH value 6.0 and reaction temperature 20° C., to phosphorylate Epimedium polysaccharide. Modified products with a molecular weight cut-off of 3.5×10 3 The dialysis bag was dialyzed with deionized water for 48 hours, and then freeze-dried to obtain phosphorylated epimedium polysaccharide. The content of phosphate in the modified product was determined by the method of Example 2, and the influence of the ratio of phosphorylation reagent on the amount of grafted phosphate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com