Metal ion complex collecting agent and preparation method and application of metal ion complex collecting agent

A technology of metal ions and collectors, applied in the field of comprehensive utilization of tungsten ore resources, can solve the problems of difficult separation in roughing and beneficiation operations, difficult separation of calcium-containing minerals, large amount of water glass, etc. The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

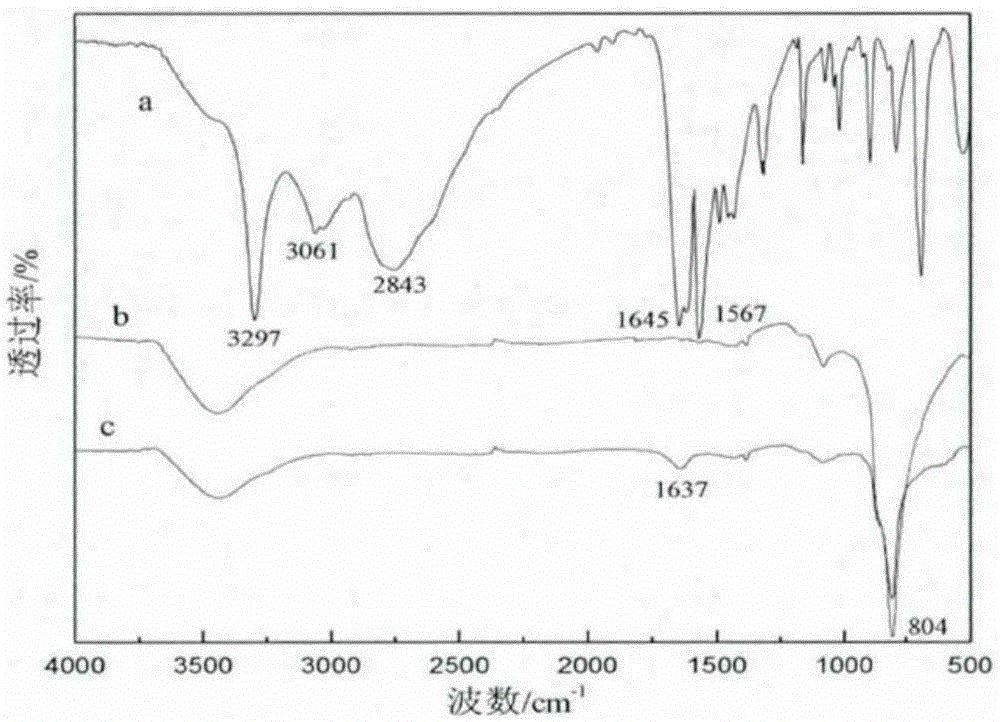

Embodiment 1

[0054] Mix 1mol / L benzoic acid with 3mol / L anhydrous methanol, slowly add 30mL of concentrated acid, add a few grains of zeolite, heat to 75°C and reflux for 2h. Distill off excess methanol with a distillation device, and the residue is washed three times to obtain the corresponding ester; add 2.2 mol of hydroxylamine hydrochloride into a single-necked flask, and add 50 mL of ethanol, stir and cool in a water bath, add 88 g of sodium hydroxide therein, Stir in a water bath for 2 hours, filter out the unacceptable free hydroxylamine to obtain free hydroxylamine hydrochloride; add free hydroxylamine hydrochloride and 25mL methanol to a three-necked flask equipped with an electric stirrer and a dropping funnel, and stir dropwise at 48°C Add 1.7 mol of the obtained ester, react for 45 minutes after the dropwise addition, add 0.5 mol of lead nitrate to the solution obtained in the third step under stirring conditions, and keep the temperature at 40°C for 1-2 hours to obtain the meta...

Embodiment 2

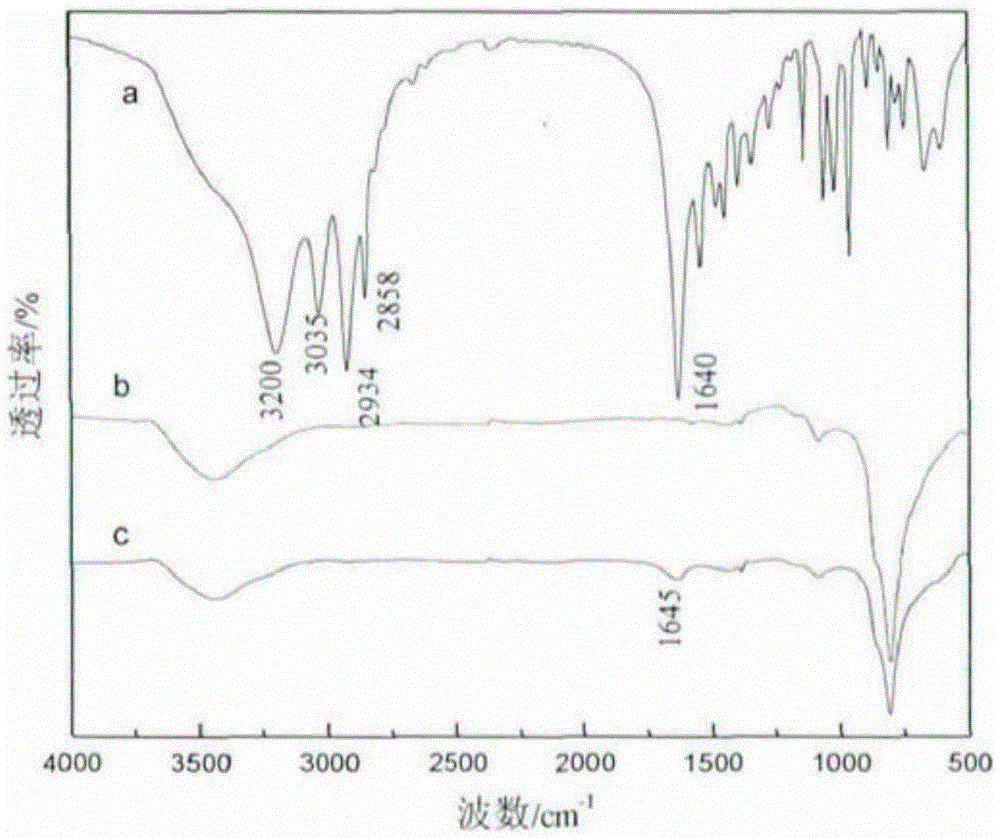

[0060] Mix 1mol / L salicylic acid with 3mol / L anhydrous methanol, slowly add 30mL of concentrated acid, add a few grains of zeolite, heat to 70°C and reflux for 1h. Distill off excess methanol with a distillation device, and the residual liquid is washed 5 times to obtain the corresponding ester; add 2.2 mol of hydroxylamine hydrochloride into a single-necked flask, and add 50 mL of ethanol, stir and cool in a water bath, add 88 g of sodium hydroxide to it, Stir in a water bath for 1.5h, filter out the incompatible free hydroxylamine to obtain free hydroxylamine hydrochloride; add free hydroxylamine hydrochloride and 25mL methanol to a three-neck flask equipped with an electric stirrer and a dropping funnel, and stir at 55°C Add 1.7 mol of the obtained ester dropwise, react for 45 minutes after the dropwise addition, add 0.25 mol of aluminum sulfate to the solution obtained in the third step under stirring conditions, and keep it at 40°C for 2 hours to obtain the metal ion compl...

Embodiment 3

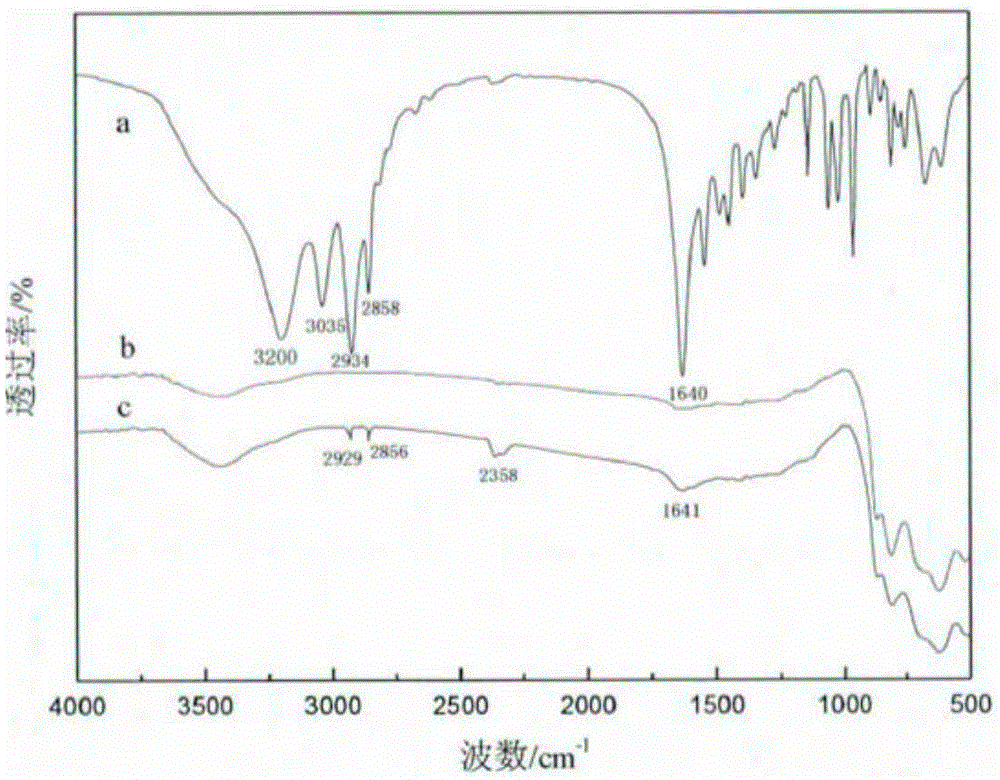

[0065] Mix 1mol / L naphthenic acid with 3mol / L anhydrous methanol, slowly add 30mL of concentrated acid, add a few grains of zeolite, heat to 76°C and reflux for 1.5h. Distill off excess methanol with a distillation device, and the residue is washed three times to obtain the corresponding ester; add 2.2 mol of hydroxylamine hydrochloride into a single-necked flask, and add 50 mL of ethanol, stir and cool in a water bath, add 88 g of sodium hydroxide therein, Stir in a water bath for 1.5h, filter out the incompatible free hydroxylamine to obtain free hydroxylamine hydrochloride; add free hydroxylamine hydrochloride and 25mL methanol to a three-necked flask equipped with an electric stirrer and a dropping funnel, and stir at 50°C Add 1.7 mol of the obtained ester dropwise, react for 45 minutes after the dropwise addition is completed, add 0.125 mol of nickel sulfate to the solution obtained in the third step under stirring conditions, and react at 40°C for 2 hours to obtain the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com