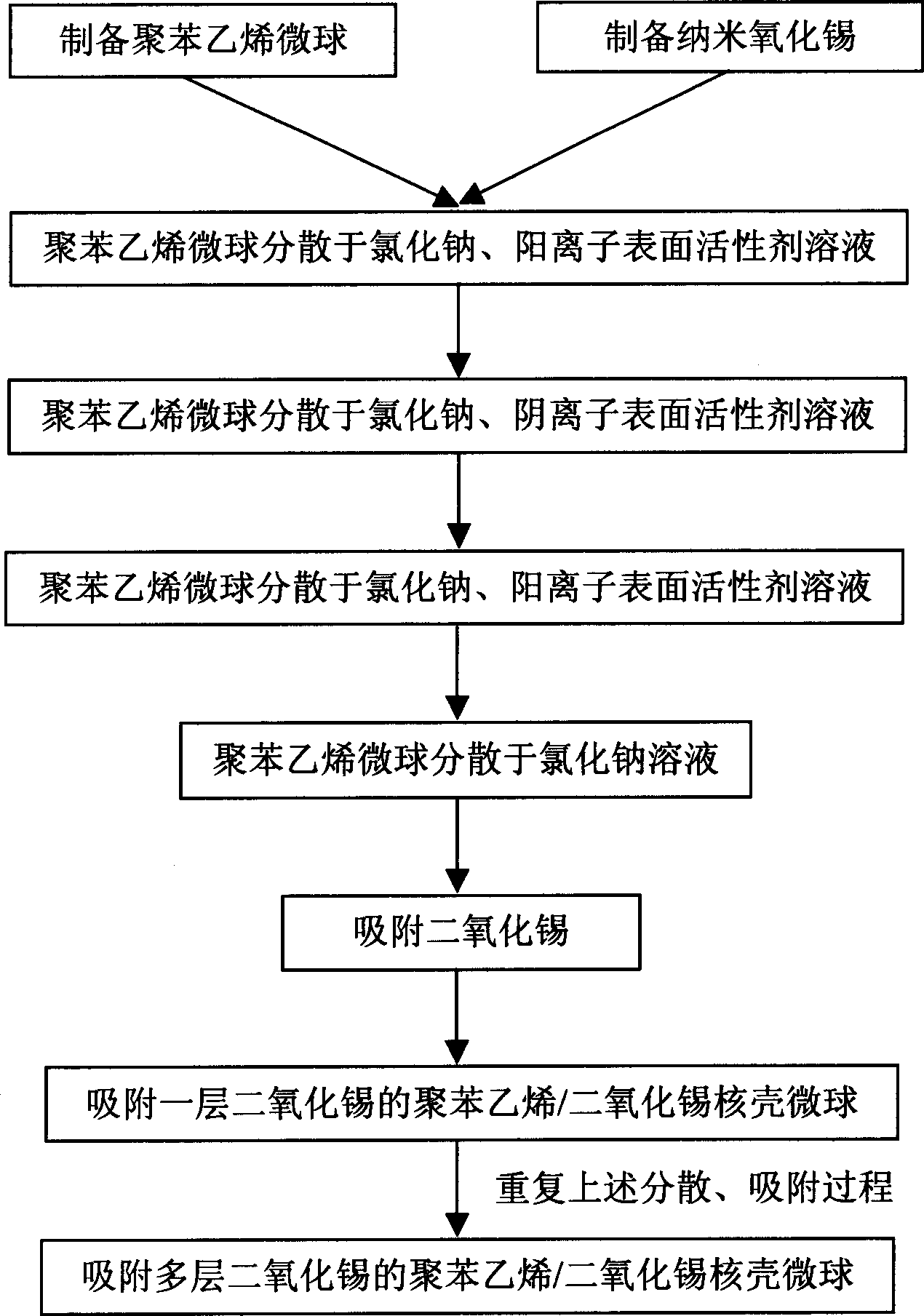

Process for preparing polyphenylethylene/tin dioxide nucleic shell microball

A technology of polystyrene microspheres and tin dioxide, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of not being able to obtain core-shell materials, and achieve the effects of uniform adsorption, uniform size, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Put sodium lauryl sulfate with a mass ratio of 0.4:560:100, high-purity water, and styrene distilled under reduced pressure into a round-bottomed three-neck flask, feed nitrogen to remove oxygen, heat up to 80°C, and add Potassium persulfate equivalent to 1 / 100 of the quality of styrene initiates polymerization. After reacting for 6 hours, it is demulsified by sodium chloride solution, filtered and washed several times, and dried at room temperature in a vacuum oven to obtain a 190-nm diameter Polystyrene microspheres.

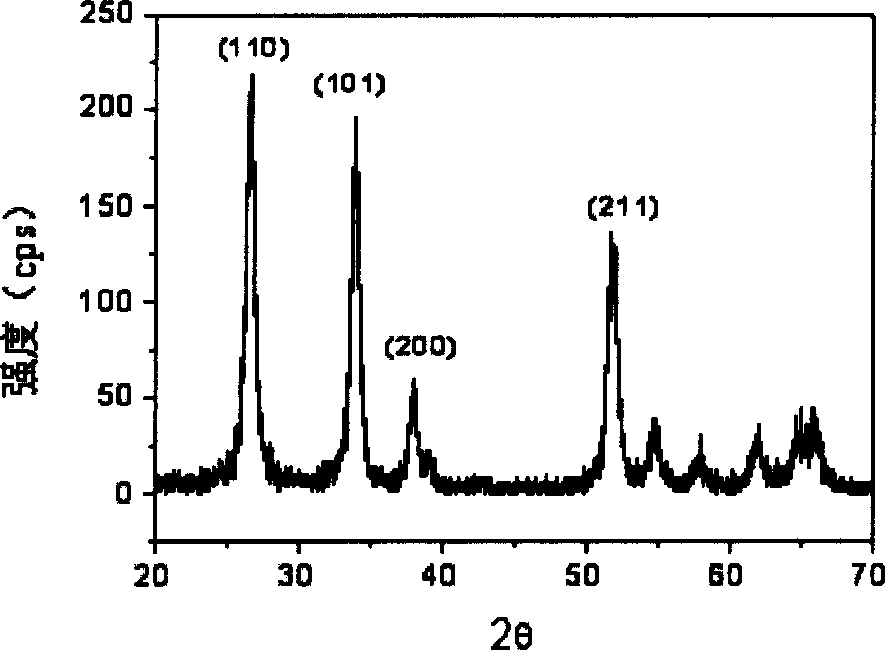

[0018] (2) Add 0.2 mol / L tin salt solution to the Erlenmeyer flask, raise the temperature to 60°C, add 2 mol / L ammonia solution dropwise under stirring, adjust the pH value of the solution to 7, react for 2 hours, and let stand for 24 hours , then filtered, washed and dried, and treated in a muffle furnace at 600°C for 2 hours, and ground to obtain tin dioxide powder with a particle size of about 20 to 30 nanometers;

[0019] (3) Add 1wt% polystyre...

Embodiment 2

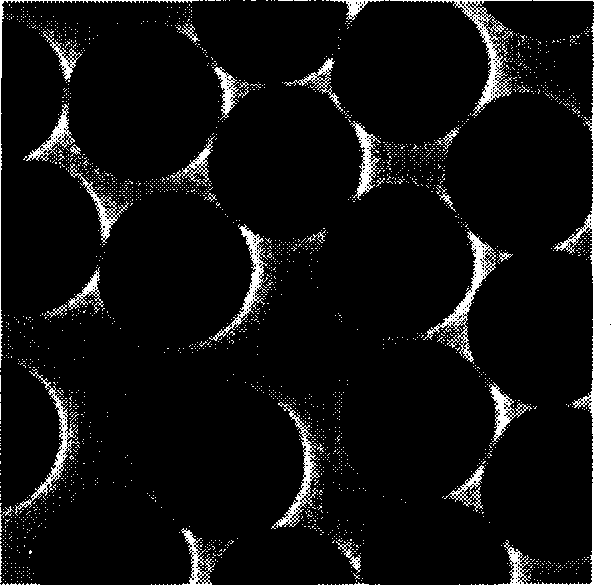

[0021] Repeat the dispersion of polystyrene microspheres and the adsorption process of tin dioxide in Example 1 to obtain polystyrene / tin dioxide core-shell microspheres adsorbing three layers of tin dioxide. Figure 5 It is the field emission scanning electron microscope photo of the obtained polystyrene / tin dioxide core-shell microspheres adsorbing three layers of tin dioxide. It can be seen that the tin dioxide layer adsorbed by the outer layer is uniform, and the particle size of the microspheres is obviously larger than Polystyrene / tin dioxide core-shell microspheres with a layer of tin dioxide adsorbed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com