Beneficiation method of antimonyore

A beneficiation method and antimony ore technology, applied in flotation, solid separation, etc., can solve the problems of large dosage of chemicals, high cost, pollution, etc., and achieve the effects of low lead content, good recovery rate, and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

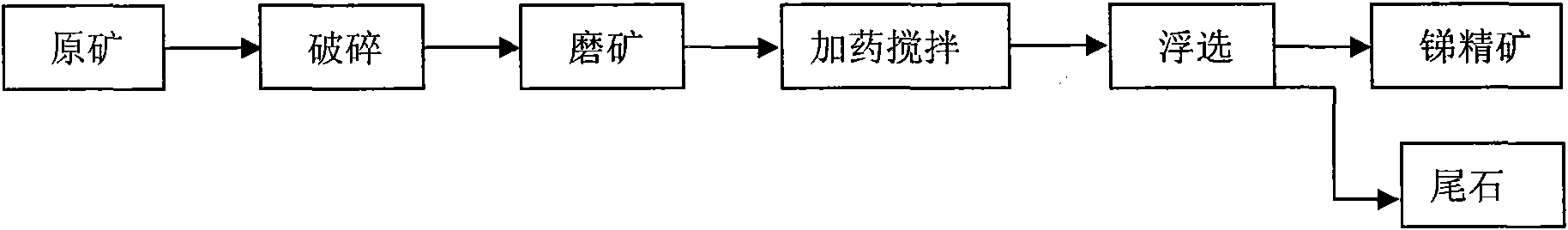

Method used

Image

Examples

Embodiment

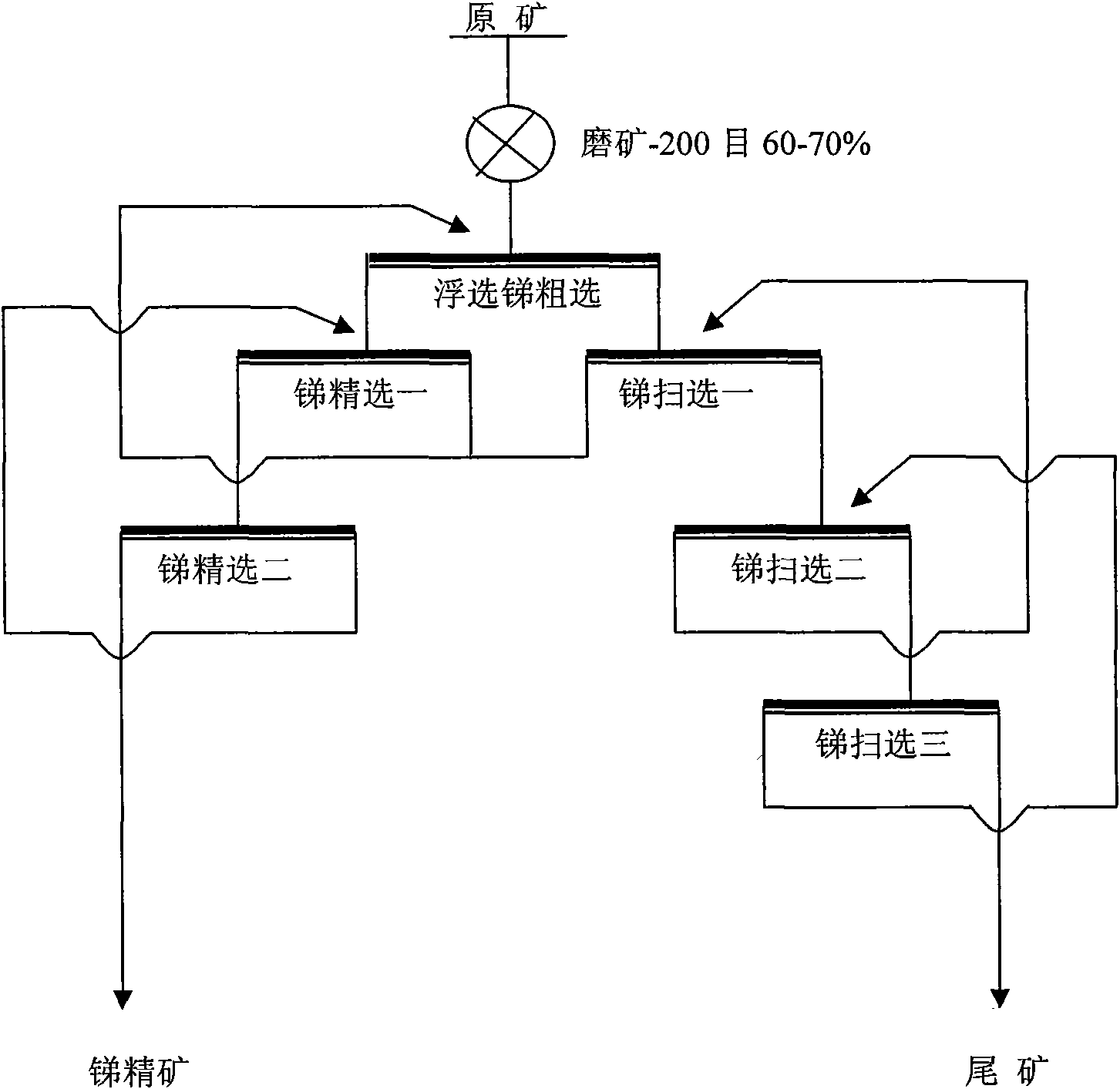

[0018] The antimony raw ore is crushed and ground to a fineness of 63.8%-200 mesh, and 1530 g / ton of sulfuric acid is added to adjust the pH value to 6.1; 2 (SO 4 ) 3 830g / ton is antimony mineral activator, 85g / ton ethyl disulfide nitrogen, 119g / ton butylammonium black medicine, 50g / ton No. 25 black medicine are used as collectors, after being stirred and activated, enter the flotation machine Antimony ore flotation. Antimony concentrate products and tailings are obtained through primary roughing, secondary beneficiation, and three-time sweeping.

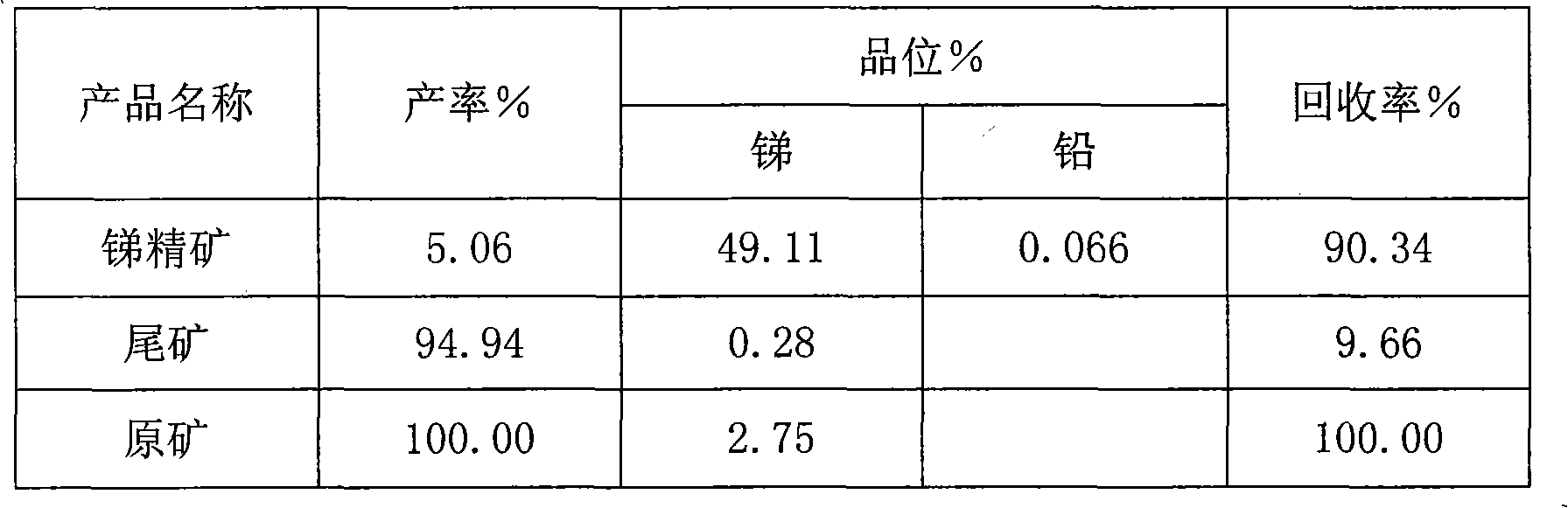

[0019] Flowchart such as figure 2 As shown, the results are shown in Table 1. The grade of the antimony concentrate reached 49.11%, the antimony recovery rate reached 90.34%, and the lead content in the antimony concentrate was only 0.066%, and the lead reduction effect was good.

[0020] Table 1 Antimony ore flotation results

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com