Flotation method for platinum-mineral-containing violarite

A technology for purple sulfur nickel ore and minerals, which is applied to the flotation field of platinum-containing mineral purple sulfur nickel ore, can solve the problems of low recovery rate and ineffective recovery of useful minerals, achieves easy operation and management, and improves ion composition and mineral composition. Surface characteristics, enhanced selective adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

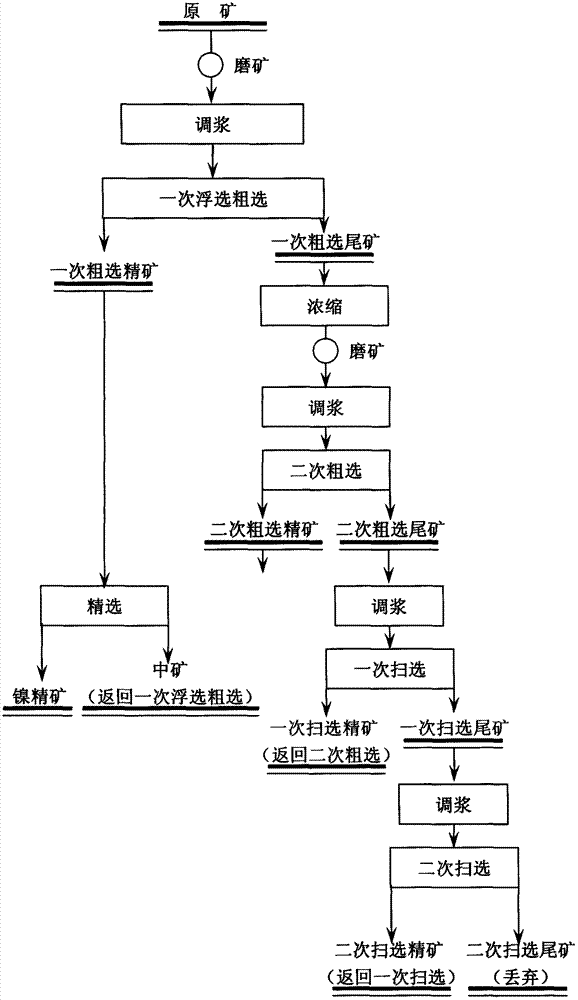

Method used

Image

Examples

Embodiment 1

[0025] Select the original ore of platinum-containing purple sulfur nickel ore in a certain place, the main mineral composition is purple sulfur nickel ore, pyrrhotite, tellurium platinum ore, arsenic platinum ore, magnetite, serpentine, chlorite, hornblende, pyroxene stone and calcite etc. Flotation was carried out according to the steps of the examples and the dosage of the reagents listed in Table 1.

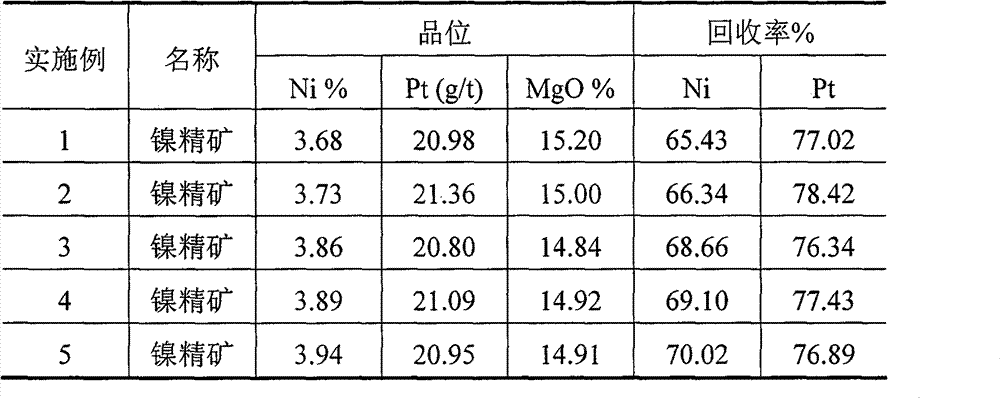

Embodiment 1~5

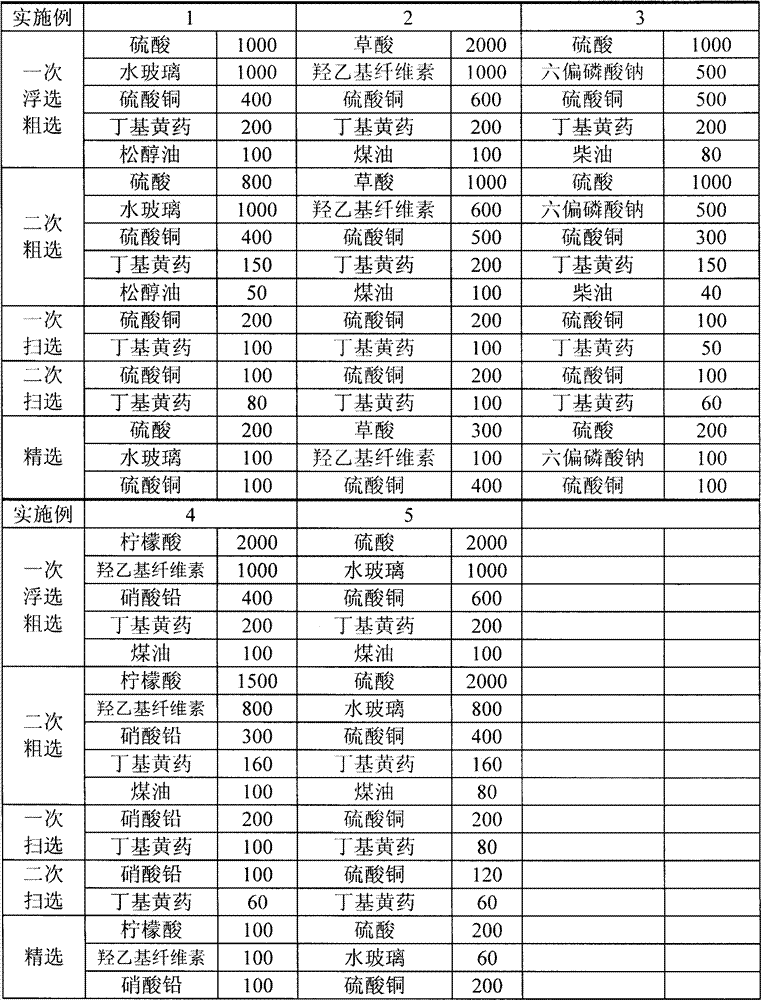

[0026] Table 1 Dosage of Examples 1-5 (g / t raw ore)

[0027]

[0028] The ore nickel grade is 0.32%, platinum grade is 0.55g / t. Grind the raw ore once to -0.074mm to account for 66%, add water to adjust the slurry to a concentration of 30%, and add 1000 grams of sulfuric acid, 1000 grams of water glass, 400 grams of copper sulfate, and 200 grams of butyl Xanthate and 100 grams of terpineol oil are stirred, and a roughing flotation operation is carried out to obtain a roughing concentrate and a roughing tailing; %, add water to adjust the slurry to a concentration of 26%. According to the raw ore per ton, add 800 grams of sulfuric acid, 1000 grams of water glass, 400 grams of copper sulfate, 150 grams of butyl xanthate and 50 grams of terpineol oil, stir, and carry out Secondary roughing flotation operation to obtain secondary roughing concentrate and secondary roughing tailings; according to each ton of raw ore, add 200 grams of copper sulfate and 100 grams of butyl xantha...

Embodiment 2

[0030] The raw ore is the same as in Example 1, the raw ore is firstly ground to -0.074mm to account for 70%, and water is added to adjust the slurry to a concentration of 33%. According to each ton of raw ore, 2000 grams of oxalic acid and 1000 grams of hydroxyethyl cellulose are added successively , 600 grams of copper sulfate, 200 grams of butyl xanthate and 100 grams of kerosene, stirred, and carried out a roughing flotation operation to obtain a roughing concentrate and a roughing tailing; Grind the ore to -0.043mm to account for 70%, add water to adjust the slurry to a concentration of 30%, and add 1000 grams of oxalic acid, 600 grams of hydroxyethyl cellulose, 500 grams of copper sulfate, and 200 grams of butyl yellow medicine and 100 grams of kerosene, stirred, and carried out the secondary roughing flotation operation to obtain the secondary roughing concentrate and the secondary roughing tailings; according to each ton of raw ore, add 200 grams of copper sulfate to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com