Method for removing impurities from organic siloxane mixed ring body

A block and impurity technology, which is applied in the impurity removal process of organosilicon chemical raw material DMC, can solve the problems of poor ion adsorption, unsatisfactory adsorption effect, and low free oxygen content, and achieve enhanced selective adsorption and impurity removal effects Significantly, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

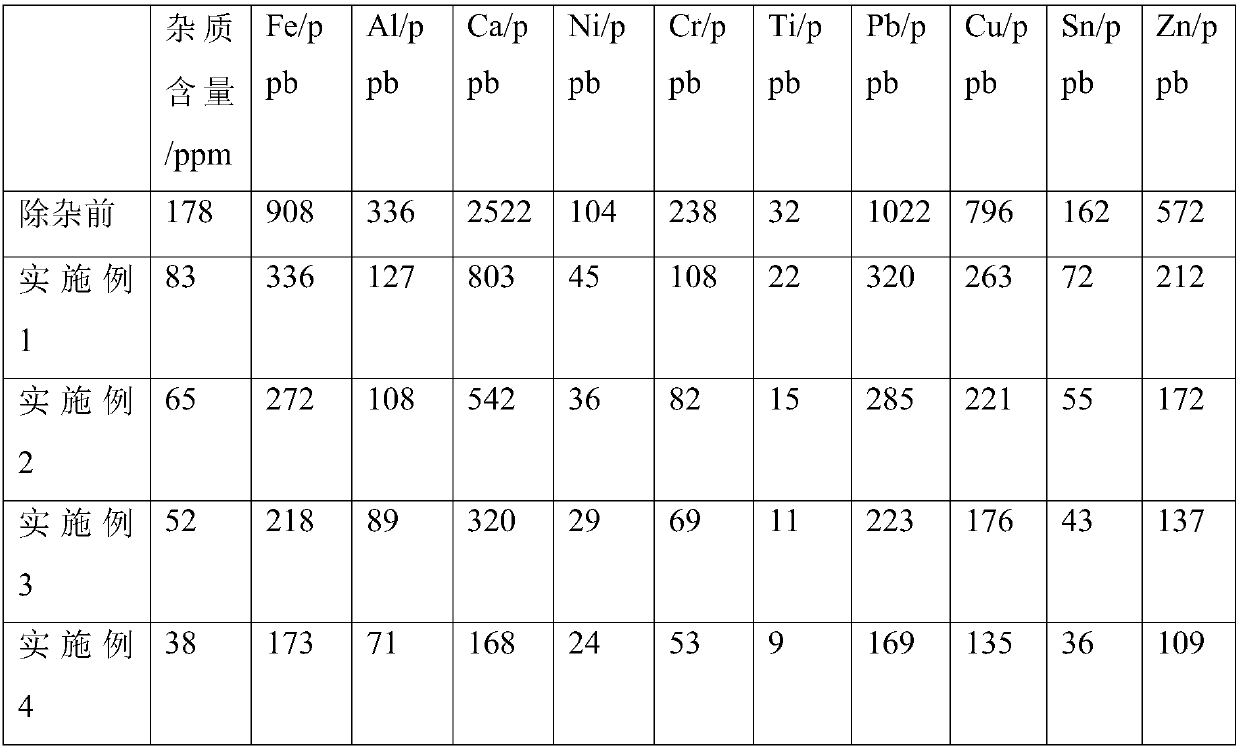

Examples

Embodiment 1

[0012] The specific surface area is 1500m 2 / g of activated carbon fiber felt is evenly cut into squares with a side length of 2-3cm, mix the cut squares with distilled water at a mass ratio of 1:50, heat to boiling, mark the liquid level, and replenish water to the marked position once every half an hour , kept heating for 2 hours, cooled, rinsed with deionized water to remove water-soluble and volatile impurities, and dried in an oven at 105°C for 4 hours. The pretreated activated carbon fiber and DMC are mixed in a mass ratio of 1:100, and the stirring is started, and a 30% hydrogen peroxide solution with a concentration of 6% of the DMC mass is added dropwise at 60° C. Stir for 1 h, filter with a polyvinylidene fluoride ultrafiltration membrane, let stand to separate layers, and dehydrate the upper DMC at 90° C. by bubbling nitrogen for 1.5 h to obtain refined DMC.

Embodiment 2

[0014] The specific surface area is 1500m 2 / g of activated carbon fiber felt is evenly cut into squares with a side length of 2-3cm, mix the cut squares with distilled water at a mass ratio of 1:50, heat to boiling, mark the liquid level, and replenish water to the marked position once every half an hour , kept heating for 2 hours, cooled, rinsed with deionized water to remove water-soluble and volatile impurities, and dried in an oven at 105°C for 4 hours. The activated carbon fiber after pretreatment and DMC are mixed by the mass ratio of 2:100, start to stir, and the concentration of 8% of DMC quality is added dropwise to wherein under the condition of 70 ℃ and is 30% hydrogen peroxide solution, keep Stir for 1 h, filter with a cellulose acetate ultrafiltration membrane, let stand to separate layers, and dehydrate the upper DMC at 90° C. by bubbling nitrogen for 1.5 h to obtain refined DMC.

Embodiment 3

[0016] The specific surface area is 1500m 2 / g of activated carbon fiber felt is evenly cut into squares with a side length of 2-3cm, mix the cut squares with distilled water at a mass ratio of 1:50, heat to boiling, mark the liquid level, and replenish water to the marked position once every half an hour , kept heating for 2 hours, cooled, rinsed with deionized water to remove water-soluble and volatile impurities, and dried in an oven at 105°C for 4 hours. The activated carbon fiber after the pretreatment and DMC are mixed by the mass ratio of 3:100, start to stir, under the condition of 80 ℃, dropwise add the hydrogen peroxide solution of 8% concentration of DMC quality wherein to be 30% hydrogen peroxide solution, keep Stir for 1.5 h, filter with a cellulose acetate ultrafiltration membrane, let stand to separate layers, and dehydrate the upper DMC at 90° C. by bubbling nitrogen for 1.5 h to obtain refined DMC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com