Nano iron-zirconium composite catalyst and preparation method thereof

A composite catalyst, nano-iron technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low activity, easy mixing and unevenness, and achieve uniform dispersion of elements, clear process, and improved The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of iron-based catalyst

[0028] 1) Dissolve 0.484g ferric nitrate in 20ml deionized water, and disperse evenly by ultrasonic. Obtaining ferric nitrate concentration is 0.1mol / L mixture A1;

[0029] 2) Add the mixture A1 obtained in step 1) into a 15mL NaOH solution with a concentration of 2mol / L, and stir for 30min to obtain the mixture B1;

[0030] 3) The mixture B1 obtained in step 2) was statically aged for 24 hours, and then placed in a 50ml polytetrafluoroethylene reactor for hydrothermal reaction for 24 hours. The hydrothermal temperature was 170°C. After the reaction was completed, it was naturally cooled to room temperature to obtain mixture C1;

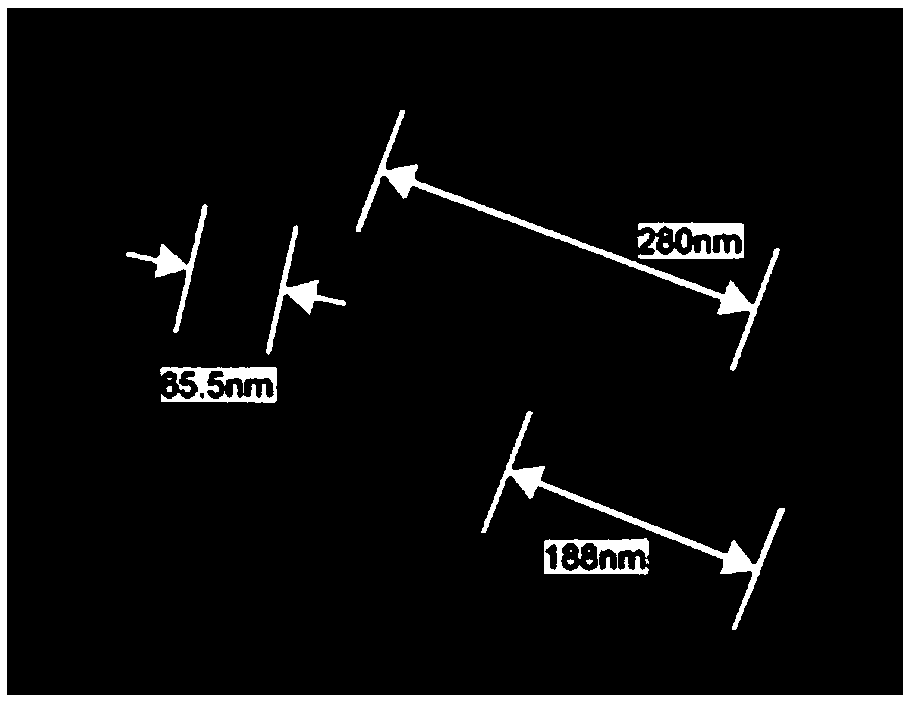

[0031] 4) Wash the mixture C1 obtained in step 3) with water and alcohol for 3 times, and then dry at 60°C; obtain the iron-based catalyst ( figure 1 ).

Embodiment 2

[0033] Preparation of Nano-hexagonal Fe-Zr Composite Catalyst

[0034] 1) Dissolve 0.4356g of ferric nitrate and 0.08586g of zirconium nitrate in 20ml of deionized water, and disperse evenly by ultrasonic. The sum of the concentrations of the two salt solutions obtained is 0.1mol / L mixture A2;

[0035] 2) Add the mixture A2 obtained in step 1) into a 15mL NaOH solution with a concentration of 2mol / L, and stir for 30min to obtain a mixture B2;

[0036] 3) The mixture B2 obtained in step 2) was statically aged for 24 hours, and then placed in a 50ml polytetrafluoroethylene reactor for hydrothermal reaction for 24 hours. The hydrothermal temperature was 170°C. After the reaction was completed, it was naturally cooled to room temperature to obtain mixture C2;

[0037] 4) After the mixture C2 obtained in step 3) is washed with water and washed with alcohol for 3 times, it is dried at 60°C; the nano-hexagonal iron-zirconium composite catalyst ( figure 2 ).

Embodiment 3

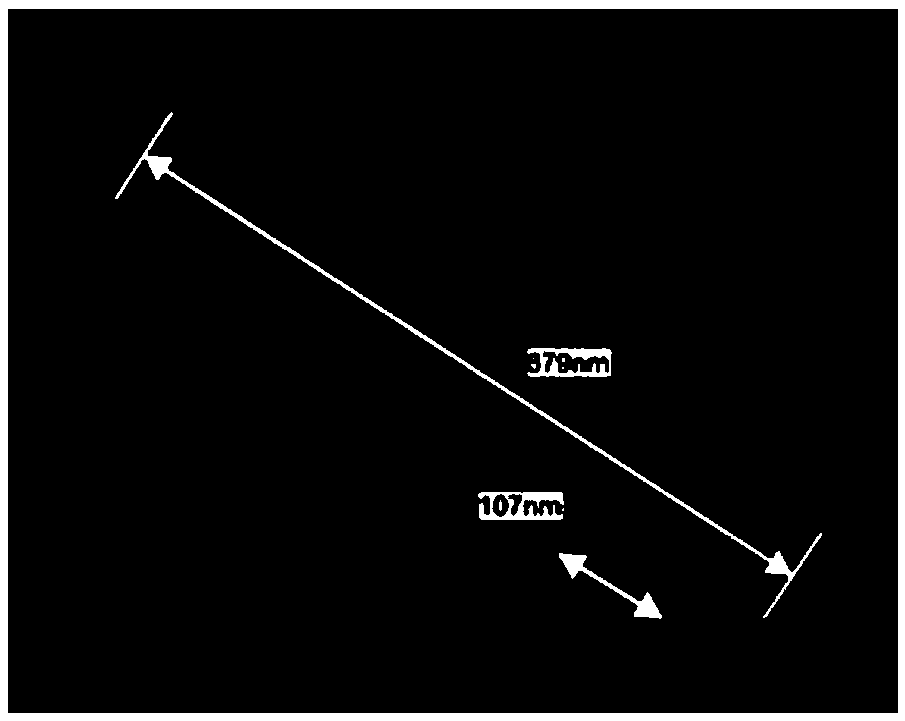

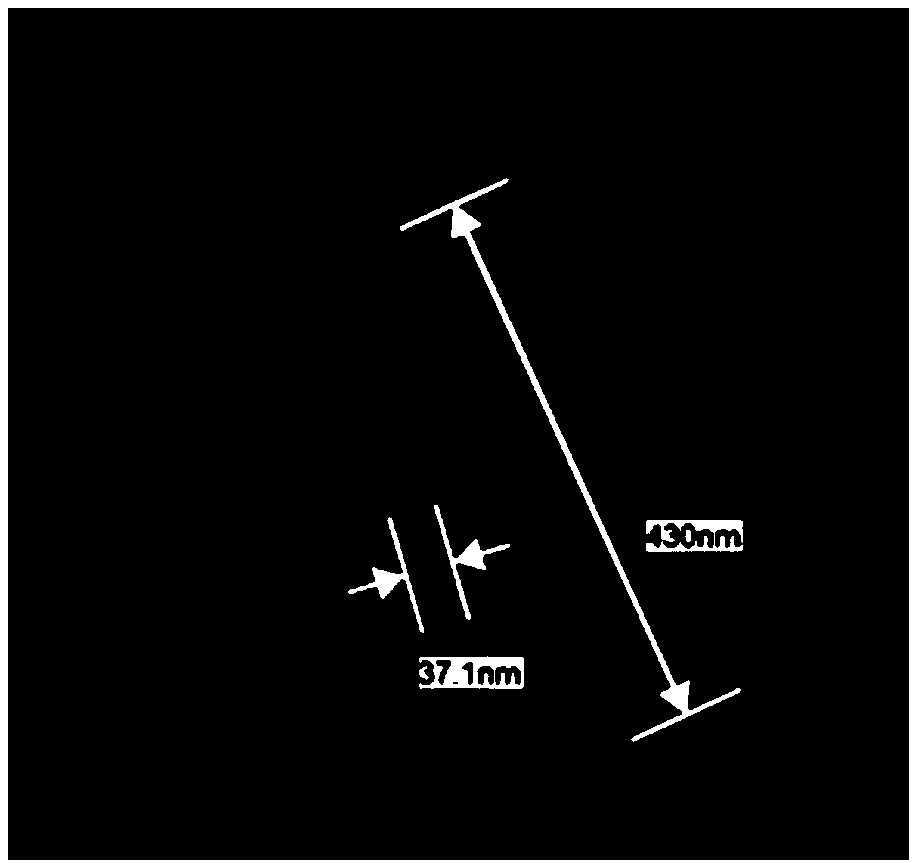

[0039] Preparation of nano-rod iron-zirconium composite catalyst

[0040] 1) Dissolve 0.4356g of ferric nitrate and 0.08586g of zirconium nitrate in 20ml of deionized water, and disperse evenly by ultrasonic. The sum of the concentration of the two salt solutions obtained is 0.1mol / L mixture A3;

[0041] 2) Add the mixture A3 obtained in step 1) into a 15mL NaOH solution with a concentration of 2mol / L, and stir for 30min to obtain a mixture B3;

[0042] 3) The mixture B3 obtained in step 2) was statically aged for 72 hours, and then placed in a 50ml polytetrafluoroethylene reactor for hydrothermal reaction for 24 hours. The hydrothermal temperature was 170°C. After the reaction was completed, it was naturally cooled to room temperature to obtain mixture C3;

[0043] 4) Wash the mixture C3 obtained in step 3) with water and alcohol for 3 times, and then dry at 60° C.; obtain nanorod-shaped iron-zirconium composite catalyst ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com