Preparation method of perovskite quantum dot and metal-organic framework (MOF) composite luminescent material

A metal-organic framework and luminescent material technology, applied in the field of optical materials, can solve problems such as the inability to achieve the stability of perovskite quantum dots, and achieve the effects of reducing professional technical requirements, simple operation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

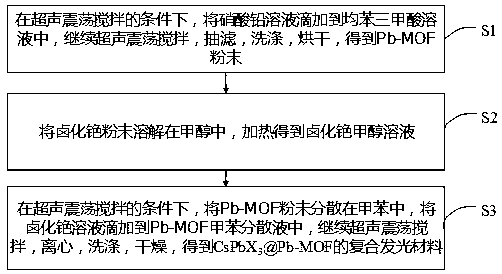

[0028] Specifically, see figure 1 , figure 1 It is a flow chart of a preferred embodiment of the preparation method of the perovskite quantum dot and metal organic framework composite luminescent material of the present invention, as shown in the figure, which includes steps:

[0029] S1. Under the condition of ultrasonic vibration and stirring, the lead nitrate solution is added dropwise to the trimesic acid solution, the ultrasonic vibration and stirring are continued, suction filtration, washing and drying are carried out to obtain Pb-MOF powder.

[0030] As a specific embodiment of the present invention, in this example, Pb(NO 3 ) 2 The solution concentration is 0.05~0.5mol / L, and the concentration of trimesic acid solution is 0.01~0.1mol / L. Compared with nitrogen-containing heterocyclic organic ligands, hydroxyl-containing trimesic acid has a stable skeleton structure of MOF, and after removing small molecule ligands, the remaining holes can exist stably.

[0031] Fur...

Embodiment 1

[0045] A method for preparing a perovskite quantum dot and metal-organic framework composite luminescent material, specifically comprising the following steps:

[0046] (1) Weigh 1.4904g lead nitrate (Pb(NO 3 ) 2 ), use a 50ml volumetric flask to prepare a 0.09mol / L lead nitrate solution; then weigh 0.9456g trimesic acid (1,3,5-H 3 BTC) into a 500ml beaker, add 450ml of ultra-pure water to make a trimesic acid solution; put the beaker containing the trimesic acid solution into an ultrasonic cleaner, at a temperature of 20°C and a stirring rate of 300r / min Under certain conditions, 50ml of lead nitrate solution was added dropwise to the trimesic acid solution, ultrasonically oscillated for 30 minutes, filtered with suction, and washed with ultrapure water three times, and the obtained product was dried in a constant temperature oven at 65°C for 12 hours to obtain white powder Pb -MOF.

[0047] (2) Weigh 100mg of cesium bromide (CsBr) into a 20ml beaker, add 5ml of methanol, ...

Embodiment 2

[0050] A method for preparing a perovskite quantum dot and metal-organic framework composite luminescent material, specifically comprising the following steps:

[0051] (1) Weigh 7.452g lead nitrate (Pb(NO 3 ) 2 ), using a 50ml volumetric flask to prepare a 0.18mol / L lead nitrate solution; then weigh 6.6213g trimesic acid (1,3,5-H 3 BTC) into a 500ml beaker, add 450ml of ultra-pure water to make a trimesic acid solution; put the beaker containing the trimesic acid solution into an ultrasonic cleaner, at a temperature of 20°C and a stirring rate of 300r / min Under certain conditions, 50ml of lead nitrate solution was added dropwise to the trimesic acid solution, ultrasonically oscillated for 30 minutes, filtered with suction, and washed with ultrapure water three times, and the obtained product was dried in a constant temperature oven at 65°C for 12 hours to obtain white powder Pb -MOF.

[0052] (2) Weigh 150mg of cesium bromide (CsBr) into a 20ml beaker, add 10ml of methanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminescence peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com