Tube curtain-wet type gradually-changed-density fiber grid composite dust remover for development machine

A fiber grid and roadheader technology, which is applied in slitting machinery, earth-moving drilling, etc., can solve the problems of bag-type dust collectors, such as sticking bags, high dust removal resistance, unstable efficiency, etc., to reduce the emission of humidity and save water and sludge. The effect of processing capacity and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

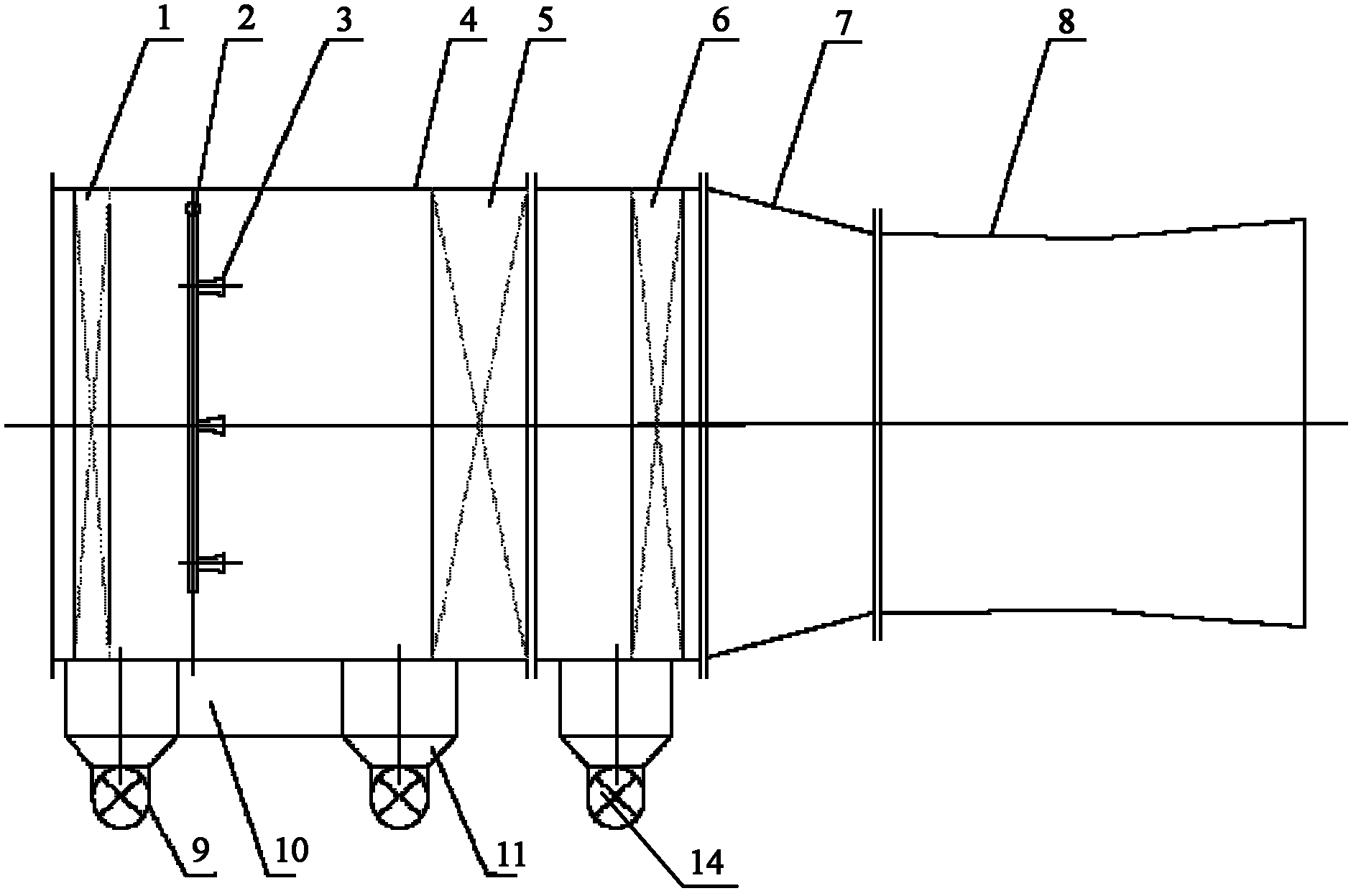

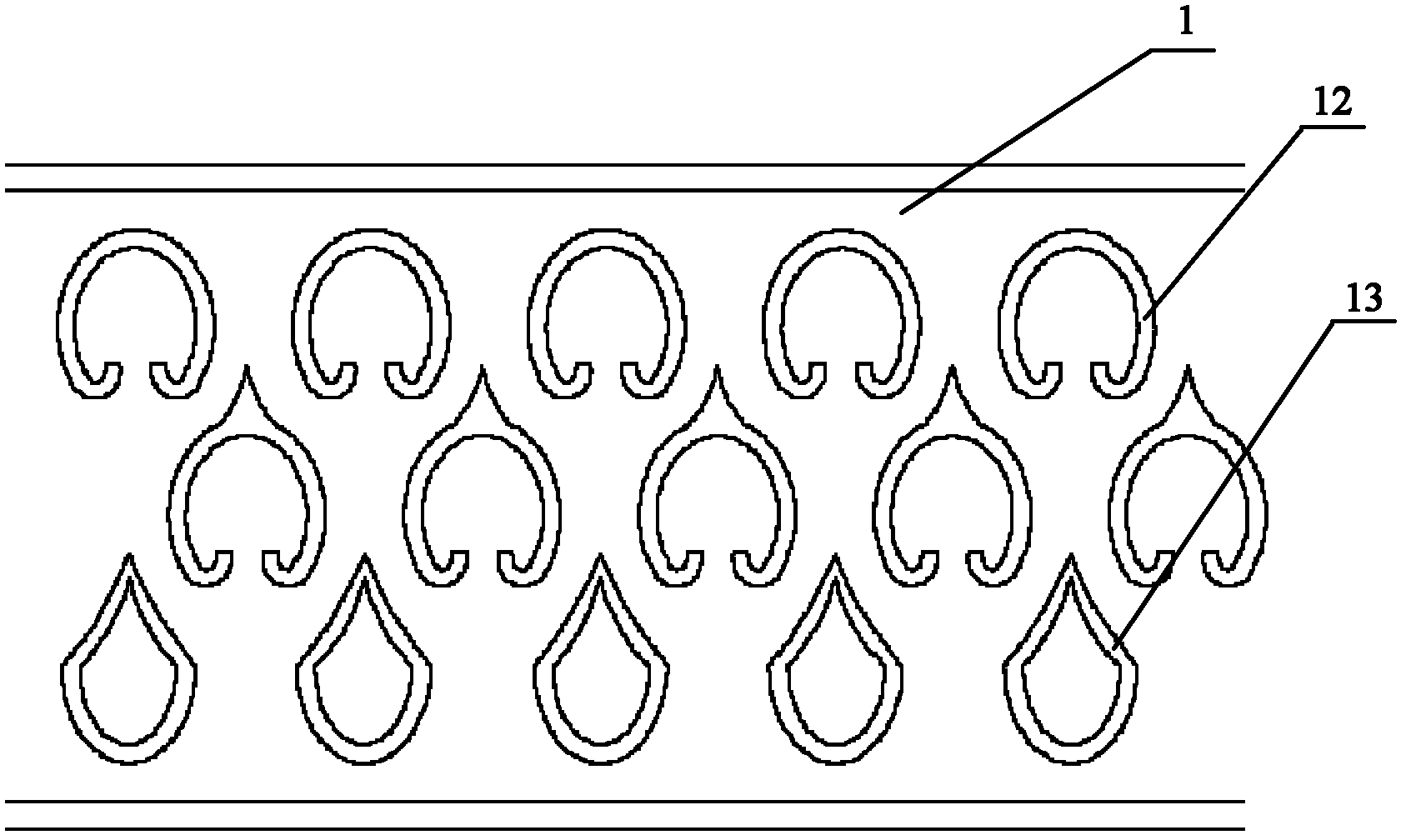

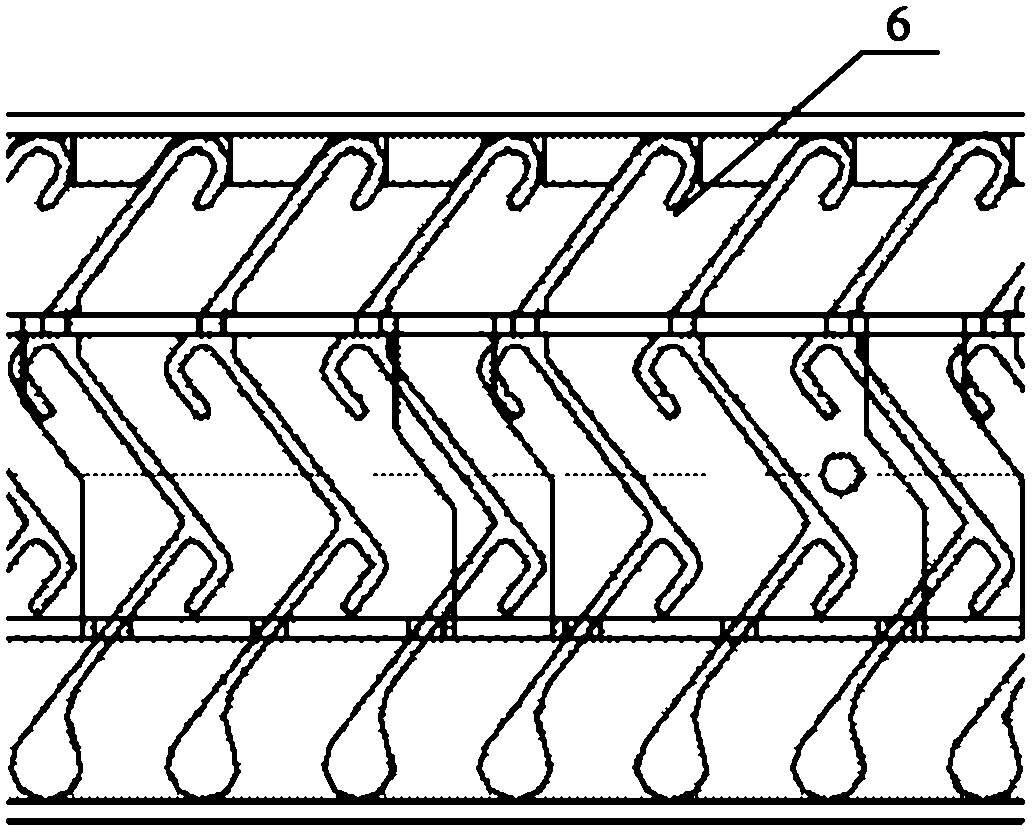

[0015] Such as figure 1 As shown, a tube curtain-wet density gradient fiber grid composite dust collector for roadheaders includes a box body 4, and a tube curtain 1, a density gradient fiber grid 5 and a labyrinth 6 are arranged in the box body 4, and in the tube A water spray pipe 2 with a water mist nozzle 3 is arranged between the curtain 1 and the density gradient fiber grid 5, and the other end of the density gradient fiber grid 5 is connected to one end of the labyrinth 6, and the other end of the labyrinth 6 is passed through a converging tube. 7 is connected with the fan 8; the lower end of the box body 4 is provided with a dry ash bin 9, a sludge bin 11 of density gradient fiber grids, a labyrinth of sludge bin 14 and a circulating water tank 10; 1, the sludge bin 11 of the density gradient fiber grid is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com