Sound insulation and noise reduction type cabin cover of wind power generator

A wind turbine and nacelle cover technology, applied in wind turbine components, wind engines, wind power generation, etc., can solve the harmful effects of wind turbines, limited sound insulation and noise reduction effects, etc., to achieve good overall mechanical performance and avoid resonance Noise, the effect of improving the overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

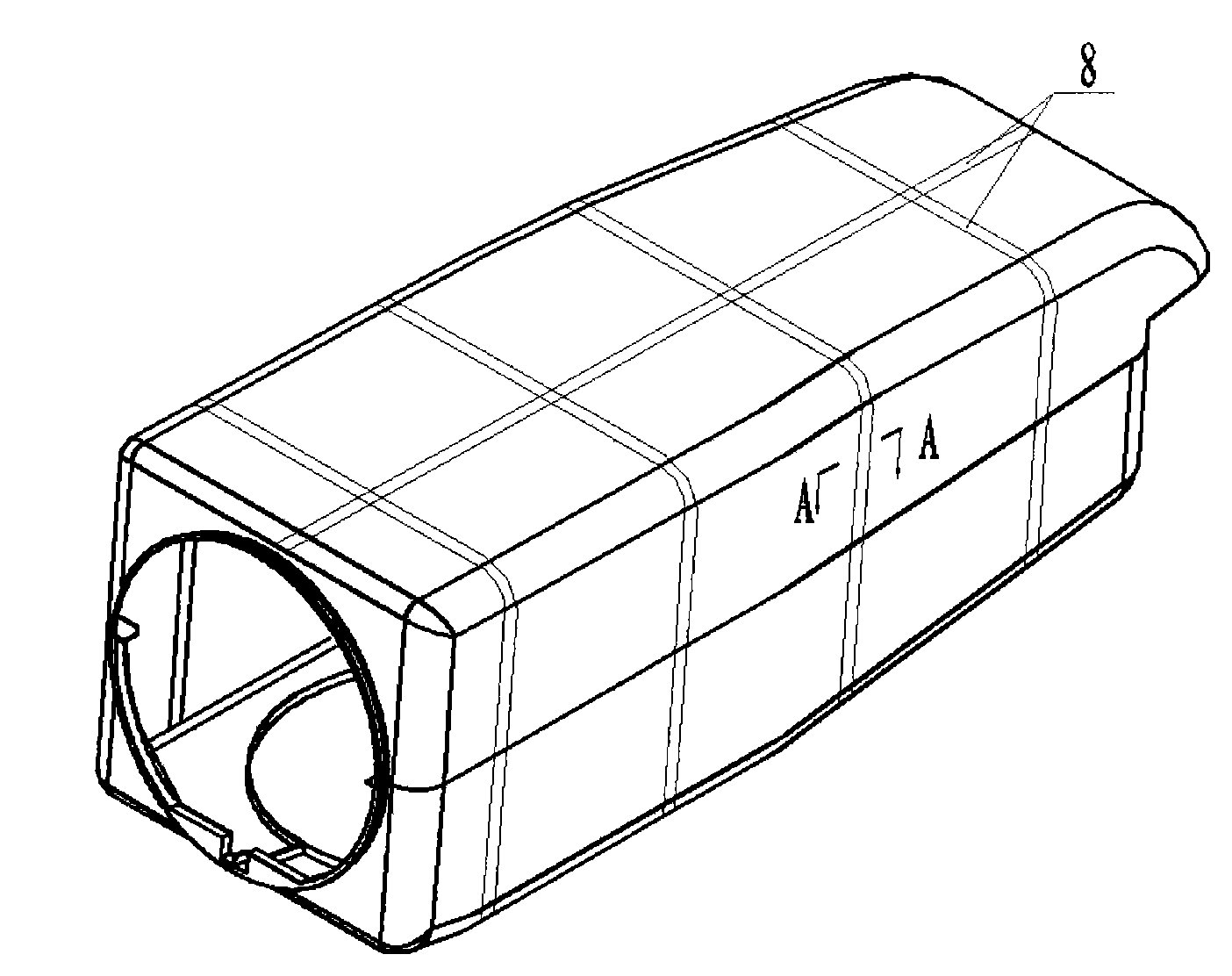

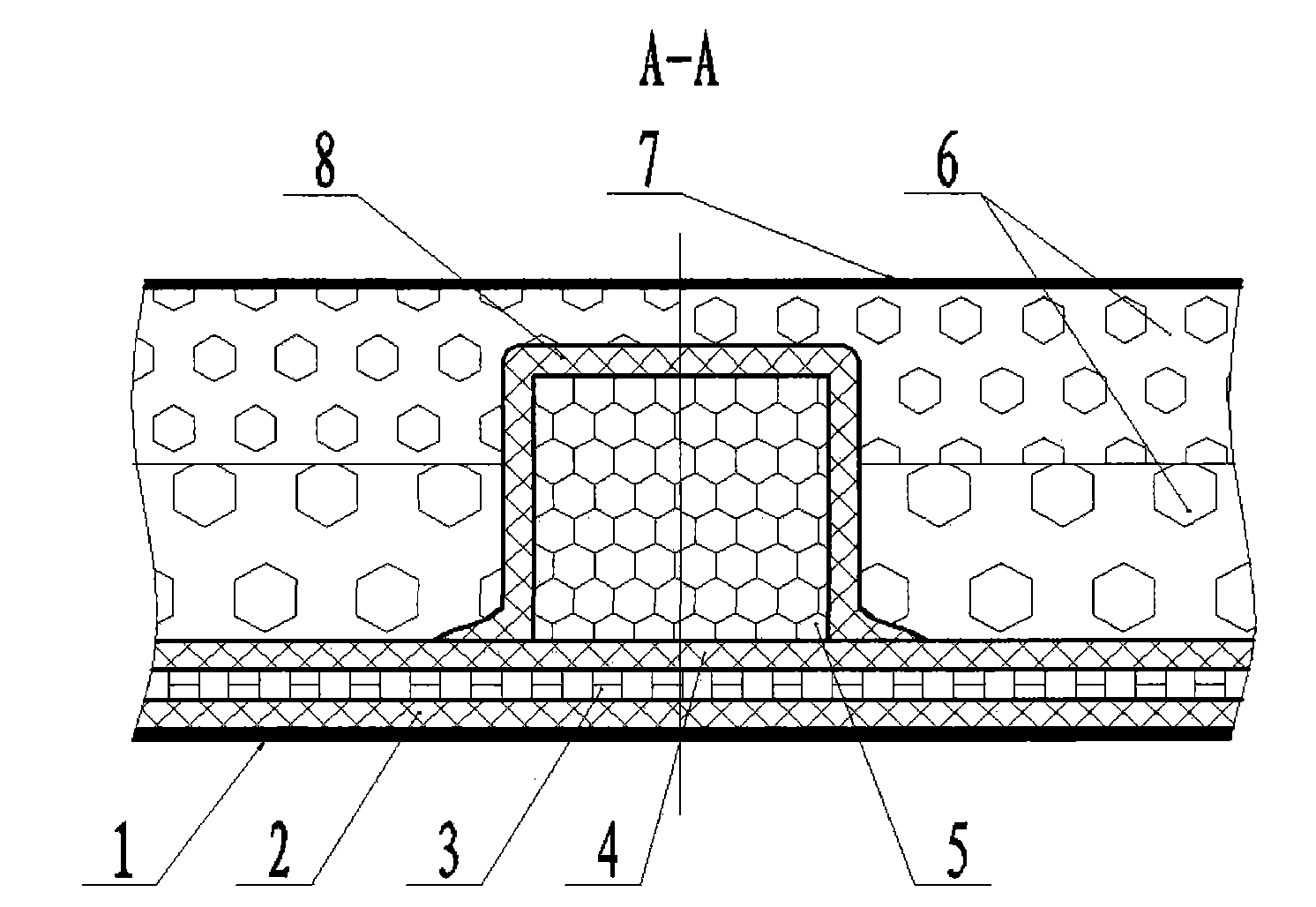

[0028] This embodiment is suitable for the nacelle cover of the 1.5MW wind power generating set in the cold temperate zone. Such as figure 1 , figure 2 As shown, a sound-proof and noise-reducing wind turbine nacelle cover, which includes a decorative protective surface layer 1, an FRP outer panel 2, a sandwich layer 3, an FRP inner panel 4, a rigid foam inner core 5, and a gradient density foam 6. Foamed plastic crust layer 7 and reinforced frame 8; the decorative protective surface layer 1 is attached to the outside of the FRP outer panel 2; the inner side of the FRP outer panel 2 is a sandwich layer 3, and the inner side of the sandwich layer 3 is attached to the FRP inner panel 4 on the outer side; the gradient density foam plastic 6 is attached on the inner side of the FRP inner panel 4, and the foamed plastic crust layer 7 is attached on the inner side of the gradient density foam plastic 6; on the inner side of the FRP inner panel 4, several reinforcement frames are al...

Embodiment 2

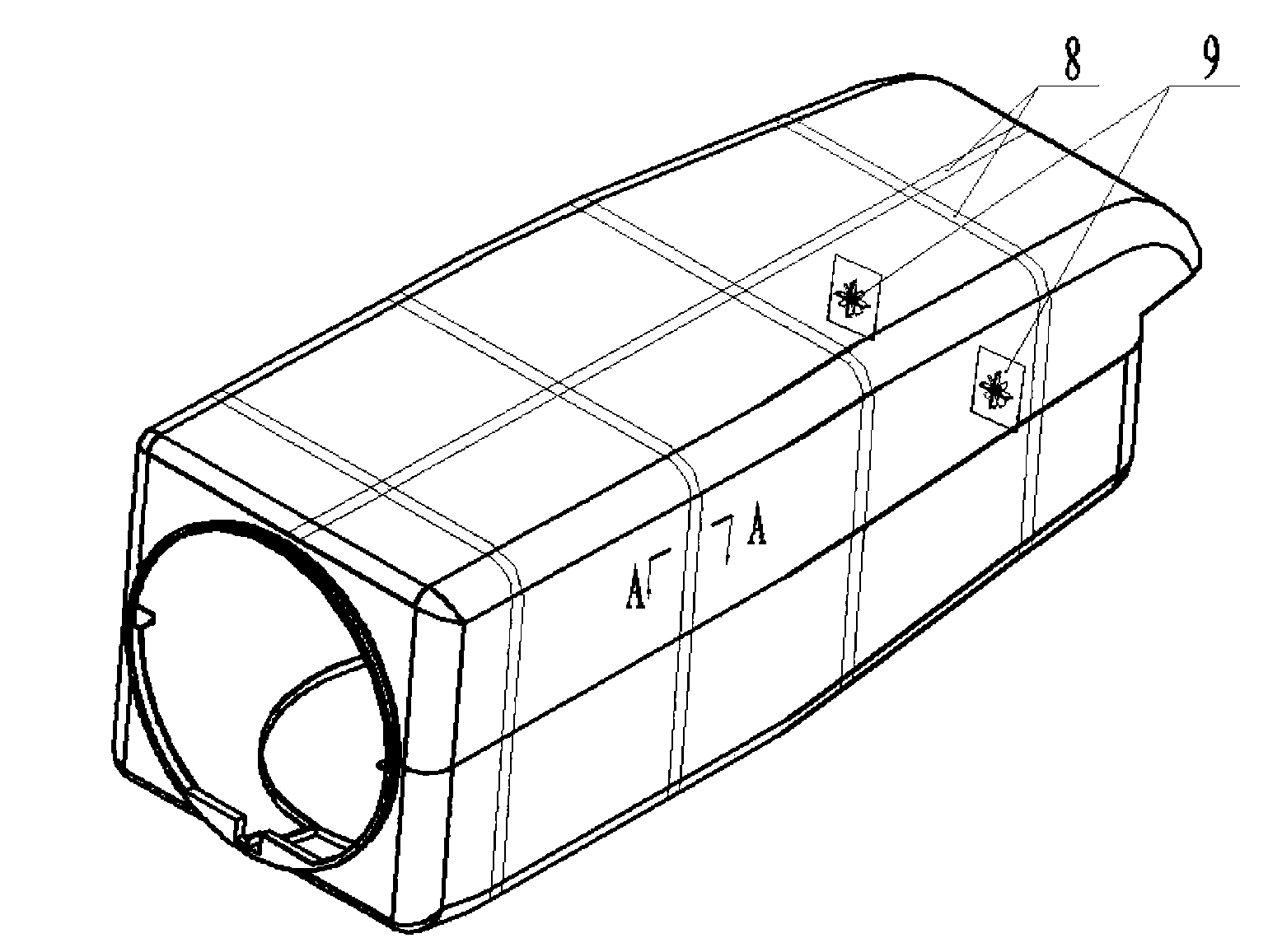

[0041] This embodiment is a wind power generating set working in a hot temperate zone. Such as figure 2 , image 3 As shown, the difference between this embodiment and Embodiment 1 is that a forced ventilation port 9 is provided on the original sound-proof and noise-reducing wind turbine nacelle cover to ensure ventilation at high temperatures. The internal temperature of the lower nacelle cover meets the working requirements of the generator set.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com