Fluid flow rate detector

A flow detection device and fluid flow technology, which are applied in measurement devices, liquid/fluid solid measurement, and fluid flow detection by measuring differential pressure. Throttling differential pressure high frequency component, impossible to detect throttling differential pressure and other problems, to achieve the effect of simple and firm structure, long service life, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

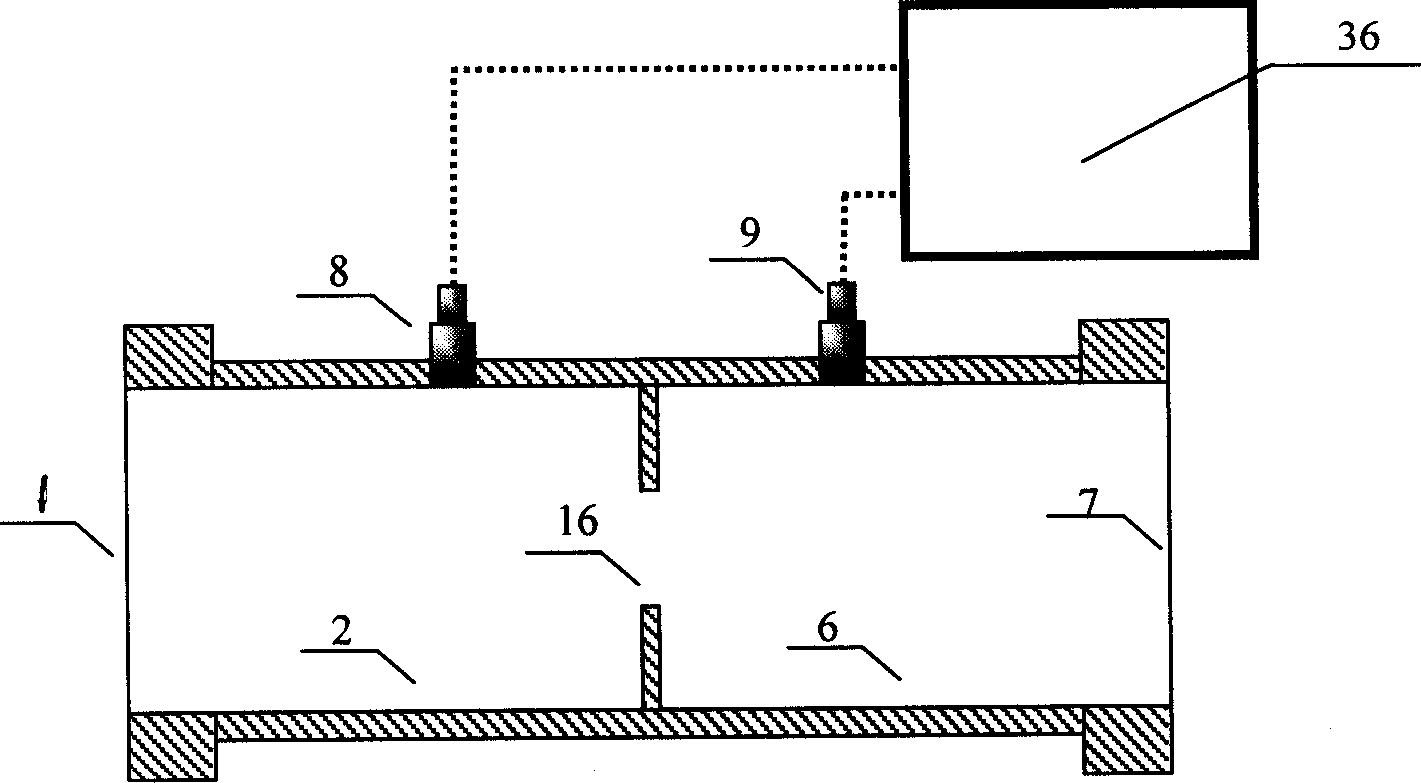

Image

Examples

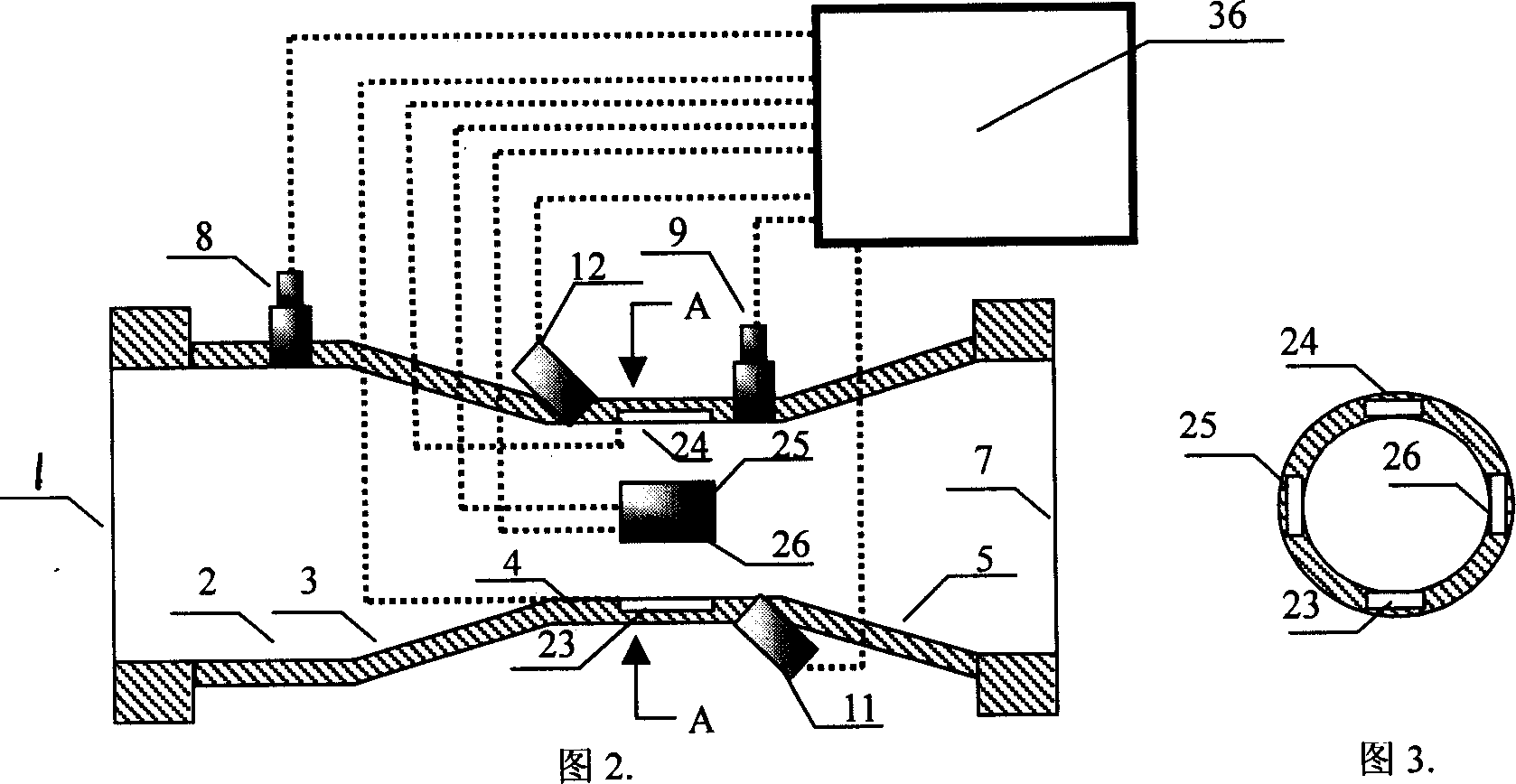

Embodiment approach 1

[0068] The configuration of Embodiment 1 can be used for flow detection of various single-phase fluids. The detection process is as follows: the first step is to carry out the calibration experiment of the flow detection device, and select several flow values within its range to perform For real-flow calibration, under each flow condition, the output signals of the two dynamic pressure sensors are recorded continuously for 10 seconds. The second step is to carry out the calibration calculation work, first calculate the difference between the two signal records under each flow condition, and then calculate and store the spectral density value of the difference. Since the spectral density presents a monotonous increase trend with the increase of the flow rate, the relationship between the two can be obtained through nonlinear interpolation. The third step is to conduct on-site flow detection. At this time, it is only necessary to directly compare the spectral density obtained...

Embodiment approach 2

[0083] Embodiment 2 This configuration can be used for flow detection of various three-phase flows. For example, the three-phase flow of oil, gas and water commonly exists in the oil and gas industry. Since the output of most oil and gas wells often contains three components: crude oil, natural gas and mineralized water, the economical and effective on-line non-separation detection of the flow of each phase in the output of oil and gas wells is very important for reservoir management, production process optimization and production. Process monitoring and so on are of great significance. But so far this detection is basically realized by a separator, which has poor precision and low efficiency, and an automatic detection device that does not need to be separated is urgently needed. Embodiment 2 The process of using this configuration to detect oil-gas-water three-phase flow is as follows:

[0084] In the first step, representative parameters of the multiphase flow are defined...

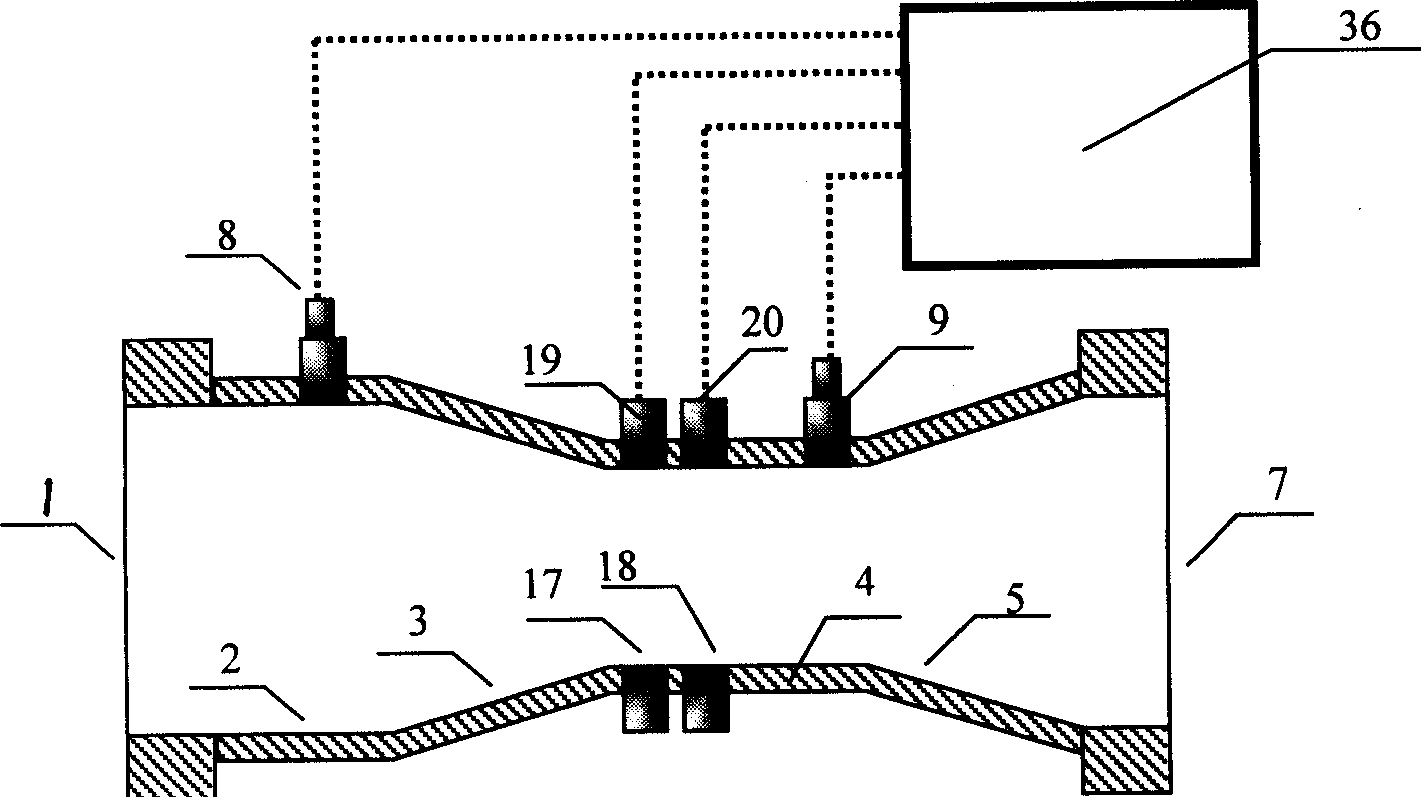

Embodiment approach 3

[0093] This configuration of Embodiment 3 can be used for flow rate and water content detection of water-carrying condensate gas and other two-phase flows containing moisture. Its detection process is similar to Embodiment 2.

[0094] Fig. 5 is a structural schematic diagram of Embodiment 4 of the present invention. It can be seen from the figure that the partial structure of this embodiment is completely the same as that of Embodiment 2, and the completely identical structure of this part will not be repeated here. The difference between the two implementations:

[0095] First of all, the throttling device can be made without insulating materials, the ultrasonic transducers 11, 12 near the inner surface of the throat 4 have changed their spatial positions, and an ultrasonic transducer 13 has been added, which is compatible with the ultrasonic transducer. The transducer 11 is directly coupled through the pipe wall, or directly coupled through other coupling materials, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com