High-speed reblading mechanism for small drilling and milling center

A tool-changing mechanism, drilling and milling technology, applied in metal processing machinery parts, clamping, support and other directions, can solve the problems of small size of BT15 spindle taper hole, troublesome development needs of precision parts, complex tool-changing mechanism, etc., to reduce labor costs. Labor intensity, high-speed and reliable tool changing mechanism, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

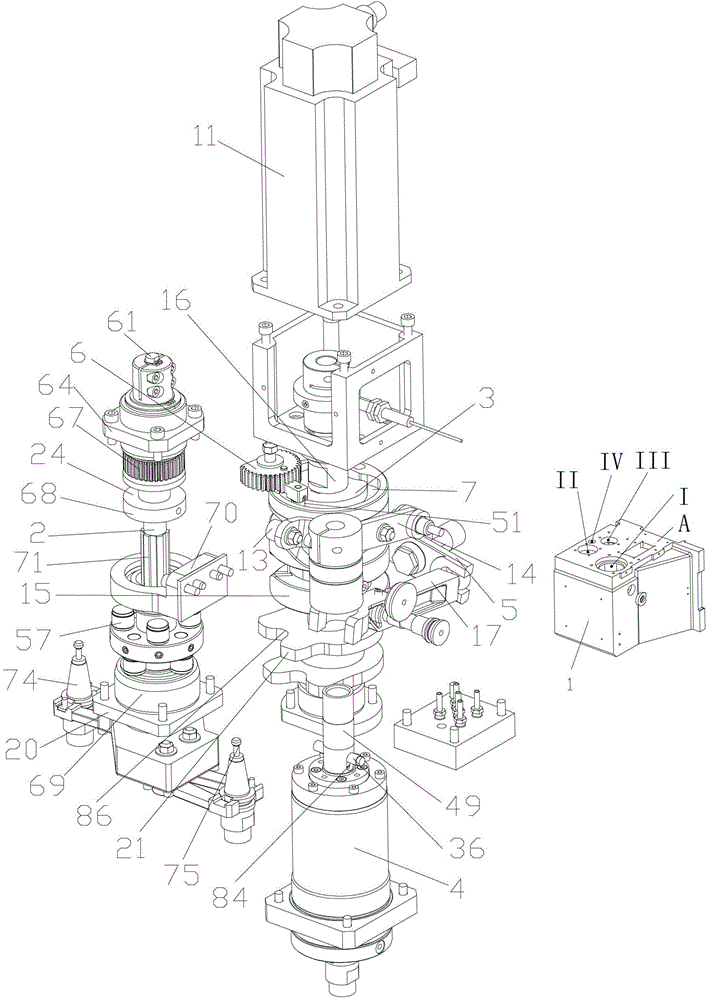

[0029] Attached below Figure 1-19 An embodiment of the present invention is described.

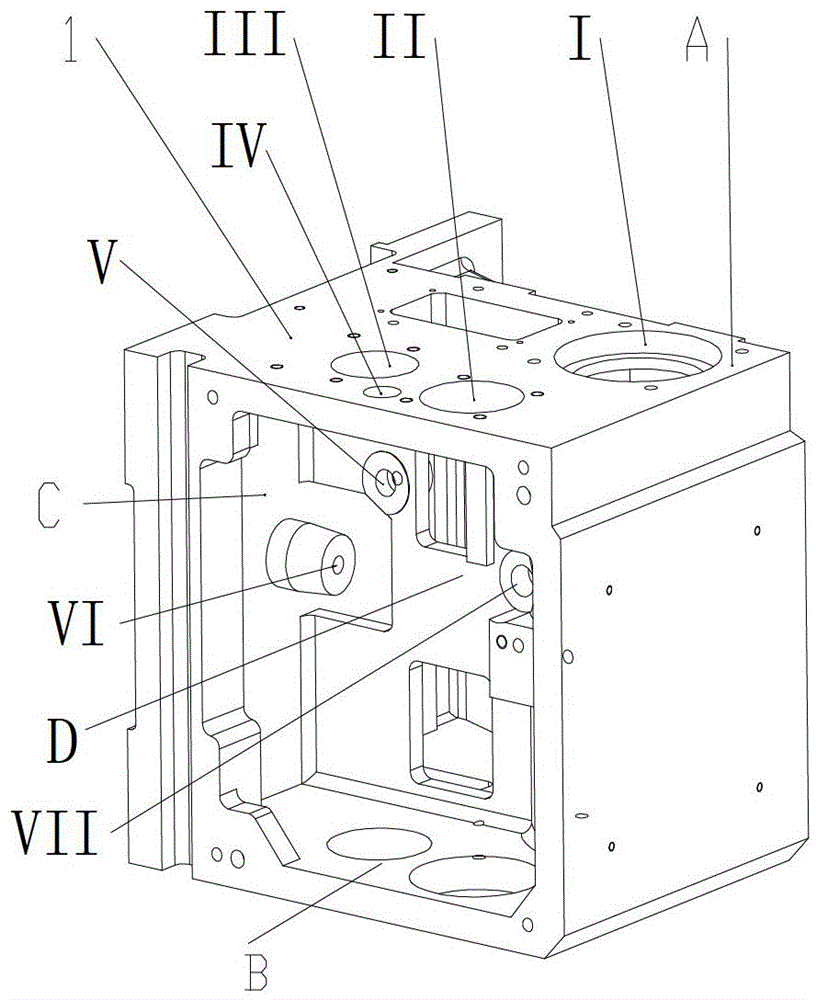

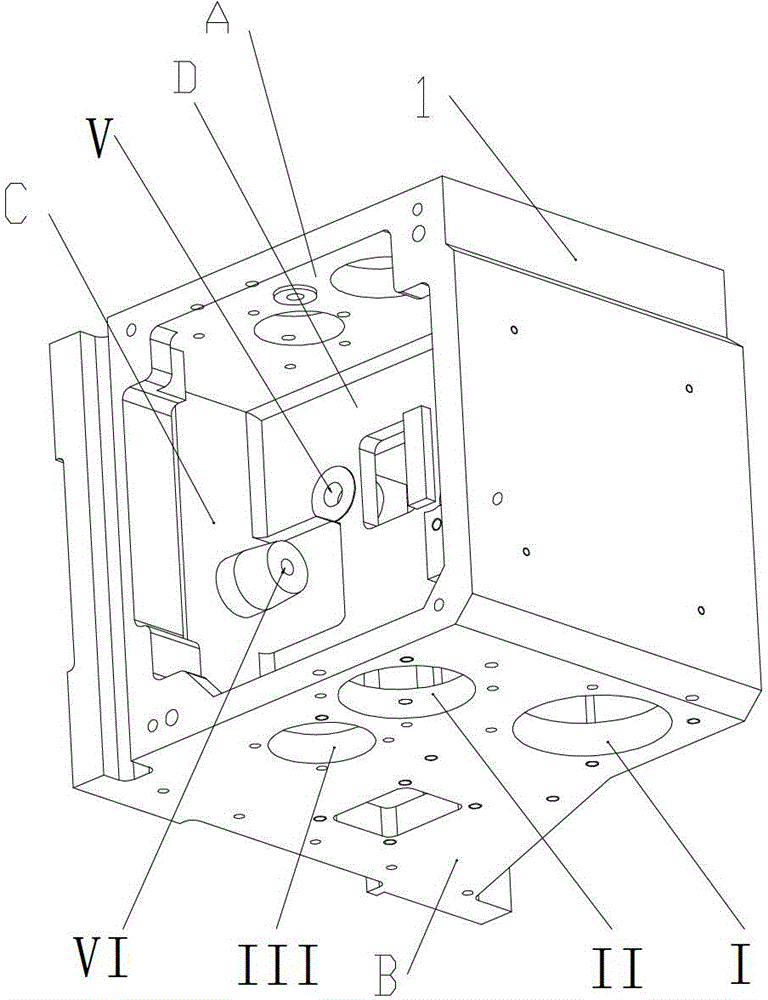

[0030] High-speed tool change mechanism for small drilling and milling centers, with spindle housing 1, such as Figure 2-3 As shown, the A surface of the spindle housing 1 is formed with I, II, III shaft holes penetrating the B surface and the IV axis hole not penetrating the B surface, the C surface is formed with the VI axis hole, and the D surface is formed with the Ⅴ and Ⅶ shaft holes; if figure 1 As shown, the main shaft system 4 is installed in the shaft hole I, and the camshaft system 3 is installed in the shaft hole III. The camshaft 16 of the camshaft system 3 is fitted with an end face cylindrical cam 15 and a plane cam 21 and the end face cylindrical cam 15 is located above the plane cam 21, the end face cylindrical cam 15 is shaped on the end face curved groove 7, the circumference curve groove I8 and the circumference curve groove II12, and the plane cam 21 is shaped on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com