Axial type energy-saving fan blade for extrusion and cutting process

A fan blade and axial flow technology, applied in the field of axial flow energy-saving fan blades, can solve the problems of energy waste, poor economic benefit, increase in manufacturing cost, etc., and achieve the effects of high operation efficiency, reduced manufacturing cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

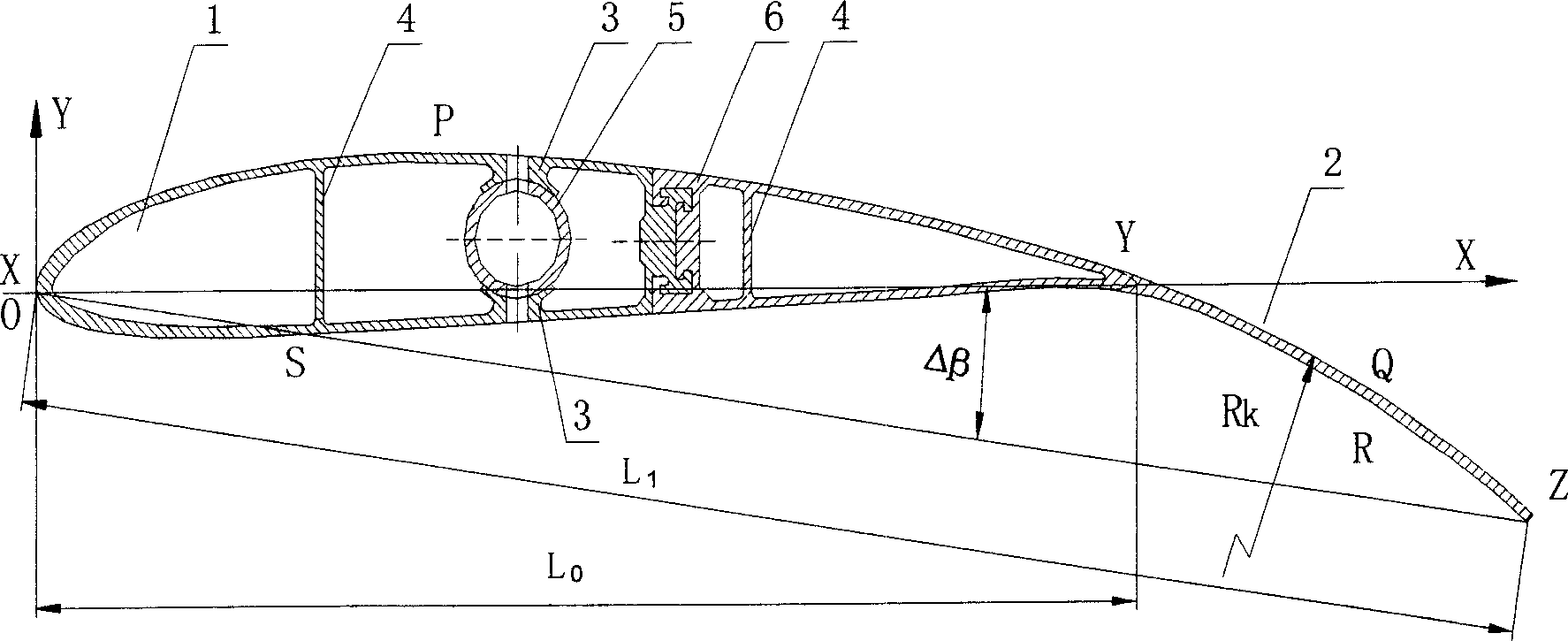

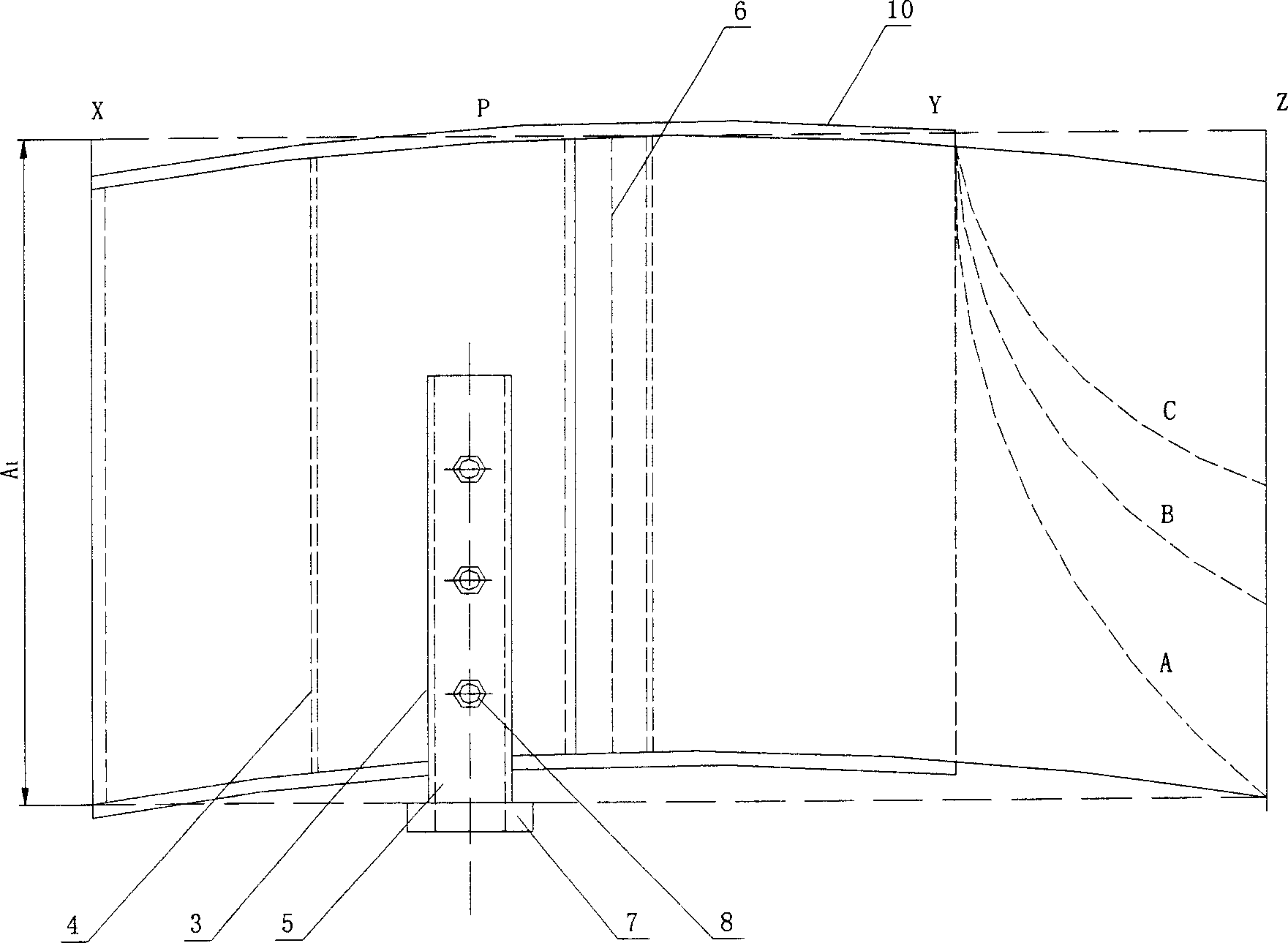

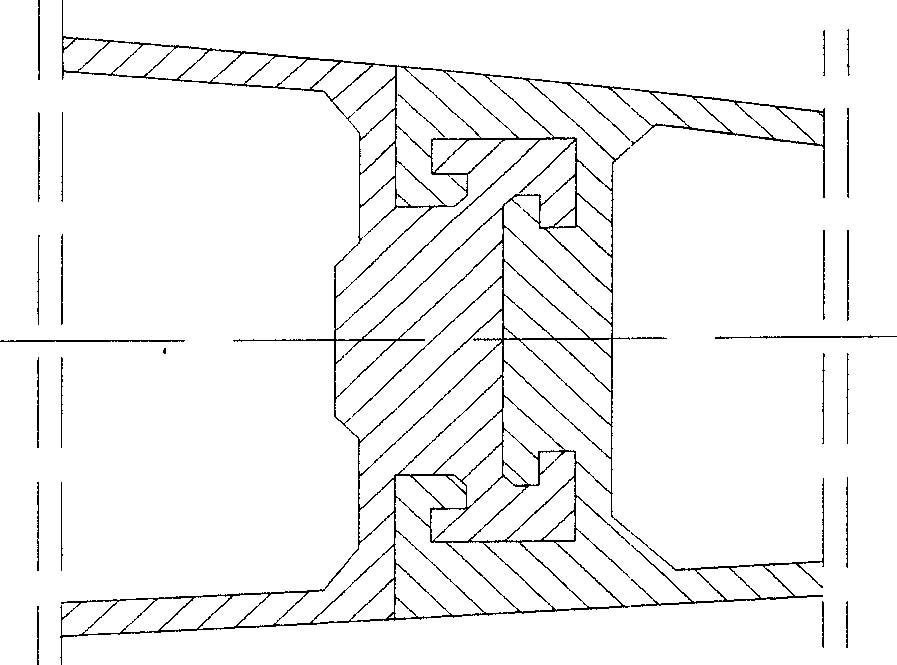

[0024] The fan blade of the present invention is an airfoil type cavity blade, and the cross-sectional view of its structure is as follows: figure 1 As shown, it is composed of a hollow airfoil-shaped main body 1 at the front section and a solid trailing edge 2 at the rear section, and the material is made of aluminum alloy or glass fiber reinforced plastic (FRP). The petiole 5 is made of steel pipe, inserted into the special arc-shaped seat 3 in the middle of the inner cavity of the airfoil main body 1, and fastened to the blade with screws, and the other end of the petiole 5 is fixed on the impeller hub through a flange. The arc-shaped seat 3 can increase the contact surface area between the airfoil-shaped main body 1 and the blade handle 5, so as to reduce the amount of contact deformation. According to the size of the chord leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com