Method for measuring gas pressure of coal seam by casing high-pressure hole sealing method

A technology of coal seam gas pressure and casing, applied in the direction of measurement, earthwork drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

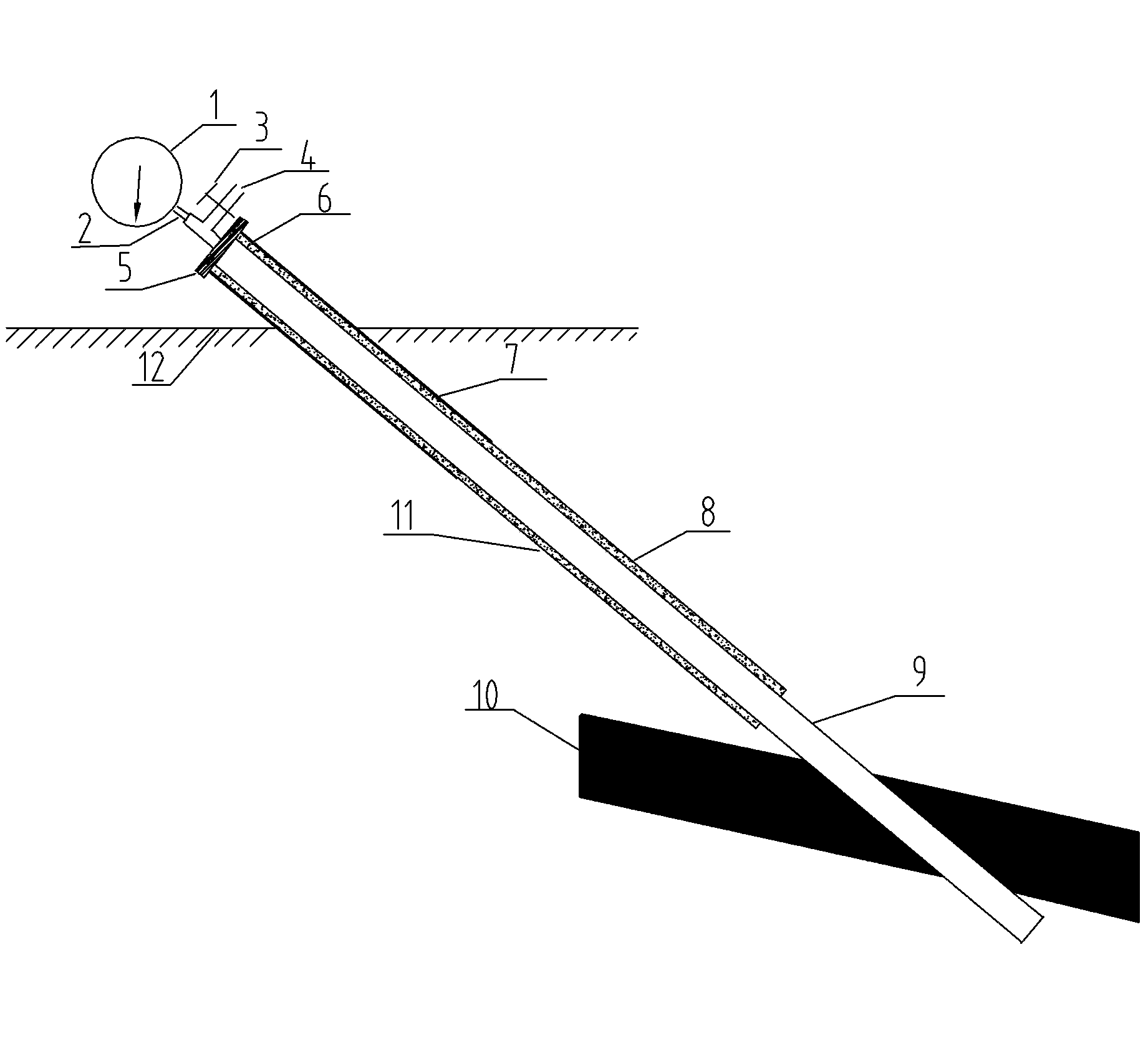

[0022] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] like figure 1 Shown, the present invention provides a kind of casing pipe high-pressure sealing method to measure the method for coal seam gas pressure, and the method comprises the following steps: a, first adopt the drill bit opening 7 of large-diameter drill bit φ 108mm, drill into 5m (this drilling depth is with It is advisable to strengthen the casing), then withdraw the drill pipe, sweep away the drilling debris in the hole 7, and send the casing 6 with the flange 5 into the hole 7. The length of the casing is 5.5 m, and the length of the exposed hole is 500mm; b. Inject the expanded cement mortar into the hole 7 by grouting to reinforce the casing 6, and the grouting pressure is 4MPa; c. After the pressure tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com