All-bridge type piezoresistance type pressure sensor digital type signal conditioning chip

A signal conditioning chip and pressure sensor technology, applied in the field of digital signal conditioning chips, can solve the problems of increasing the cost of chips, achieve low cost, high conditioning precision, and overcome low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

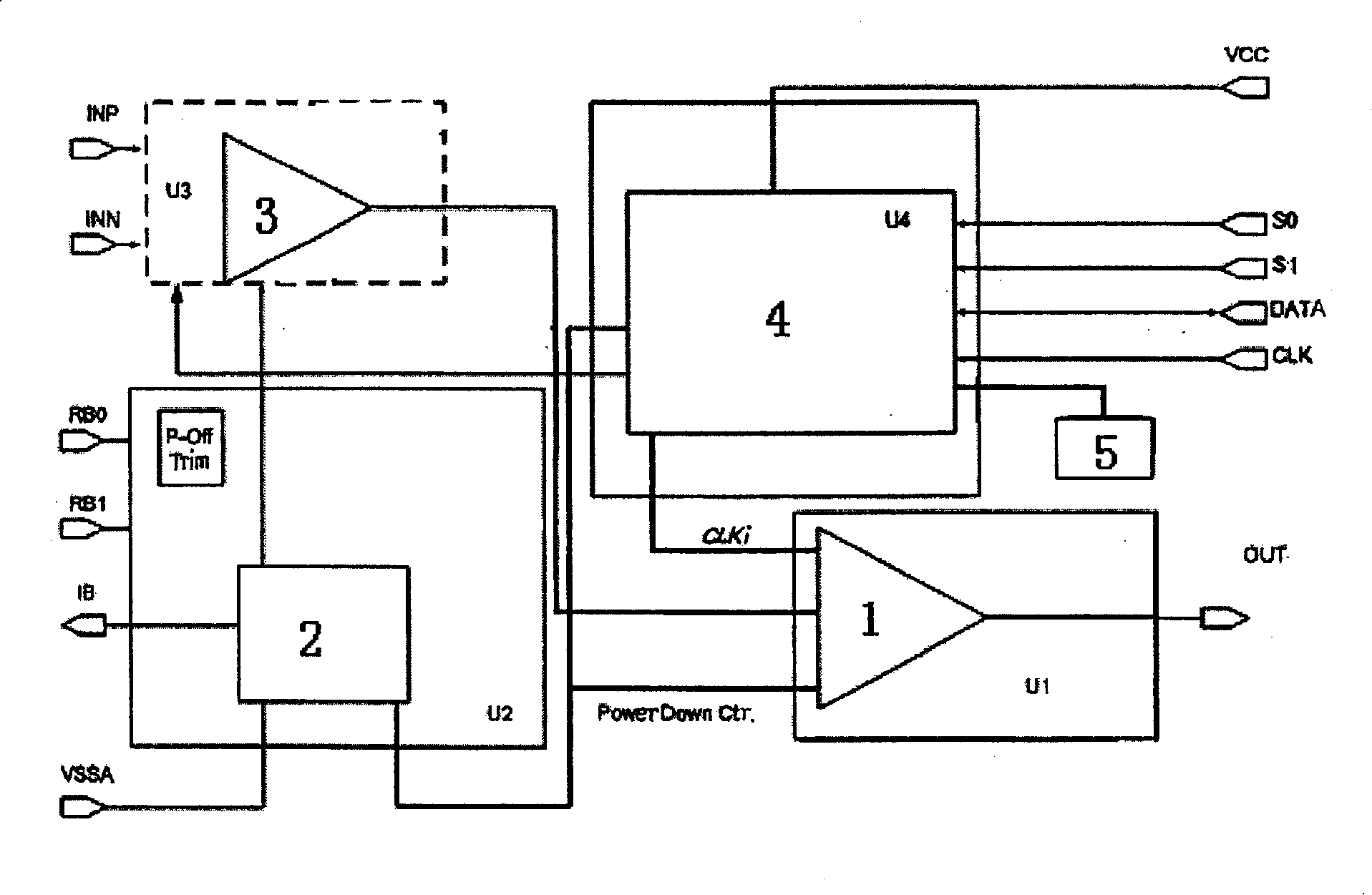

[0019] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0020] Working principle of the present invention:

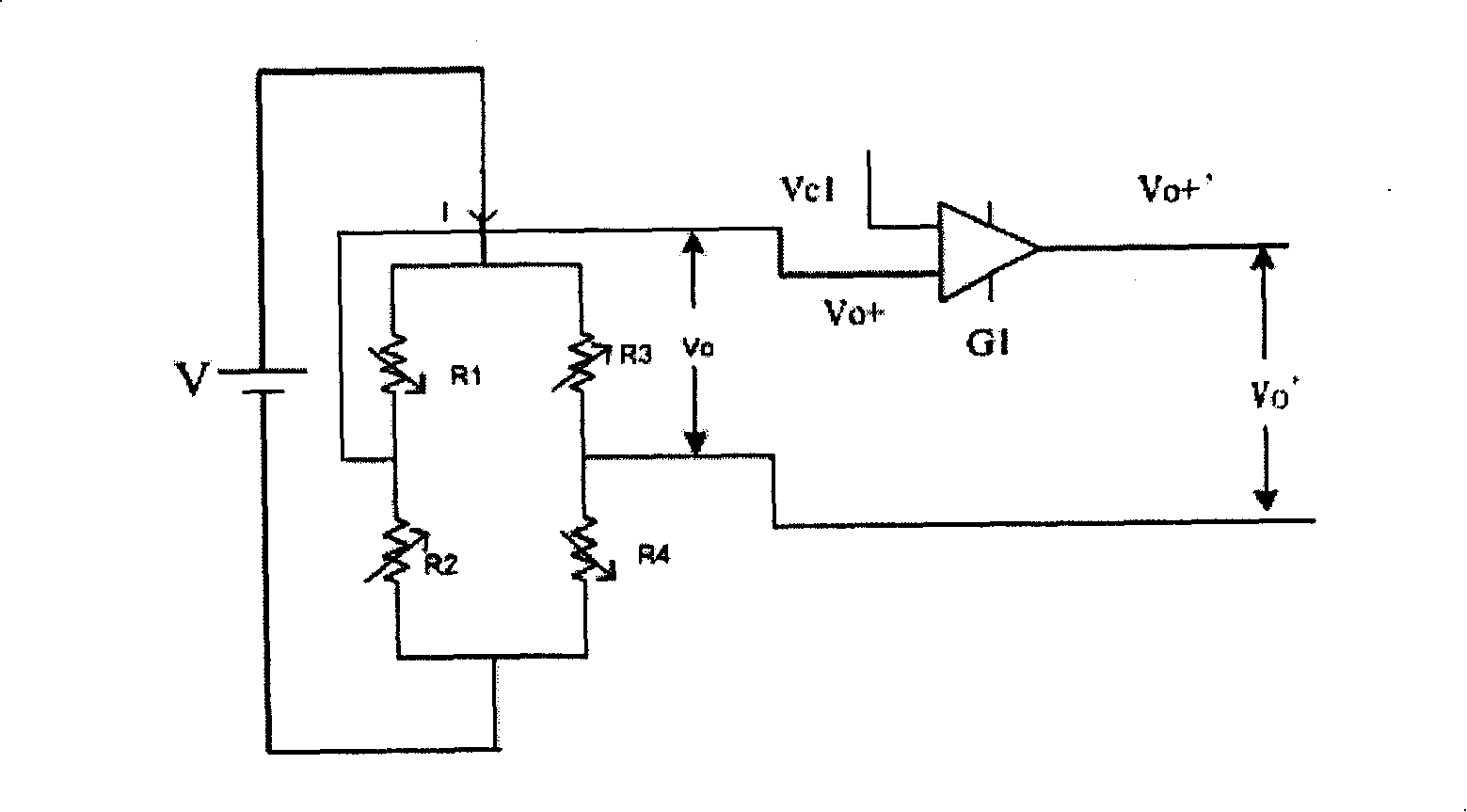

[0021] For the principle of zero temperature drift compensation, see image 3 , under zero pressure, test the high and low temperature data of the sensor, and obtain the temperature function expression of the sensor zero output:

[0022] V o = k 0 T + b · 0

[0023] V c1 The expression is: V c1 =K 0 T+B 0 . There are two registers corresponding to it: RSV 1 、RSV 2 . RSV 1 Store parameter K 0 , whose value is the k calculated by testing 0 , RSV 2 store parameter B 0 , whose value is b calculated by testing 0 .

[0024] K 0 The range is: 0.01:0.1

[0025] B 0 The range is: -15:+15

[0026] Sensitivity temperature compens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com