NEMS piezoresistive pressure sensor chip and its making process

A pressure sensor and piezoresistive technology, which is applied in the field of MEMS devices, can solve the problems of poor uniformity of pressure-sensitive film thickness, poor piezoresistive consistency, and difficult leakage current, so as to improve yield, reduce leakage current, and reduce zero point output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

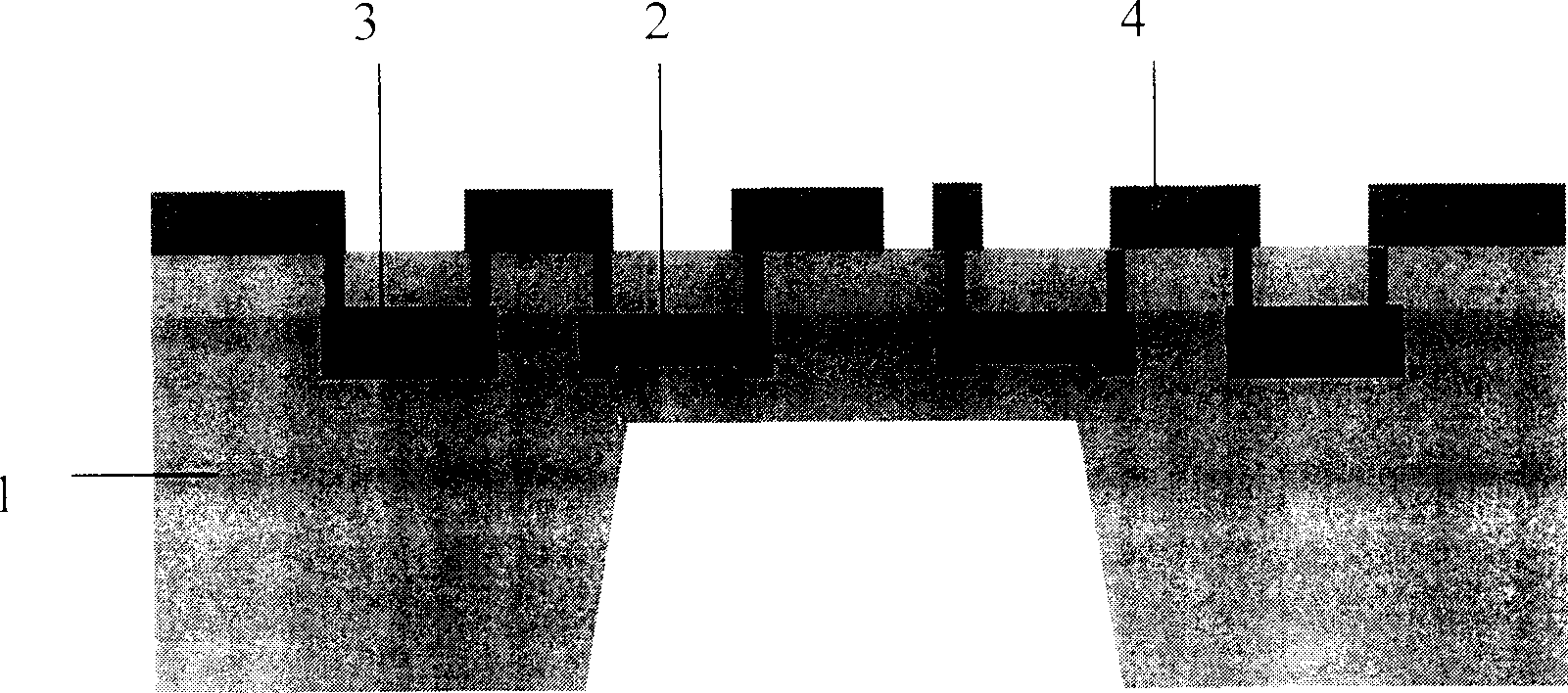

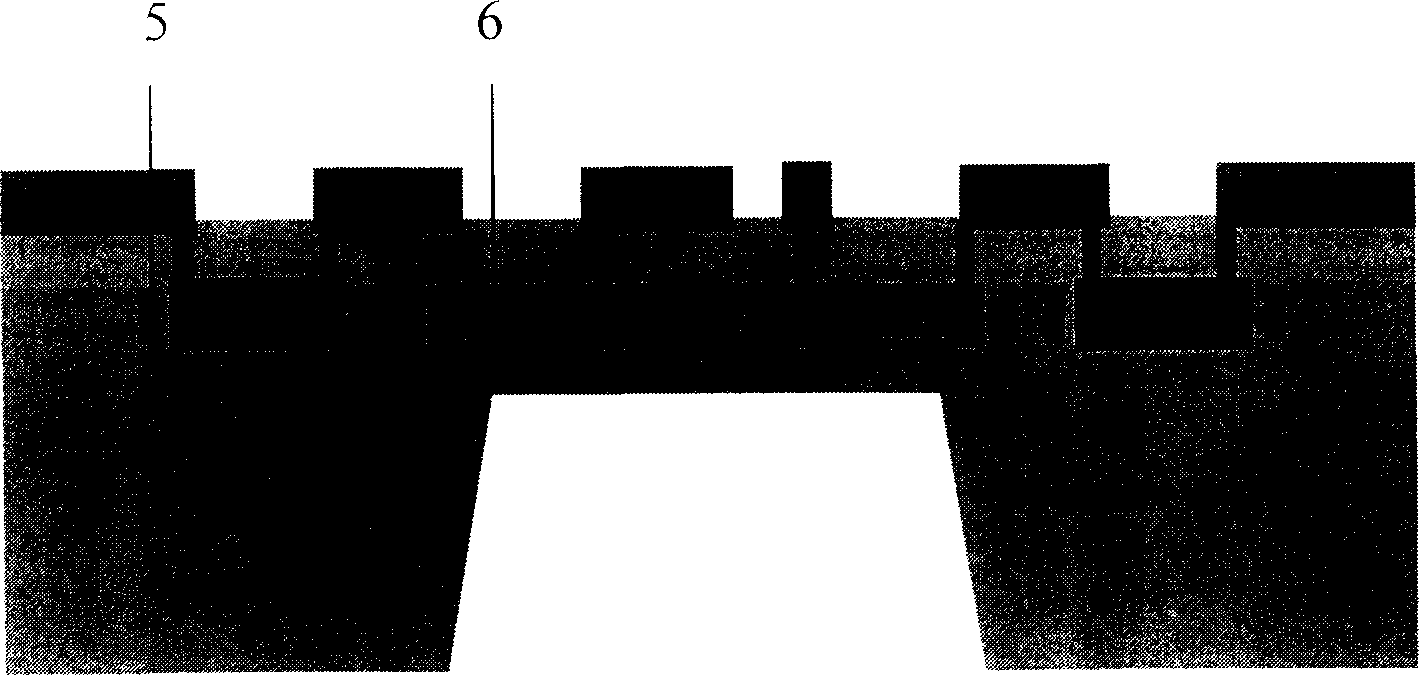

[0023] A 4-inch 400-micron-thick N-type double-sided polished single crystal silicon wafer is used, with a resistivity of 2-4Ωcm.

[0024] 1. After the silicon wafer is cleaned, perform original oxidation of 300-350nm;

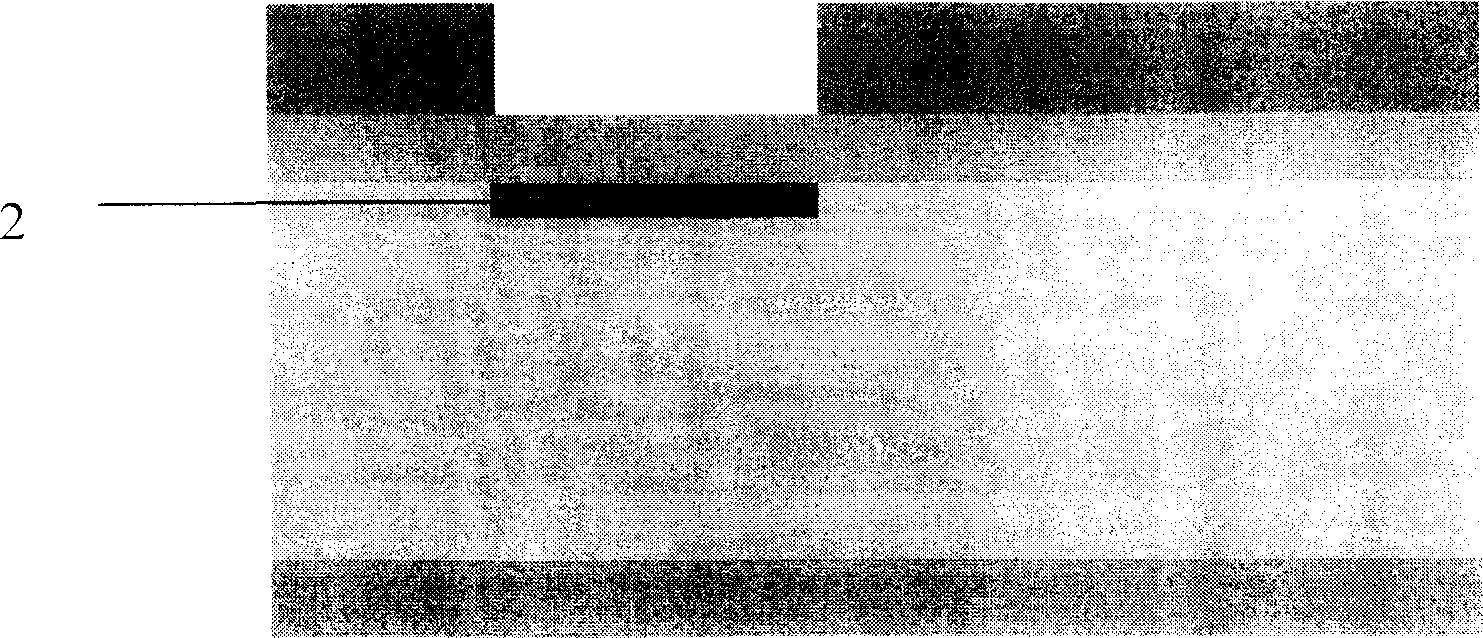

[0025] 2. The high-precision piezoresistor is prepared by ion implantation technology, and the implantation conditions are: 90-120KeV, 1.0×10 14 cm -2 -2.0×10 14 cm -2 , and then carry out boron drive-in, the condition is 1000-1500 ℃, 80-120 minutes;

[0026] 3. Diffusion of concentrated phosphorus forms n + Isolation, body concentration > 1.0×10 after annealing 19 cm -3 ;

[0027] 4. Concentrated boron diffuses to form p + Connection, body concentration > 5.0×10 after annealing 18 cm -3 ;

[0028] 5. KOH corrodes the back cavity, and the thickness of the film is controlled by the mark on the front of the pressure-sensitive film;

[0029] 6. Engraving lead holes, sputtering aluminum, alloy, 400-420°C, 30 minutes;

[0030] 7. Bonding, dicing, fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com