Piezoresistive pressure sensor and preparation method thereof

A pressure sensor and piezoresistive technology, which is applied in the measurement of fluid pressure by changing ohmic resistance and the measurement of the property force of piezoresistive materials. It can solve problems such as poor biocompatibility and reduce transmission channels. , the effect of increasing the forbidden band width and increasing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

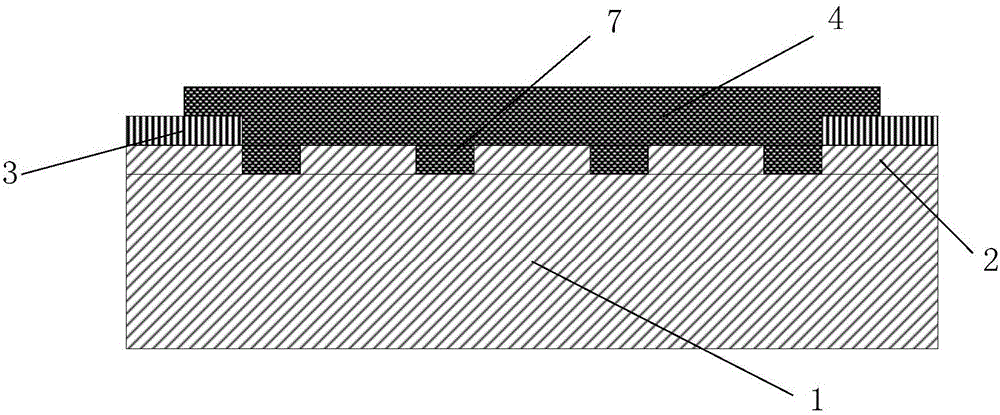

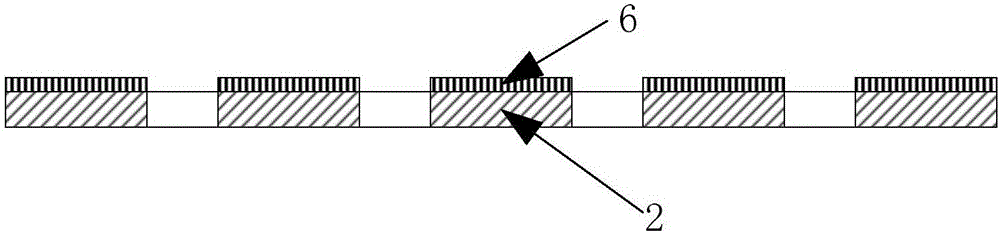

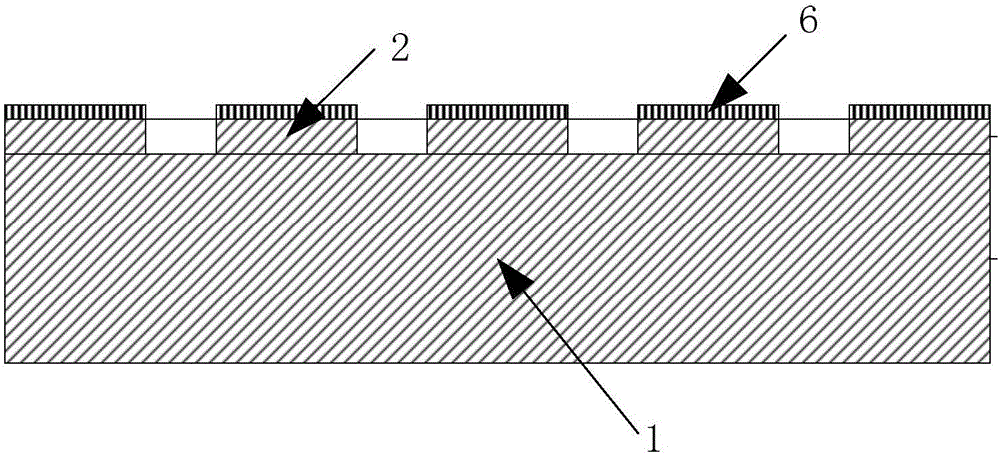

[0033] Such as figure 1 As shown, a piezoresistive pressure sensor according to an embodiment of the present invention includes an LCP substrate 1 , an LCP film layer 2 , a metal electrode 3 , a graphene film layer 4 and a graphene array layer 7 . The LCP thin film layer 2 is fixedly connected on the LCP substrate 1 , the LCP thin film layer 2 is provided with through holes in an array structure, and the metal electrodes 3 are connected above the two ends of the LCP thin film layer 2 . The graphene film layer 4 is connected on the LCP film layer 2, and the graphene film layer 4 fills the gap between the metal electrodes 3 and covers the metal electrodes 3. The graphene array layer 7 is filled in the through hole of the LCP film 2, and the graphene film layer 4 and the graphene array layer 7 are connected.

[0034] Liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com