Pressure sensor

A pressure sensor and piezoresistive element technology, applied in the measurement of fluid pressure, instruments, and fluid pressure measurement through electromagnetic elements, can solve problems such as dependence and measurement error, and achieve the effect of improved sensitivity and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

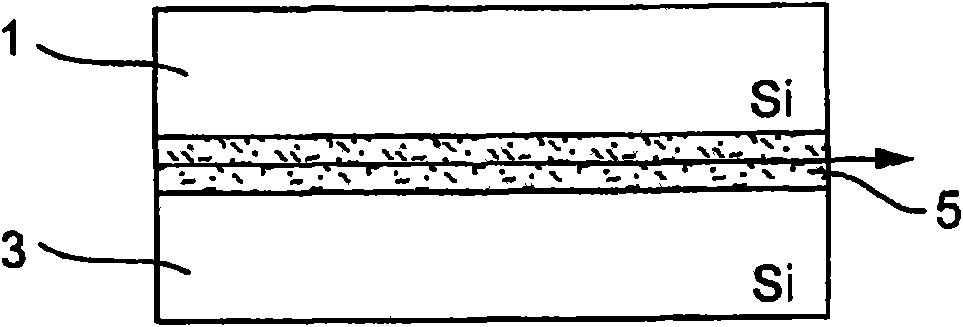

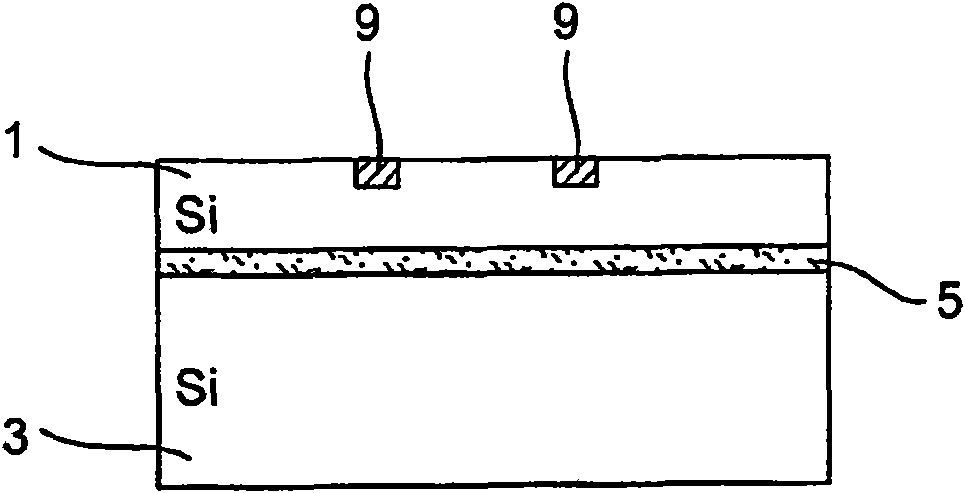

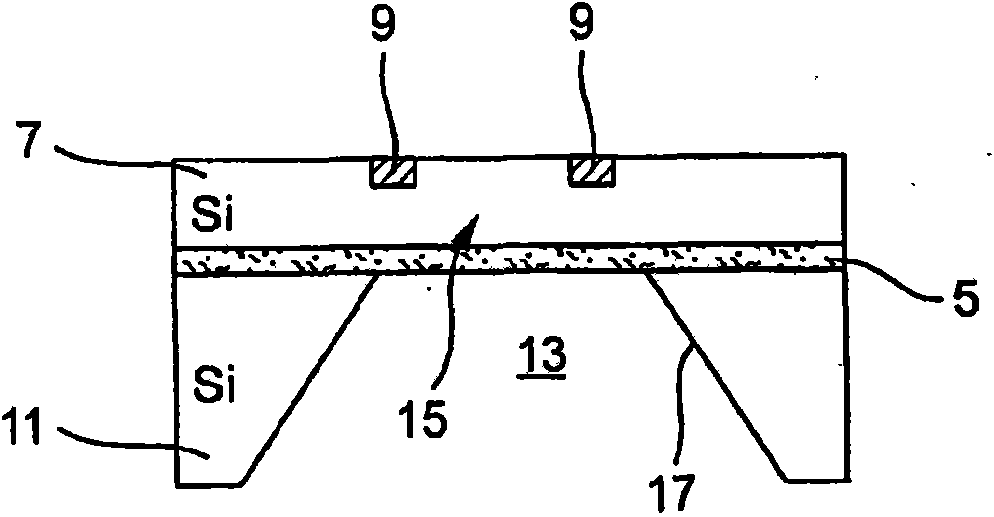

[0049] The pressure sensor of the present invention is a semiconductor sensor on a silicon substrate, which is produced by using silicon-on-insulator (SOI) technology. Here, the conventional BESOI (Bonded and etchback silicon on insulator: silicon wafer bonding and backside etching) wafer is used as the starting material. BESOI wafers are produced, for example, from two silicon oxide wafers which are oriented opposite and bonded under pressure and high temperature. In this way, obtaining a figure 1 A three-layer wafer is shown having first and second silicon layers 1,3. An oxide layer 5 is located between the first and second silicon layers 1,3. The buried oxide layer 5 is called BOX (Buried oxide layer), and its thickness is several nm to several μm.

[0050] This compound is thinned and polished from one side. The thinned and polished side forms the active layer 7 . The active layer can be several μm thick and is called, for example, device wafer or silicon overlayer (S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com