Piezoresistive pressure sensor chip adopting face down bonding and preparing method thereof

A pressure sensor, flip-chip welding technology, applied in the field of micro-electromechanical systems (MEMS) devices, can solve the problems of poor consistency of piezoresistors, easy breakage of metal wires, limiting the wide application of MEMS piezoresistive pressure sensors, etc., to reduce packaging. cost, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

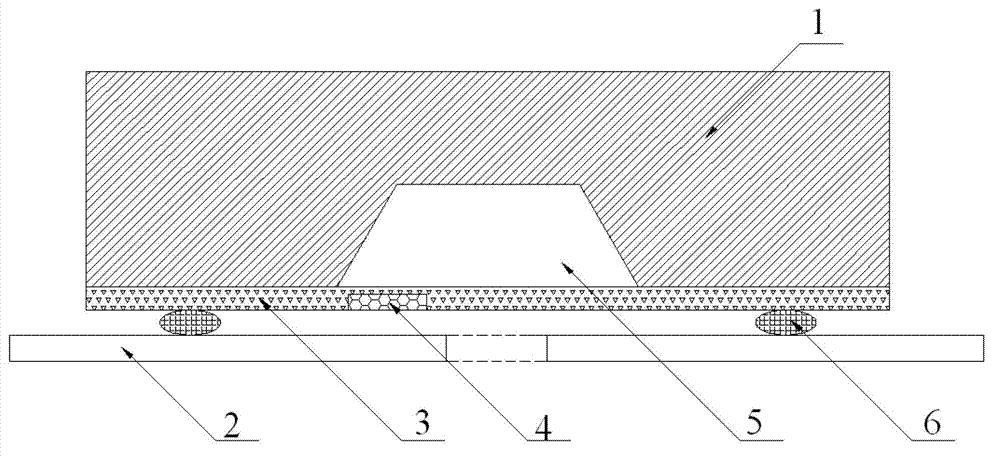

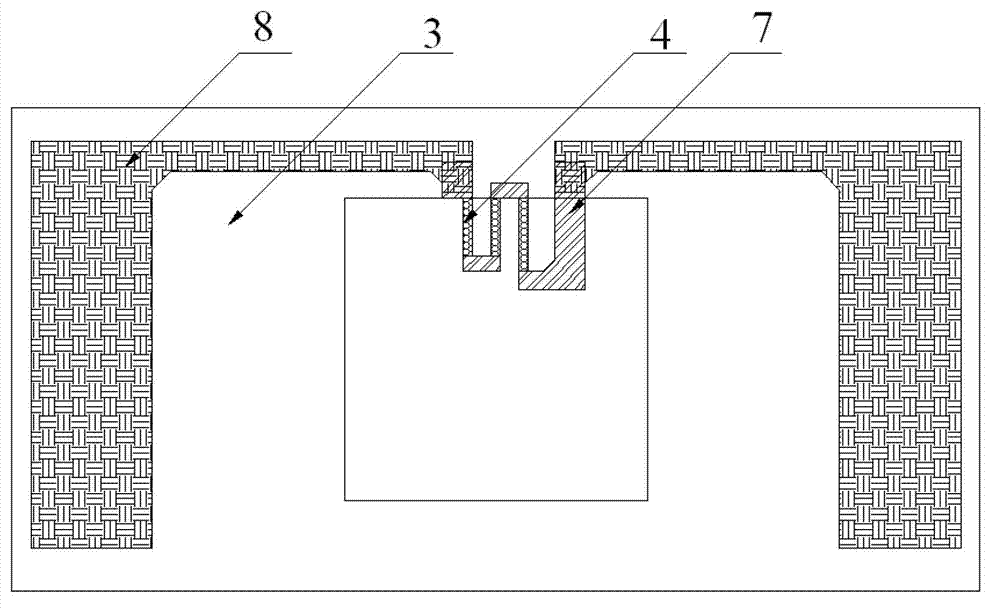

[0038] Such as figure 1 and 2 As shown, the embodiment of the piezoresistive pressure sensor chip adopting flip-chip welding is provided with a chip body, and the chip body is provided with a silicon substrate 1 and a silicon film 3 with a square pressure chamber 5, and the surface of the silicon film 3 is provided with There is a piezoresistor 4, the silicon substrate 1 and the silicon film 3 are bonded directly through silicon and silicon; the chip of the piezoresistive pressure sensor is welded on the PCB board 2 by flip-chip welding; the piezoresistor 4 3 resistors with the same resistance as the varistor 4 in the external circuit form a complete Wheatstone bridge for sensitive pressure changes.

[0039] The chip body may be a cup-shaped structure.

[0040] The embodiment of the piezoresistive pressure sensor chip using flip-chip welding is formed by direct bonding of SOI wafers and silicon wafers. The process for realizing the chip is mainly divided into three stages, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com