Pressure sensitive layer applied to piezoresistive pressure sensor and piezoresistive pressure sensor

A pressure sensor and sensitive layer technology, applied in the direction of fluid pressure measurement, instrument, and measurement force by changing ohmic resistance, can solve the problems of high cost and low sensitivity, and achieve high sensitivity, good flexibility, and easy miniaturization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

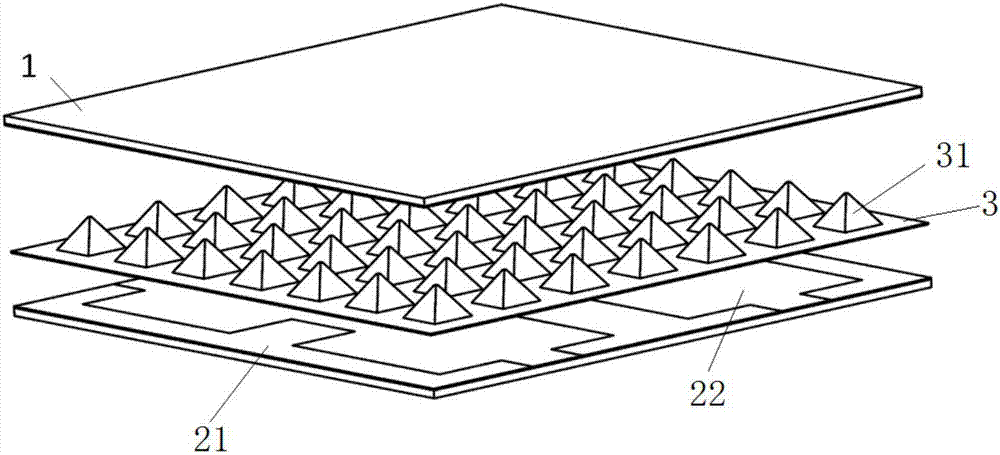

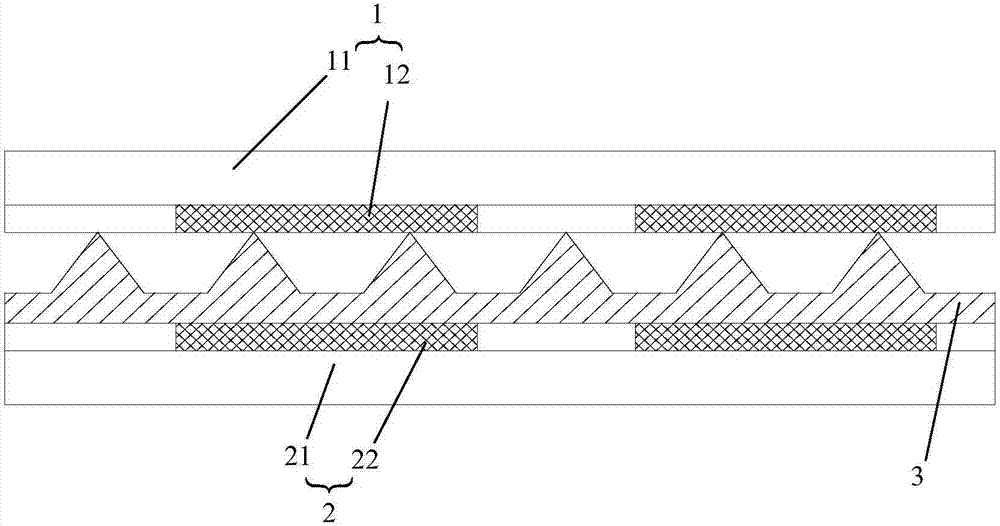

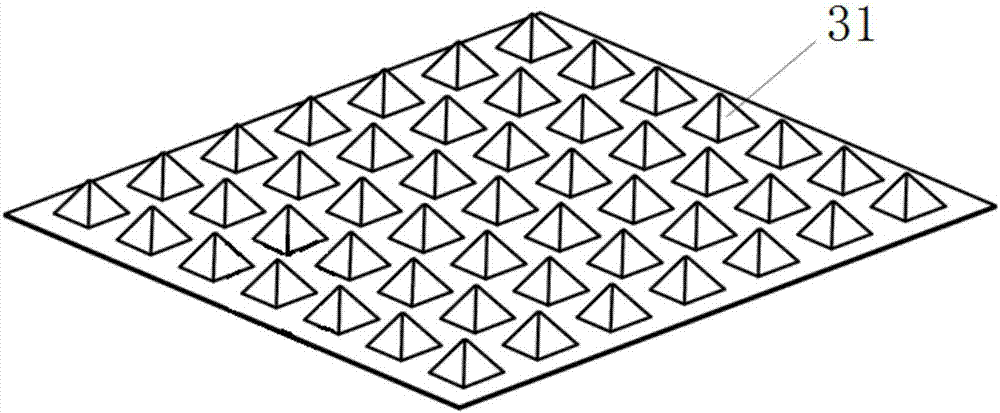

[0035] Such as figure 1 with figure 2 As shown, the piezoresistive pressure sensor includes a first electrode plate 1, a second electrode plate 2 and a pressure sensitive layer 3 sandwiched between the two. The pressure sensitive layer has one layer, and at least one microstructure 31 in its microstructure array is connected to the The electrodes of the first electrode plate 1 are in contact, and the first electrode plate 1 , the pressure sensitive layer 3 and the second electrode plate 2 are bonded to each other. Wherein, the first electrode plate 1 comprises the first substrate film 11 and the first electrode 12, the second electrode plate 2 comprises the second substrate film 21 and the second electrode 22, the first electrode 12 and the second electrode 22 can adopt Certain shapes of ITO (indium tin oxide), silver nanowires. Conductive film materials such as graphene, polymer materials such as PET and PMMA can be used for the first substrate film 11 and the second subst...

Embodiment 2

[0046] In this example, a patterned silver nanowire film is selected as the first electrode and the second electrode to extract electrical signals. The main difference between this example and example 1 is that the pressure sensitive layer has two layers. Such as Image 6 As shown, the fabrication process of the piezoresistive pressure sensor is as follows:

[0047] S1, utilizing silicon wet etching process (potassium hydroxide solution can be used, the proportion is: KOH: 70g, H 2 O: 190mL, isopropanol (IPA): 40mL; magnetic stirring in a water bath at 80°C) to make a microstructure silicon mold with a pitch of 50μm and a microstructure height of 20μm and silanize the surface (in this example, use 1H, 1H, 2H, 2H - Perfluorodecyltrichlorosilane, treated at 120°C for 3h) to obtain a hydrophobic surface;

[0048] S2. Coating liquid polyimide on the microstructured silicon mold, curing and forming at a high temperature of 400°C;

[0049] S3. Using a laser 6 with a power of 5.5W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com