Pressure sensitive core with thermistor

A technology of thermistors and sensitive resistors, which is applied in the direction of fluid pressure measurement, fluid pressure measurement, and measurement devices by changing ohmic resistance, and can solve problems such as limited compensation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

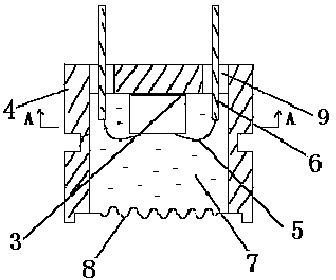

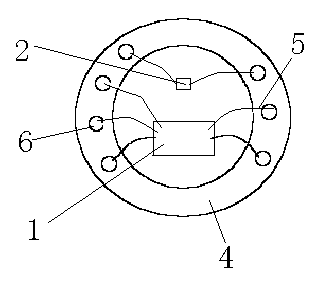

[0023] A pressure sensitive core with a thermistor, such as figure 1 As shown, the silicon-based pressure-sensitive chip 1 and the NTC thermistor 2 are bonded on the tube base 4 through the adhesive 3, and the bottom of the tube base 4 is packaged with a corrugated diaphragm 8, and the silicon-based pressure-sensitive chip 1 and the NTC thermistor 2 pass through The gold wire 5 is electrically connected to the Kovar pin 6, wherein the silicon-based pressure sensitive chip 1 is electrically connected to the five Kovar pins 6 respectively, and the NTC thermistor 2 is electrically connected to the two Kovar pins 6 The diameter of the tube base 4 is Φ15.6mm, the tube base 4 is filled with silicone oil 7, and the corrugated diaphragm 8 seals the silicone oil 7 and isolates the external medium. Said gluing way finally forms the thickness of the rubber compound which is less than 0.2mm. The silicon-based pressure-sensitive chip is a commercially available product, such as the MEMS s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com