High doping point electrode SOI piezoresistance type pressure sensor and manufacturing method thereof

A technology of a pressure sensor and a manufacturing method, which is applied in the direction of fluid pressure measurement by changing ohmic resistance, measurement of the property force of piezoelectric resistance materials, instruments, etc., can solve the problems of long metal electrodes and reduced reliability, and achieve Effects of reduced leakage current, improved reliability, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

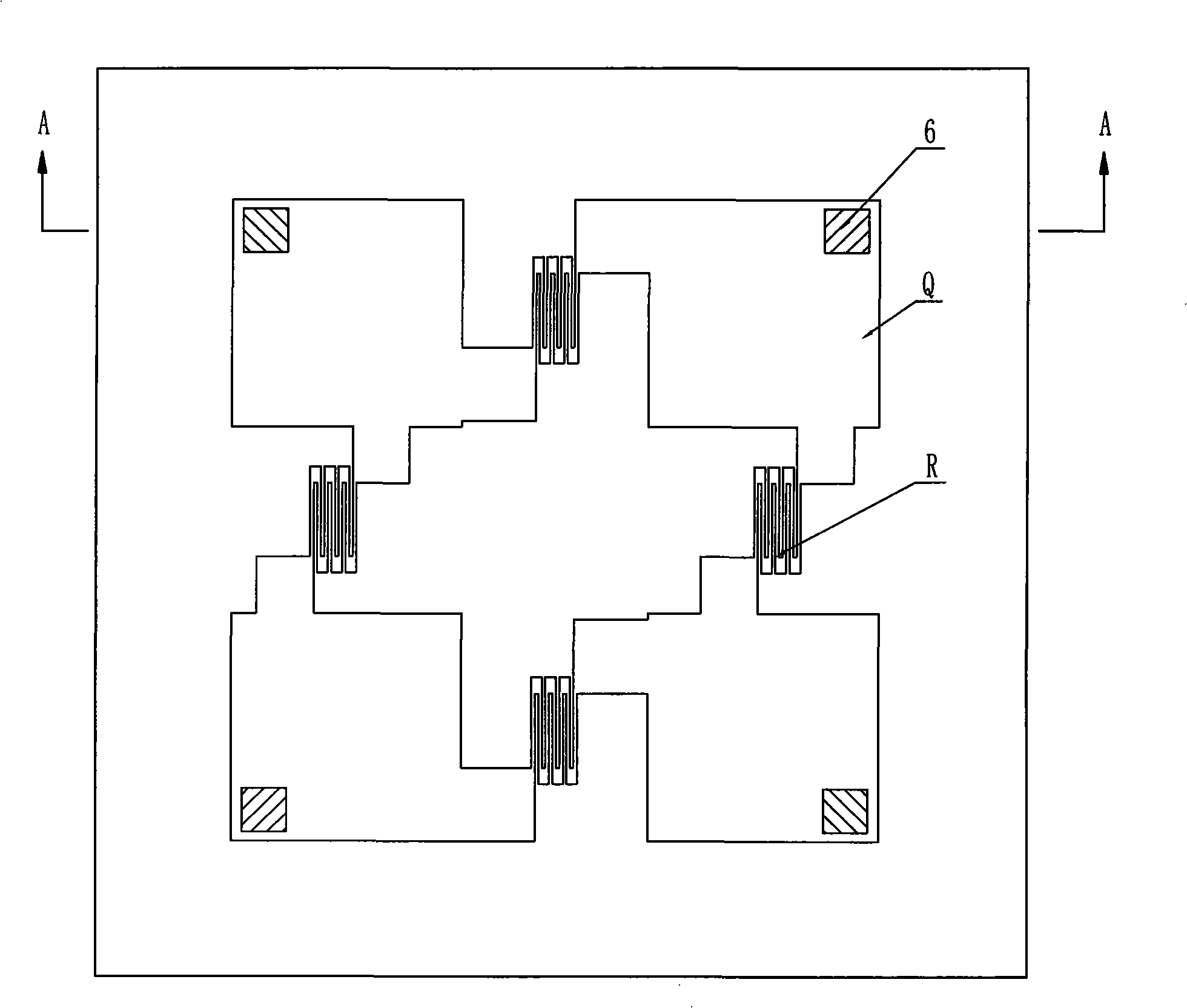

[0019] Specific implementation mode one: combine figure 1 and Fig. 9 illustrate the present embodiment, the highly doped point electrode SOI piezoresistive pressure sensor of the present embodiment consists of a silicon substrate 1, a first silicon dioxide layer 2, a thin silicon dioxide layer 3, a second silicon dioxide layer 4. A silicon nitride layer 5, an electrode 6 and a highly doped layer 7; the silicon substrate 1, the first silicon dioxide layer 2 and the highly doped layer 7 constitute an SOI diaphragm sequentially from bottom to top; A thin silicon dioxide layer 3, a second silicon dioxide layer 4 and a silicon nitride layer 5 are sequentially oxidized and grown on the outside of the SOI diaphragm from the inside to the outside; the highly doped layer 7 and the upper thin silicon dioxide layer 3 Etched into the pattern of the highly doped region Q and the sensitive resistor R, the electrode 6 penetrates the upper second silicon dioxide layer 4, the upper silicon nit...

specific Embodiment approach 2

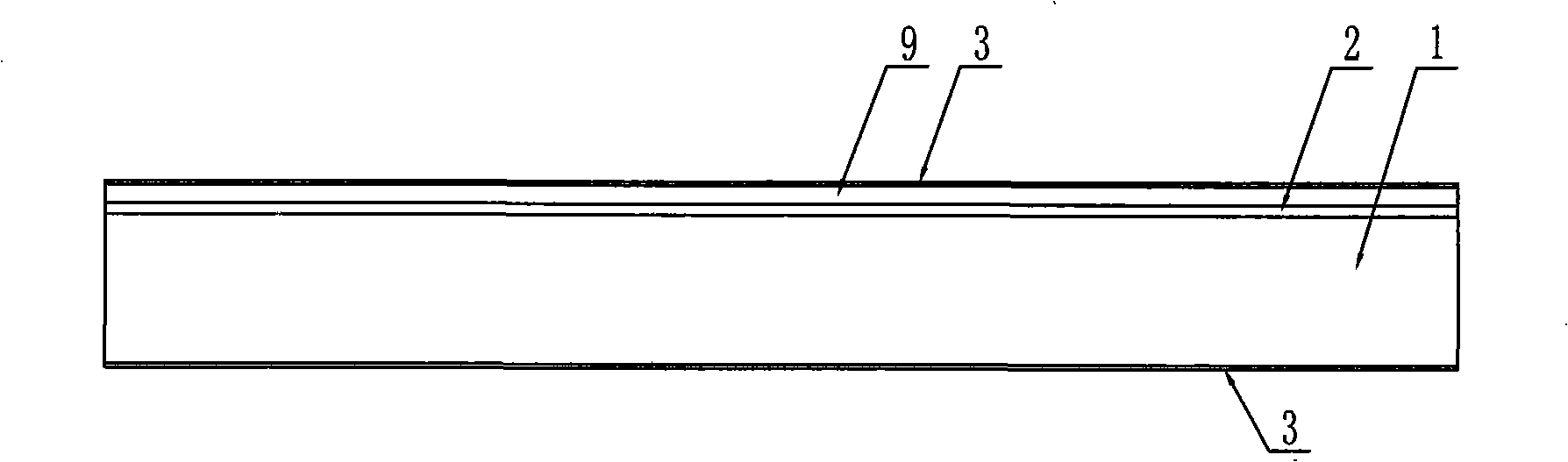

[0020] Specific implementation mode two: combination figure 2 Referring to FIG. 9 to illustrate this embodiment, the manufacturing steps of the highly doped point electrode SOI piezoresistive pressure sensor are as follows:

[0021] Step 1: Clean and oxidize the SOI diaphragm composed of the silicon substrate 1, the first silicon dioxide layer 2 and the device layer 9 to form a thin silicon dioxide layer 3 with a thickness of 50 nm; the first silicon dioxide layer 2 As a buffer layer injected with concentrated boron; cleaning is carried out by standard cleaning process of semiconductor planar technology;

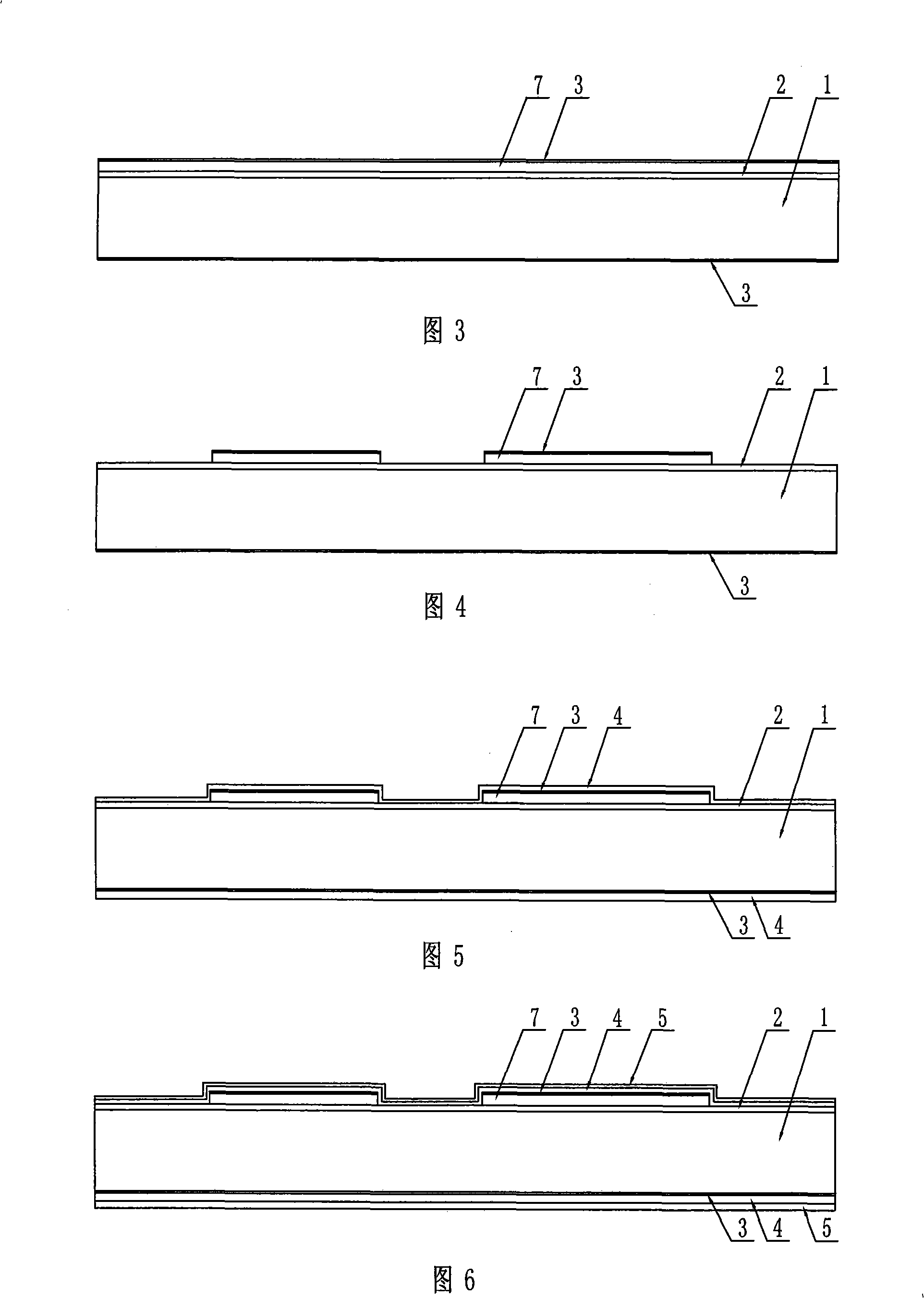

[0022] Step 2: As shown in FIG. 3 ; implant the device layer 9 with a concentration of 2×10 through a large beam implanter 20 cm -3 , implanting concentrated boron with an energy of 80 keV to form a highly doped layer 7;

[0023] Step 3: As shown in Figure 4; photolithography and etching are carried out on the highly doped layer 7 and the thin silicon dioxide layer 3 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com