Capacitance type minitype silicon microphone and preparation method thereof

A silicon microphone and capacitive technology, applied in the field of silicon microphone and its preparation, can solve the problems of extremely high process control requirements, increased process complexity, poor repeatability, etc., and achieves easy process, flexible design and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

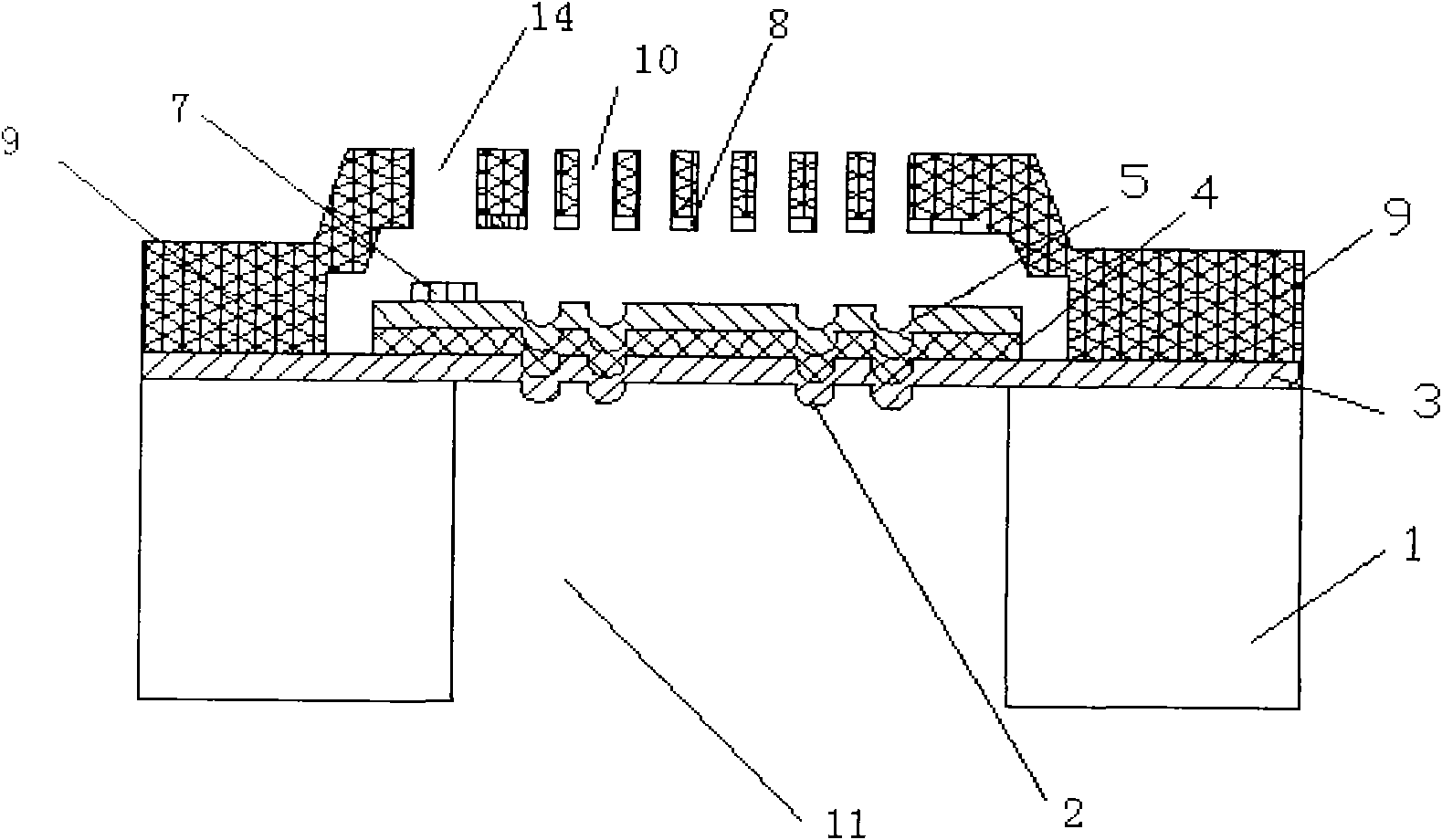

[0026] Such as Figure 1 to Figure 11 As shown: the present invention includes a substrate 1, a film groove 2, an insulating support layer 3, an insulating layer 4, a diaphragm 5, a sacrificial layer 6, a diaphragm electrode 7, a back plate 8, an insulating material layer 9, an acoustic hole 10, Acoustic cavity 11, movable beam 12, etching hole 13 and metal injection hole 14

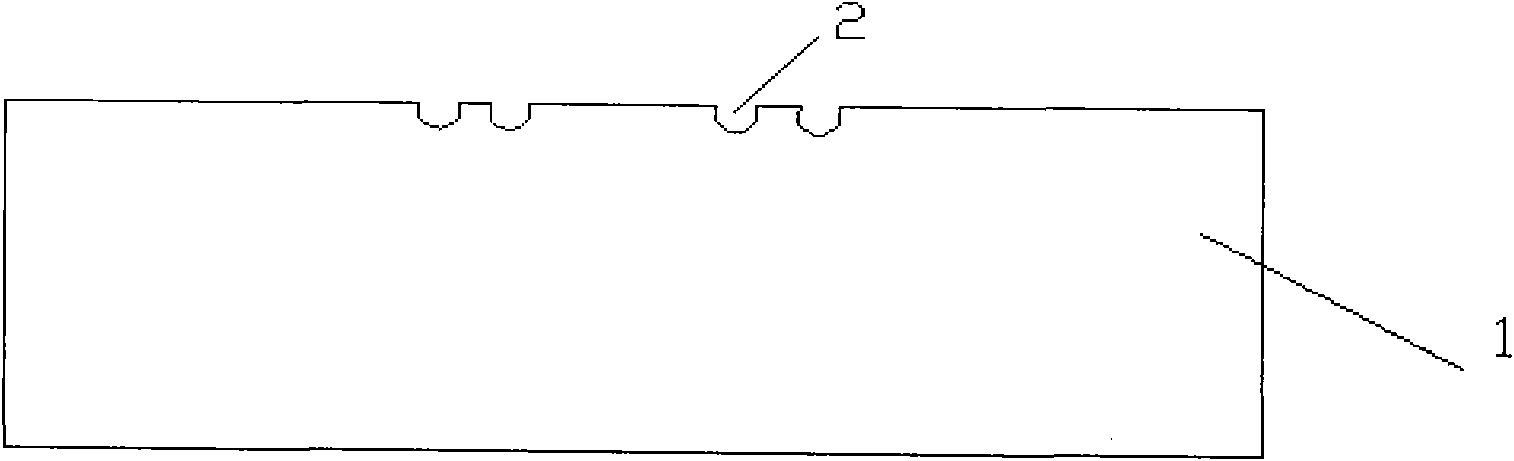

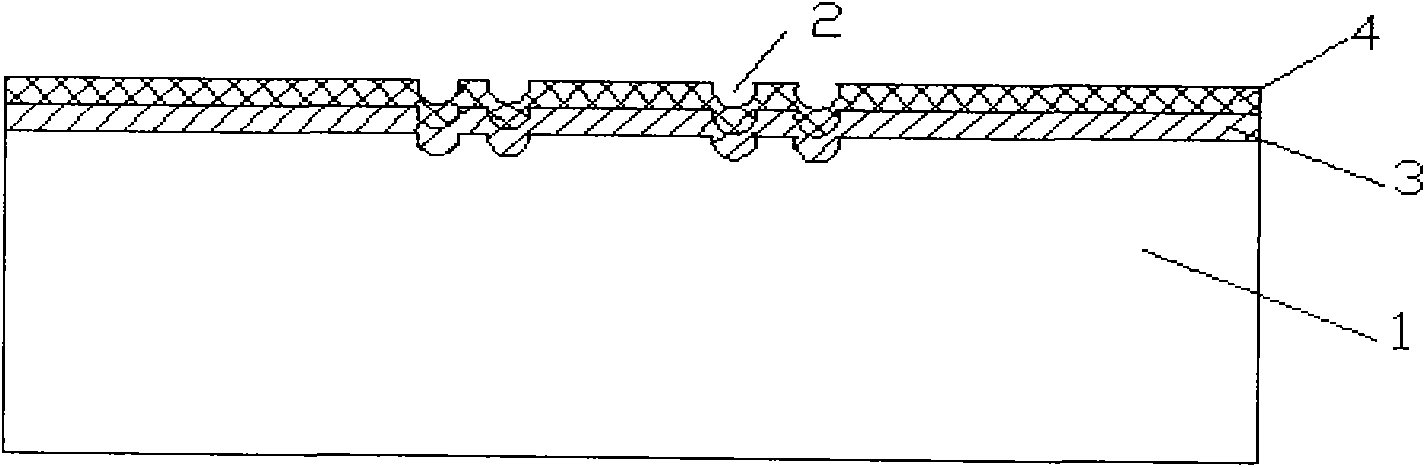

[0027] Such as figure 1 with Figure 10 As shown: the surface of the substrate 1 is concavely provided with a film groove 2 , and the substrate 1 corresponds to the surface on which the film groove 2 is provided with a deposited diaphragm 5 . The diaphragm 5 is conductive polysilicon or an insulating support layer 3 , an insulating layer 4 and a conductive layer form a composite structure. When the vibrating film 5 is an insulating support layer 3, the insulating layer 4 and the condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com