Method for knowledge extraction and evolution in machine parts processing technological procedure

A technology of processing technology and machine tool parts, applied in the field of knowledge extraction of parts processing technology, can solve problems such as lack of intelligent management, increased knowledge difficulty, unreasonable knowledge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A method for knowledge extraction and evolution in a machine tool part machining process specification of the present invention will be described in detail below in combination with embodiments and drawings.

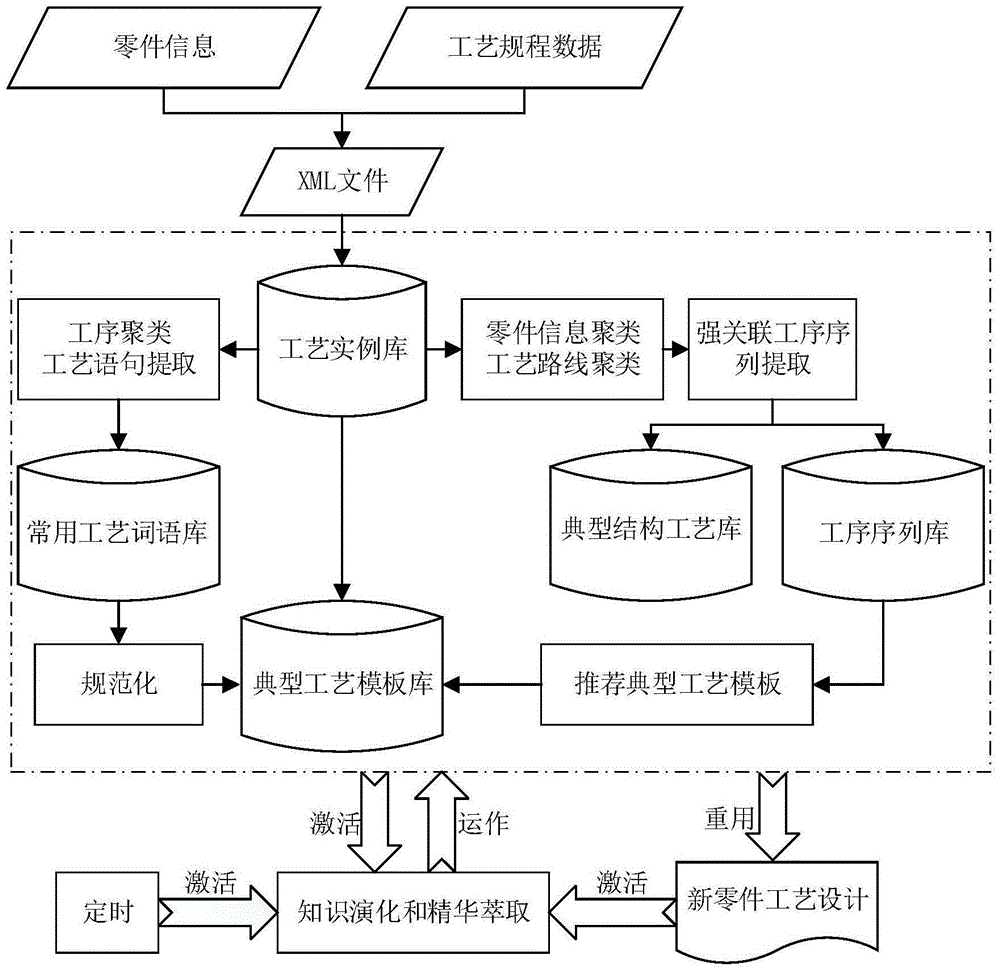

[0035] Such as figure 1 As shown, the method for knowledge extraction and evolution in a kind of machine tool part machining process specification of the present invention comprises the following steps:

[0036] 1) Establish a machine tool part information description model and sort out the corresponding process specification data, and use XML technology to realize the unified expression of the two; among them,

[0037] The described establishment of machine tool part information description model is to refer to the product part information list and the CAD model of the part, and simplify the two, from the management characteristics, geometric structure characteristics, precision characteristics, blank material characteristics, heat treatment characteristics of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com