Automobile covering part sheet metal forming technology optimizing method based on STL grid feature recognition

A technology for automobile panels and grid features, which is applied in the field of sheet metal stamping process optimization for automobile panels, can solve the problems of low standardization, difficulty in obtaining structural features, low efficiency of stamping process design, etc., and achieves increased stability and consistent pattern. , The effect of improving process design efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

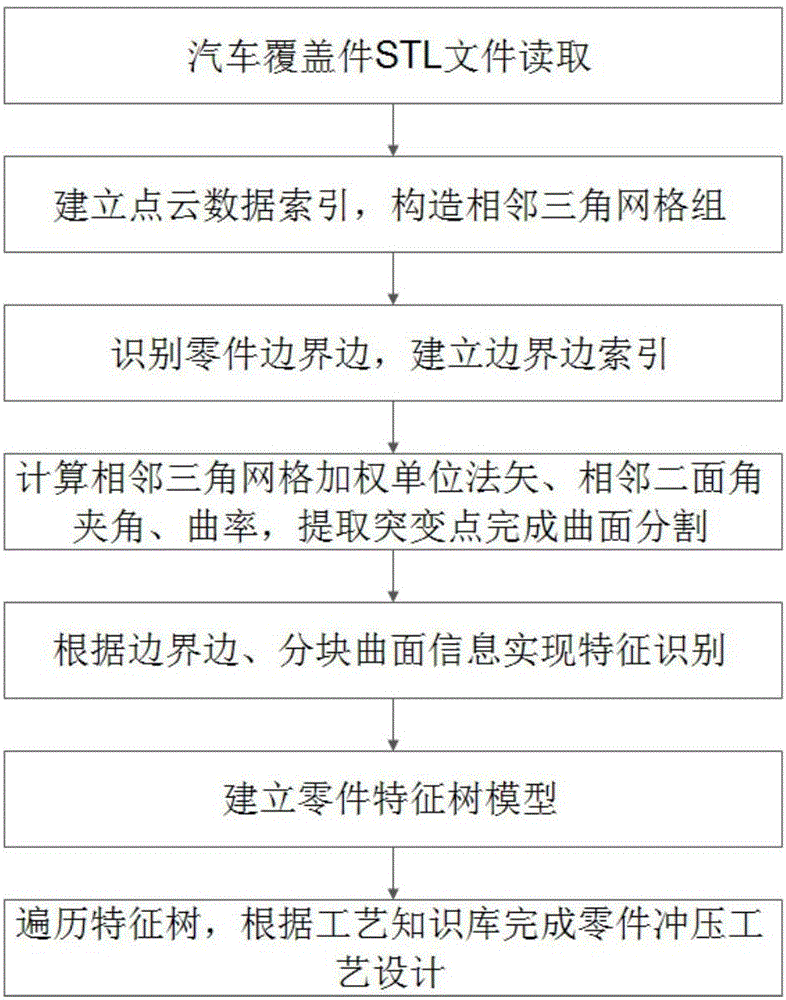

[0033] In a preferred embodiment of the present invention, a method for optimizing the sheet metal stamping process of automobile panels based on STL grid feature recognition, such as figure 1 shown, including the following steps:

[0034] S1. Convert the vehicle panel solid model into an STL file composed of triangular meshes through CAD software, read the STL file, import the triangular mesh model of the part, and obtain the vertex coordinates and exterior of each triangular mesh according to the description method of the file field normal vector coordinates;

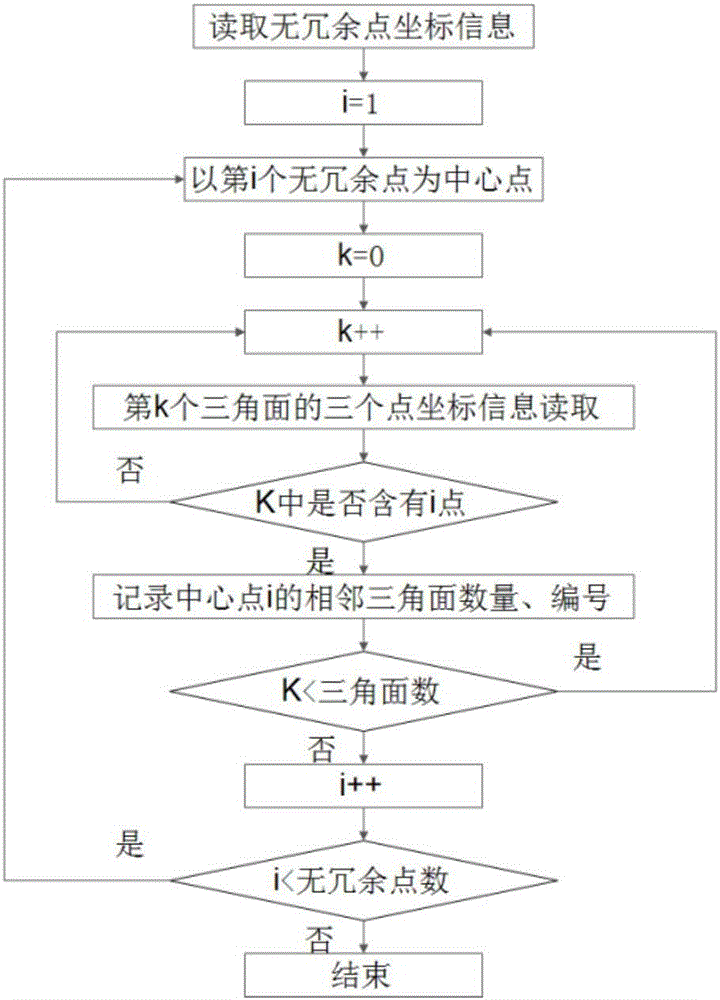

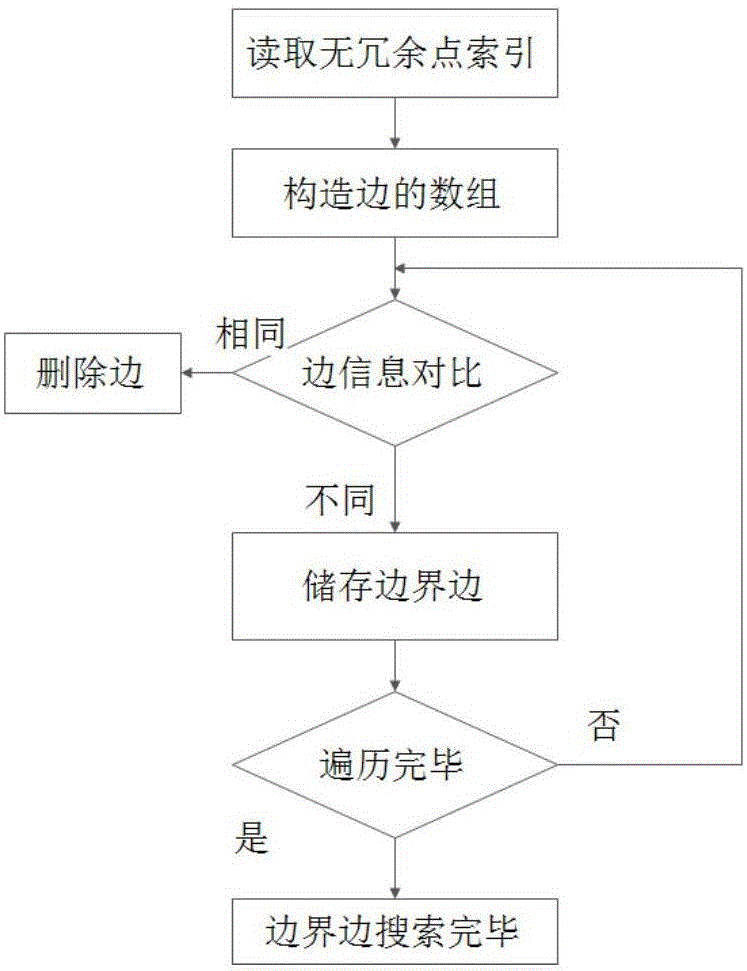

[0035]S2. Use the triangle grid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com