Patents

Literature

34results about How to "Improve quality management level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

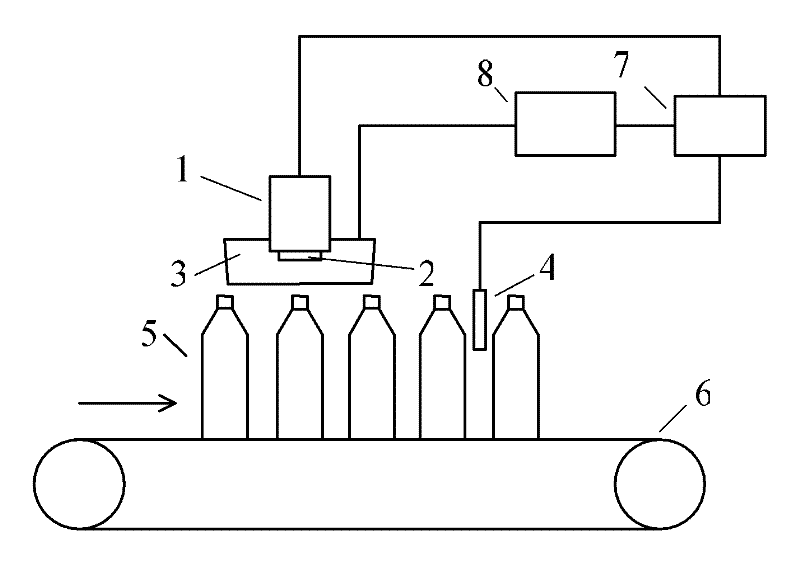

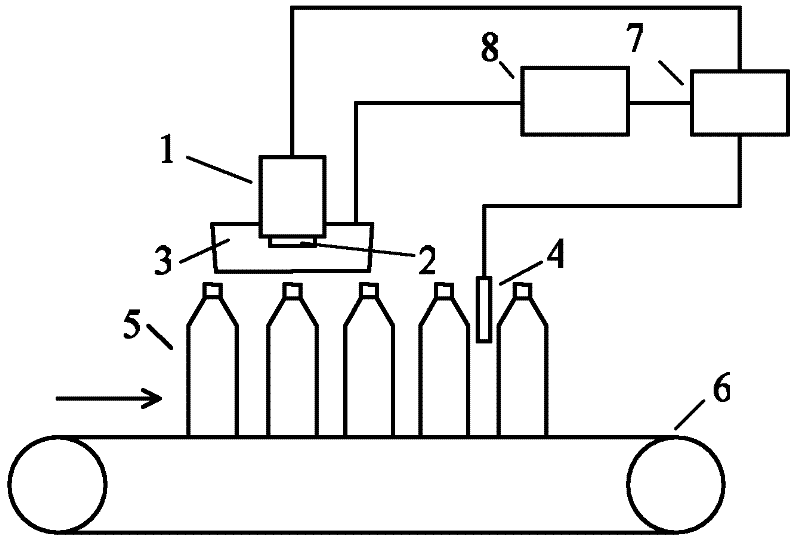

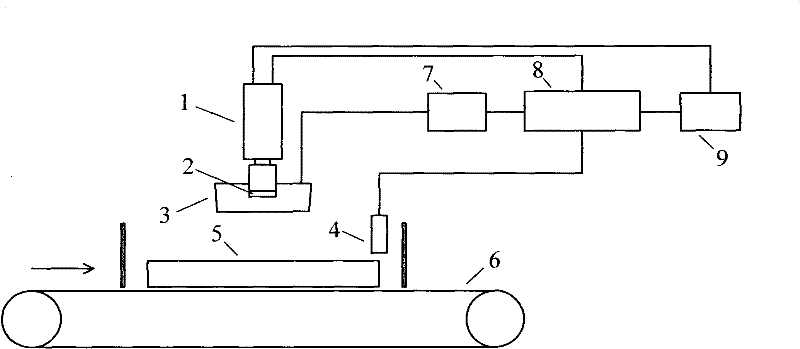

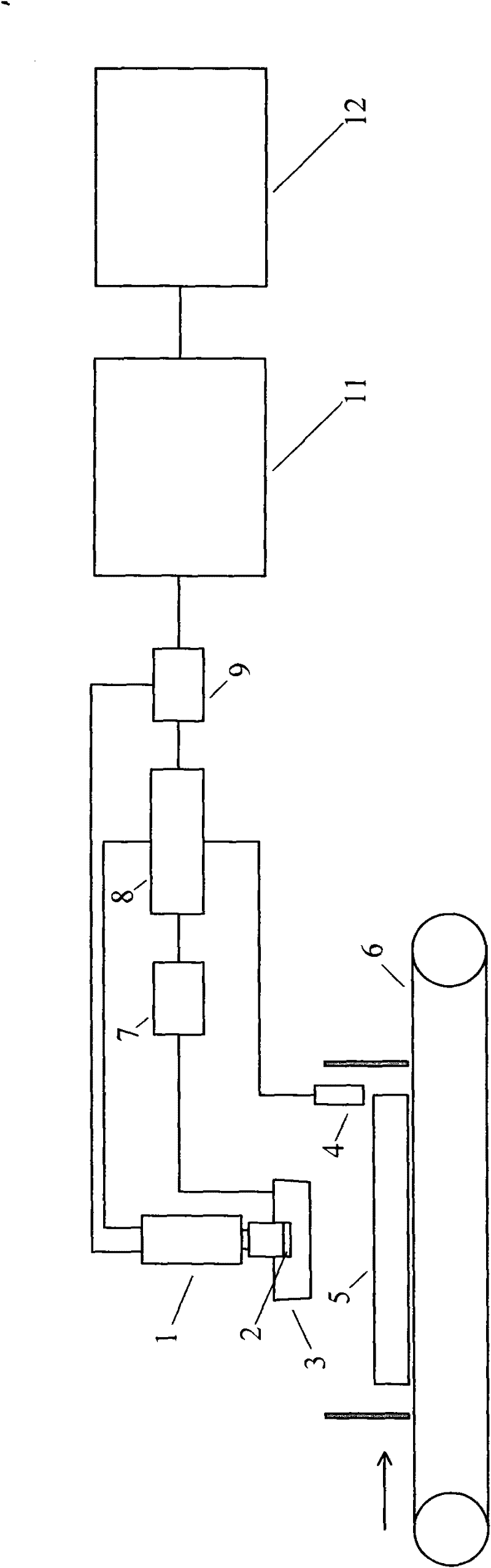

Device and method for acquiring product coded identifier information

ActiveCN101885391AIncrease brightnessImprove recognition rateCharacter and pattern recognitionPackagingOpto electronicImaging equipment

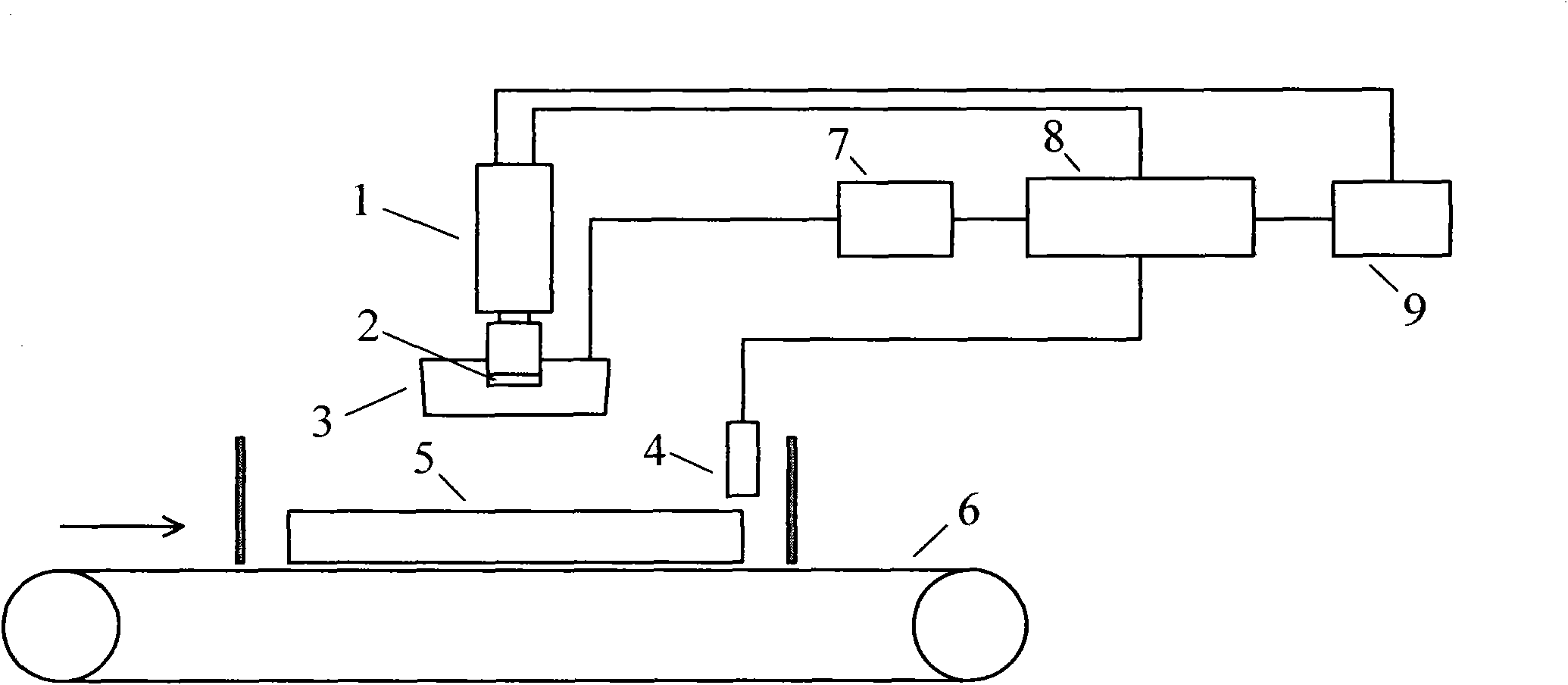

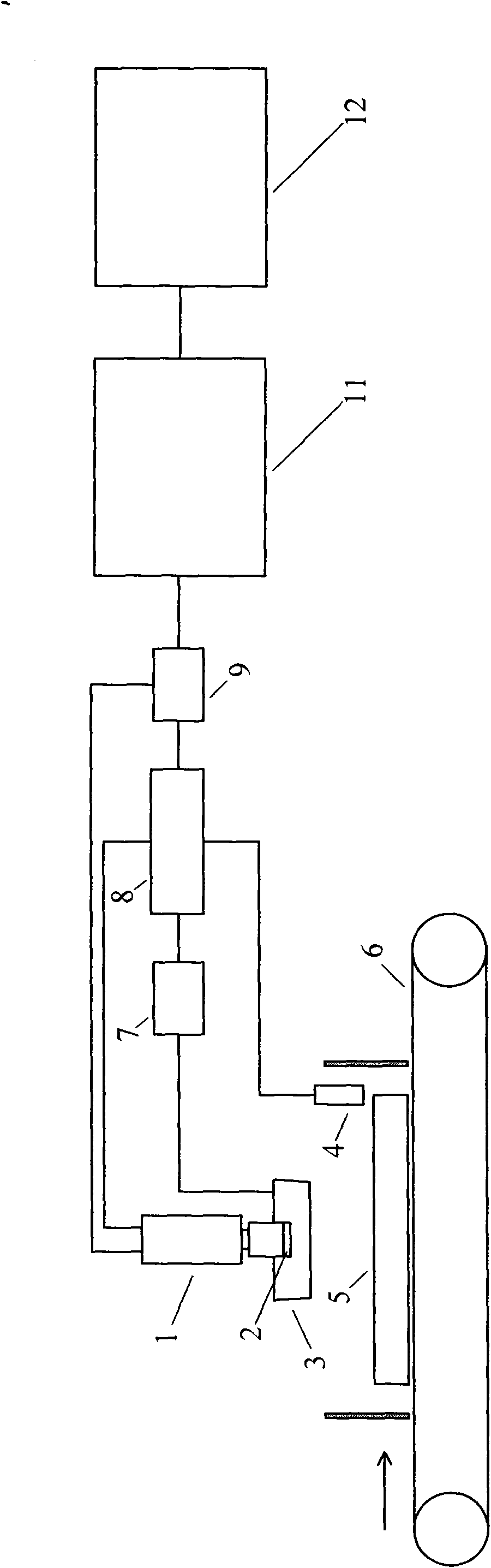

The invention relates to a device and a method for acquiring product coded identifier information. The device comprises a data acquisition unit, a data identification unit and a control unit, wherein the data acquisition unit is positioned above a convey belt and comprises an image device, a lighting device and a position photoelectric switch; the image device is used for photographing product coded identifier to obtain image data; the lighting device is used for irradiating the product coded identifier; the position photoelectric switch is used for sensing the position of the product on the convey belt; the data identification unit is used for identifying and processing the image data acquired by the data acquisition unit to obtain the product coded identifier information and storing the information and is also connected with the image device and the control unit respectively through a data line; and the control unit is used for controlling the data acquisition unit, and connected with the data identification unit, the image device, the lighting device and the position photoelectric switch respectively through data lines. The invention also provides the method for acquiring the product coded identifier information.

Owner:北京赛腾标识系统股份公司

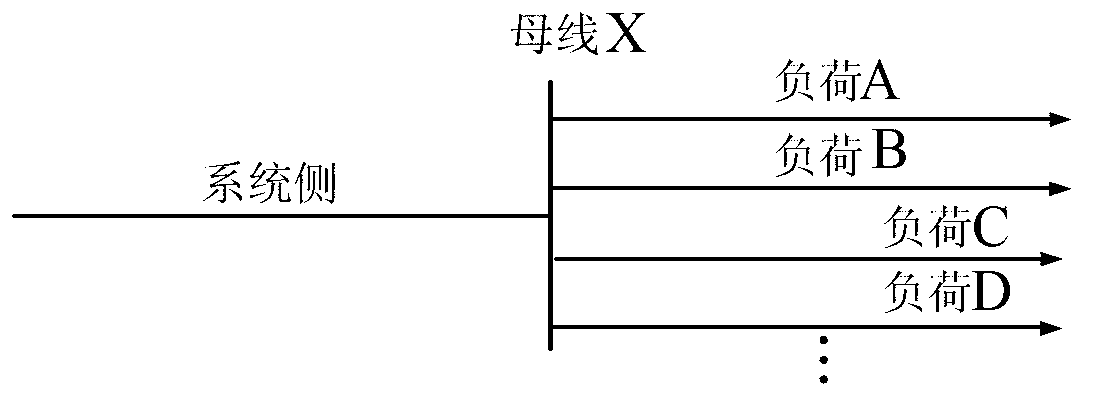

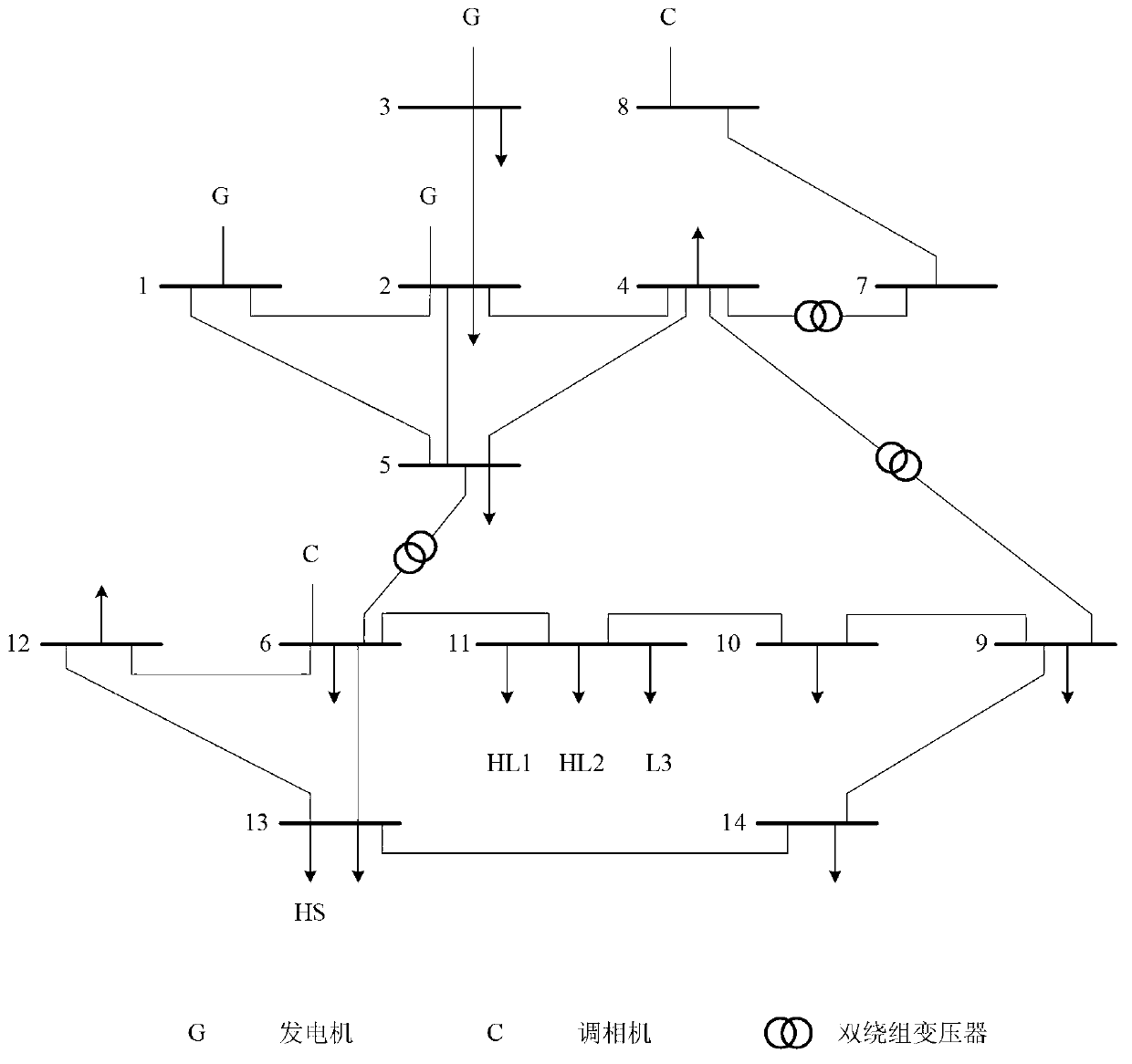

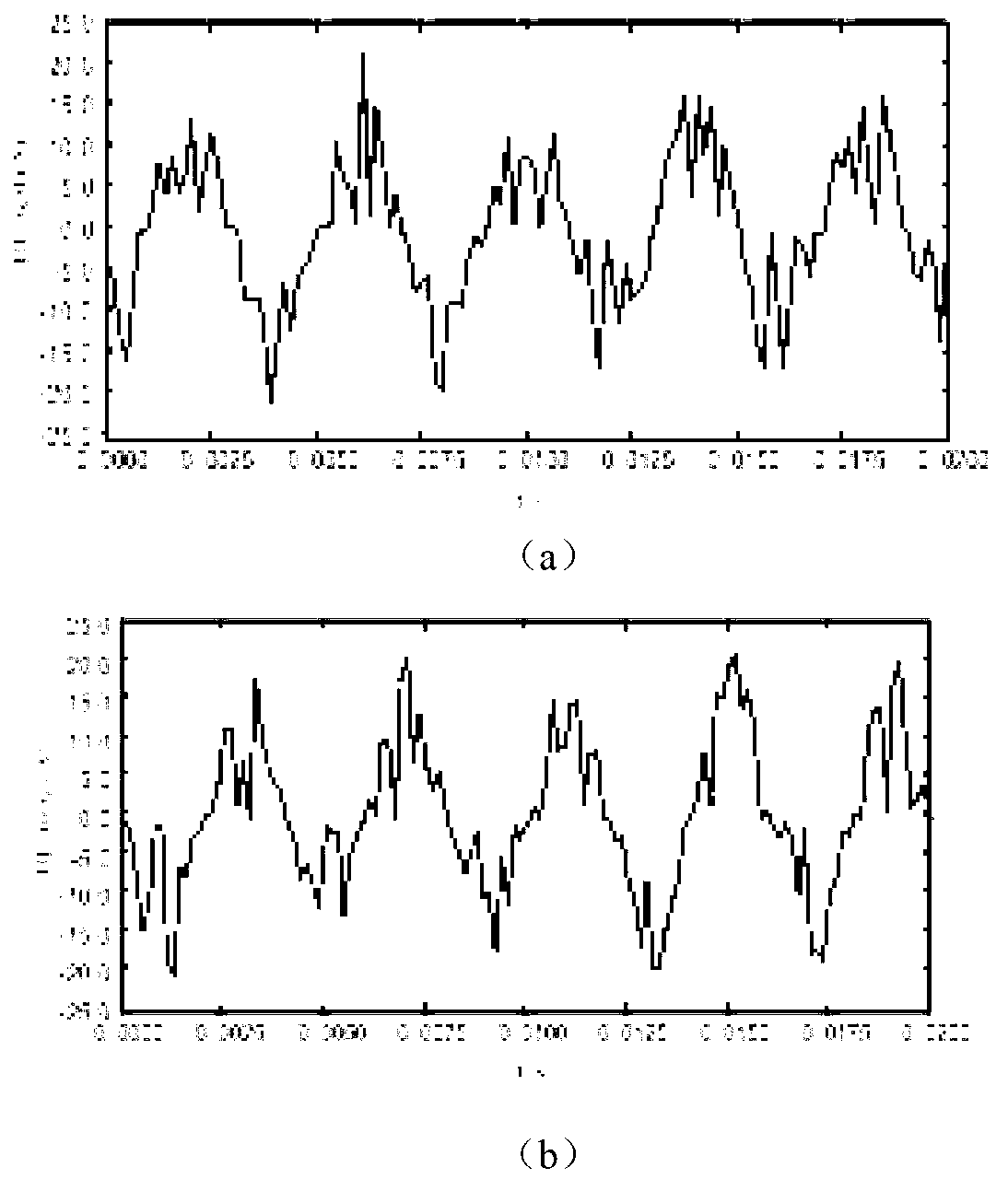

Method for computing harmonic impedance of system based on maximum likelihood estimation theory

InactiveCN102998535AImprove quality management levelAccurate calculationResistance/reactance/impedencePower qualityComplex normal distribution

The invention discloses a method for computing harmonic impedance of a system based on maximum likelihood estimation theory. The method is characterized by comprising the following steps: collecting bus voltage instantaneous value of common coupling point and current instantaneous value of user access system, and establishing a relation between harmonic voltage phasor and harmonic current phasor; on the basis of defining a complex covariance, deriving to obtain a probability density function of unary complex normal distribution so as to obtain a maximum likelihood estimation function; establishing the maximum likelihood estimation theory of complex field estimated by the harmonic impedance of system; utilizing an extreme value theory to solve the maximum likelihood estimation function so as to obtain the estimated value of harmonic impedance of the system finally. The method has the beneficial effects that the method for computing harmonic impedance of the system based on maximum likelihood estimation theory is capable of relatively accurately computing equivalent harmonic impedance of the system and has important meanings for further solving the problem of harmonic pollution and improving the management level of electric energy quality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

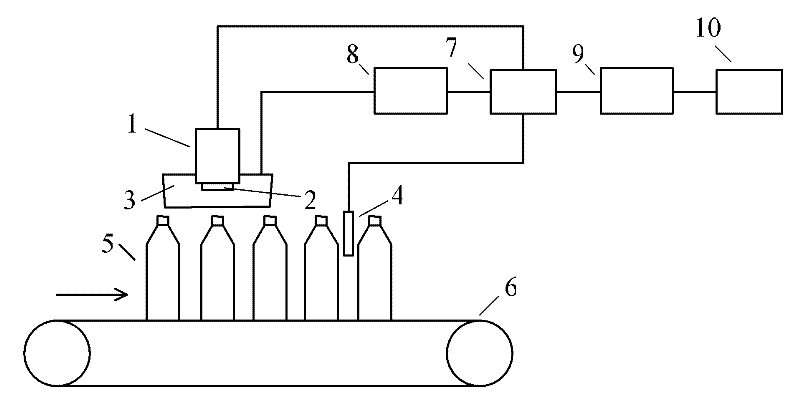

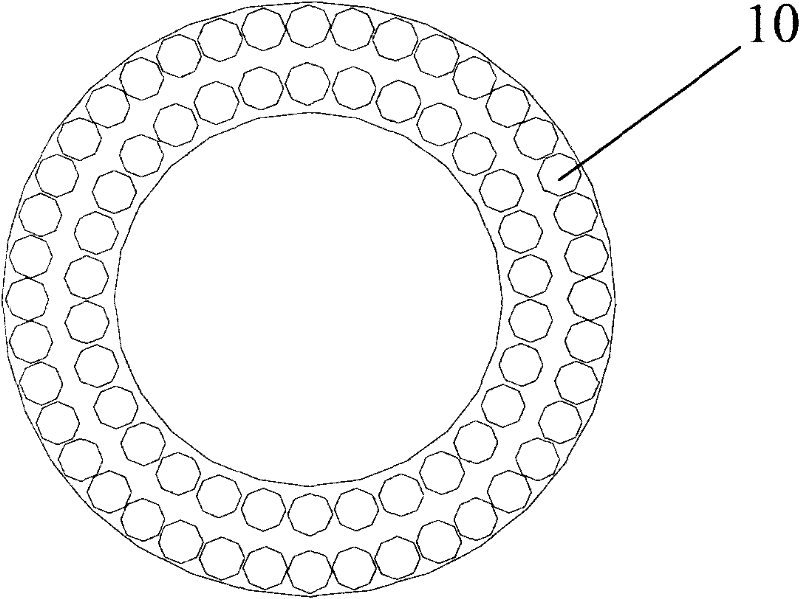

Collection method of bar code information data of product

InactiveCN102446263ARealize acquisitionAdapt to speed requirementsRecord carriers used with machinesSensing by electromagnetic radiationInformatizationCollection methods

The invention relates to a collection method of bar code information data of a product. The method comprises the following steps of: irradiating a bar code of the product by a light source; reading and collecting the bar code by utilizing a bar code reader to obtain and store the bar code information data, wherein a light filter is arranged in front of a scanner window of the bar code reader; and the bar code is a one-dimensional bar code and / or a two-dimensional bar code which are / is obtained by fluorescent ink in a spray printing way. With the adoption of the method provided by the invention, the rapid and accurate reading and collection of the bar code which is printed on the product by the fluorescent ink can be realized; the reading and collection rate is high and the reading effect is good, thereby realizing the reading and the collection of post-relevant type product information and solving the problems including misreading, incorrect reading and the like which are caused by an insufficient color contrast ratio between the bar code and a substrate; therefore, the quality management level of enterprises can be greatly improved, complicated artificial recording work in the quality management is greatly alleviated, the management flow of the enterprises is optimized and the informatization level of the enterprises is promoted.

Owner:北京赛腾标识系统股份公司

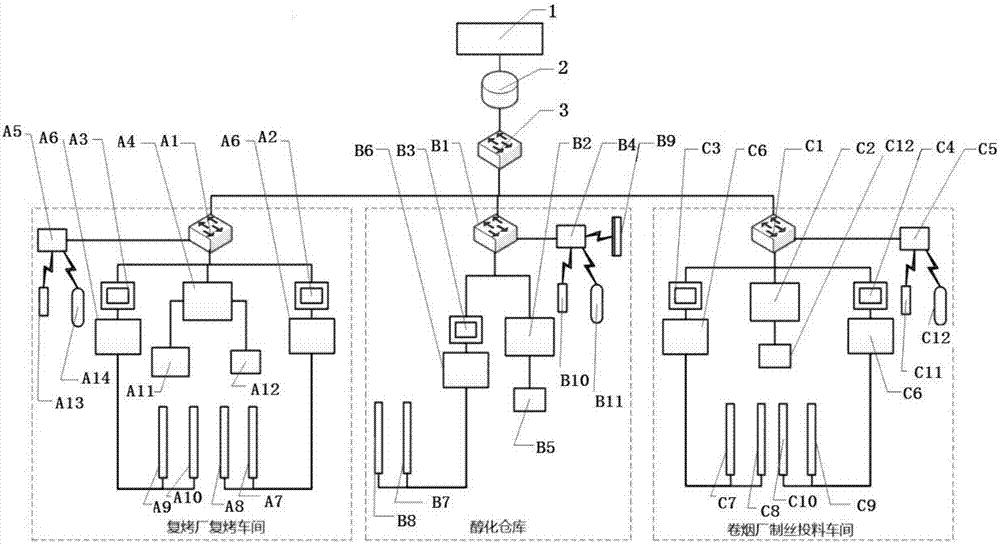

Lamina whole life cycle quality traceability system and traceability method

InactiveCN107423991AGrasp the quality situation in timeAccurate trackingCo-operative working arrangementsCommerceFeed consumptionUsability

The invention discloses a lamina whole life cycle quality traceability system and a traceability method. The system is composed of a server, a database and a general switch in sequential connection. The general switch is connected with a redrying factory lamina production off-line code printing system, a redrying ex-warehouse code scanning system, an alcoholization warehouse in-warehouse and ex-warehouse code scanning and warehouse temperature and humidity acquisition system and a cigarette enterprise formula bank cigarette processing and feeding consumption code scanning system. Each cigarette box is assigned with a unique lamina code, and the purposes that the quality traceability system can completely track the quality information during the whole life cycle of a single product and batches of lamina from redrying off-line to cigarette processing and feeding. The system and the method have the beneficial effects that the system can perform itemized evaluation analysis and integrated evaluation analysis on the redrying processing process, a warehouse in-stock maintenance scheme, an external environmental factor and the like which influence the lamina quality based on the lamina self quality index, lamina usability analysis and lamina production and maintenance technical scheme optimization are thus supported, the lamina quality management level is finally improved, and improvement of the overall management benefits of tobacco leaves is driven.

Owner:北京金蝶云基科技有限公司

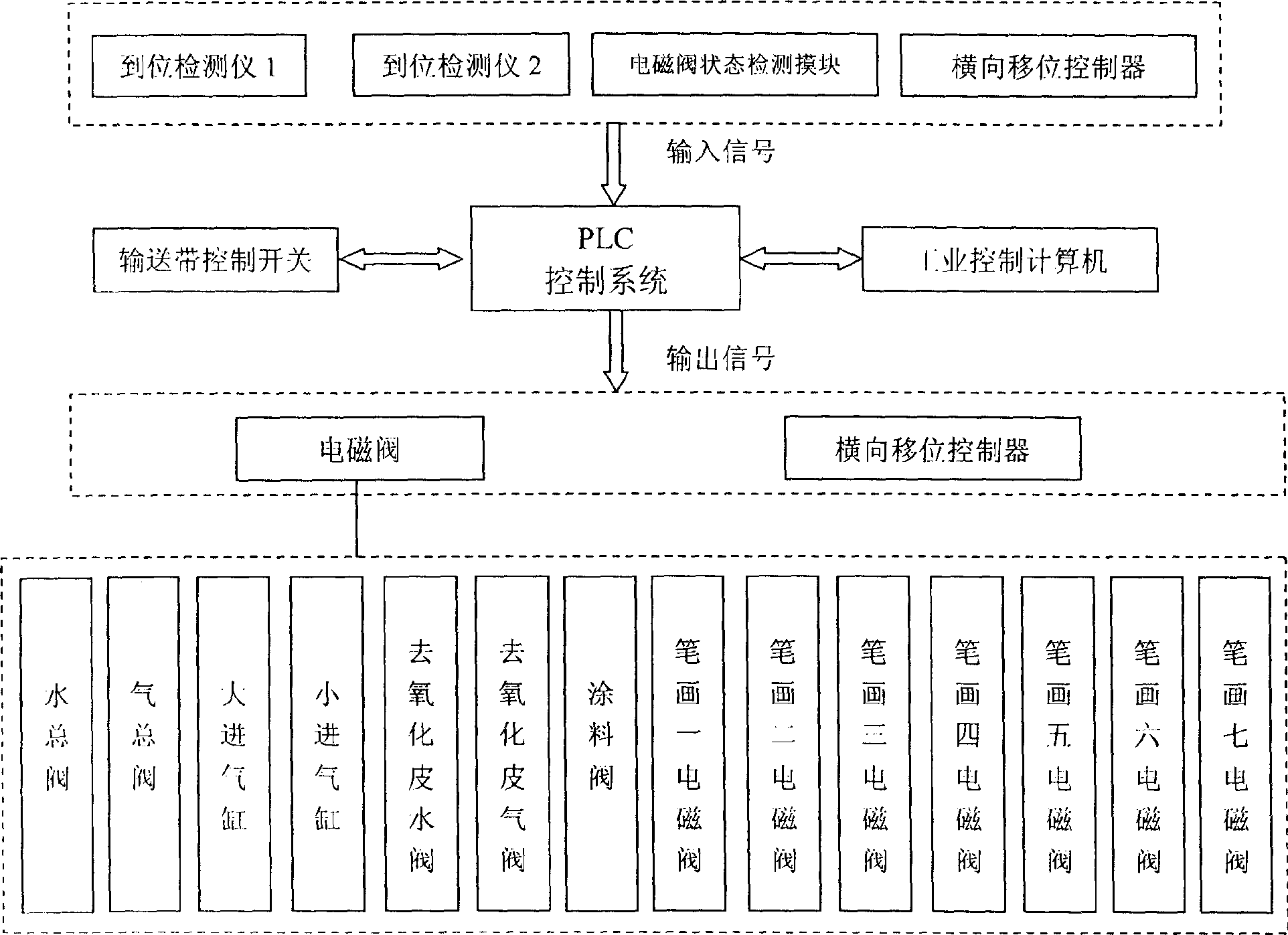

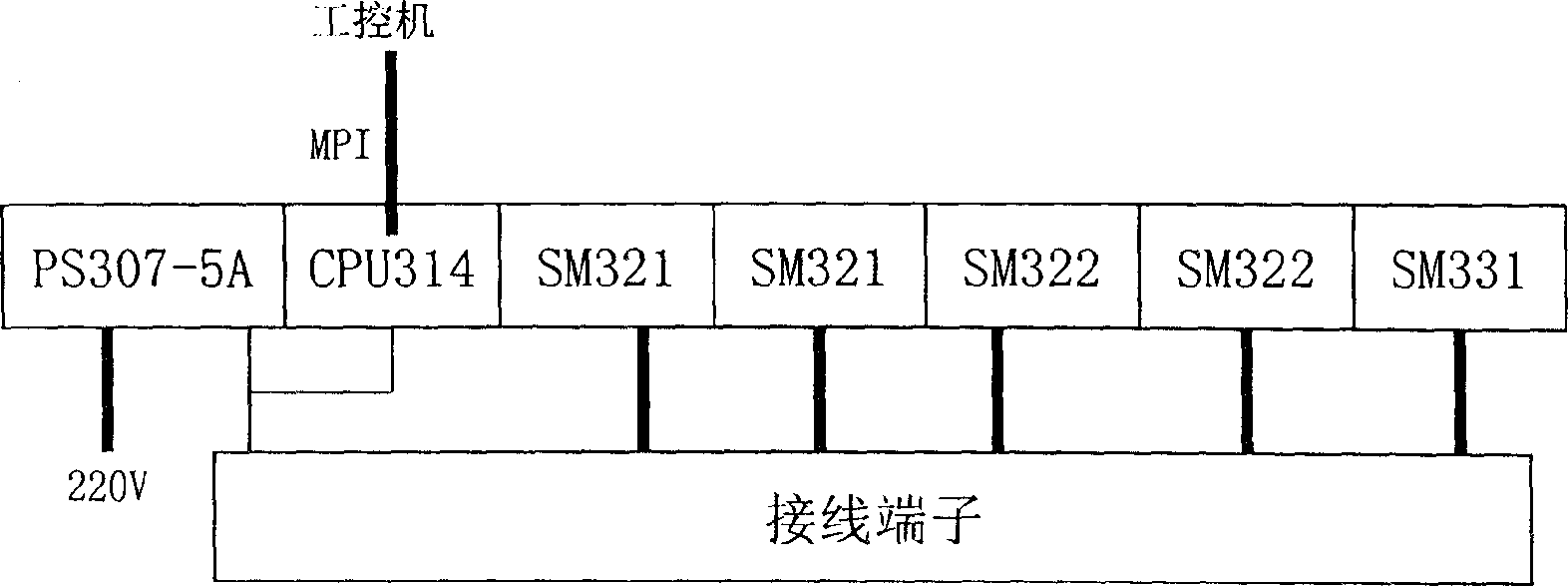

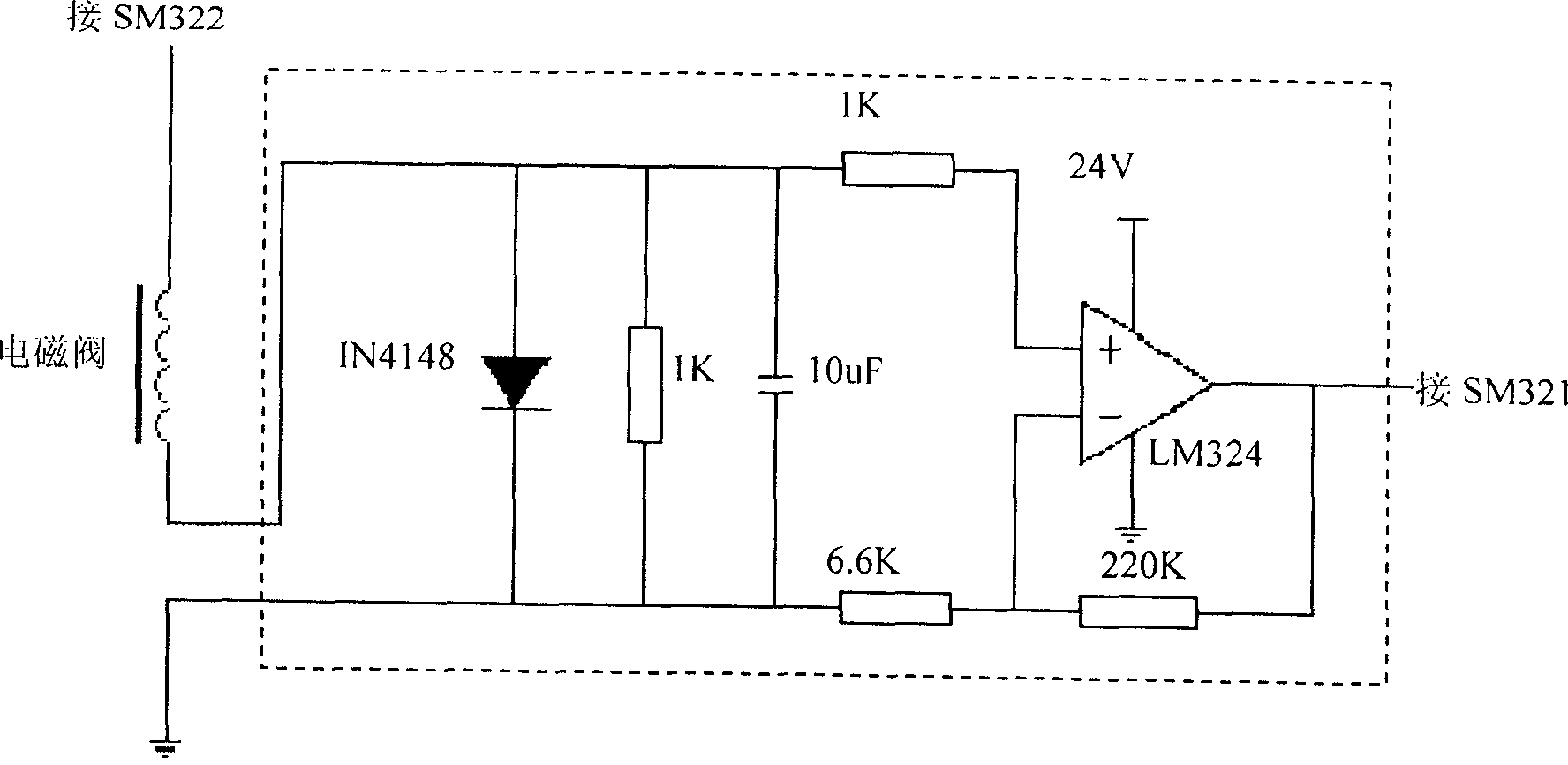

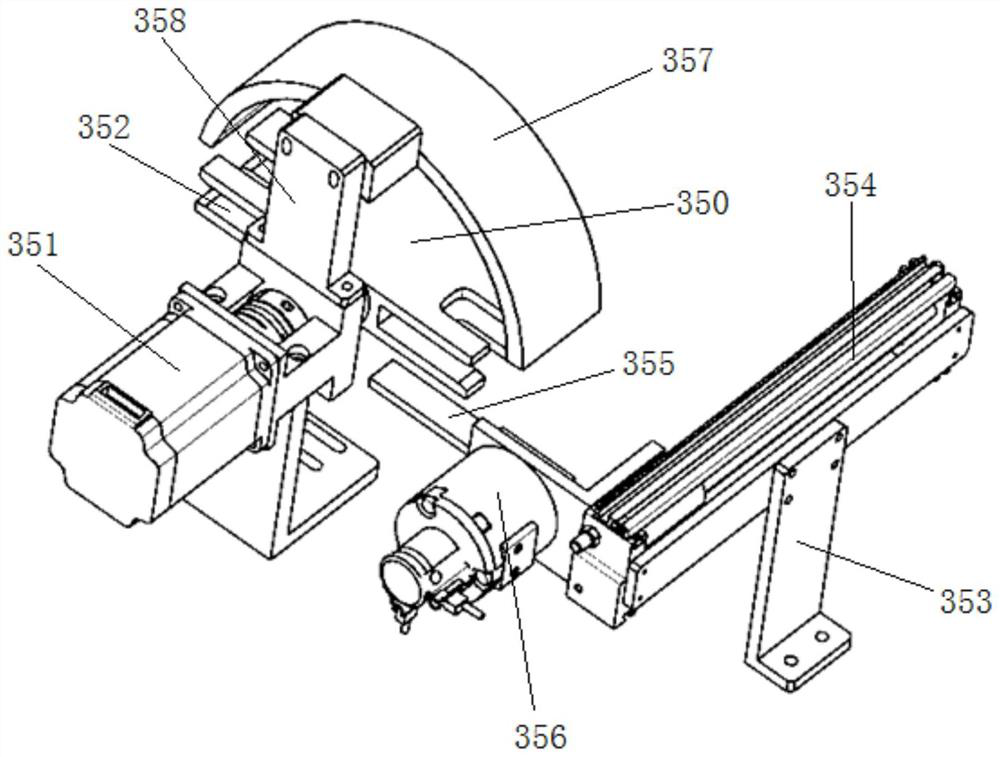

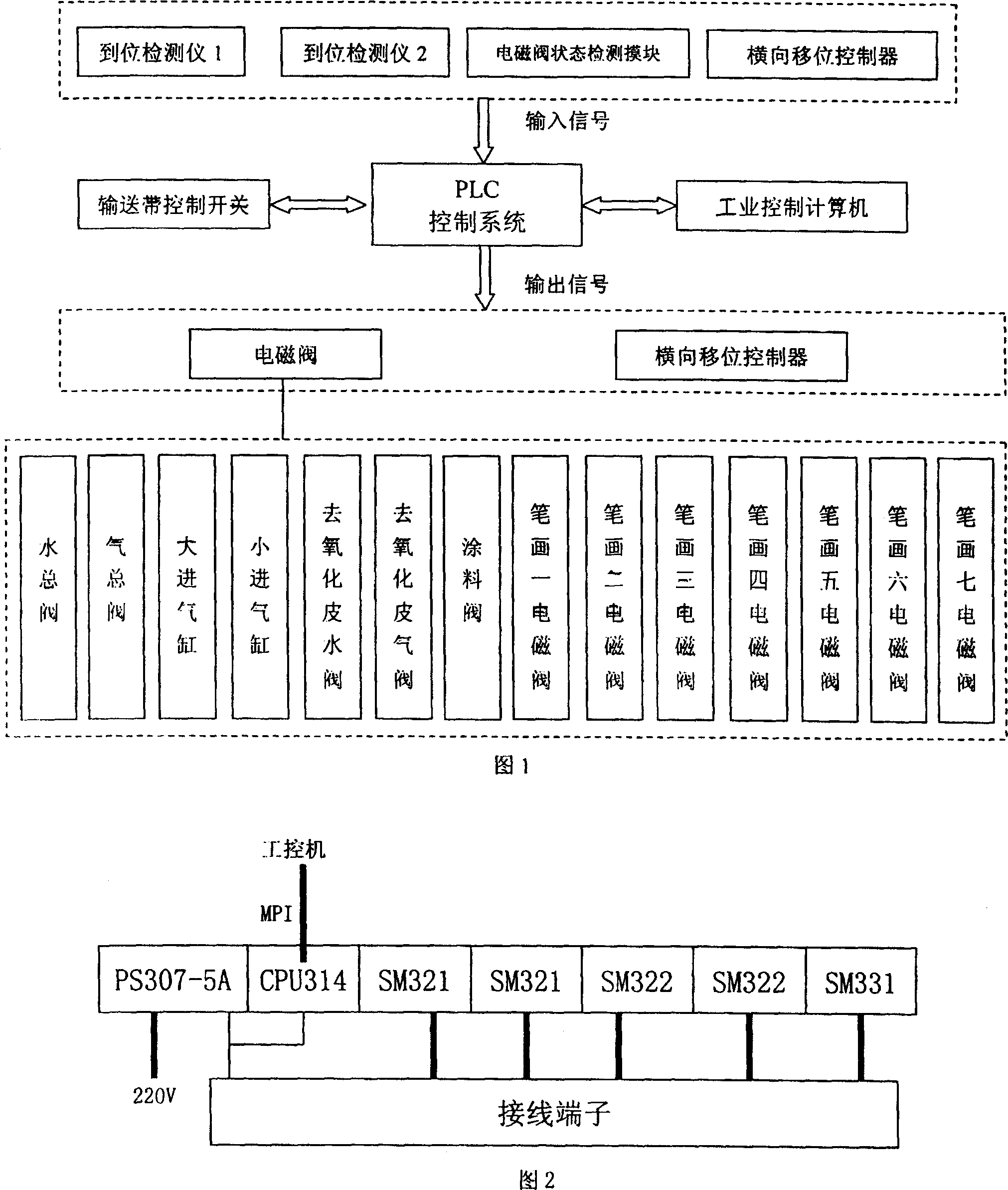

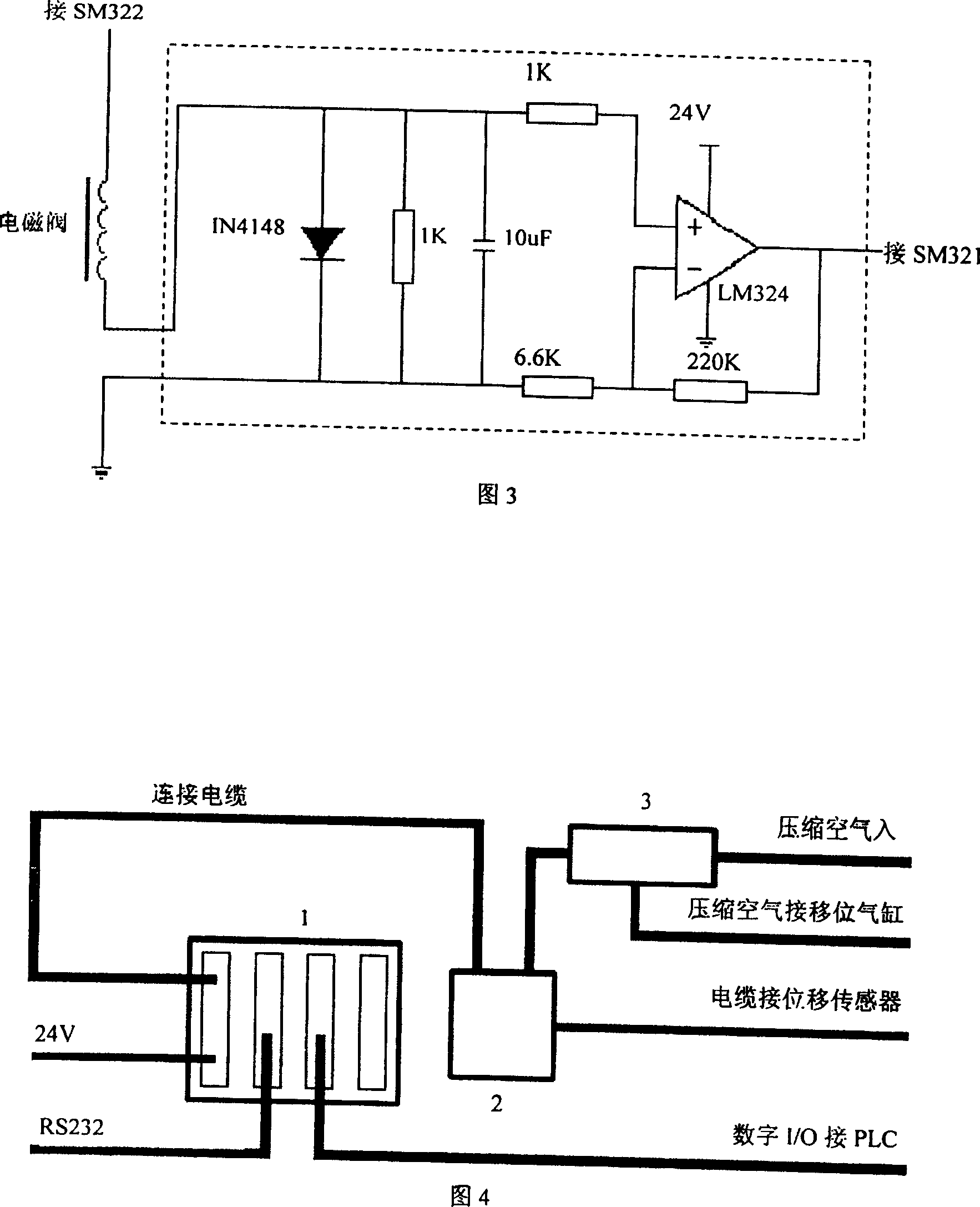

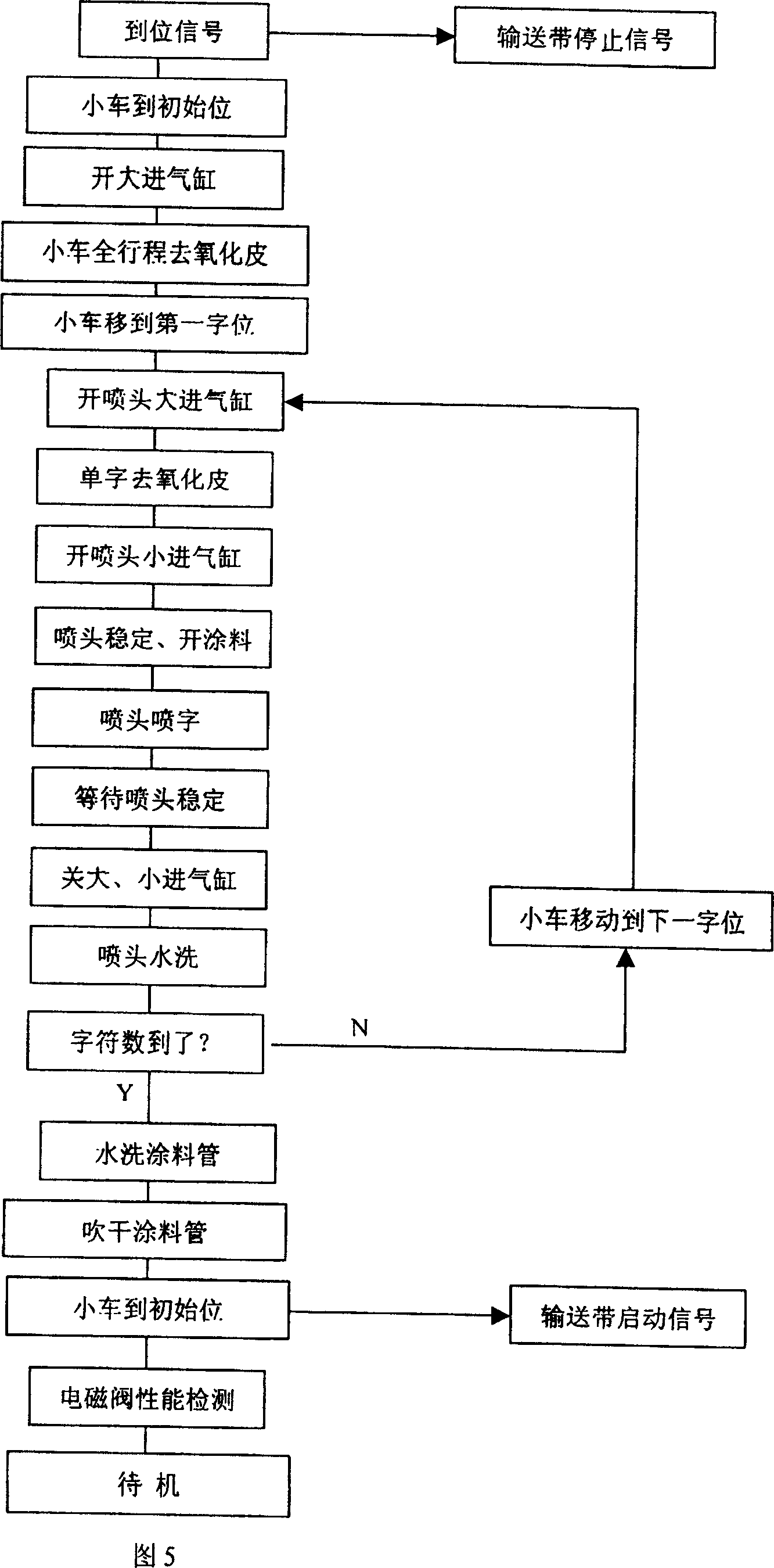

Machine set for spraying number on hot steel billet in real time based on PLC control system

InactiveCN1827226AIncrease the level of automationImprove quality management levelLiquid surface applicatorsLiquid spraying apparatusSprayerControl system

The invention discloses a real-time hot steel blank spray machine set based on PLC, which comprises a spray main machine and an electric controller. Wherein, the spray main machine has a slide frame, on which the traverse vehicle, the displacement sensor, the transverse displace cylinder, and the transverse displace controller are arranged; the transverse vehicle has a longitudinal vehicle, and a big inlet cylinder; the longitudinal vehicle has a sprayer element, and a small inlet cylinder; the spray main machine has a coating material feeding system; the electric controller uses the PLC control system which is connected to the industry control computer, the on-place detector, the electromagnetic valve condition detecting module, the transverse displacement controller, the feeding belt control switch, and the electromagnetic valve. The invention via improving the mechanical structure of sprayer, and using PCL control system, realizes the full-automatic, accuracy and online real-time multiple digit continuous mark in high temperature, to confirm the sharpness of mark, and apply the long time operation of spray machine set in bad condition. The invention can improve the automatic level and the quality management level of steel blank.

Owner:ZHEJIANG UNIV

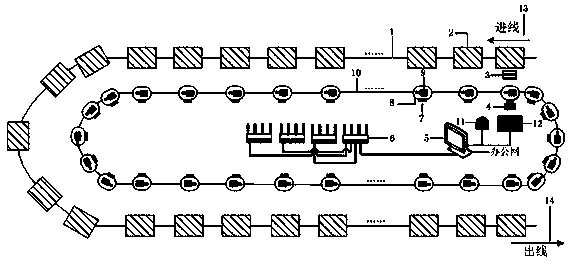

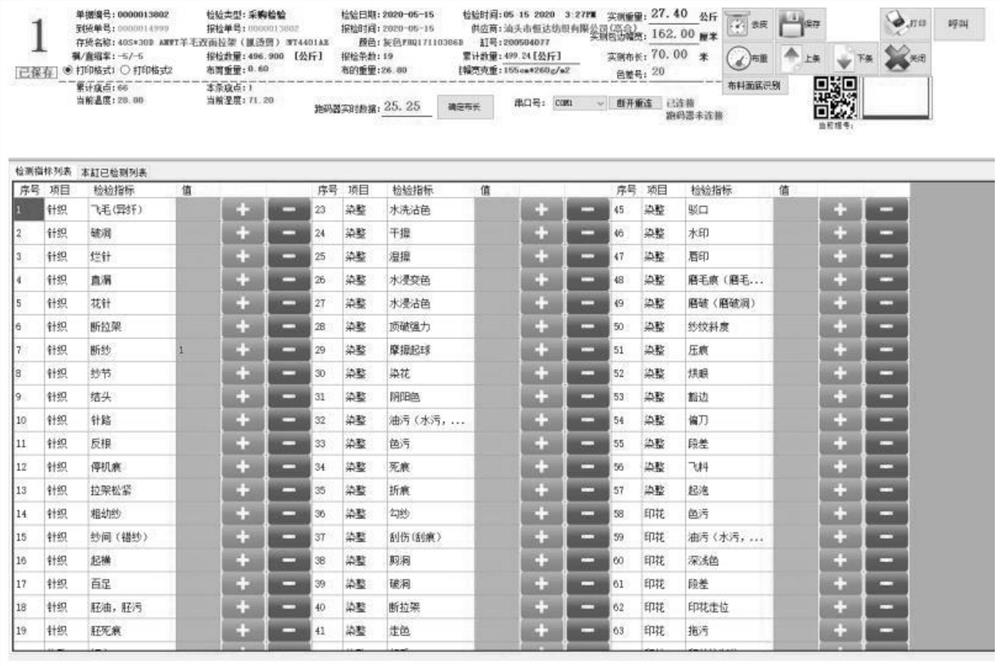

Real-time traceable rotation detection production pipeline data acquisition system

ActiveCN108520289ARealize real-time trackingImprove quality management levelCo-operative working arrangementsAlarmsWireless routerCommunication interface

A real-time traceable rotation detection production pipeline data acquisition system includes detection stations installed on a rotation detection production pipeline and moving circularly; the detection stations are sequentially numbered from 1; and communication interfaces are arranged on the detection stations. The system is characterized in that WIFI serial port servers are added on the communication interfaces of the detection stations and are connected with the industrial control integrated machine through a wireless router; and a SCADA data acquisition system and a database are arrangedin the industrial control integrated machine; and data acquisition is performed by using a communication protocol of the detection stations, and the acquired data is stored in the database. The real-time traceable rotation detection production pipeline data acquisition system realizes the binding of the detection stations, the acquisition data and the products, makes the data traceable, and predicts the maintenance time of the detection stations through the data analysis.

Owner:QINGDAO PENGHAI SOFT CO LTD

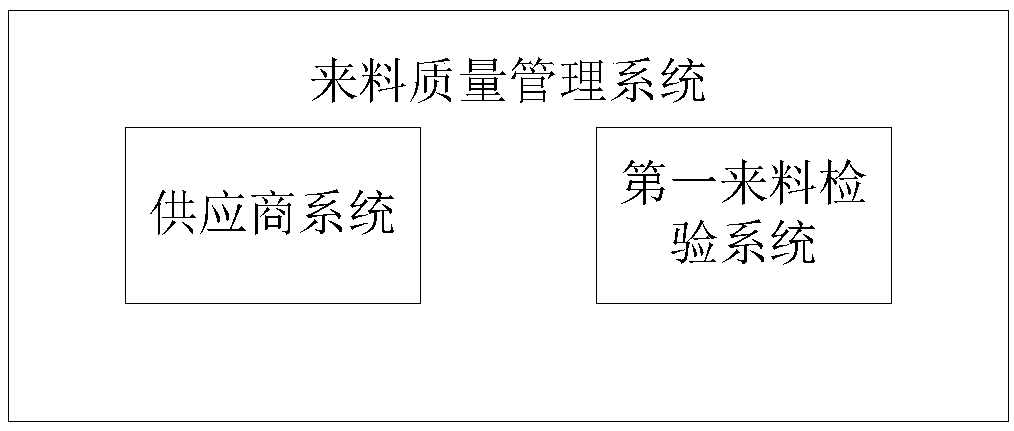

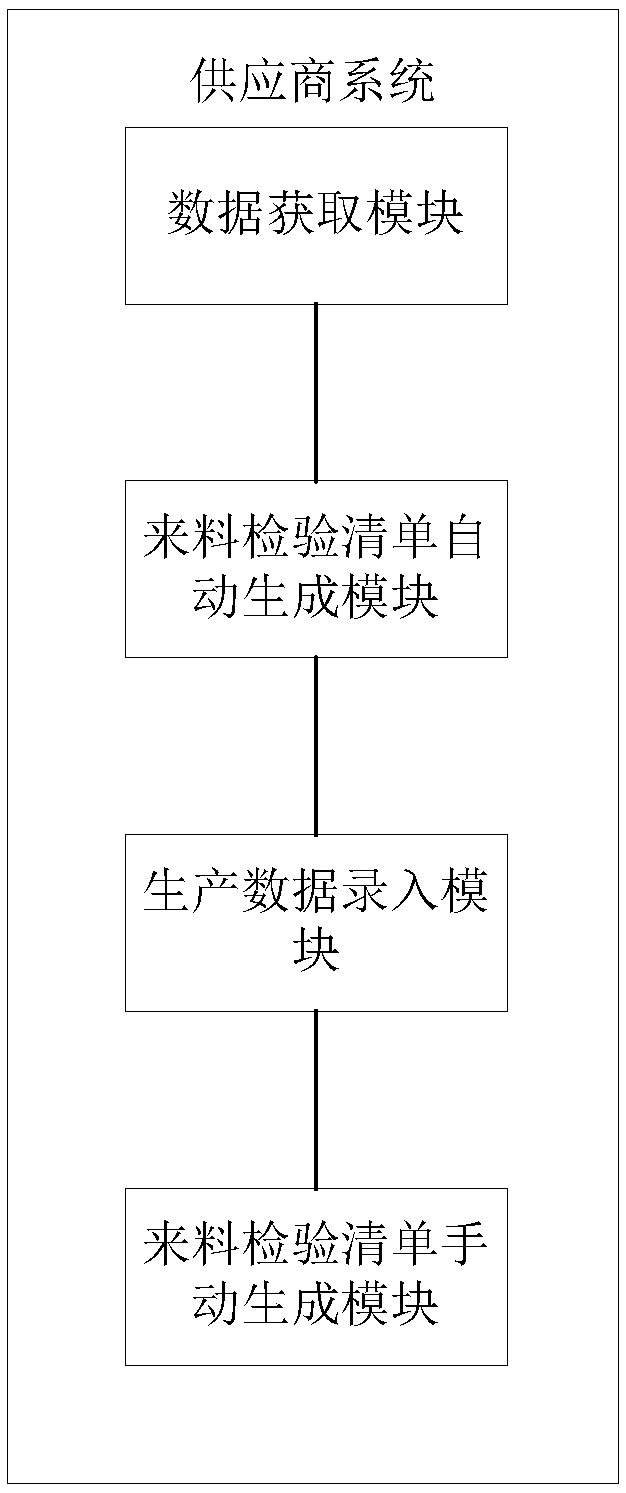

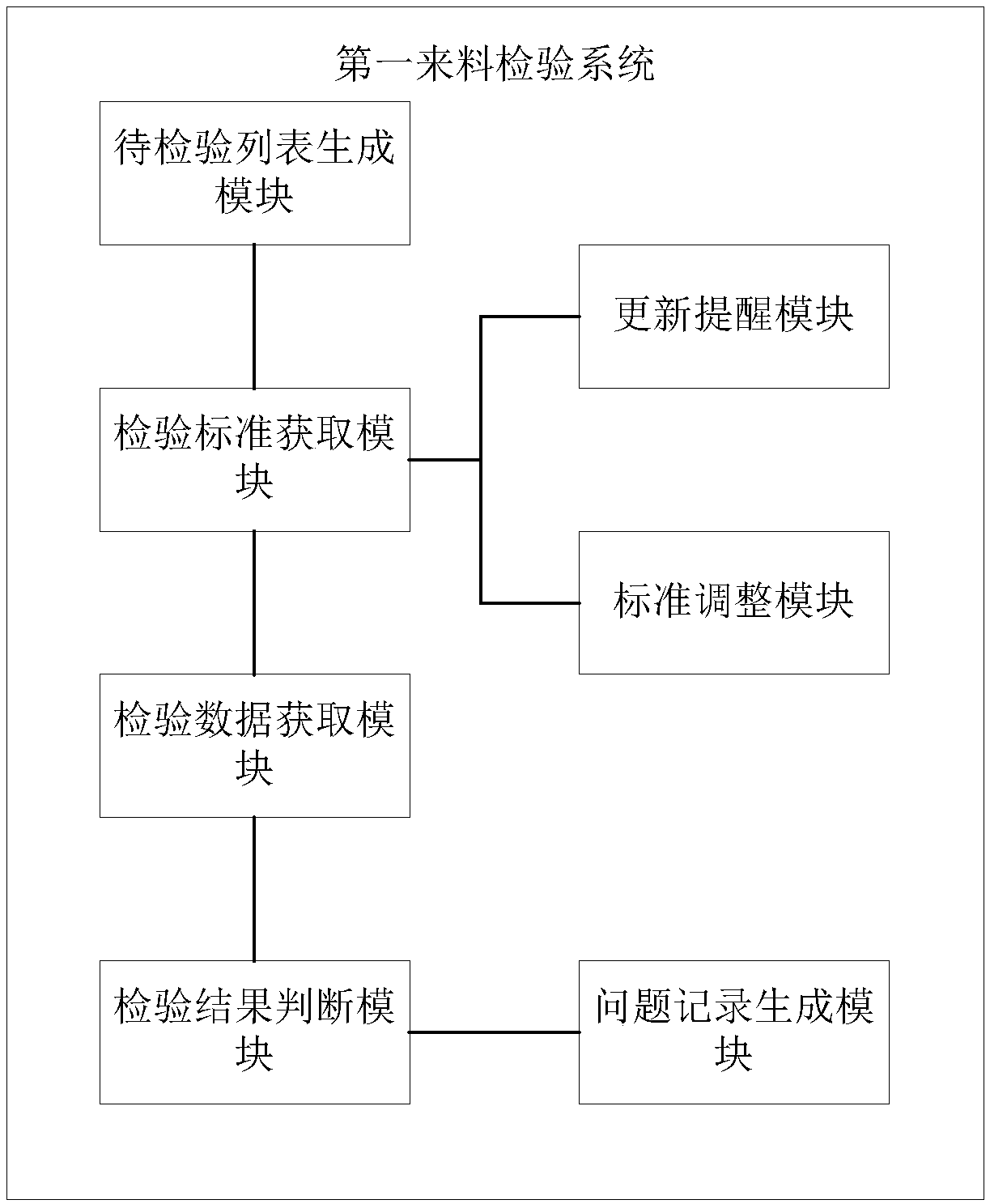

A system and method for incoming material quality management

InactiveCN109389316AImprove quality management levelReduce workloadBuying/selling/leasing transactionsResourcesWorkloadManagement system

The embodiment of the invention provides an incoming material quality management system and method. The incoming material quality management system comprises a supplier system and a first incoming material inspection system. The supplier system is used for generating an incoming material inspection list and inputting the production data of the products listed in the incoming material inspection list. The first incoming material inspection system is used for extracting the products listed in the part of the incoming material inspection list to generate the to-be-inspected list, and judging whether the obtained inspection data of the products listed in the to-be-inspected list conforms to the corresponding inspection standard. The incoming material quality management system of the embodimentof the invention can reduce the workload of the incoming material inspector, improve the work efficiency of the incoming material inspector, improve the incoming material quality management level, and reduce the incoming material quality management cost.

Owner:LCFC HEFEI ELECTRONICS TECH

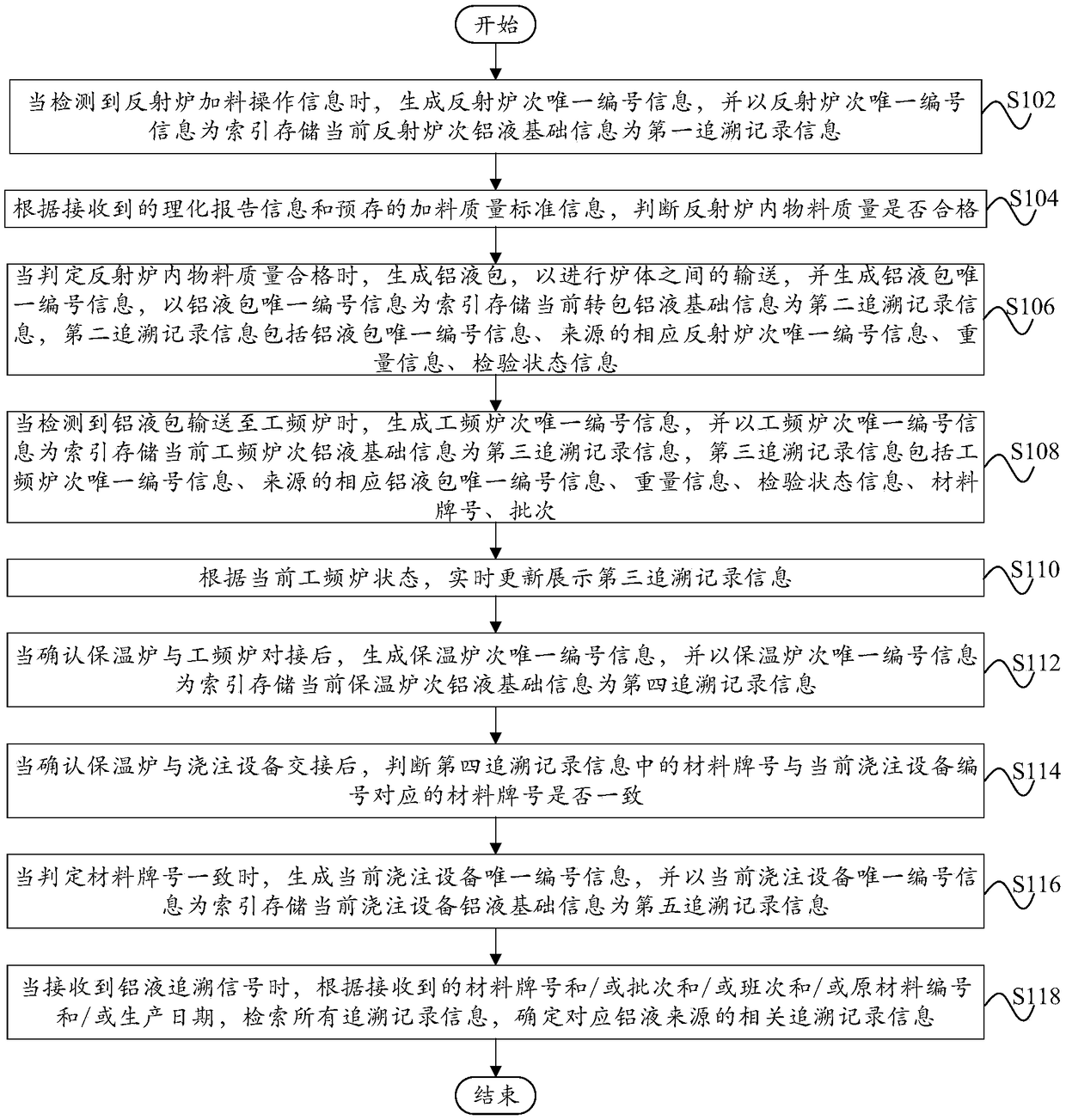

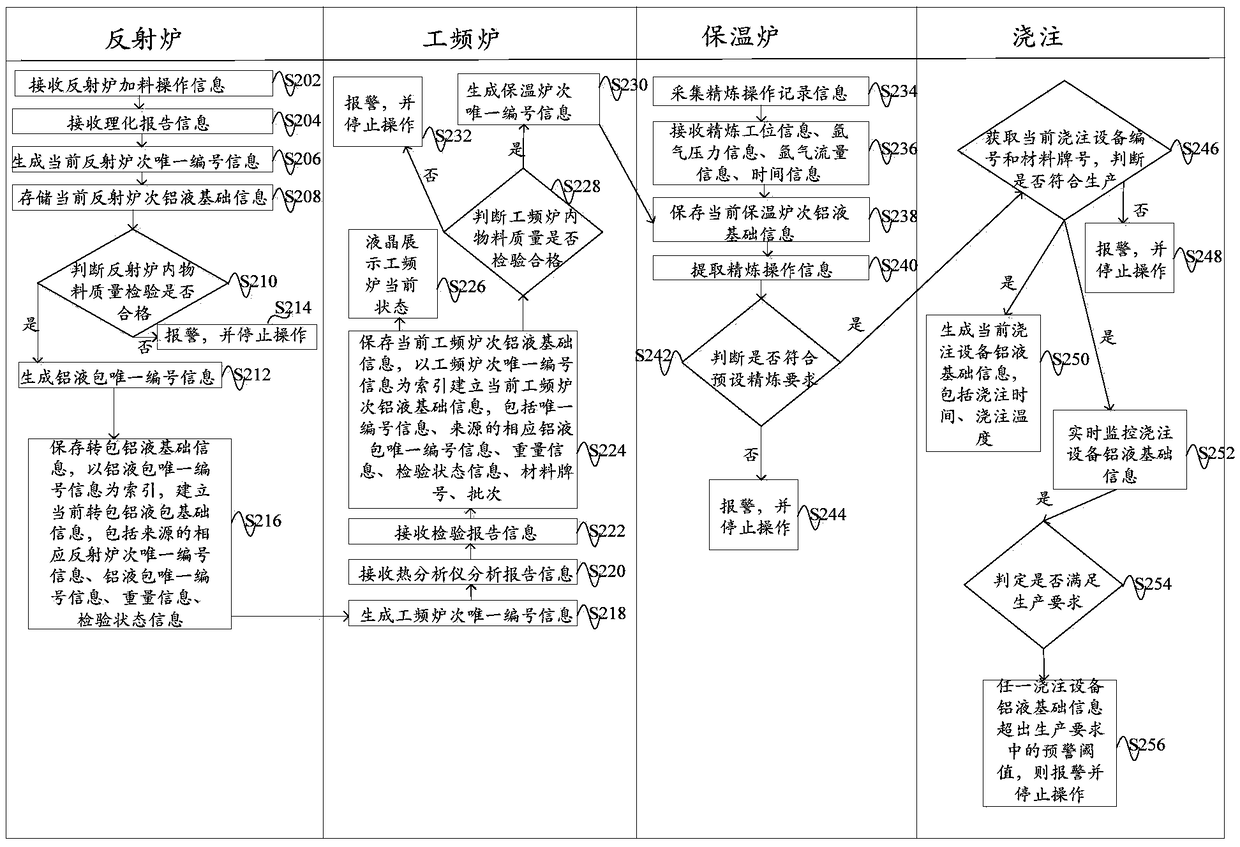

Method for tracing aluminum liquid smelting

InactiveCN109272256AGuaranteed achievabilityReduce production accidentsCasting safety devicesResourcesReverberatory furnaceControllability

A method for tracing aluminum liquid smelting is provided, which includes storing basic information of aluminum liquid of a current reverberatory furnace as first tracing record information with unique numbering information of reverberatory furnace as index, storing the basic information of the current subpackaged aluminum liquid as second traceability record information with the unique numberinginformation of the molten aluminum pack as the index; When the aluminum liquid ladle is detected to be transported to the power frequency furnace, storing the aluminum liquid basic information of thecurrent power frequency furnace as third tracing record information with the power frequency furnace unique number information as the index; When the heat preservation furnace is confirmed to be butted with the power frequency furnace, the unique number information of the heat preservation furnace is generated, and the basic information of the aluminum liquid of the current heat preservation furnace is stored as the fourth traceability record information based on the unique number information of the heat preservation furnace. All traceability record information is retrieved to determine the relevant traceability record information corresponding to the source of the molten aluminum. The technical scheme of the invention realizes the intelligent smelting production of aluminum liquid, the collection automation, the problem transparency, the abnormal early warning, the tracing precision and the process controllability.

Owner:BINZHOU BOHAI PISTON CO LTD

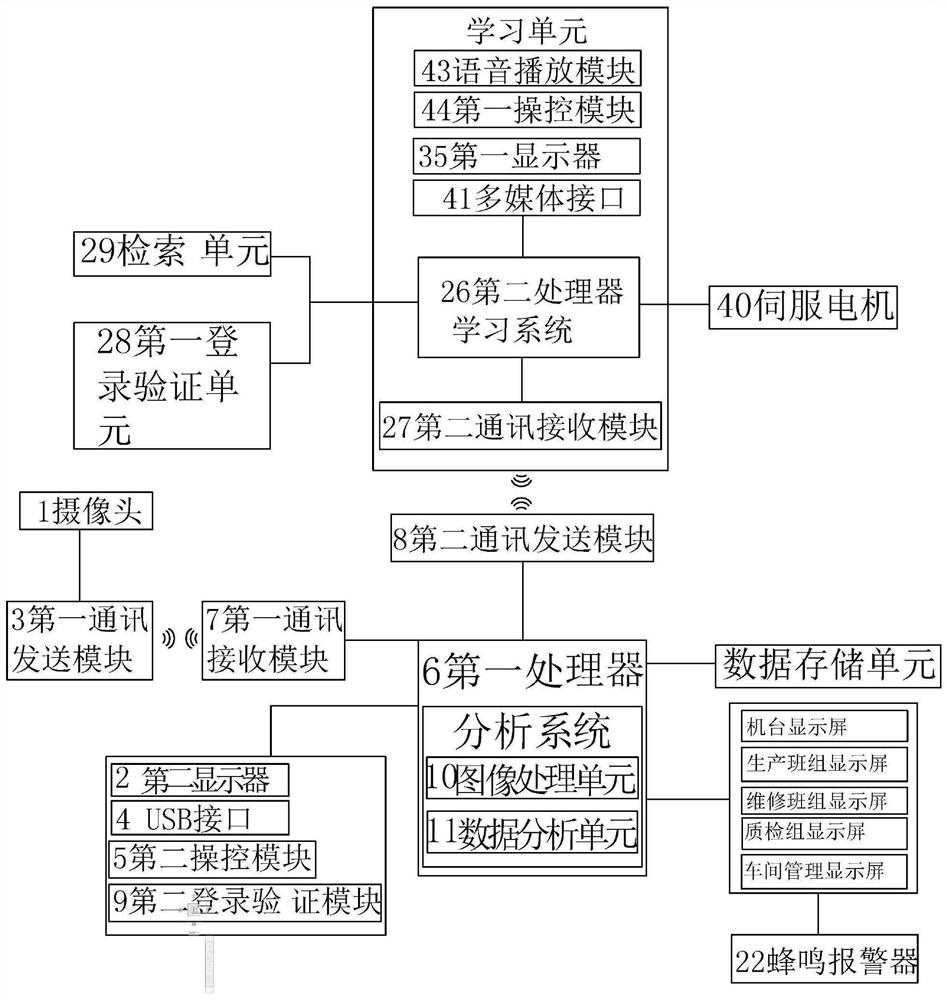

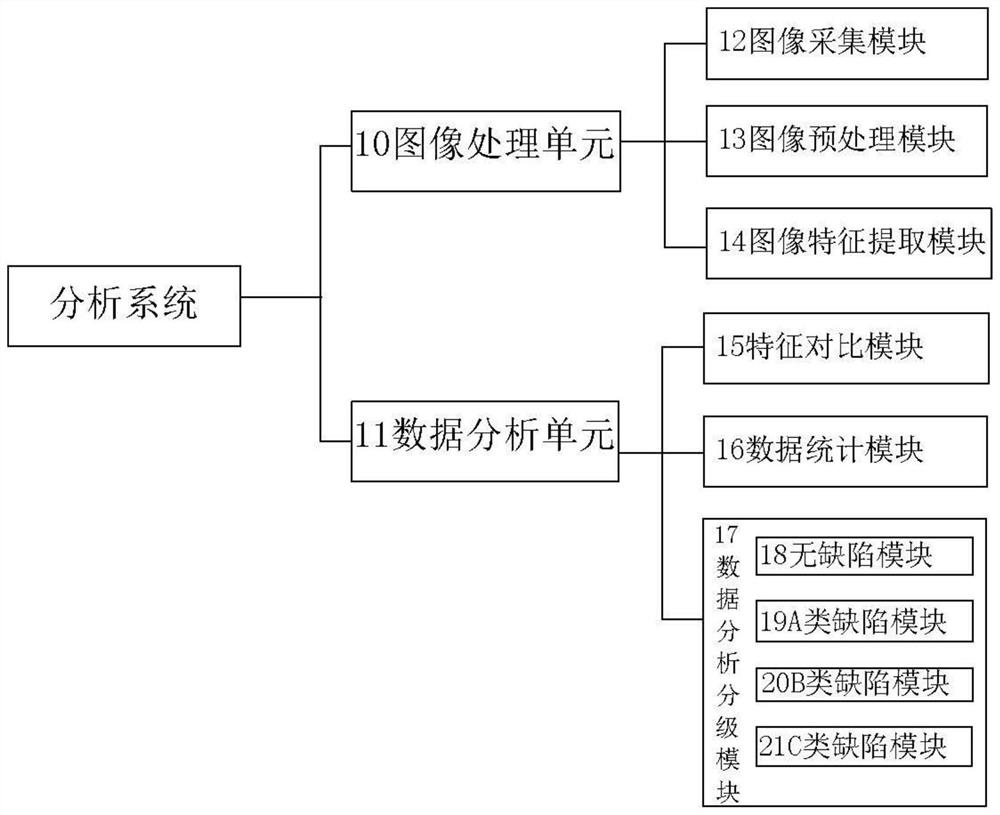

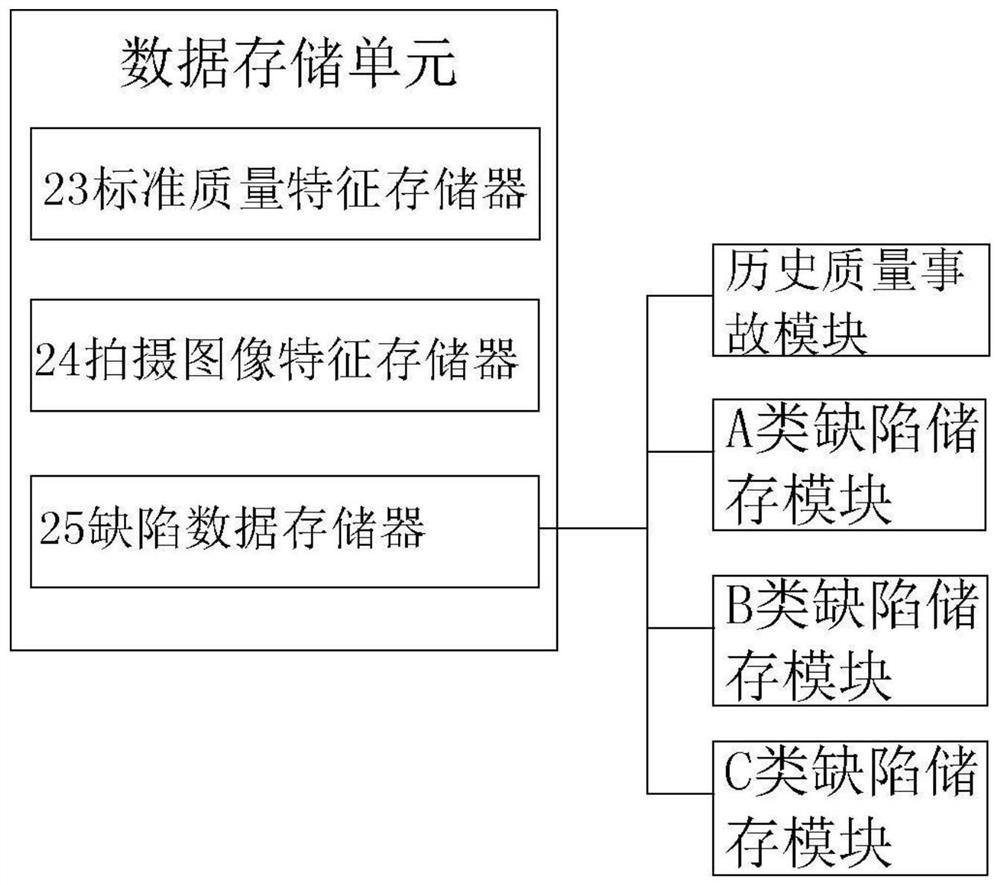

Cigarette product quality defect prevention and control learning system and method based on big data

PendingCN114708584AImprove skillsImprove quality management levelDigital data information retrievalNeural architecturesQuality controlData processing

The invention relates to the technical field of quality control learning systems, and discloses a cigarette product quality defect prevention and control learning system and method based on big data, and the system comprises a data collection unit, a data processing unit, a data storage unit, and a learning unit. The data acquisition unit comprises a camera; the data processing unit comprises a first processor, the first processor is provided with an analysis system, and the analysis system comprises an image processing unit and a data analysis unit; the learning unit comprises a second processor, the second processor is electrically connected with a first display, a voice playing module and a first control module, and the second processor is provided with a multimedia interface. According to the method, the problems of cigarette physical quality, appearance defects and the like on the cigarette production line can be automatically collected, reasons and solutions are analyzed, a cigarette product quality defect prevention and control learning database is formed for workers to learn, and the service capacity of the workers is improved.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

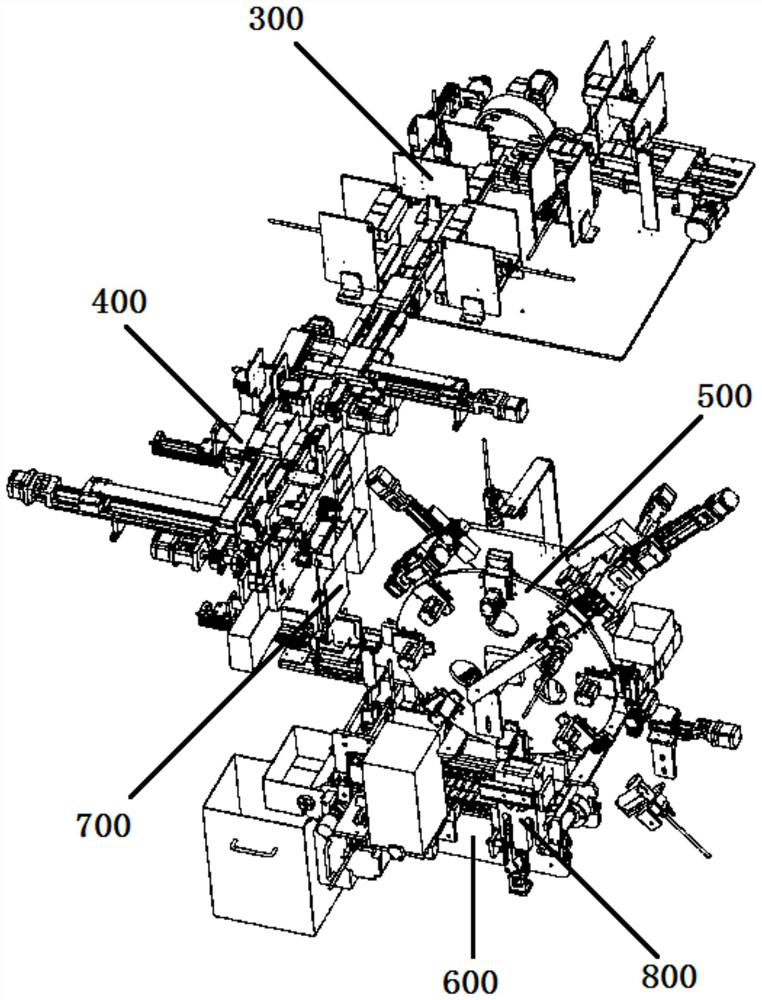

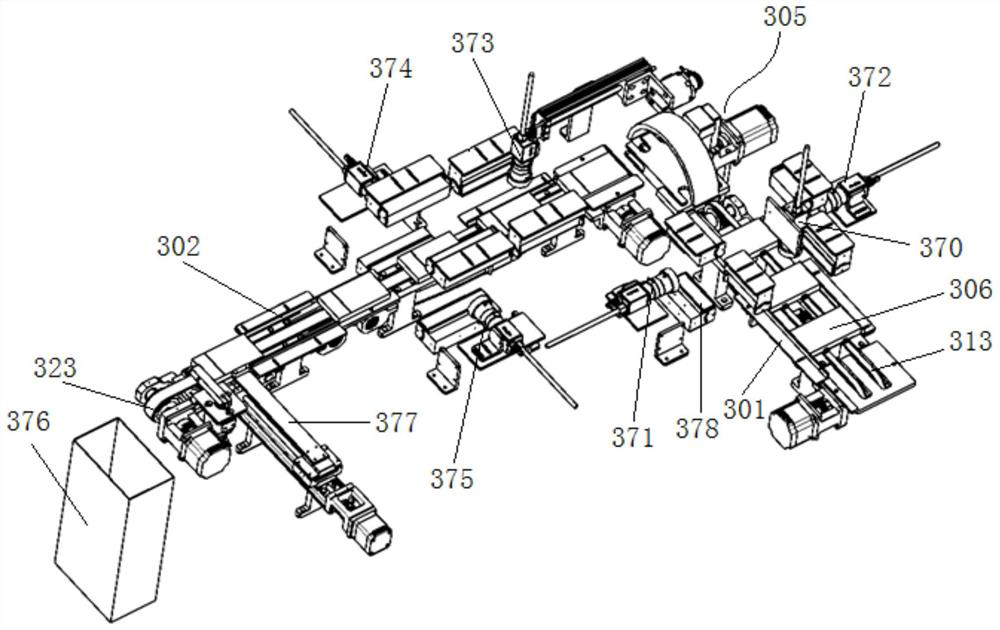

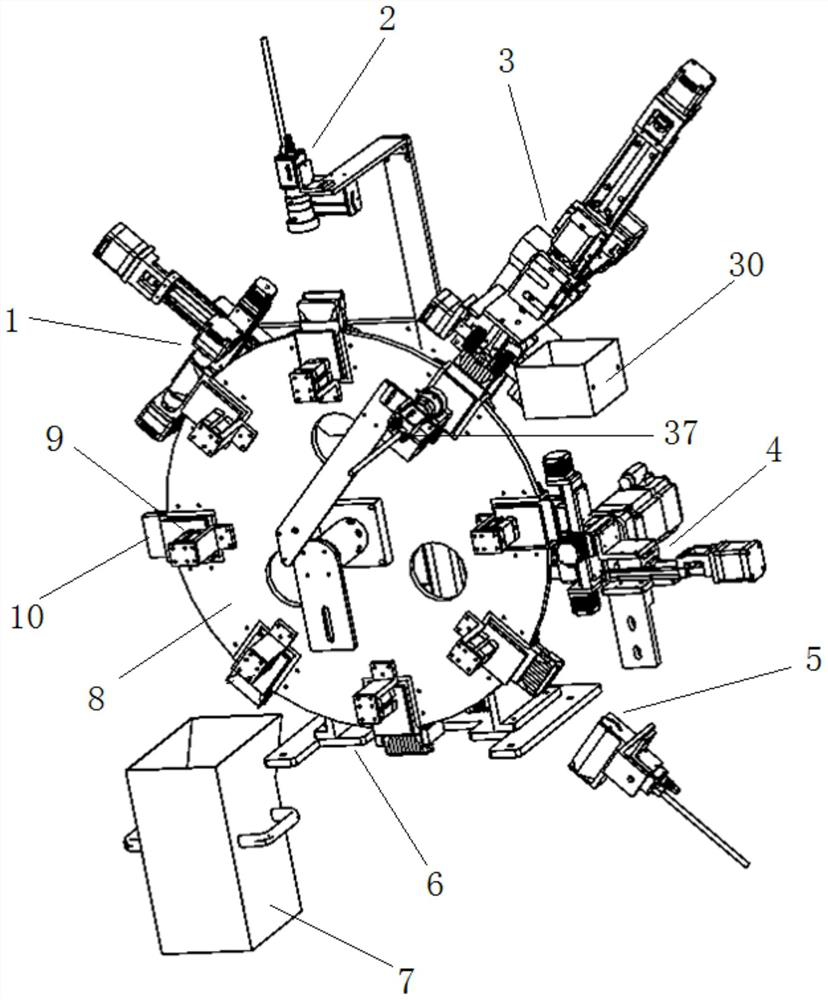

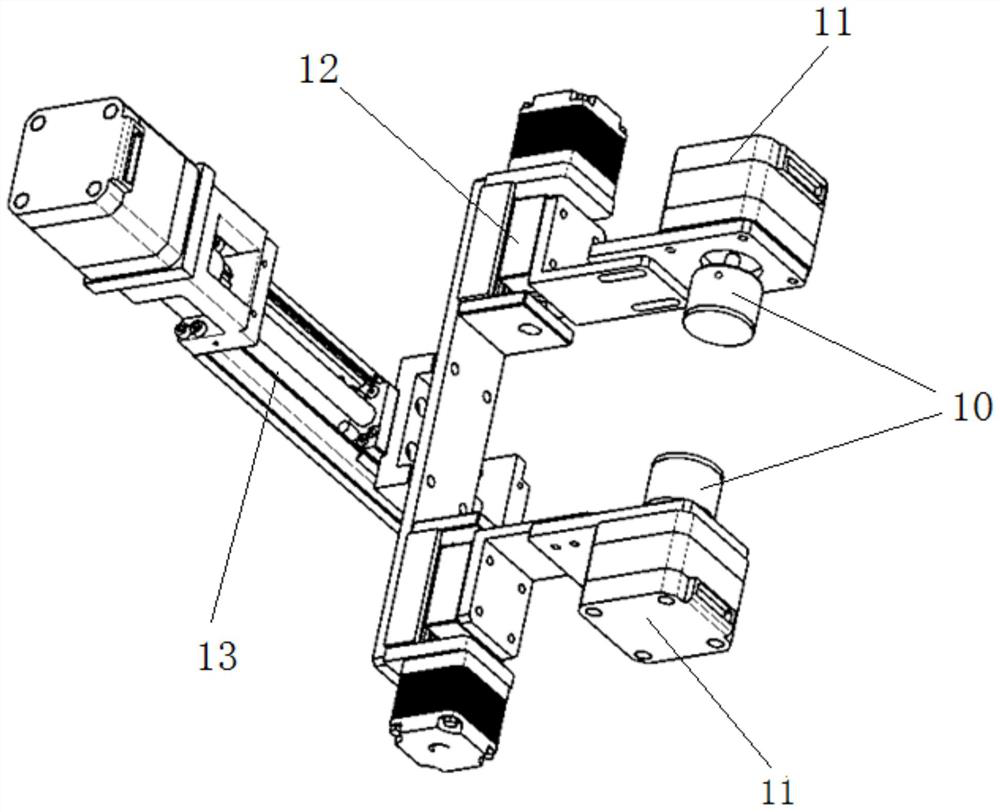

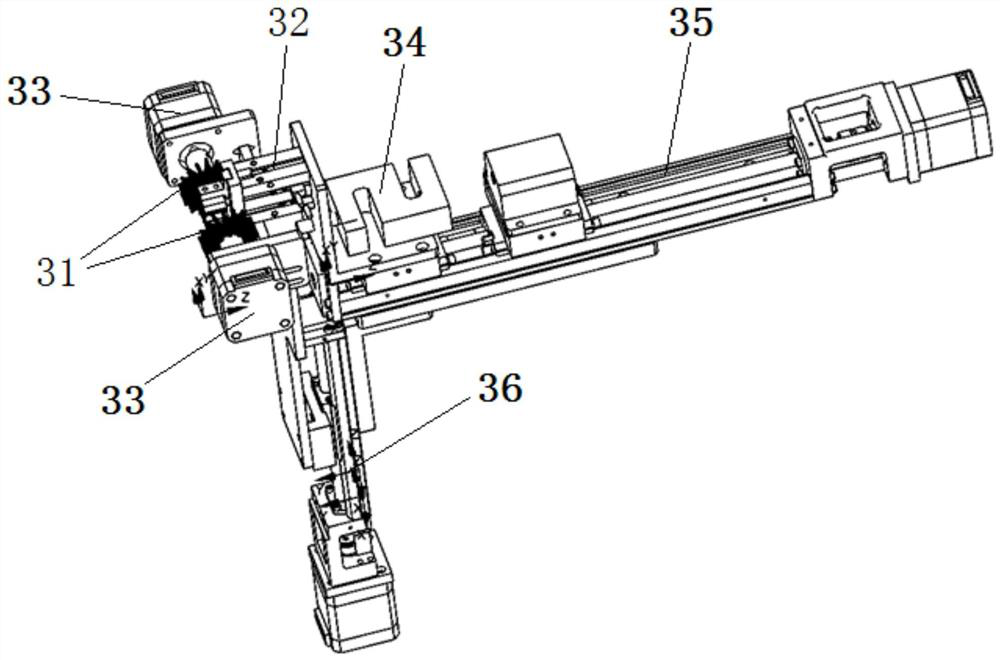

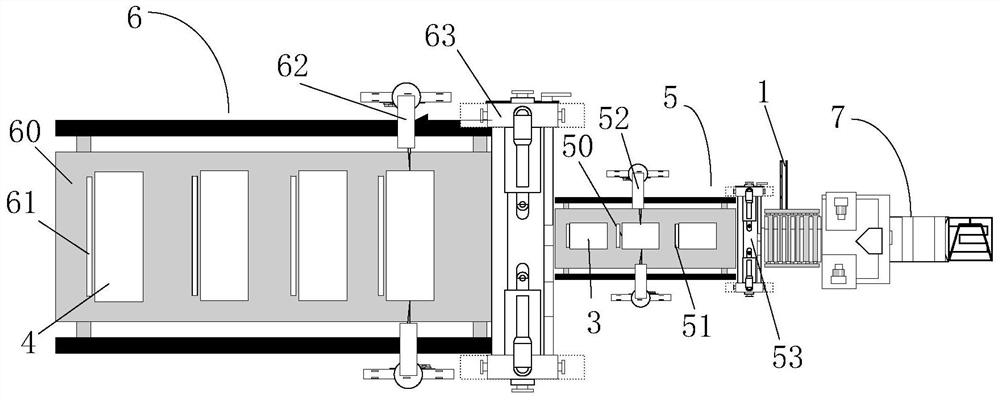

Cigarette packet inspection device capable of comprehensively detecting cigarette packet and cigarette appearance

ActiveCN113998242AReduce work intensityReduce labor costsOptically investigating flaws/contaminationConveyor partsEngineeringCellophane

The invention relates to a cigarette packet inspection device capable of comprehensively detecting cigarette packet and cigarette appearance. The device comprising cigarette packet appearance detection equipment, cigarette packet cellophane disassembling equipment and cigarette packet shell disassembling equipment, the cigarette packet cellophane disassembling equipment is arranged at the rear end of the cigarette packet appearance detection equipment, and the cigarette packet shell disassembling equipment is arranged at the rear end of the cigarette packet cellophane disassembling equipment. According to the device, the cigarette packets can be automatically disassembled, the quality of the cigarette packets or cigarettes can be fully automatically detected, the technical blank of related equipment is filled up, comprehensive appearance detection can be rapidly carried out on the cigarette packets, and the cigarettes can be automatically disassembled and taken out for detection. On one hand, the working intensity of quality inspectors can be reduced; and on the other hand, detection results can be quantified, detection data can be automatically stored, the problems of cigarettes with quality defects can be quickly found, and the quality management level is improved.

Owner:云南烟草机械有限责任公司 +1

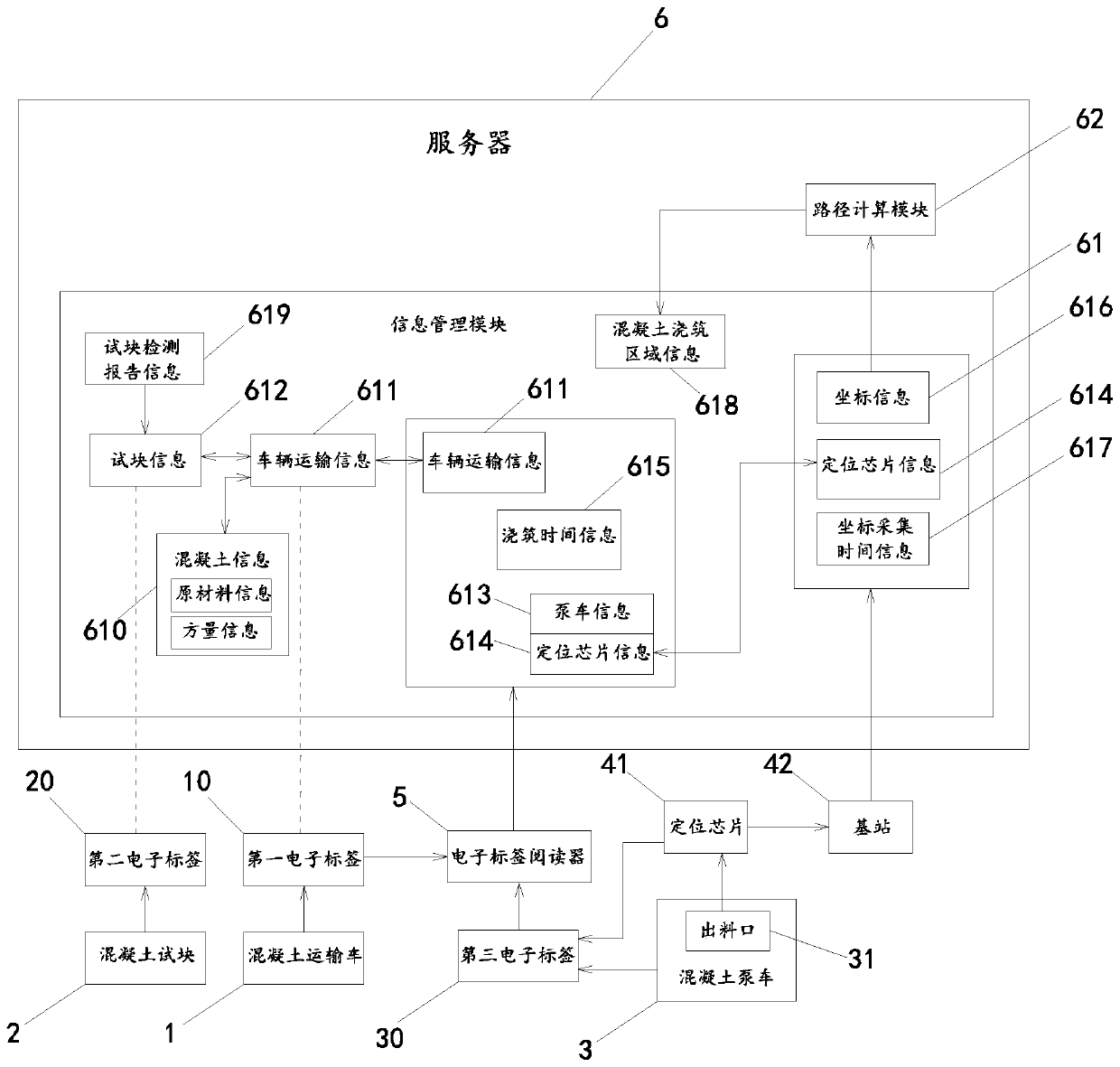

Concrete quality tracking method and system

PendingCN109829609ARealize the whole process trackingQuality assuranceCo-operative working arrangementsResourcesInformatizationBlock detection

The invention relates to a concrete quality tracking method and system. The system comprises a first electronic tag, a second electronic tag, a third electronic tag, an electronic tag reader, a positioning device and a server, The server comprises an information management module and a path calculation module; The path calculation module is used for determining a concrete pouring area in the concrete transport vehicle; And the information management module associates the concrete pouring area information with the test block information, and associates the concrete test block detection report information with the concrete test block information. The invention provides a concrete quality tracking method and system. According to the invention, information association of concrete information,vehicle transportation information, concrete test block information, concrete test block detection report information, concrete pump truck information and concrete pouring area information can be realized through an informatization means, and whole-process tracking of concrete quality is realized, so that the quality of an engineering construction project is guaranteed.

Owner:SHANGHAI CONSTRUCTION GROUP +1

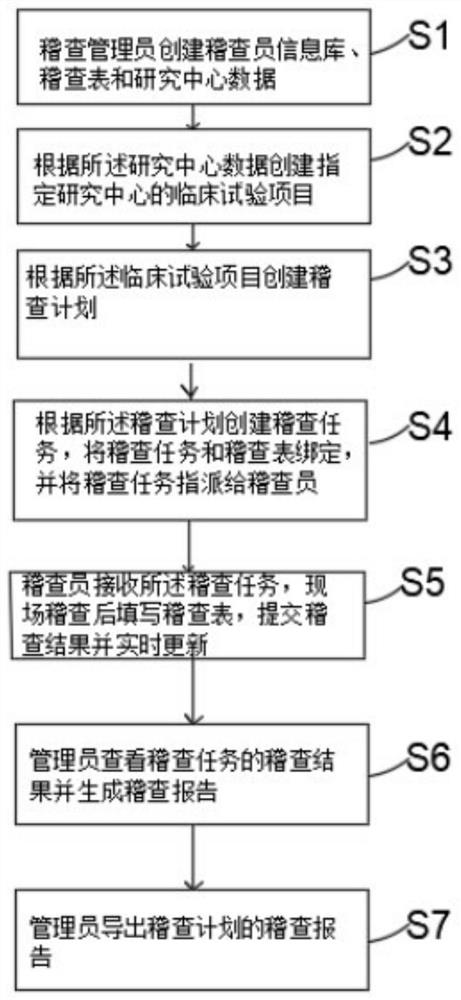

An electronic inspection method and system for clinical trials

ActiveCN113743886BPromote scientific orderImprove quality management levelDatabase management systemsOffice automationInformation repositoryClinical tests

The invention discloses an electronic inspection method for clinical trials, which includes the following steps: S1, an inspection administrator creates an auditor information database, an inspection table, and research center data; S2, creates a clinical trial of a designated research center according to the research center data Test project; S3. Create an audit plan according to the clinical trial project; S4. Create an audit task according to the audit plan, bind the audit task to the audit table, and assign the audit task to the auditor; S5. The auditor receives all Describe the audit task, fill in the audit form after the on-site audit, submit the audit result and update it in real time; S6, the administrator checks the audit result of the audit task and generates an audit report; S7, the administrator exports the audit report of the audit plan. The invention also provides an electronic inspection system for clinical trials, which includes an auditor terminal and a management user terminal.

Owner:成都华西临床研究中心有限公司

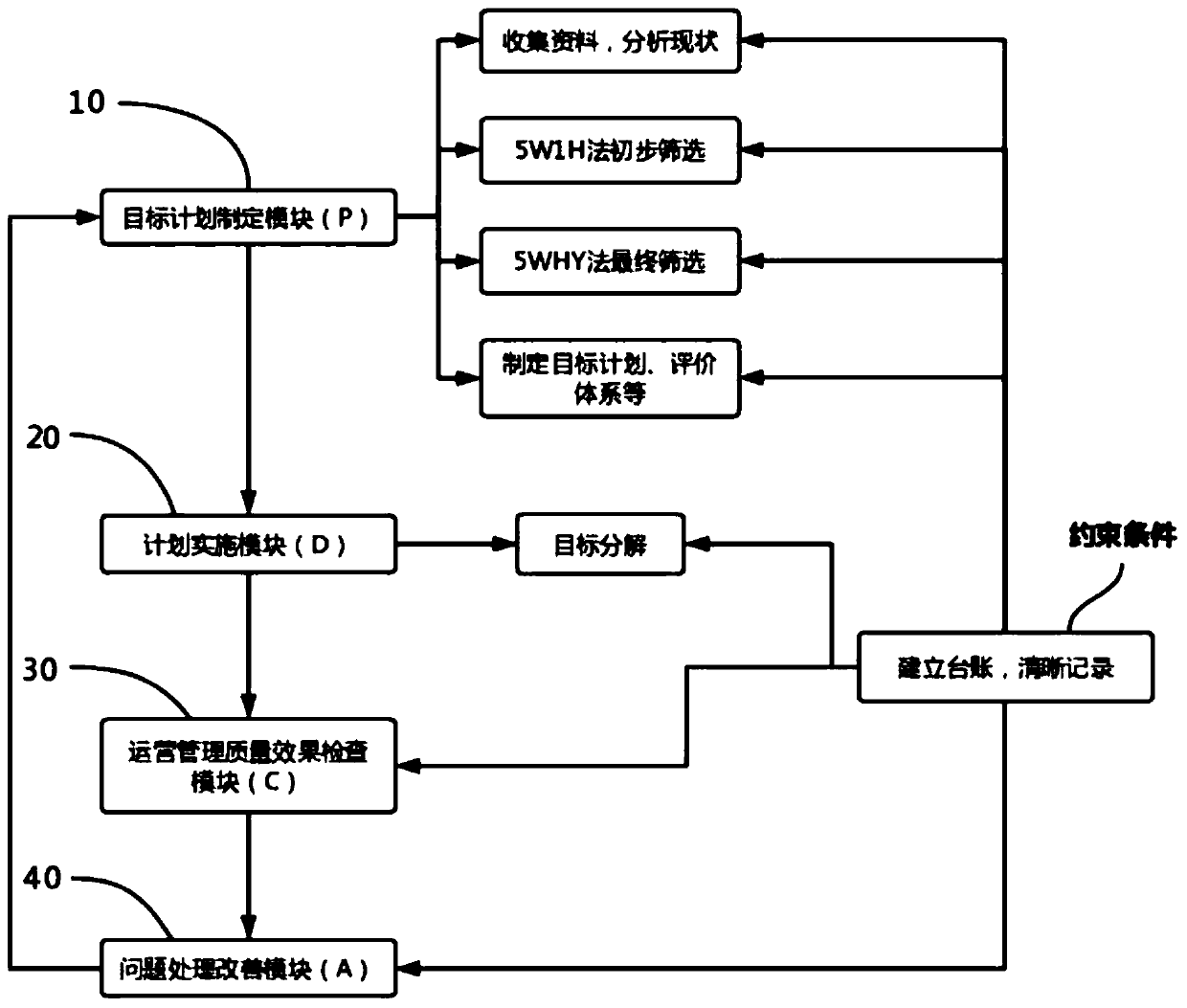

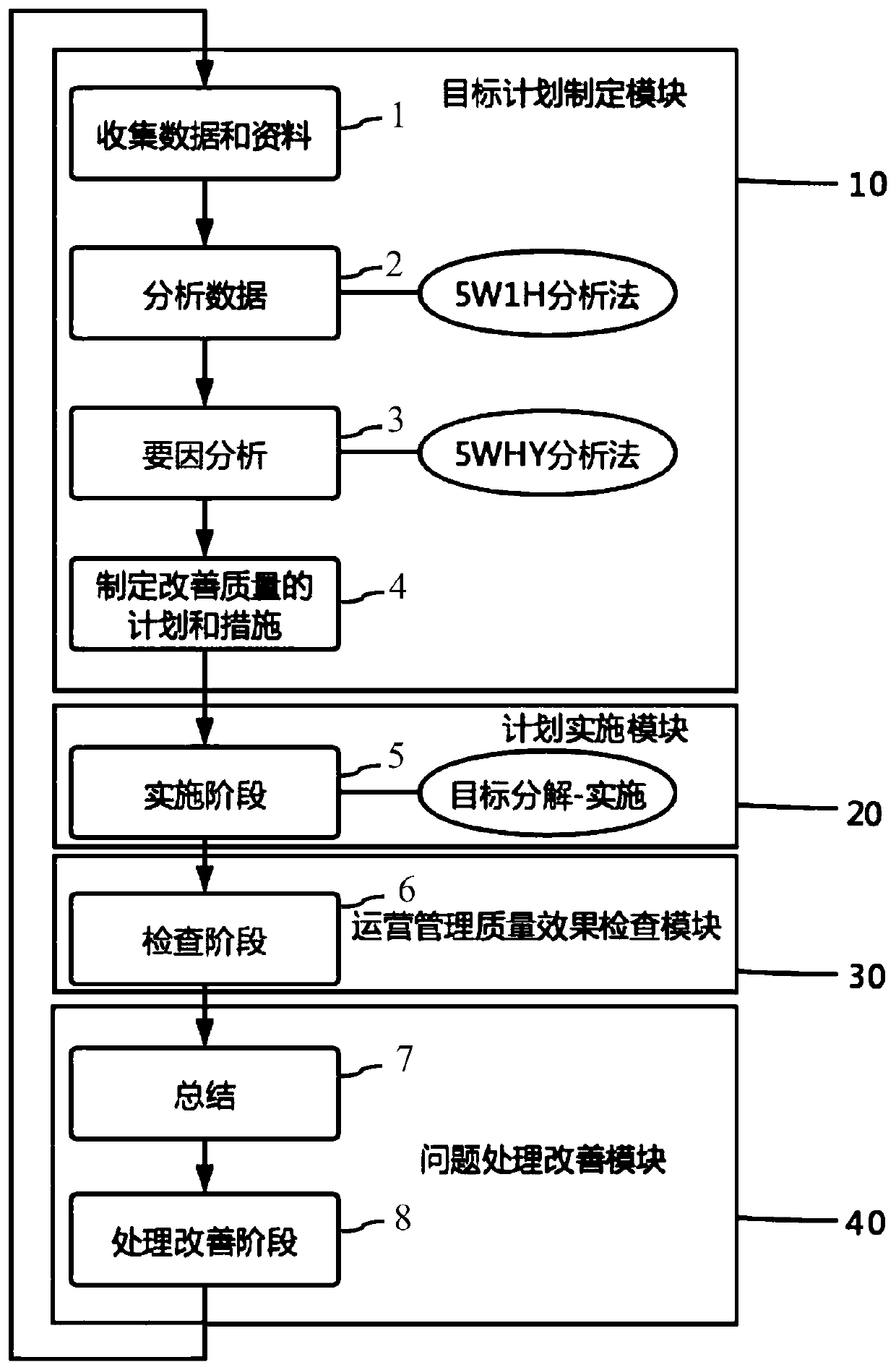

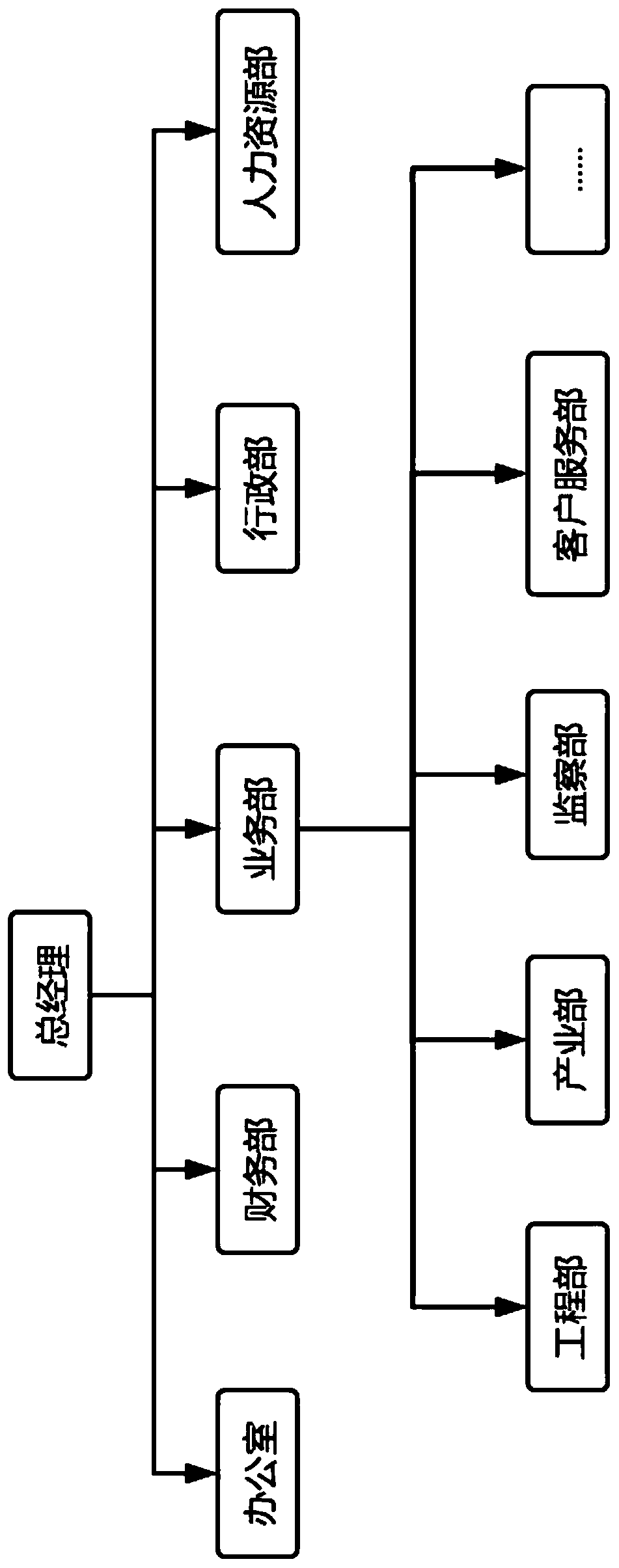

Public building operation quality management system and method based on PDCA and target decomposition

PendingCN111008766AImprove quality management levelSmooth out the quality management workflowResourcesAnalysis dataPDCA

The invention discloses a large-scale public building operation quality management system and method based on PDCA and a target decomposition method. The system comprises a target plan making module (10) running on a server, and a plan implementation module (20), an operation management quality effect inspection module (30) and a problem processing and improving module (40) running on a client. The plan implementation module (20), the operation management quality effect inspection module (30) and the problem processing and improving module (40) communicate with the server. The management method comprises the steps of data and information collection, data analysis, cause analysis, quality improvement plan and measure making, plan and measure implementation, implementation result inspection,inspection result summary and processing improvement. Compared with the methods in the prior art, the beneficial effects are that the quality management workflow is smoothened by standardizing the large-scale public building operation management system and method, and the building operation quality management level is improved.

Owner:TIANJIN UNIV

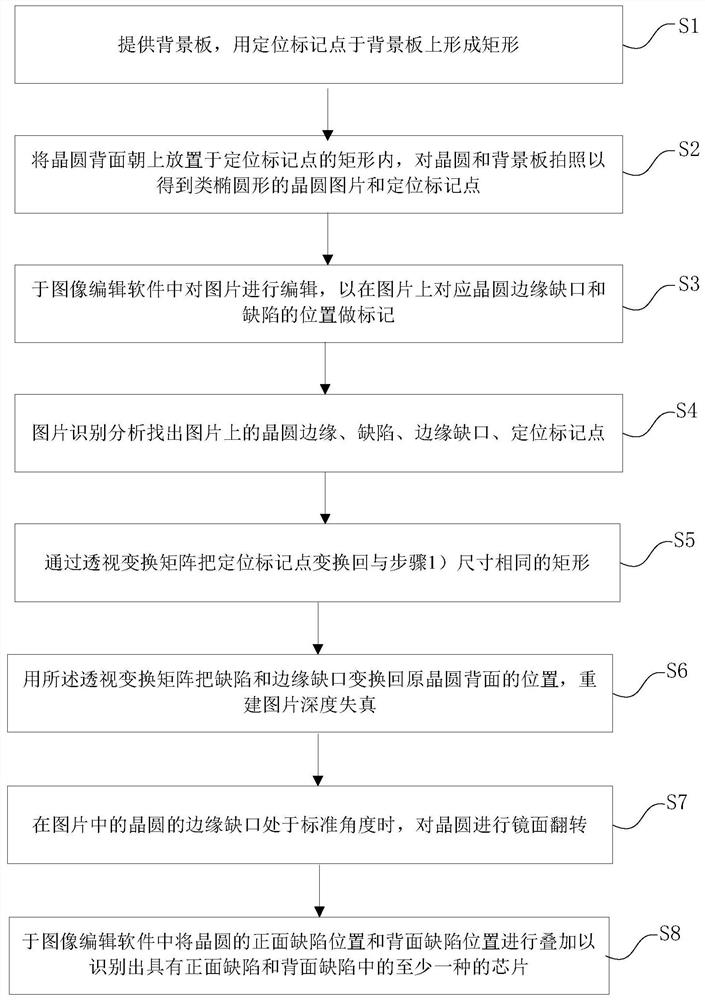

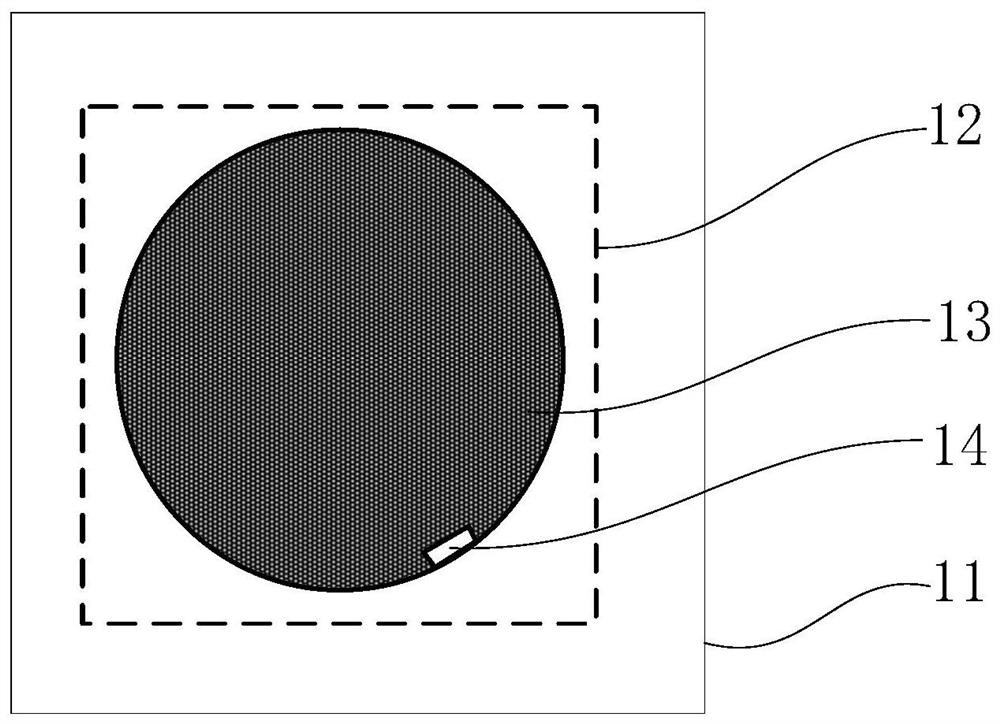

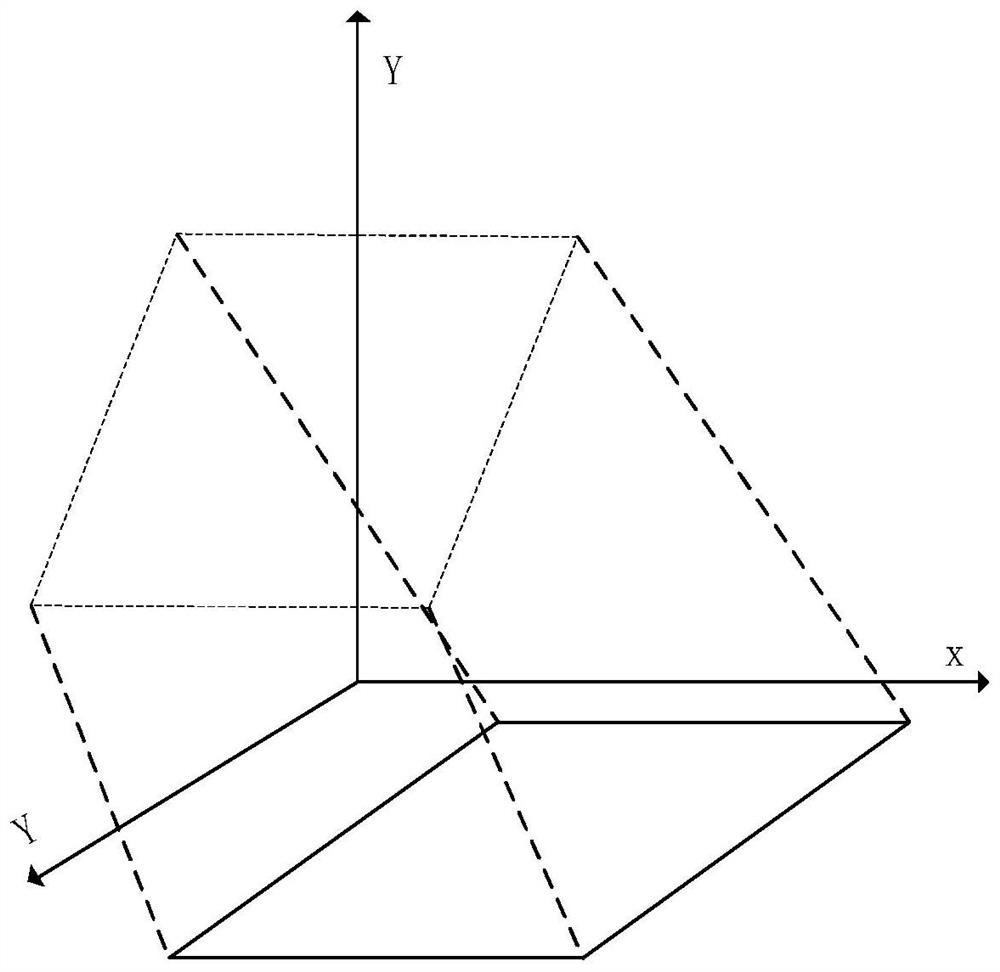

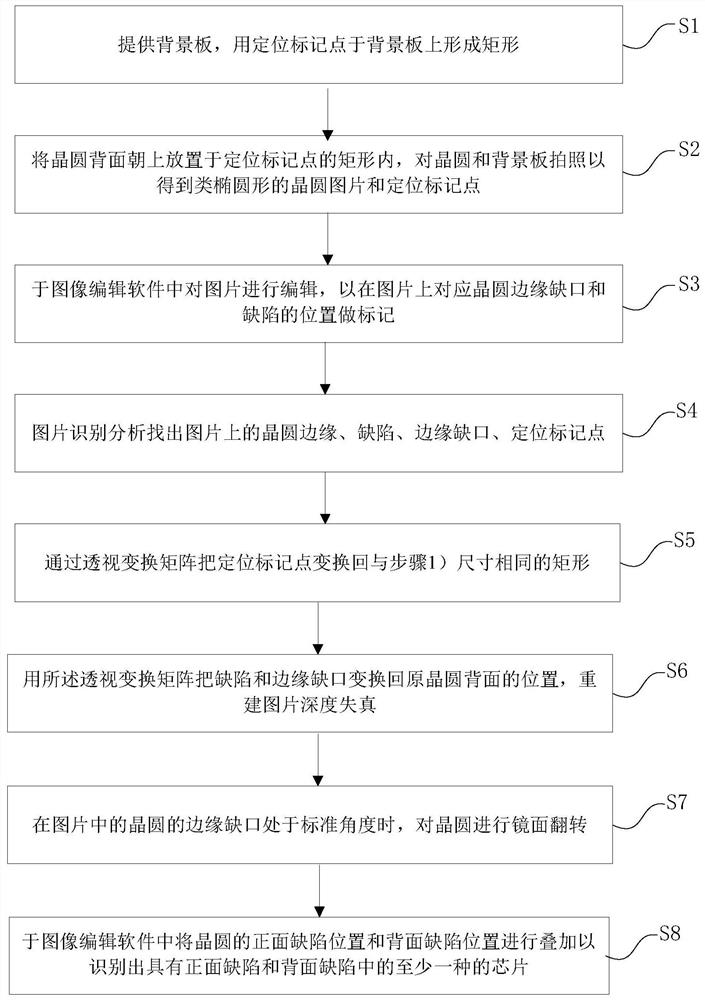

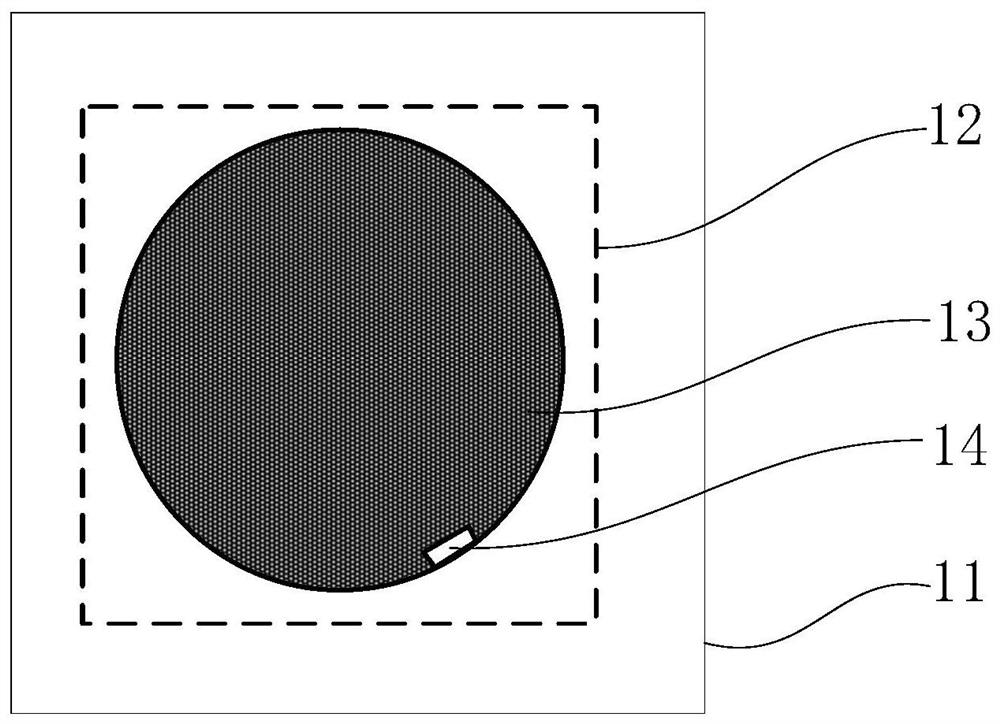

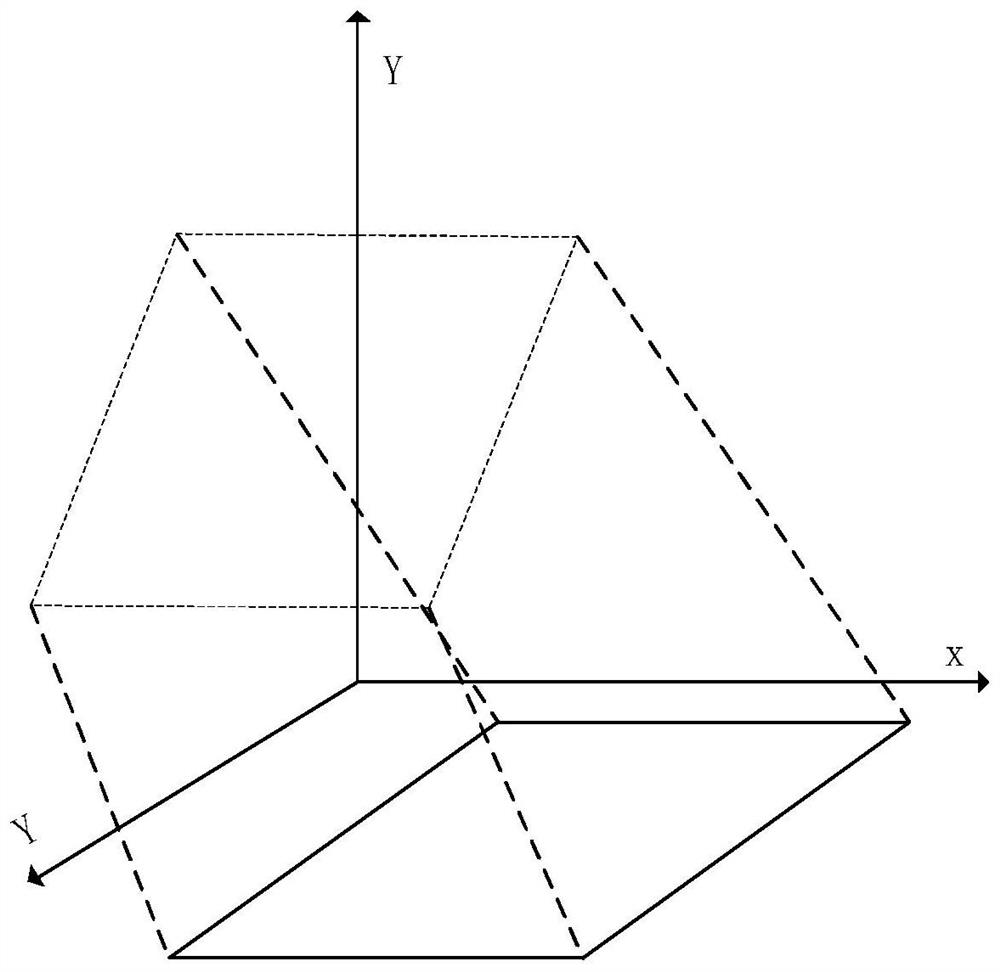

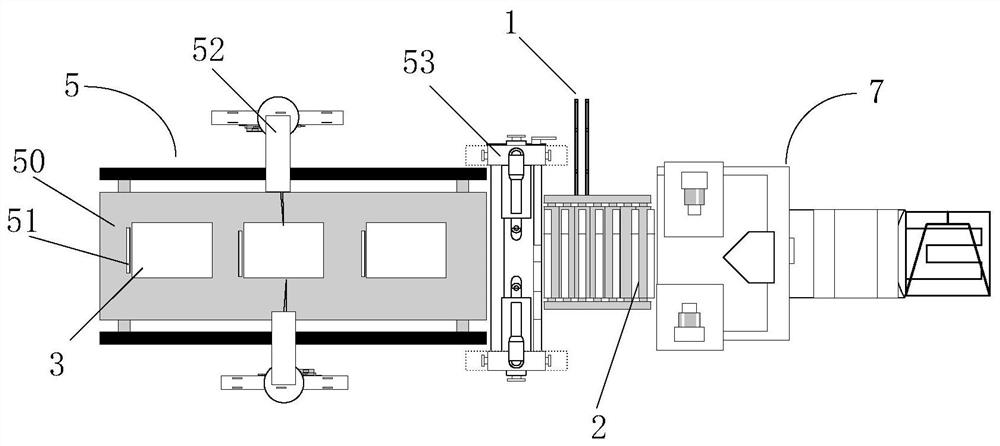

Semiconductor process method

ActiveCN113327863AAccurate detectionImprove quality management levelSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsWaferEngineering

The invention provides a semiconductor process method, which comprises the following steps of 1) providing a background plate, and forming a rectangle on the background plate by using a positioning mark point, 2) placing the wafer in the rectangle of the positioning mark point with the back face upward, and photographing to obtain an ellipse-like wafer picture and the positioning mark point, 3) editing the picture, and marking the positions corresponding to the edge gaps and the defects of the wafer, 4) finding out wafer edges, defects, edge gaps and positioning mark points on the picture, (5) transforming the positioning mark points into rectangles with the same size as the rectangles in the step 1), 6) transforming the defect and the edge gap back to the position of the back of the original wafer, and reconstructing the depth distortion of the picture, 7) performing mirror surface overturning on the wafer, and 8) superposing the front defect position and the back defect position of the wafer to identify the chip with at least one of the front defect and the back defect. The defect of the back surface of the wafer can be accurately reflected to the front surface of the wafer, so that all defective chips can be accurately detected.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

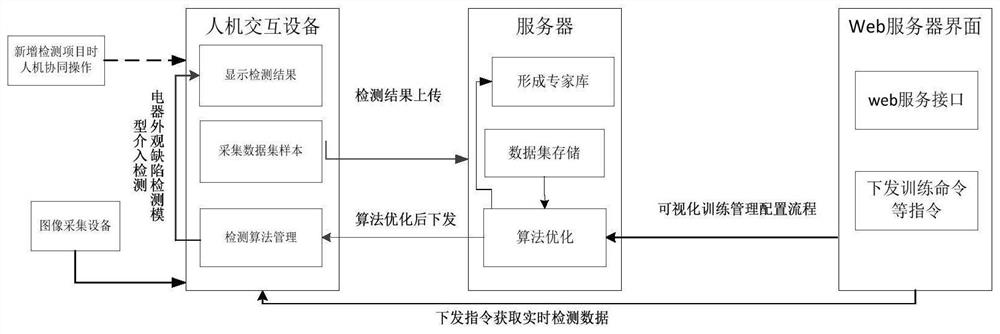

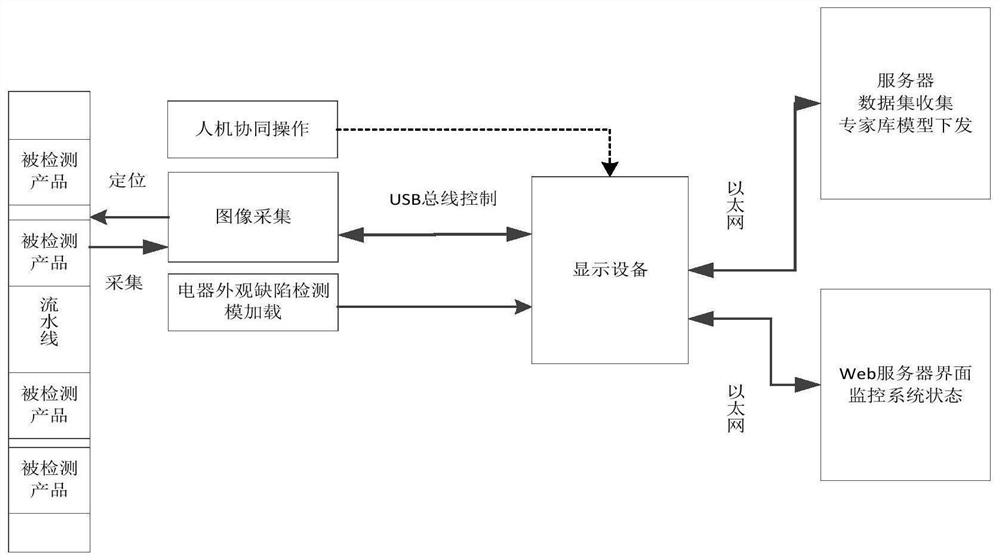

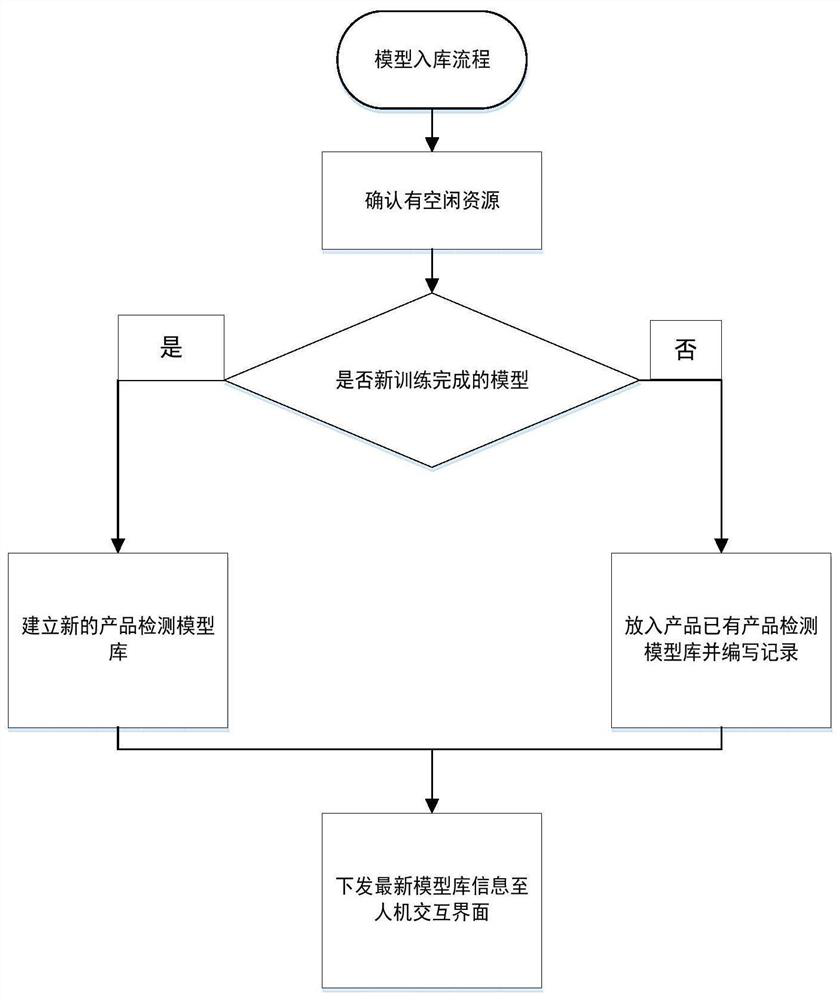

Electrical product appearance defect detection method based on network collaboration

PendingCN113838015AImprove detection qualityReduce deploymentImage enhancementImage analysisLearning machineEngineering

The invention relates to an electrical product appearance defect detection method based on network collaboration. In electrical product appearance detection, a man-machine cooperation technology is utilized to collect detection samples, a deep learning mechanism is superposed to dynamically optimize an electrical appliance appearance detection model, and finally an electrical appliance appearance detection model expert database is formed. At present, a traditional appearance detection system in the electric appliance industry is high in requirement and can be operated by professionally trained personnel, and the system adopts detection data automatic learning, realizes an intelligent quality management analysis system, realizes detection standardization, reduces the influence of human factors on a detection result, improves the quality management level, reduces personnel deployment, and saves the production cost.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

Box-shaped object unpacking equipment and unpacking method thereof

PendingCN112777070ASimple structureReduce work intensityPackaging automatic controlUnpacking by expelling contentsWorkbenchIndustrial engineering

The invention relates to box-shaped object unpacking equipment and an unpacking method thereof. The box-shaped object unpacking equipment comprises a working table, a mold box, a cover turning device, an aluminum paper pulling piece dismantling device, an aluminum paper stretching device and an extruding device, and the mold box is arranged on the working table; and the cover turning device, the aluminum paper pulling piece dismantling device, the aluminum paper stretching device and the extruding device are sequentially arranged in the moving direction of the workbench and correspond to the mold box. The box-shaped object unpacking equipment has the beneficial effects that the equipment can detect the appearance quality in a box while disassembling the box, is simple in structure, can detect the quality of contents in a box-shaped object while automatically disassembling a cigarette packet, achieves multiple purposes, and fills the technical blank of related equipment.

Owner:云南烟草机械有限责任公司 +1

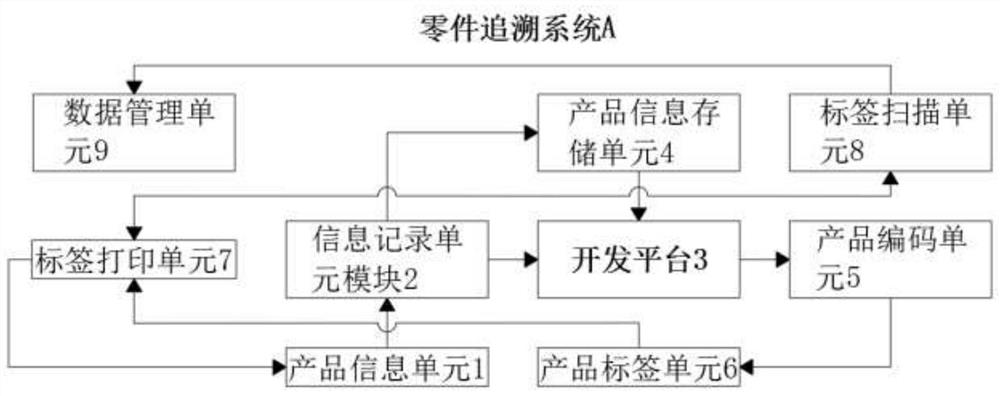

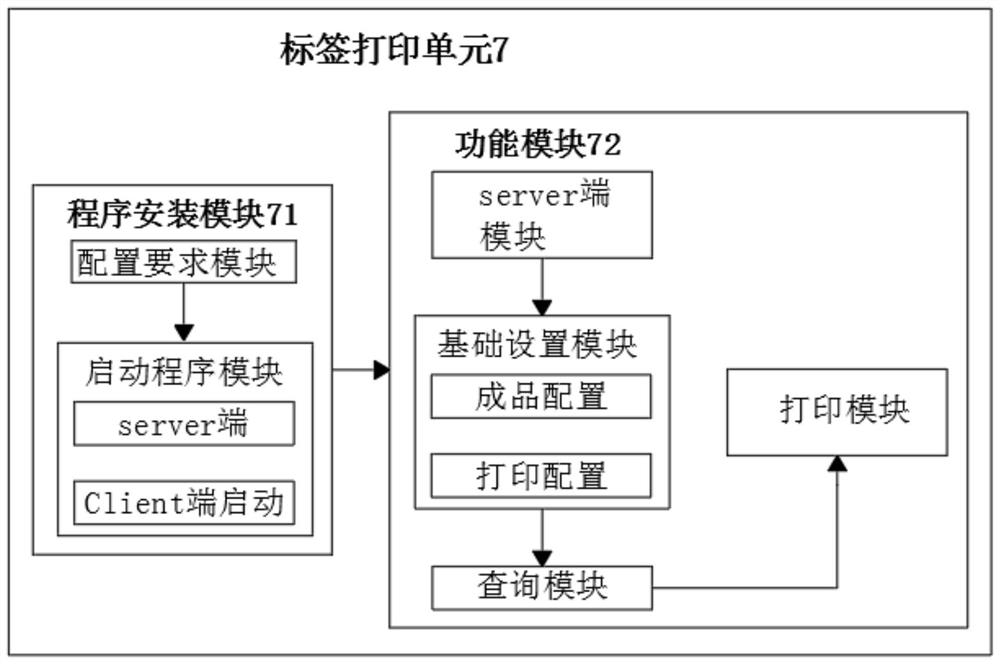

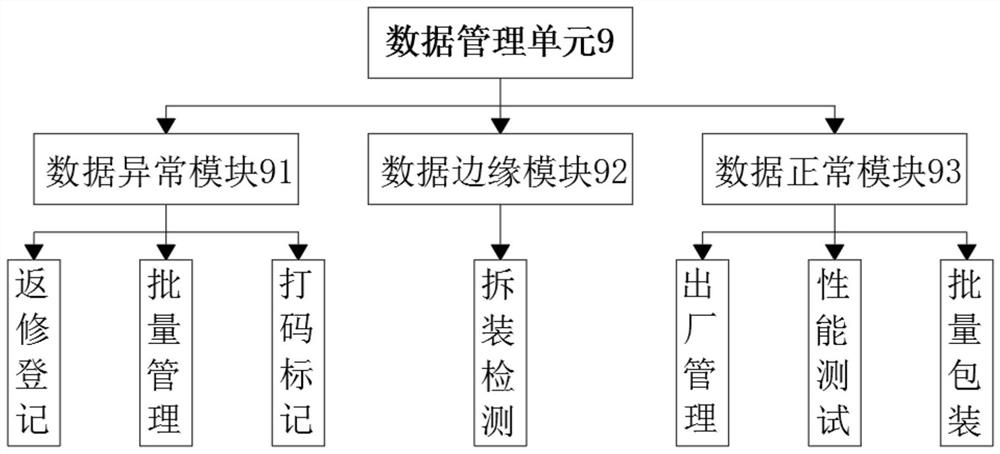

Part tracing system of communication product assembly line

InactiveCN112183961AImprove product quality managementFast trackCo-operative working arrangementsResourcesManagement unitProcess engineering

The invention discloses a part tracing system for a communication product assembly line, and the invention comprises a part tracing system which comprises a product information unit, an information recording unit, a development platform, a product information storage unit, a product coding unit, a product label unit, a label printing unit, a label scanning unit, and a data management unit. The output end of the product information unit is connected with the input end of the information recording unit. The invention relates to the technical field of communication product. According to the parttracing system of the communication product assembly line, recording is conducted according to material batch information in the product production process, a product code is given; when a product isoffline, a finished product label is given, and the material batch information used in the production process can be traced by scanning the finished product label; by using the whole process quality tracing system, the invention can achieve the quick and accurate tracing of the quality of the remanufactured product, improves the accuracy and efficiency of the quality tracing of the manufactured product, and improves the quality management level of the manufactured product of an enterprise.

Owner:湖北迈睿达供应链股份有限公司

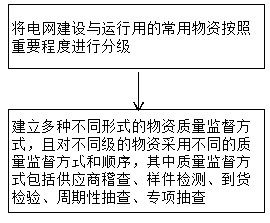

Quality inspection and supervision method and system

InactiveCN109325710AImprove quality management levelGuaranteed uptimeResourcesInformation technology support systemIntrinsic safetyPower grid

The invention relates to a quality detection and supervision method and system. The method comprises the steps of classifying the common materials used for power network construction and operation according to the importance degree; establishing a variety of different forms of material quality supervision, and different levels of material quality supervision methods and sequences, wherein the material quality supervision forms include supplier inspection, sample testing, arrival inspection, periodic sampling, special sampling. The invention is conducive to comprehensive and high-efficient supervision and management, and ensures the intrinsic safety of power grid materials and the stable operation of the power grid.

Owner:CHINA ELECTRIC POWER RES INST +1

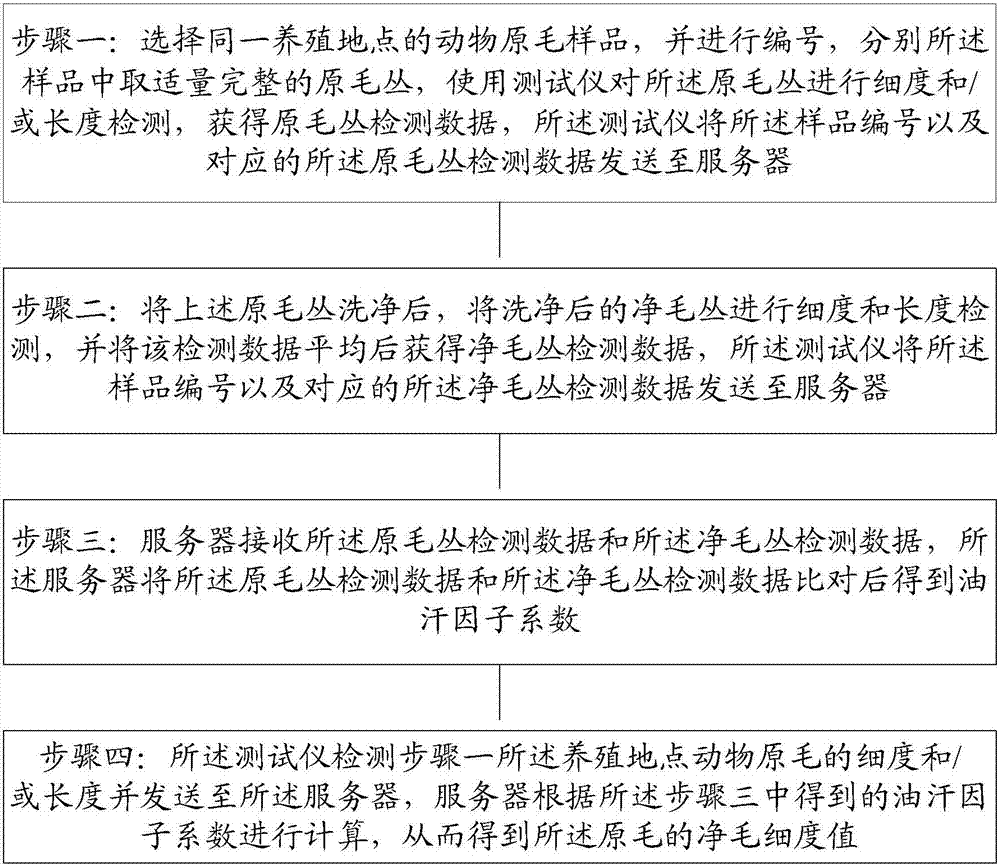

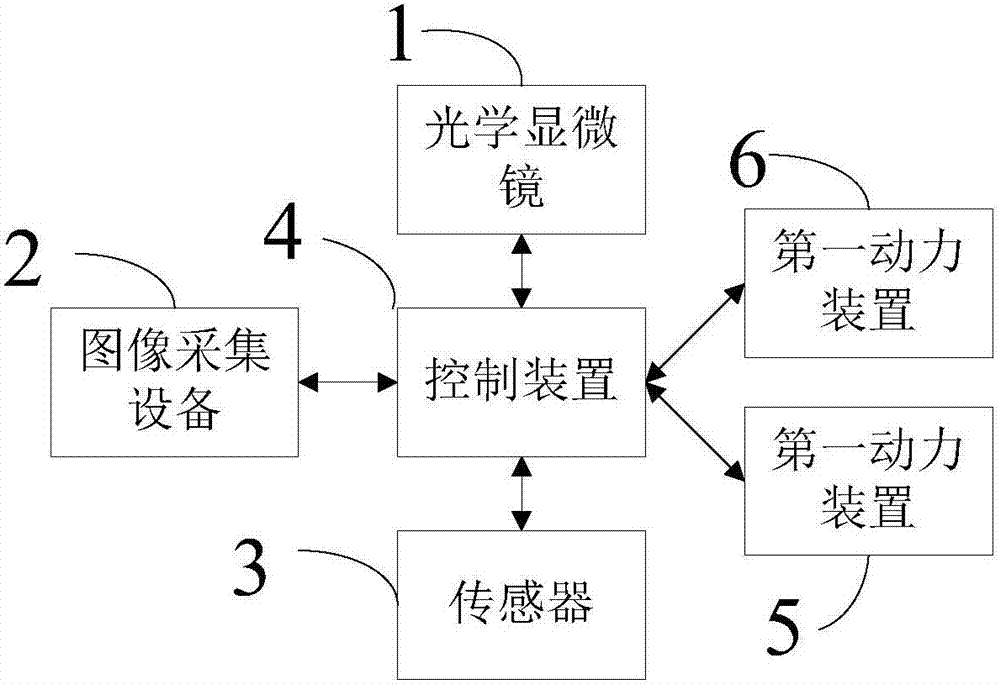

A method for rapid detection of raw wool

ActiveCN106091957BReduce preprocessing timeSave resourcesUsing optical meansSample numberComputer science

The invention discloses a method for fast detecting raw wool. The method comprises steps of choosing animal wool samples from a same cultivation place to perform numbering; proper amount of complete raw wool clusters are taken from the samples; a tester is adopted to perform detection on a fineness and / or length of the raw wool cluster; raw wool cluster detection data is obtained; the tester transmits the sample number and corresponding raw wool cluster detection data to a server; detection on fineness and length of cleaned clean wool cluster is performed after the raw wool cluster is cleaned; clean wool cluster detection data is obtained after averaging the detection data; the tester transmits the sample number and the corresponding clean wool cluster detection data to the server; the server receives raw wool cluster detection data and clean wool cluster detection data; the server compares the raw wool cluster detection data with the clean wool cluster detection data to obtain an oil sweat factor coefficient; the tester detects fineness and / or length of the animal raw wool of the cultivation place and transmits the fineness and or / length to the server; and the server performs calculation according to the oil-sweat factor coefficient to obtain a clean wool fineness value of the raw wool.

Owner:XINJIANG TIANTONG XINGYE AGRI & ANIMAL HUSBANDRY TECH CO LTD

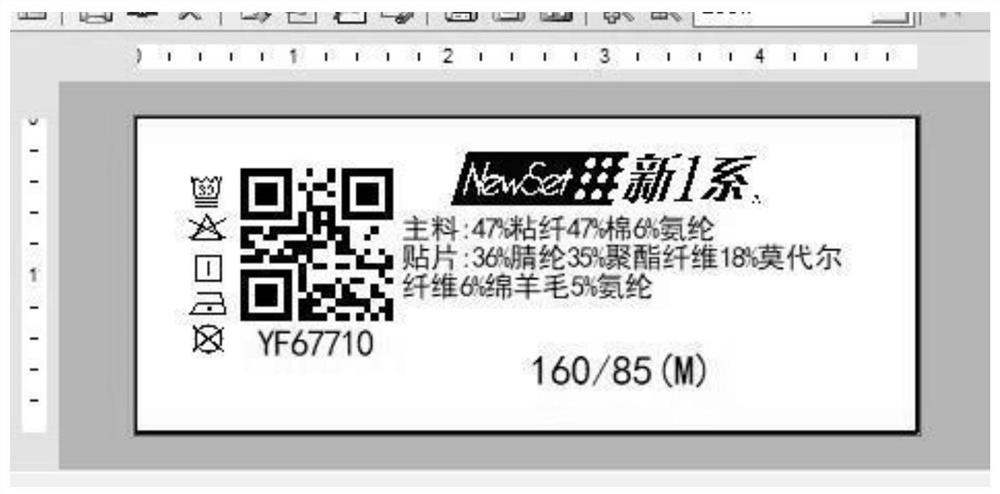

Garment manufacturing method based on industrial two-dimensional code technology

PendingCN111859478AImprove quality management levelImprove product qualityData processing applicationsComputer aided designProcess engineeringManufacturing engineering

The invention discloses a garment manufacturing method based on the industrial two-dimensional code technology, and mainly relates to the field of garment processing. The method comprises the steps ofcollecting a fabric two-dimensional code with fabric information and defect information, fixing the fabric two-dimensional code on a fabric, comparing the fabric two-dimensional code with a cutting system in a cutting stage to realize automatic positioning of defective cutting parts, summarizing the information of the fabric two-dimensional code into ready-made clothes two-dimensional code information, and printing and fixing the fabric two-dimensional code information on the inner side of ready-made clothes. The method has the beneficial effects that management and recording are carried outbased on a two-dimensional code technology in the whole process from incoming materials to ready-made clothes, so that the two-dimensional code on the ready-made clothes can realize whole process andraw material tracing, and the quality control level is improved.

Owner:广东新一系实业有限公司

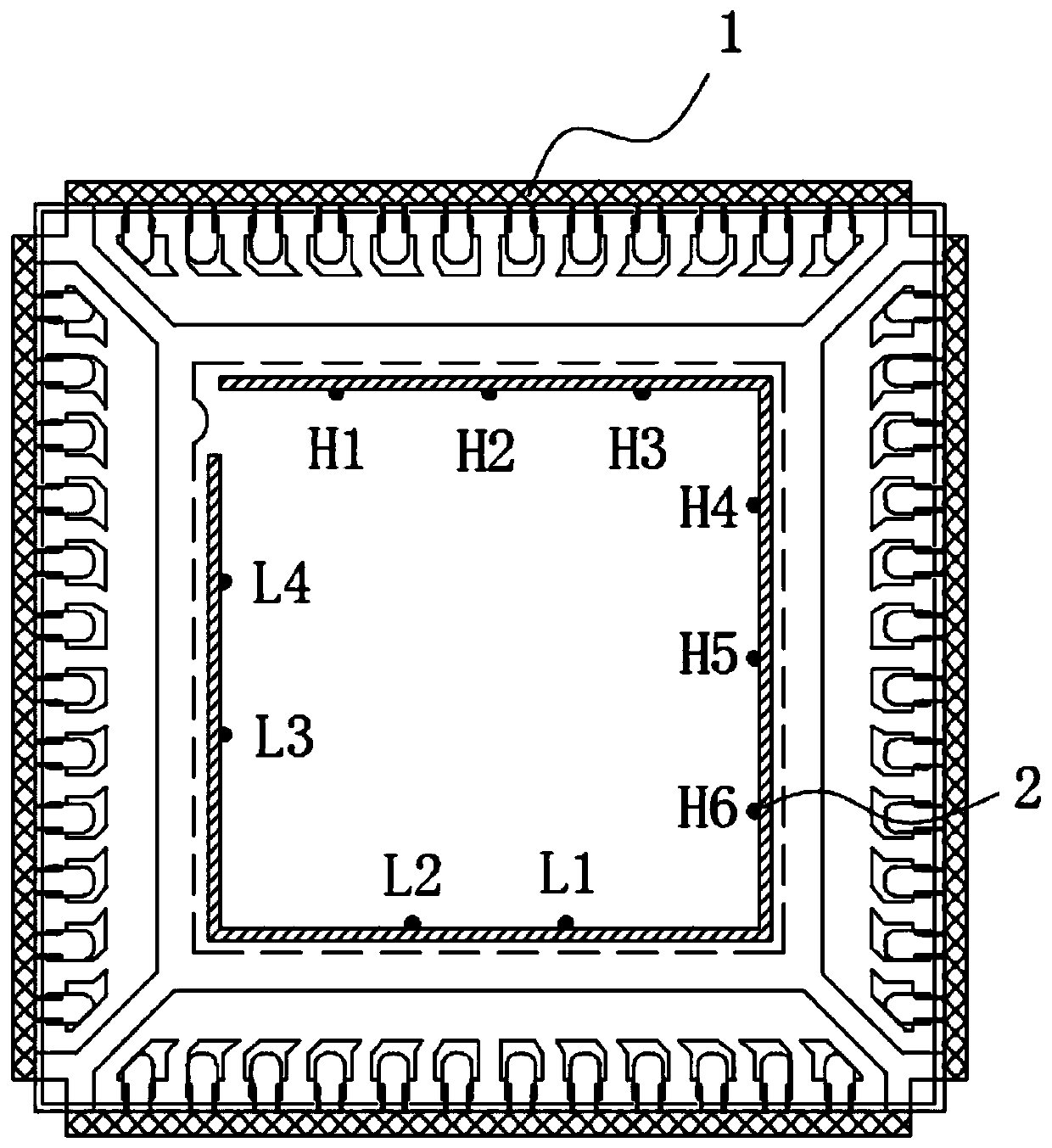

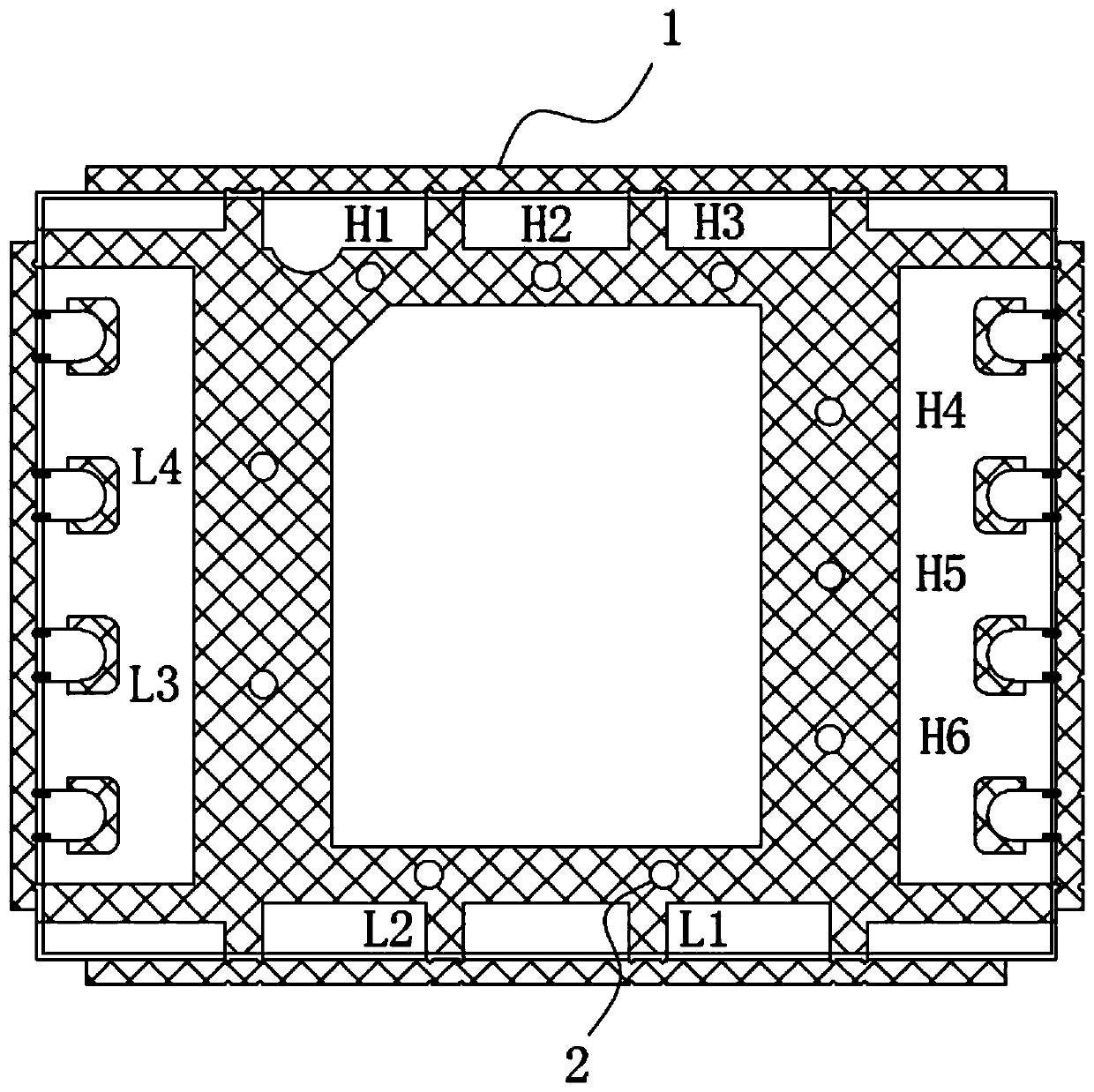

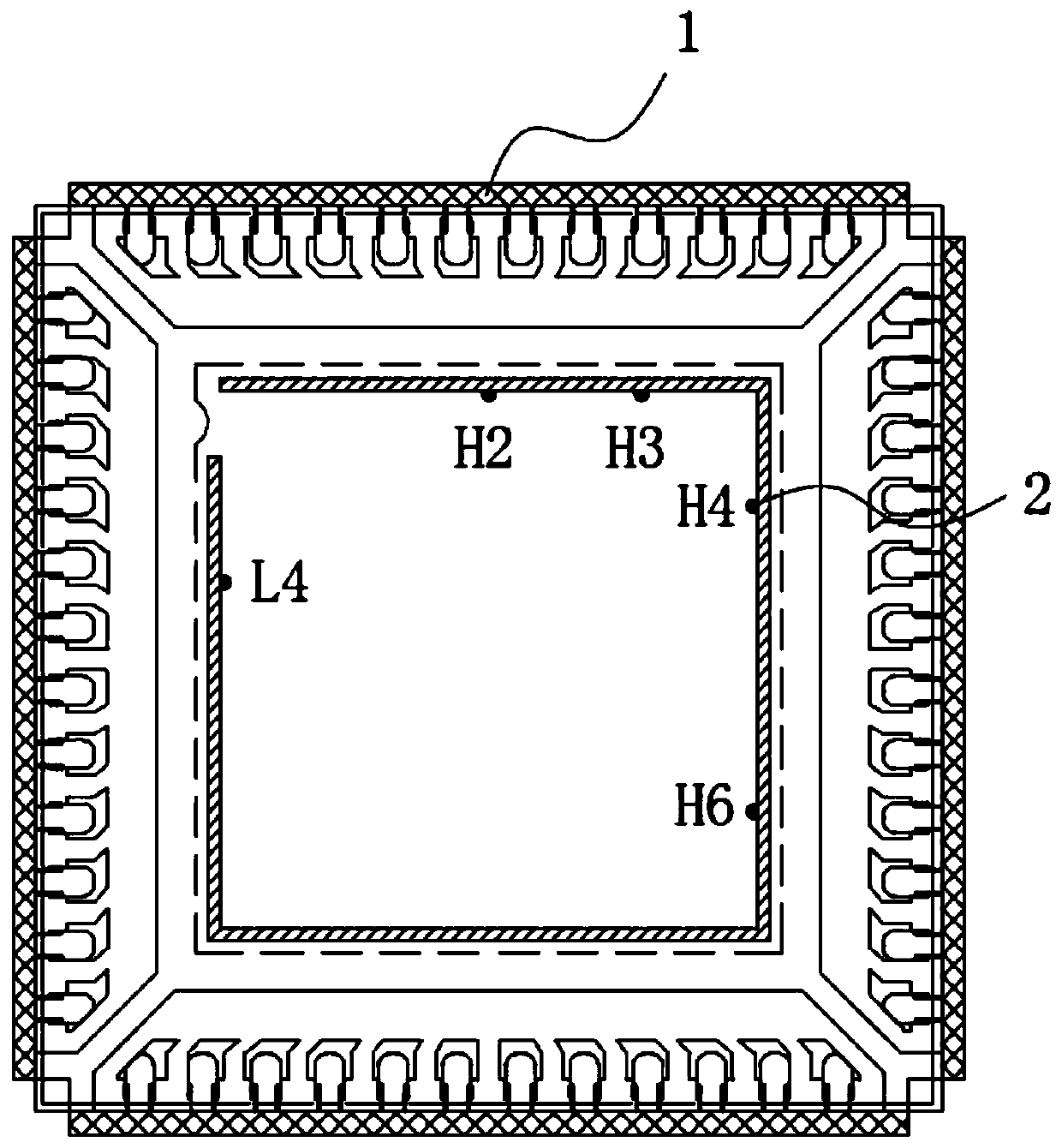

Traceable QFN bracket structure and design method

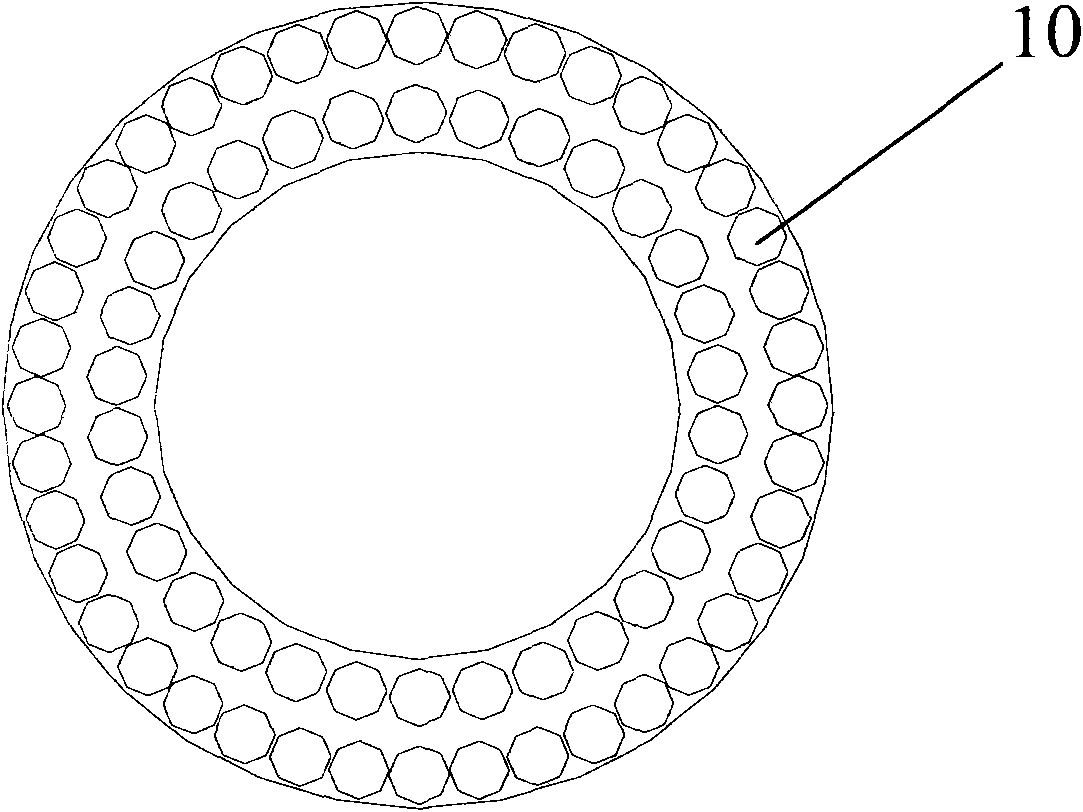

PendingCN110808239AImprove quality management levelSmall sizeSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringDesign methods

The invention discloses a traceable QFN bracket structure and a design method and relates to the technical field of QFN package to solve the problem that a conventional QFN bracket has no marks and the position of a single bracket on the entire bracket cannot be determined so as to cause a difficulty in tracing defective products and determining the causes of the defects. The traceable QFN bracketstructure include a bracket bar, which includes a plurality of brackets, wherein each bracket is provided with an etched mark, and the brackets on the bracket bar have different etched marks. The traceable QFN bracket structure can distinguish and display the position of a single bracket on the entire bracket bar, so as to trace the defective products and research the causes of the defects, thereby improving the quality management level.

Owner:POWERTECH TECH SUZHOU

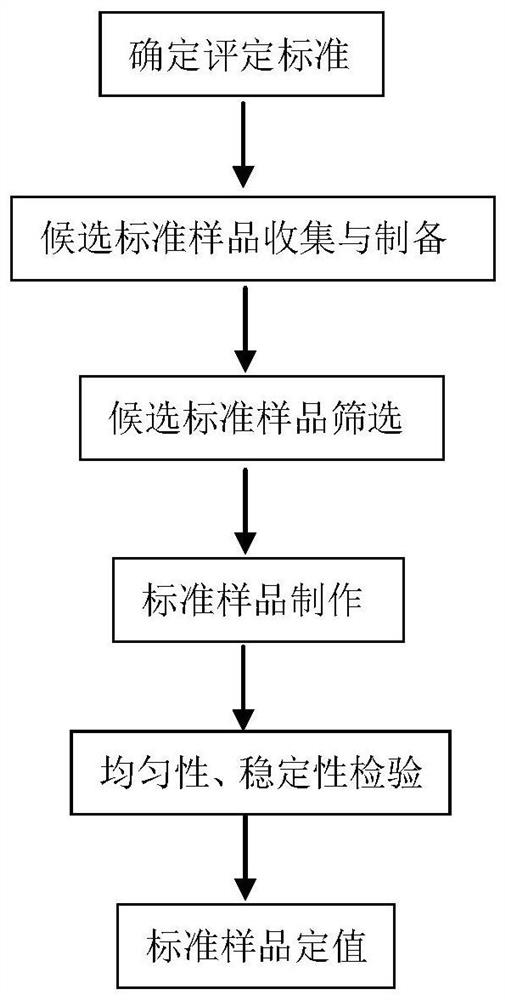

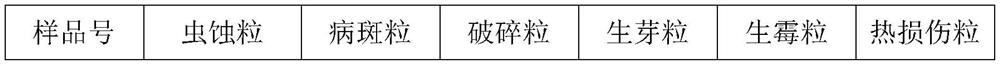

Corn imperfect kernel standard sample and its preparation method

ActiveCN110926905BHigh transparencyEasy to observe fine structurePreparing sample for investigationLaboratory Test ResultBiochemical engineering

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

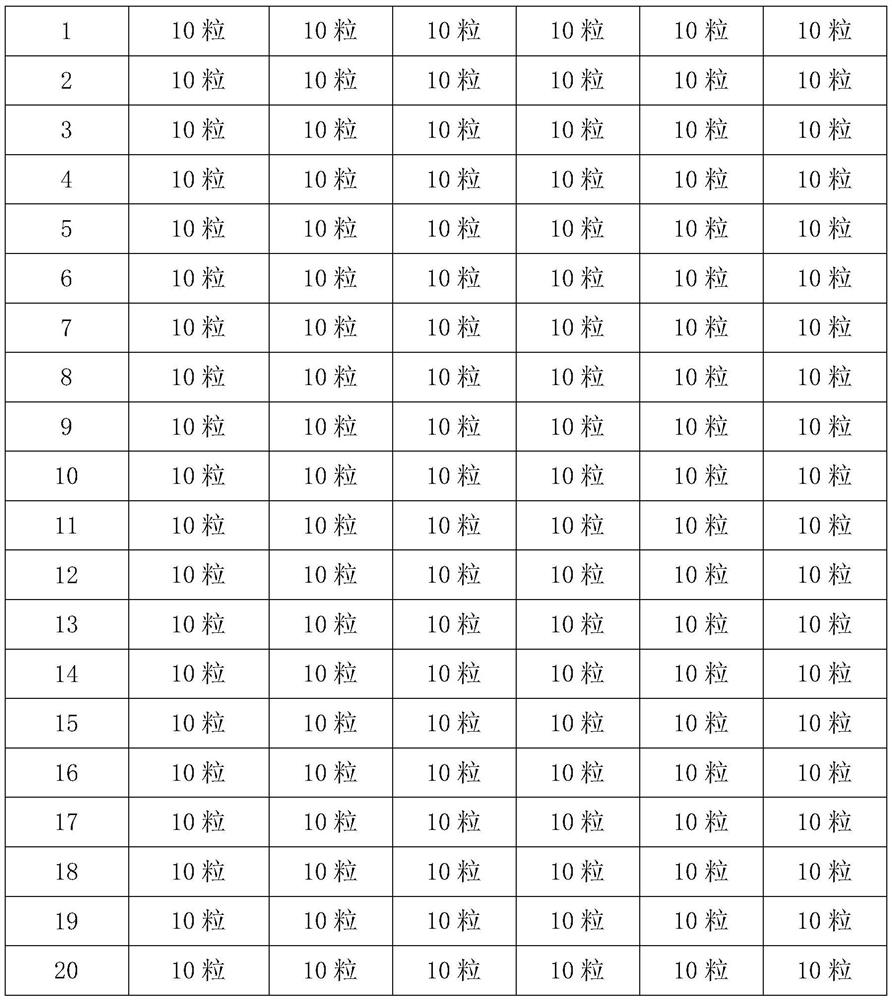

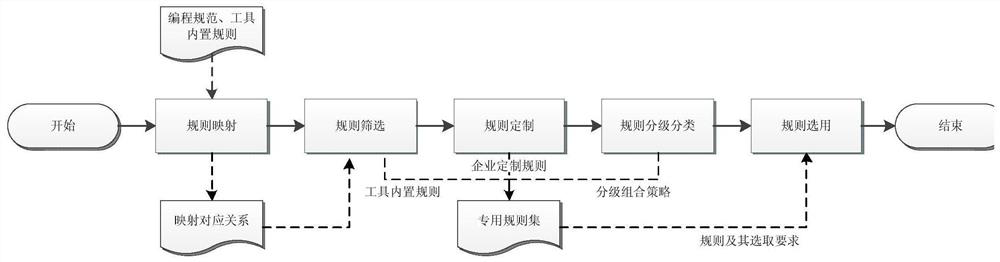

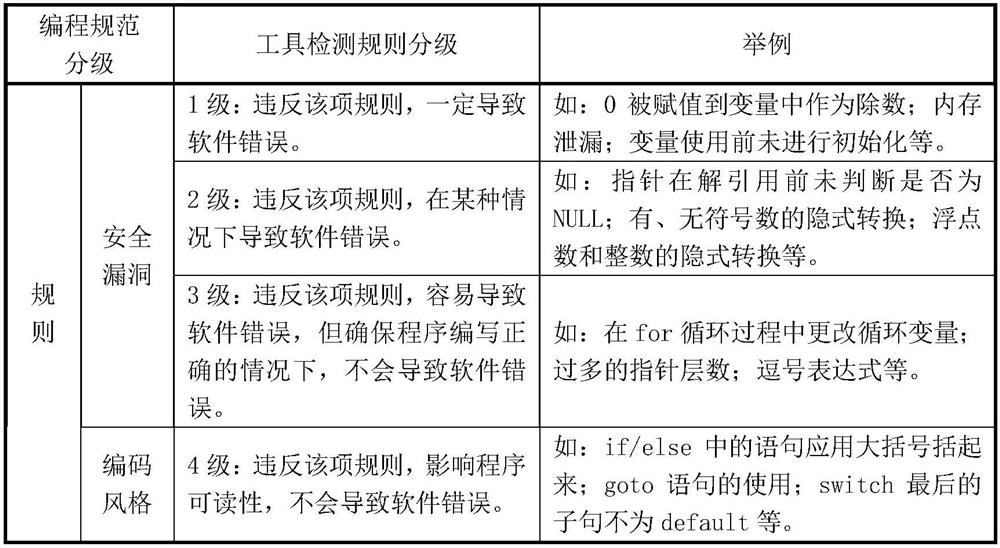

Software defect detection rule grading and combination strategy method for large complex information system

PendingCN111651344AImprove quality management levelControl defect densitySoftware testing/debuggingBusiness enterpriseComplex information system

The invention discloses a software defect detection rule grading and combining strategy method for a large complex information system. The method comprises the following steps: (1) mapping, screeningand customizing detection rules, promoting software code compliance, and screening code defect detection Klockwork tool built-in rules to form a mapping corresponding relationship between programmingspecifications and the Klockwork tool built-in rules; (2) grading and classifying detection rules; implementing resilient management, wherein a special code defect detection rule set for large complexinformation system software is divided into security vulnerabilities and programming styles, on the basis, rule grading and rule combination strategies are determined in combination with developmentcharacteristics of executed projects, and management of detection rules in the research and development process of the large complex information system is standardized according to rule selection requirements in the project life cycle. (1) the code quality management level is improved, and the code defect density in the enterprise research and development process is effectively controlled; takinga certain project as an example, the code defect density is quickly reduced to 1.5 from 7 per thousand rows in the early stage and is reduced to 1.0 in the later stage, so that the code quality is remarkably improved.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Device and method for acquiring product coded identifier information

ActiveCN101885391BIncrease brightnessImprove recognition rateCharacter and pattern recognitionPackagingComputer scienceImaging data

The invention relates to a device and a method for acquiring product coded identifier information. The device comprises a data acquisition unit, a data identification unit and a control unit, wherein the data acquisition unit is positioned above a convey belt and comprises an image device, a lighting device and a position photoelectric switch; the image device is used for photographing product coded identifier to obtain image data; the lighting device is used for irradiating the product coded identifier; the position photoelectric switch is used for sensing the position of the product on the convey belt; the data identification unit is used for identifying and processing the image data acquired by the data acquisition unit to obtain the product coded identifier information and storing theinformation and is also connected with the image device and the control unit respectively through a data line; and the control unit is used for controlling the data acquisition unit, and connected with the data identification unit, the image device, the lighting device and the position photoelectric switch respectively through data lines. The invention also provides the method for acquiring the product coded identifier information.

Owner:北京赛腾标识系统股份公司

Semiconductor Process Method

ActiveCN113327863BAccurate detectionImprove quality management levelSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsWaferEngineering

The invention provides a semiconductor process method, comprising the steps of: 1) providing a background plate, and forming a rectangle on the background plate with positioning mark points; Oval wafer picture and positioning mark points; 3) Edit the picture to mark the positions corresponding to wafer edge notches and defects; 4) Find the wafer edge, defects, edge notches, and positioning mark points on the picture ; 5) transform the positioning mark point back to a rectangle with the same size as step 1); 6) transform the defects and edge gaps back to the position on the back of the original wafer, and reconstruct the depth distortion of the picture; 7) carry out mirror flipping on the wafer; 8) The front-side defect locations and the back-side defect locations of the wafer are overlaid to identify chips having at least one of the front-side defects and the back-side defects. The invention helps to accurately reflect the defects on the back side of the wafer to the front side of the wafer so as to accurately detect all defective chips.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

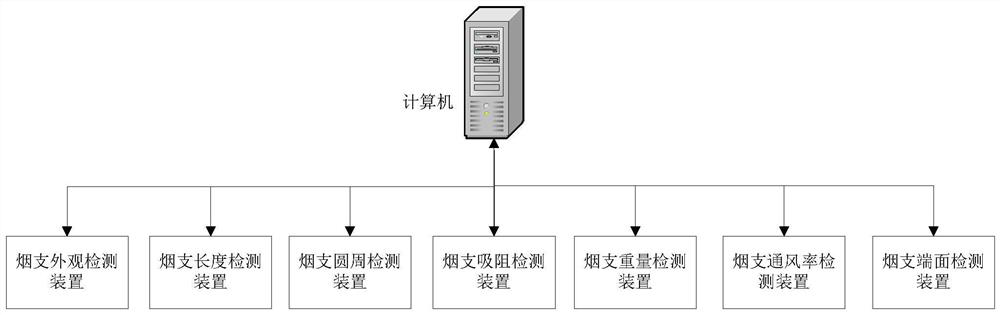

Finished cigarette comprehensive quality detection equipment

PendingCN114426127AData comprehensionImprove quality management levelCigarette manufactureUnpacking by cuttingAutomotive engineeringTobacco industry

The invention relates to finished cigarette comprehensive quality detection equipment which comprises a mounting table, and one or more of a cigarette length detection device, a cigarette circumference detection device, a cigarette suction resistance detection device, a cigarette weight detection device and a cigarette ventilation rate detection device are arranged on the mounting table. And the mounting table is connected with a cigarette packet disassembling device and / or connected with a cigarette inlet for directly placing cigarettes. The detection equipment has the beneficial effects that the comprehensive quality detection result of the finished cigarette is quantified, the data is comprehensive, the detection data is automatically stored, the computer can analyze the comprehensive quality of the cigarette, the problem of the quality defect of the cigarette is quickly found, and the quality management level is improved. By using the equipment, the stability of the cigarette quality can be ensured; the labor cost of an enterprise can be effectively reduced; the management difficulty is reduced, standardized operation is achieved, and intelligent manufacturing of the tobacco industry is achieved.

Owner:云南烟草机械有限责任公司 +1

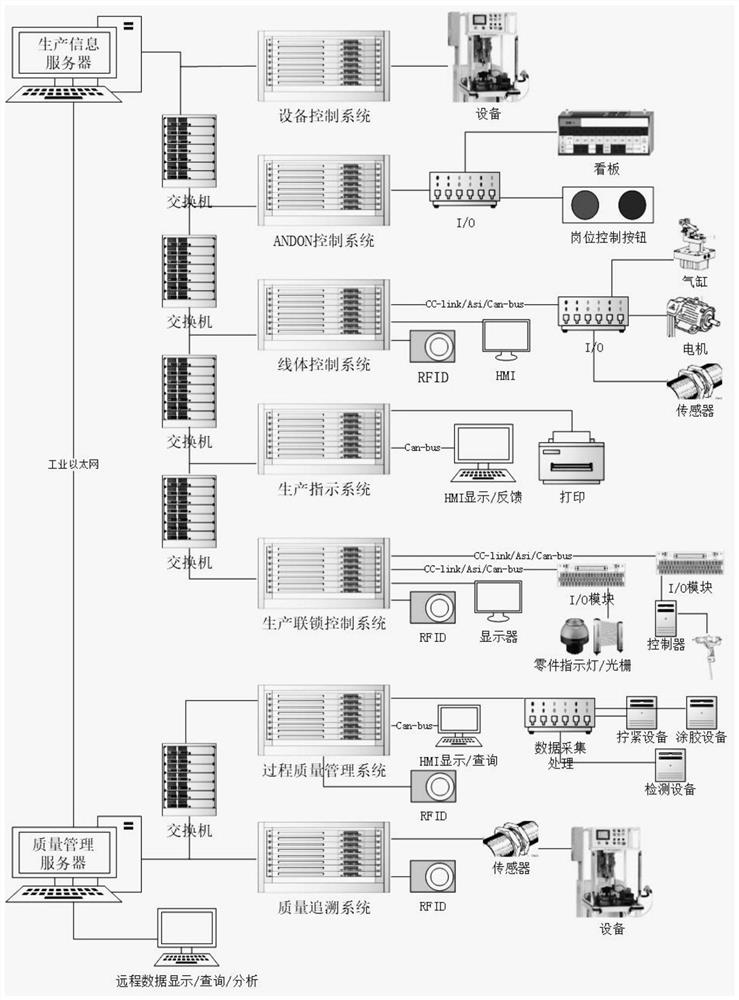

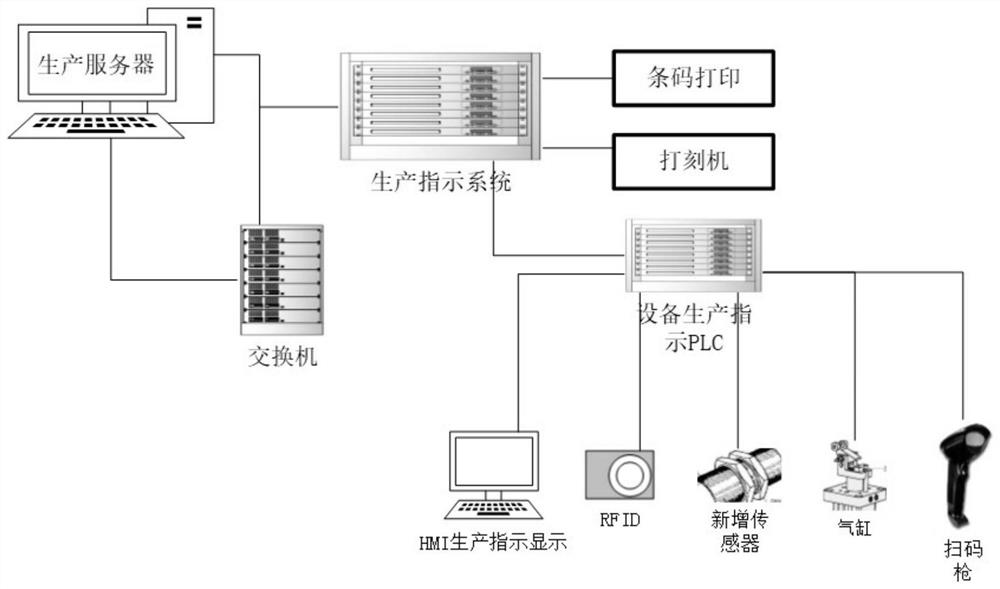

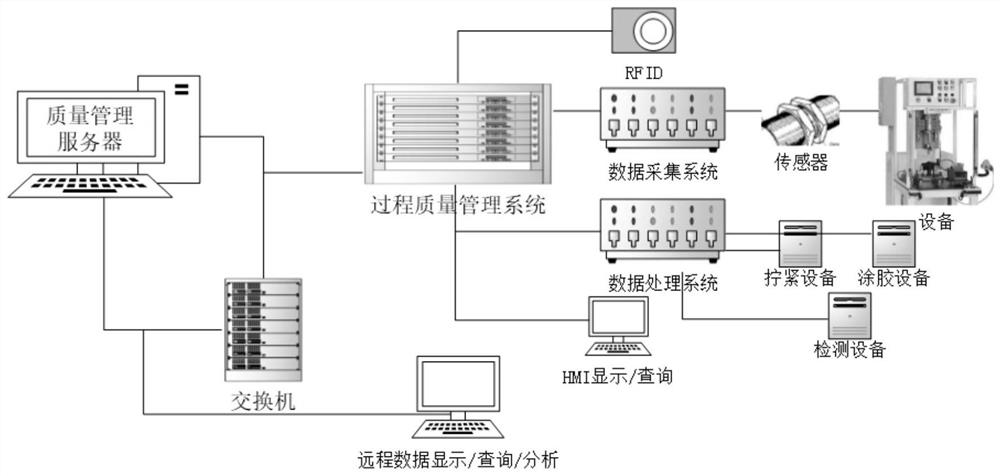

Information management method and system for engine mixed-flow assembly line

ActiveCN112130537BPrecise managementImproved error proofingResourcesTotal factory controlInformatizationAssembly line

The invention discloses an information management method and system for an engine mixed-flow assembly line, which belongs to the technical field of production line management. A production information server is constructed through a switch and connected with an equipment control system, an ANDON control system, a line body control system, a production indication system and production interlocking The contact of the control system to manage the production process, specifically including: obtaining equipment information collected in real time by the equipment control system, line stop information collected by the ANDON control system, production line body information and RFID cards collected by the line body control system information; send the engine information arranged by the production sequence issued by the upper system to the production instruction system; send the production plan to the production interlocking control system; the quality management server interacts with the process quality management system and the quality traceability system through the switch, and Feedback information to the production information server. It can strengthen the informatization level of production line operation, improve the error prevention ability of production line and reduce operation waste.

Owner:DONGFENG MOTOR CORP HUBEI

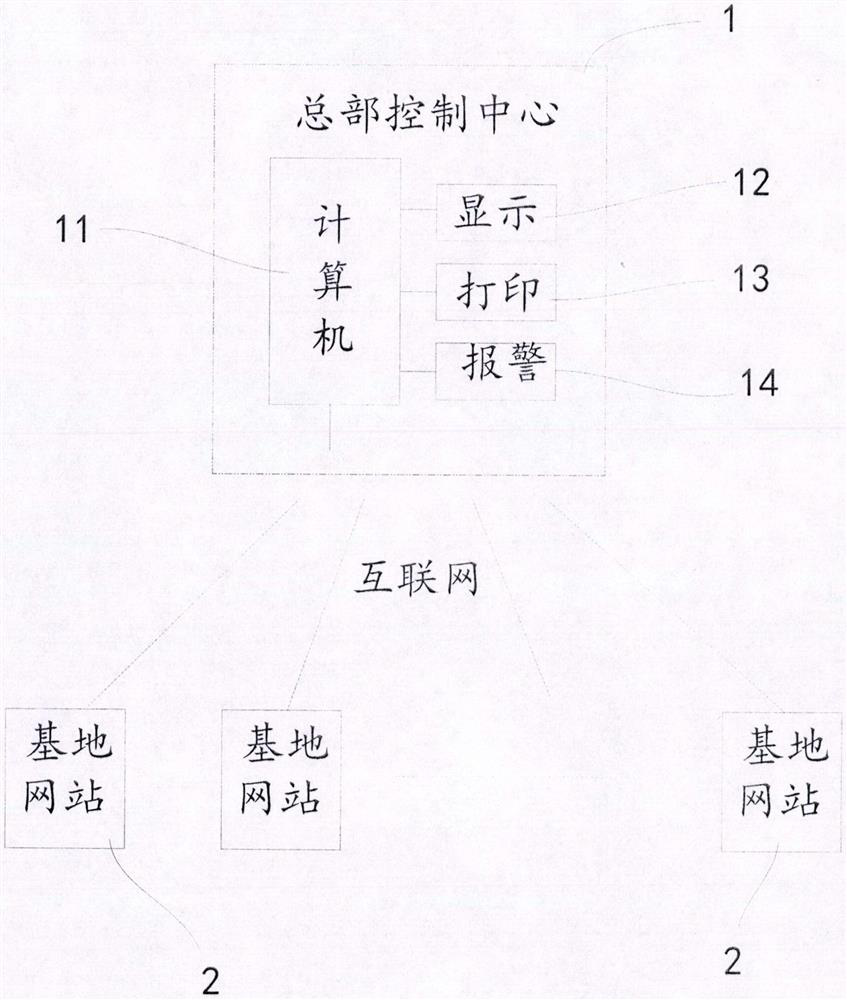

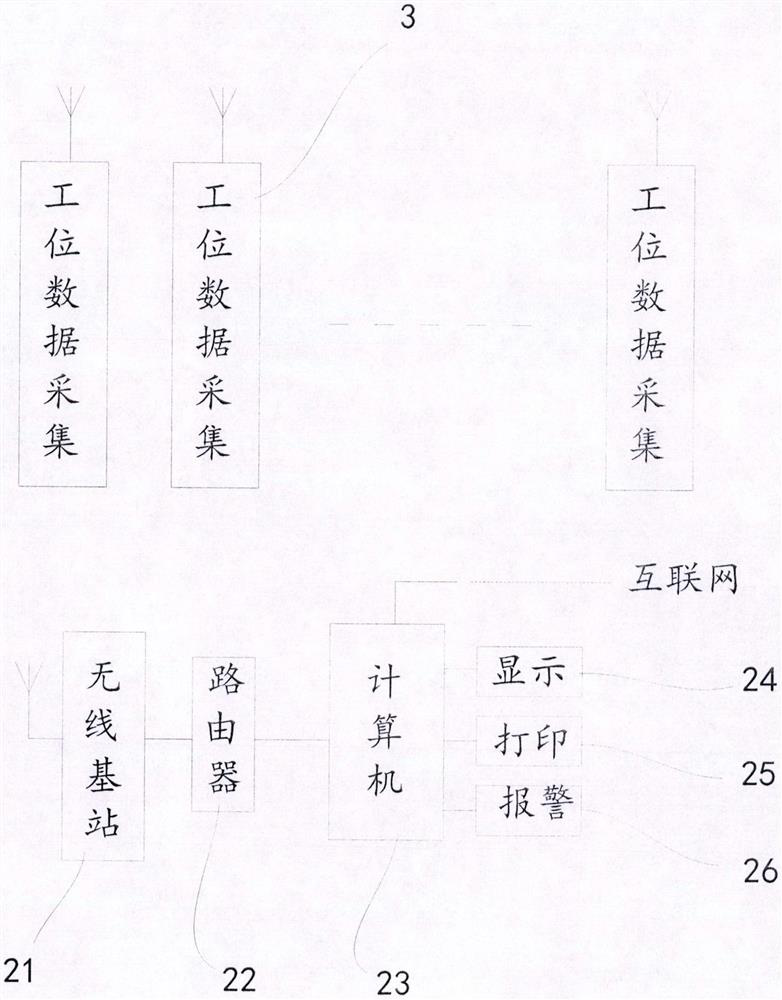

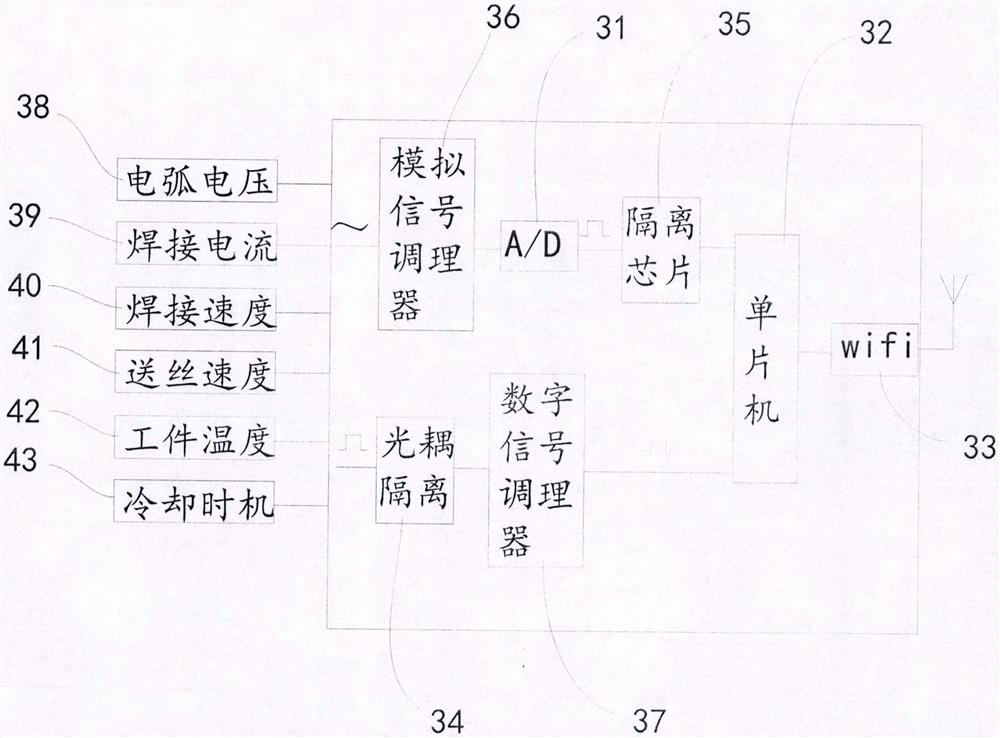

Central control system for hardfacing production

PendingCN112935604AWidely used valueImprove quality management levelWelding/cutting auxillary devicesAuxillary welding devicesEmbedded systemRouter

The invention relates to a welding production quality control system, in particular to a central control system for hardfacing production. The system comprises a headquarters monitoring center and a base website, wherein the headquarters monitoring center is provided with a headquarters computer, a display, a printer and an alarm device, wherein the display, the printer and the alarm device are connected to the headquarters computer, the base website comprises a plurality of station data acquisition devices, a wireless base station, a router, a base computer, a display, a printer and an alarm device, wherein the plurality of station data acquisition devices are connected to the wireless base station through WiFi, the wireless base station is connected to the base computer through the router, and the base computer is connected to the headquarter computer through the Internet. Surfacing parameters of surfacing production stations can be automatically collected and analyzed in real time, remote monitoring is achieved, and the quality management level of enterprises and the quality of surfacing products are greatly improved.

Owner:刘振英

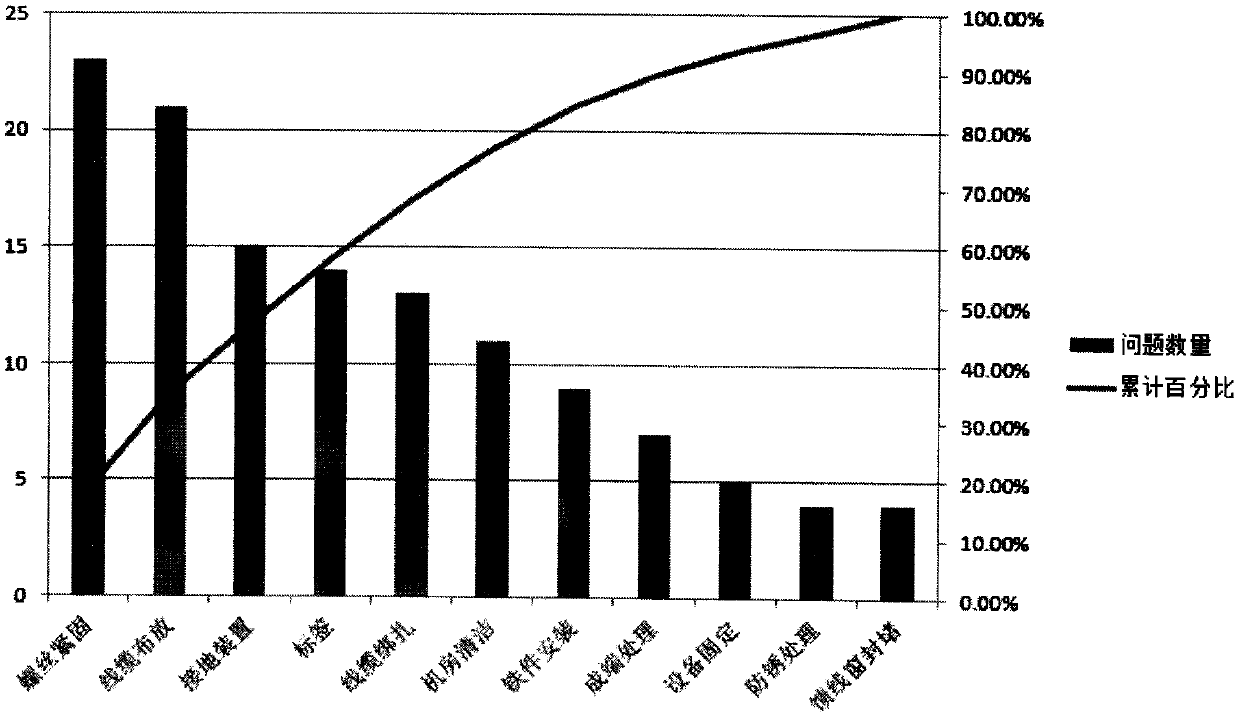

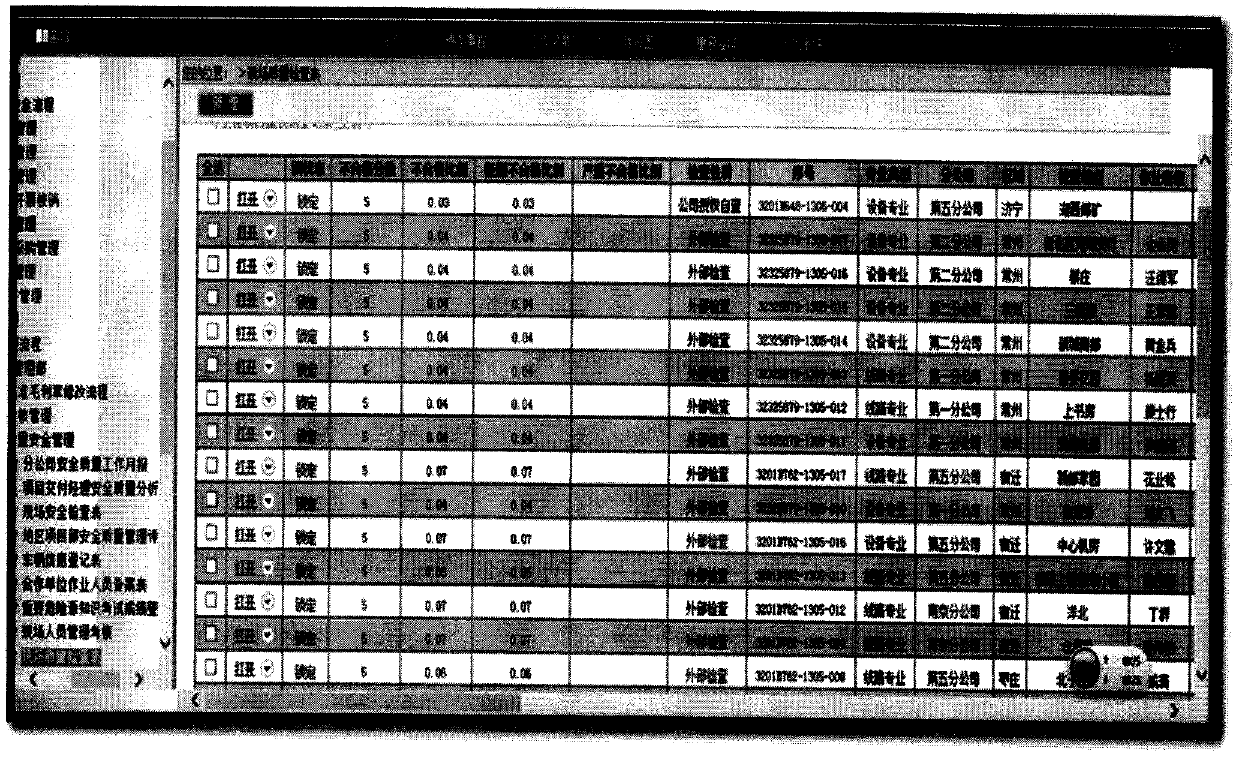

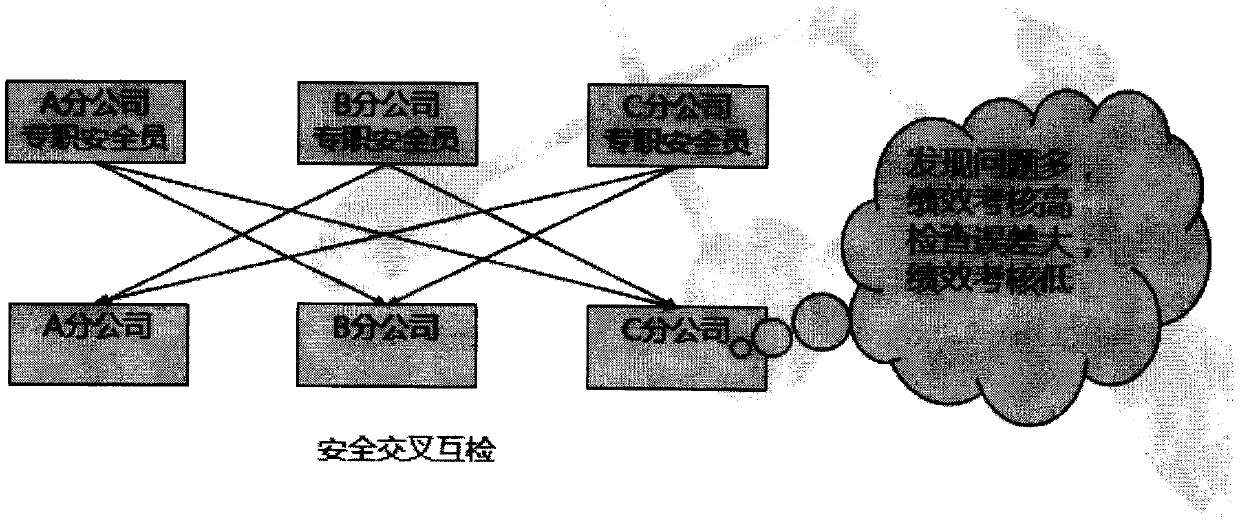

Quality management method applied to communication engineering

PendingCN110322152AImprove work efficiencyStrengthen and improve the quality mutual inspection mechanismResourcesInformatizationManagement tool

The invention discloses a quality management method applied to communication engineering. The method comprises the following steps that step 1) enabling a management layer to highly pay attention to quality management work; step 2) establishing a perfect quality supervision and management network; step 3) decomposing and implementing quality management responsibilities; step 4) strengthening and perfecting a quality mutual inspection mechanism. step 5) organizing and developing quality monthly activities; 6) promoting quality management informatization. According to the invention, a quality management system is established, key points of communication engineering quality control are defined, a quality management tool is scientifically used, and the working efficiency of quality managementis greatly improved. Quality management responsibilities are decomposed and implemented, and a quality mutual inspection mechanism is well enhanced and perfected. Effective practice and innovation arecarried out on communication engineering quality management, the quality management level is continuously improved from the aspects of construction of a quality management system, perfection of the quality management system and innovation of quality management means, and the goals of focusing on customers and improving customer satisfaction are well achieved.

Owner:中邮建技术有限公司

Machine set for spraying number on hot steel billet in real time based on PLC control system

InactiveCN100364671CIncrease the level of automationImprove quality management levelLiquid surface applicatorsLiquid spraying apparatusSprayerControl system

The invention discloses a real-time hot steel blank spray machine set based on PLC, which comprises a spray main machine and an electric controller. Wherein, the spray main machine has a slide frame, on which the traverse vehicle, the displacement sensor, the transverse displace cylinder, and the transverse displace controller are arranged; the transverse vehicle has a longitudinal vehicle, and a big inlet cylinder; the longitudinal vehicle has a sprayer element, and a small inlet cylinder; the spray main machine has a coating material feeding system; the electric controller uses the PLC control system which is connected to the industry control computer, the on-place detector, the electromagnetic valve condition detecting module, the transverse displacement controller, the feeding belt control switch, and the electromagnetic valve. The invention via improving the mechanical structure of sprayer, and using PCL control system, realizes the full-automatic, accuracy and online real-time multiple digit continuous mark in high temperature, to confirm the sharpness of mark, and apply the long time operation of spray machine set in bad condition. The invention can improve the automatic level and the quality management level of steel blank.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com