Patents

Literature

35results about How to "Improved error proofing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

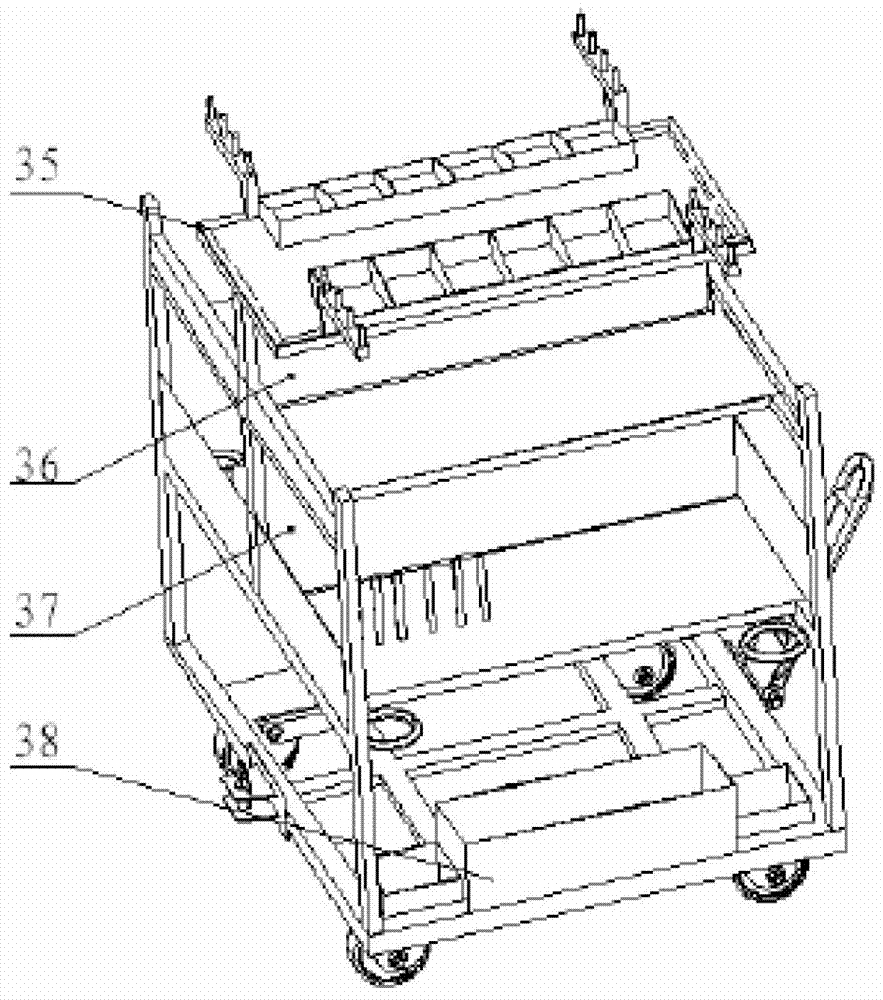

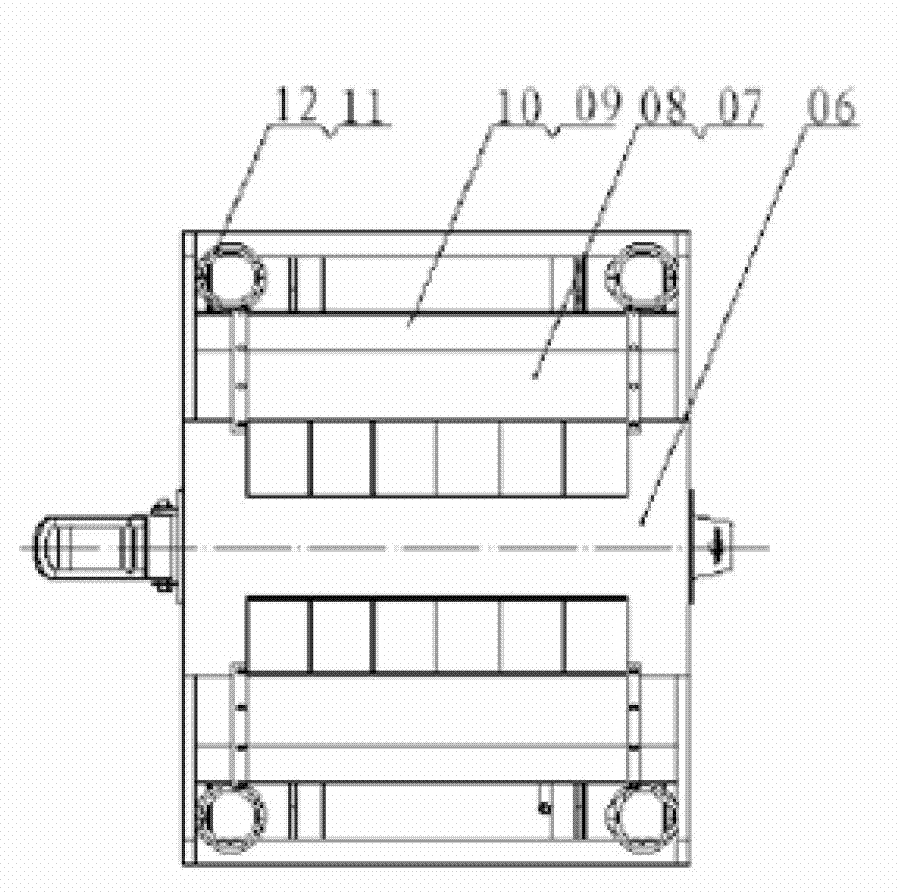

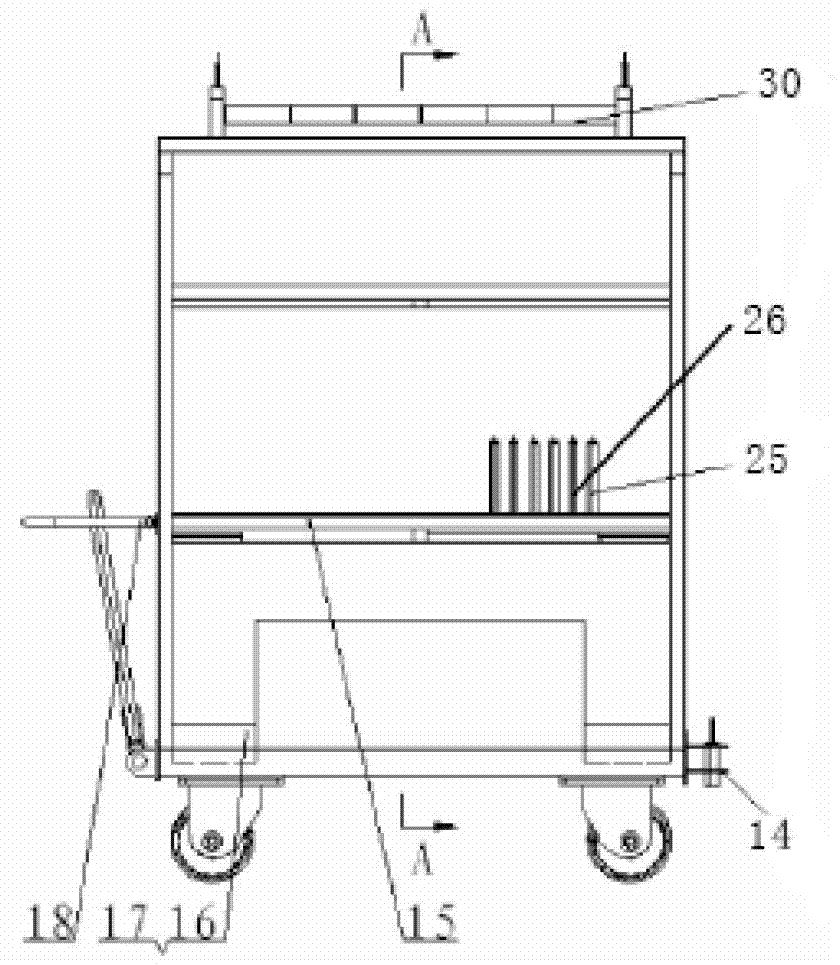

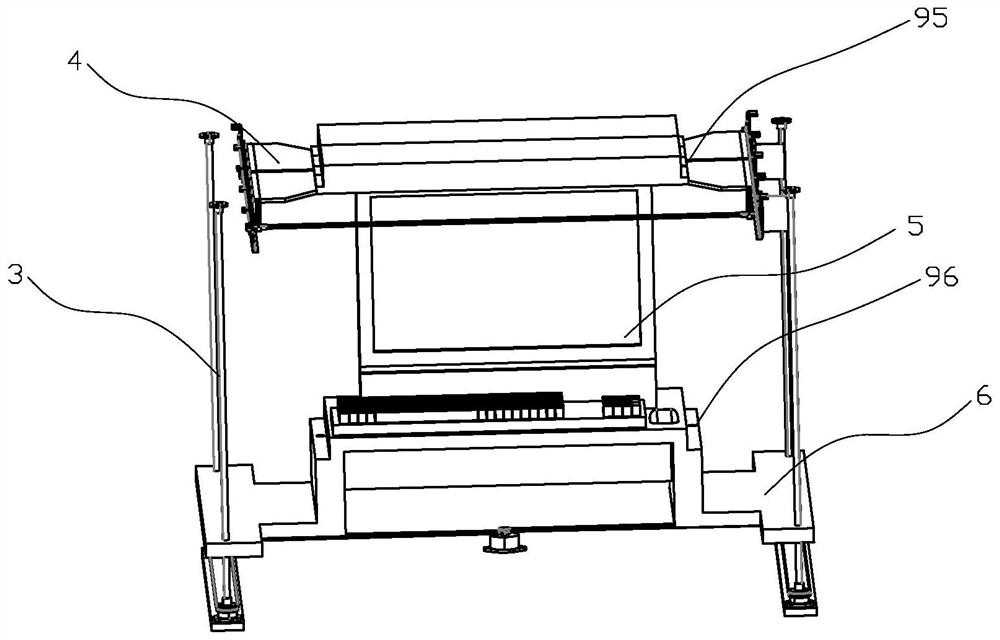

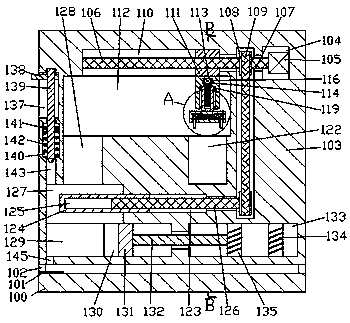

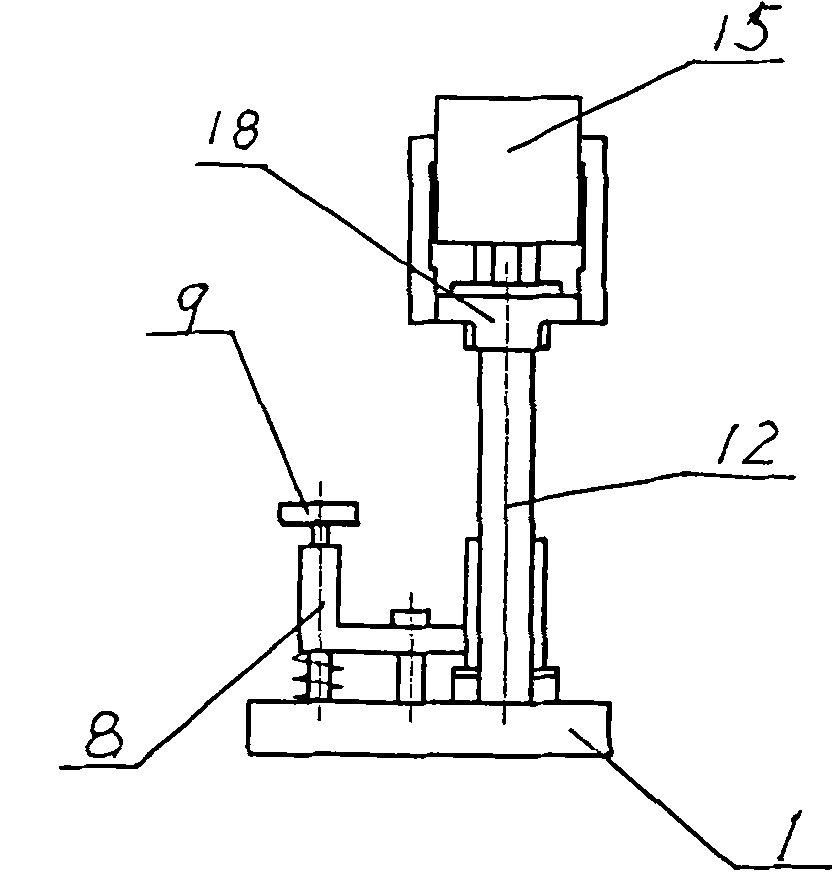

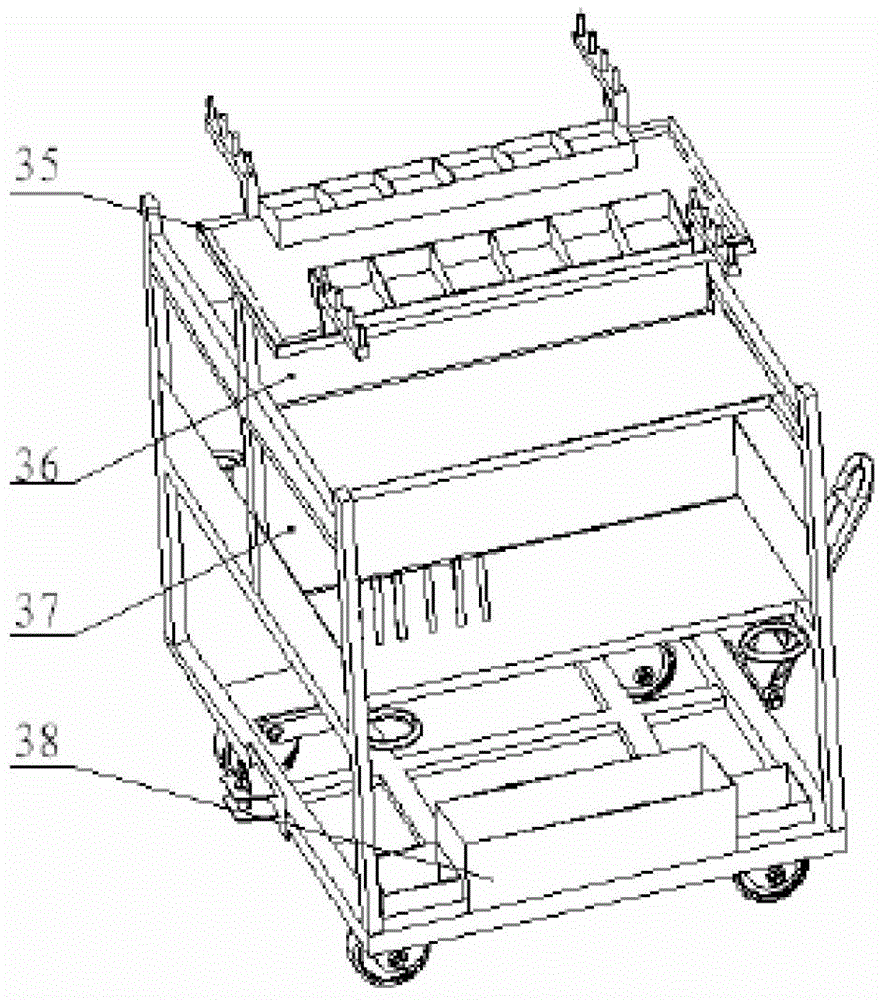

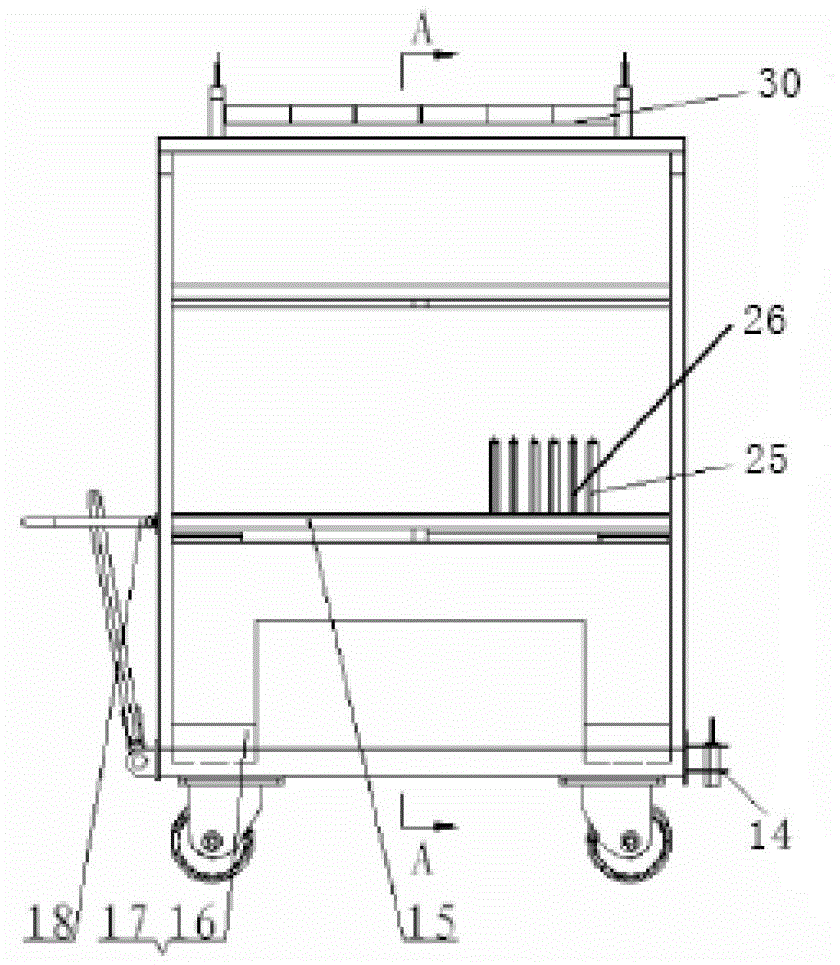

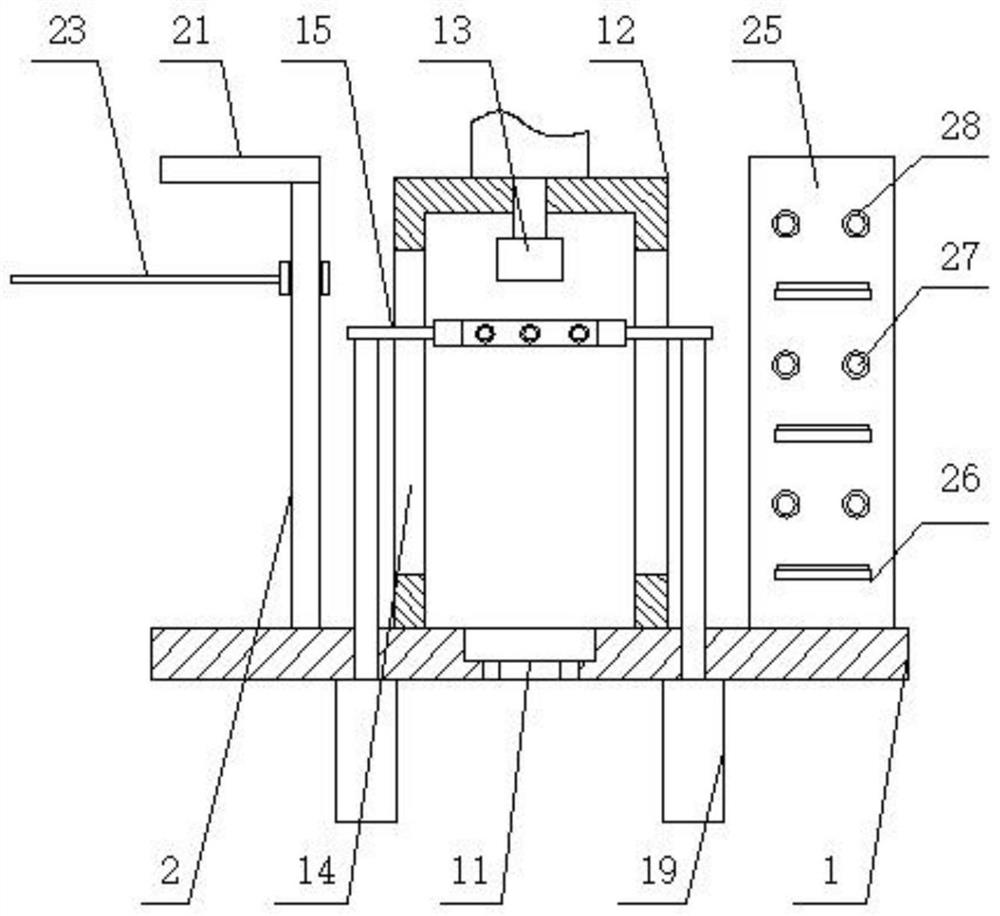

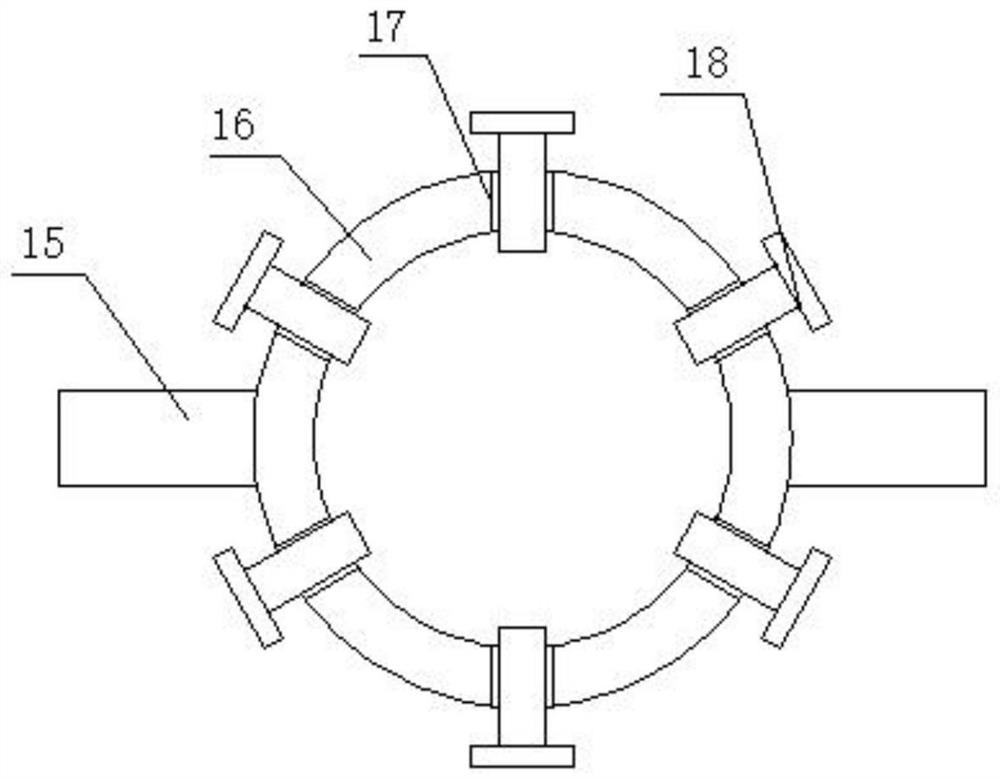

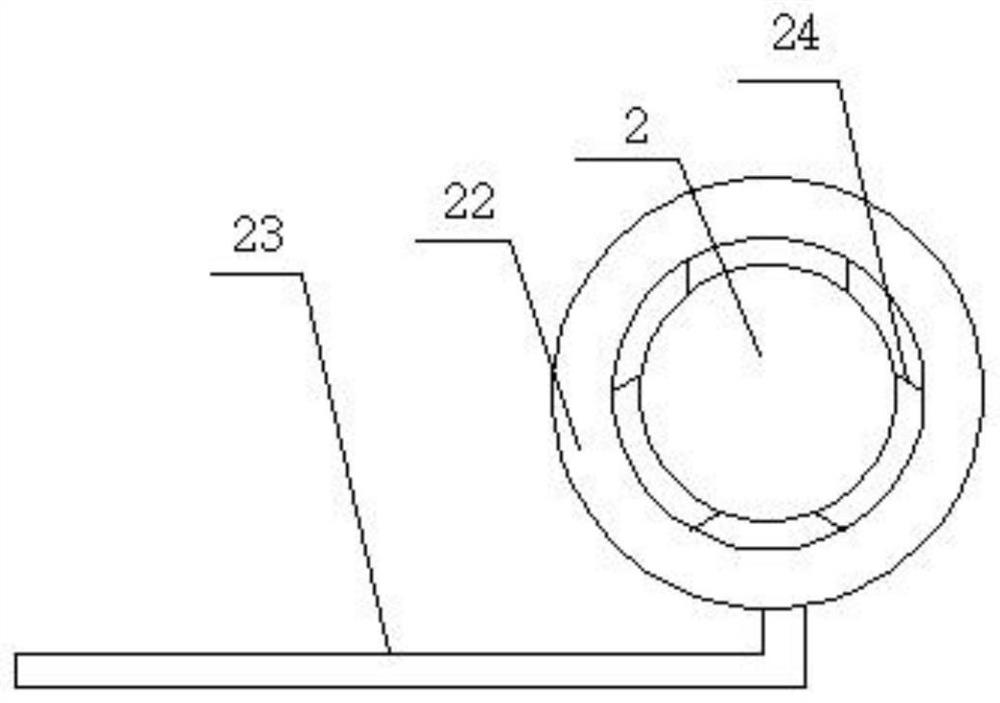

Material transfer unit for automobile production lines

ActiveCN103112483AImproved error proofingImprove protectionHand carts with multiple axesProduction lineVertical tube

The invention relates to a material transfer unit for automobile production lines. The material transfer unit comprises a multilayer frame structure formed by at least four vertical tubes fixed together and adjustable universal wheels fixed on a bottom frame. One end of each vertical tube is fixedly connected to the bottom frame. A shelf is disposed between each two adjacent layers of the multilayer frame. The multilayer frame structure is provided with corresponding layered structures according to different weights, sizes and shapes of automobile parts to be transferred. A pull bar and a draw bar are disposed at front and rear ends of the transfer unit respectively. The material transfer unit for automobile production line is applicable to classified storage of various automobile parts, better prevents mistaken placement of materials and better protects the materials. Effective connection between the front pull bar and the rear draw bar enables the material transfer unit to more adapt to material supply and transfer for batch production lines.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

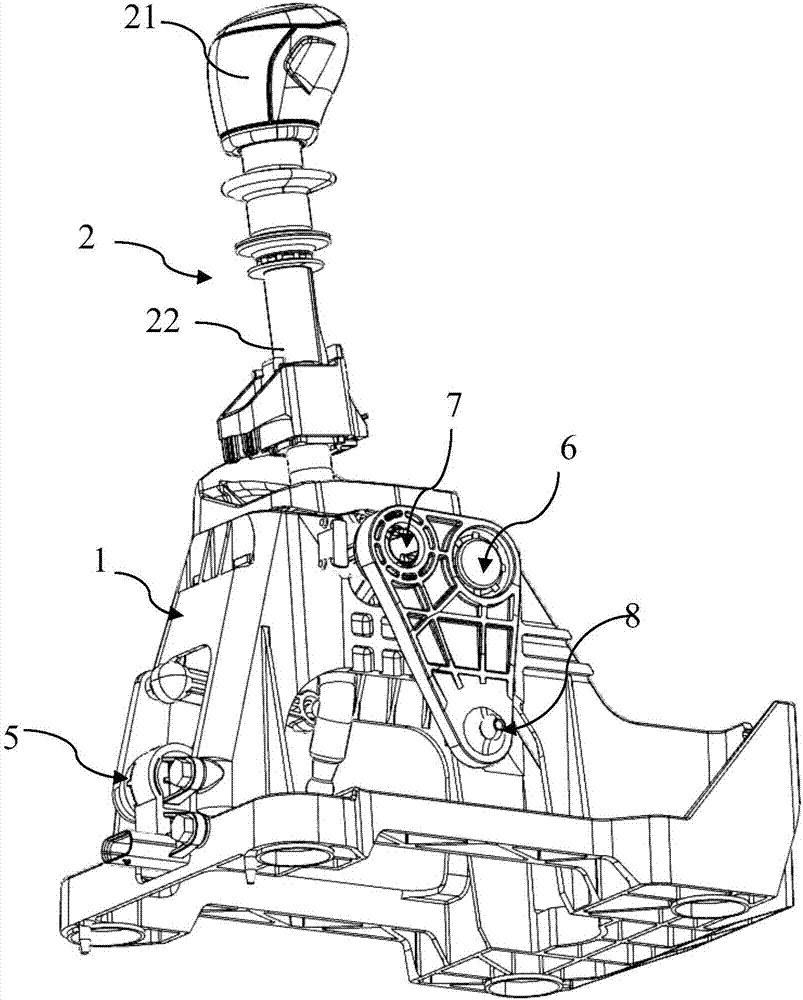

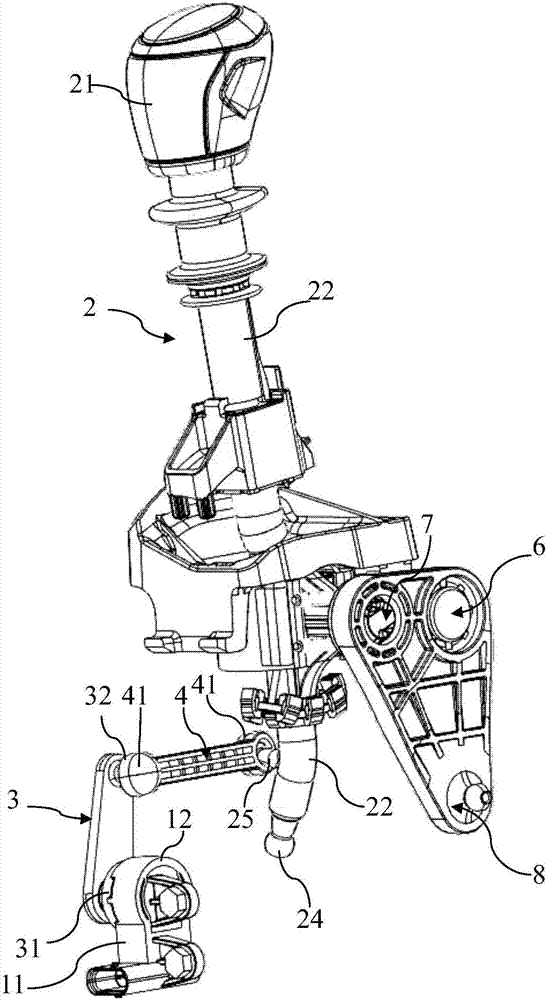

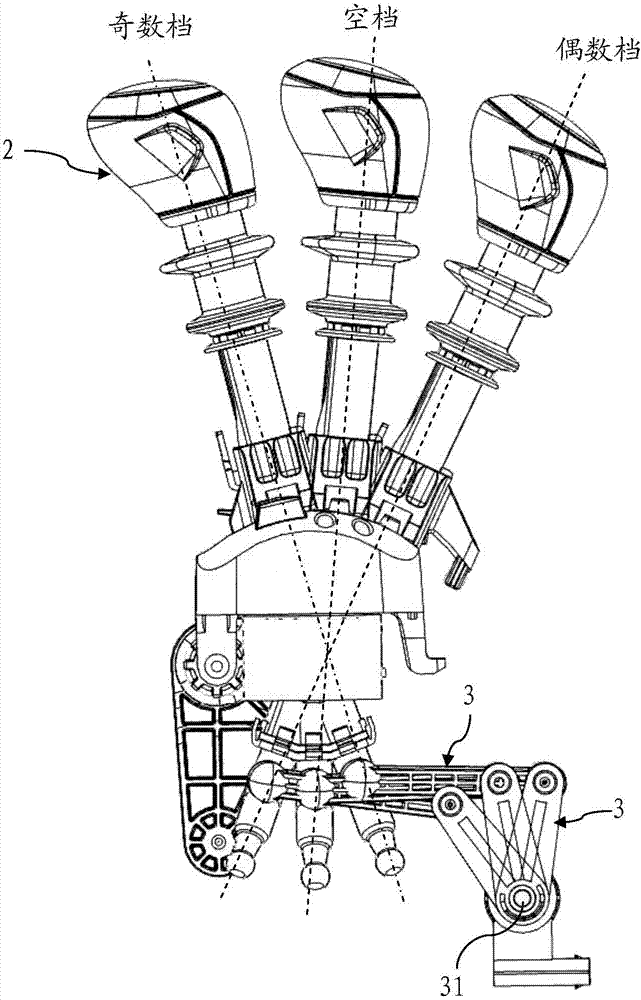

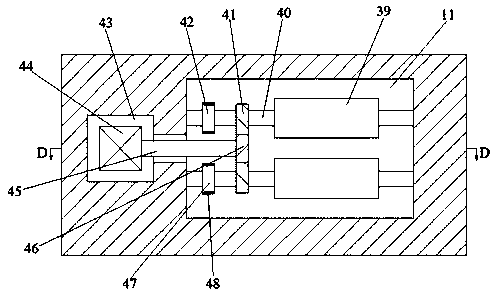

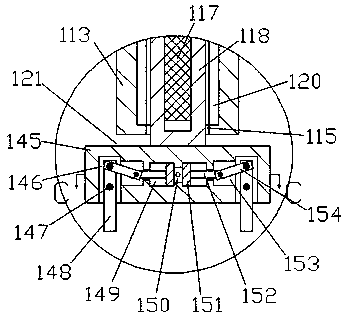

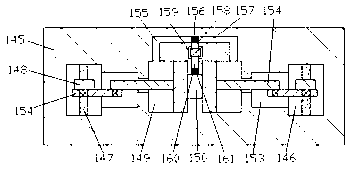

Manual gear shifter, manual gear shifter component and control method thereof

InactiveCN107023667APromote intelligent developmentReduce the difficulty of operationGearing controlRocker armAutomation

The invention discloses a manual shifter, which comprises a casing and a shift lever; the shift lever includes a shift lever handle, a shift lever main body and a shift lever ball head; Rotate to shift gears, the shift lever can swing along the left and right direction of the housing to select gears; the housing is also provided with a rocker arm that can rotate with the rotation of the gear shift lever; the housing is also equipped with a useful An angle sensor for monitoring the rotation angle of the rocker arm. The invention also discloses a manual shifter assembly and a control method thereof. The manual shifter, the manual shifter assembly and the control method thereof disclosed by the present invention can not only realize the shifting function, but also can recognize the driver's shifting intention and convert it into an electrical signal output, so that the working stability is higher, and the shifting The intention response output is more direct, providing a more efficient and reliable signal source for the clutch automation system, and taking into account the reliability and versatility of parts.

Owner:SAIC GENERAL MOTORS +1

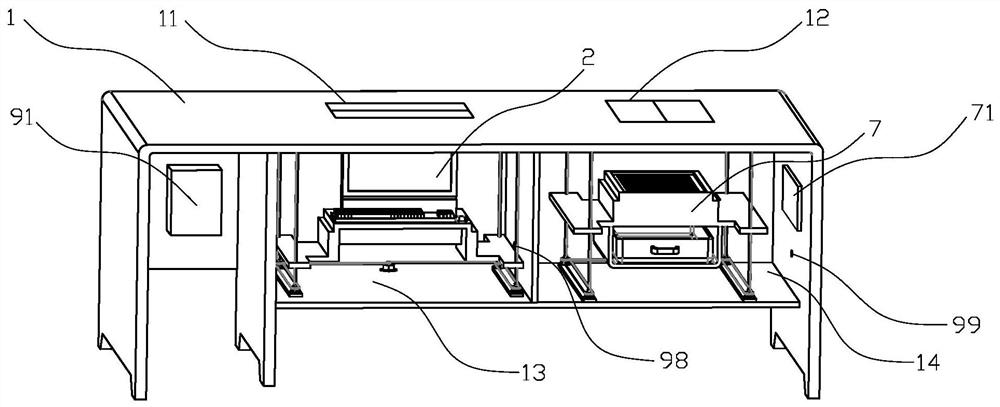

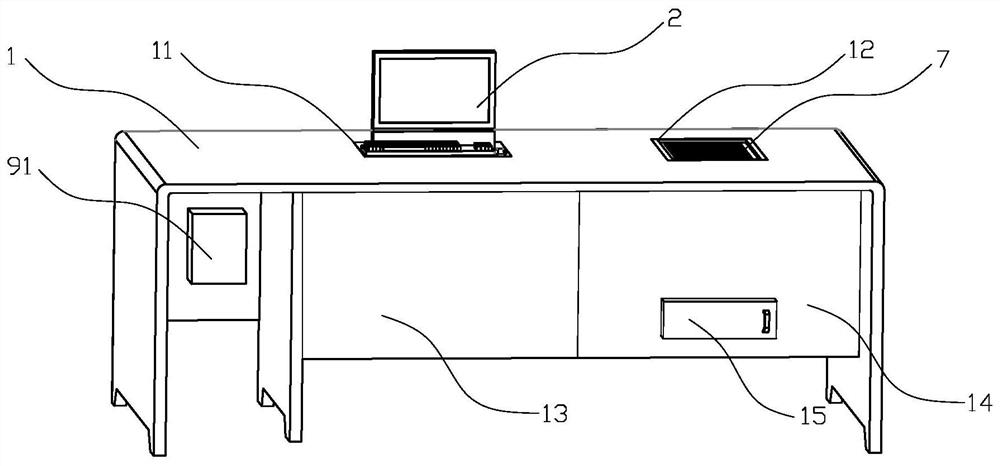

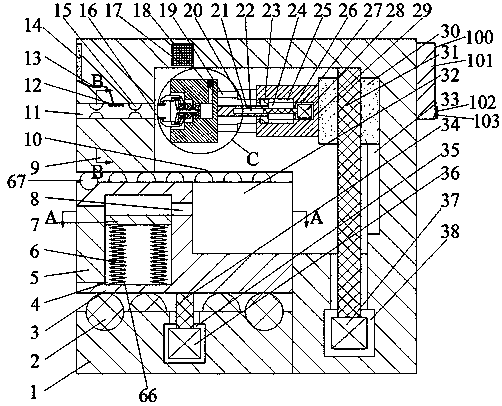

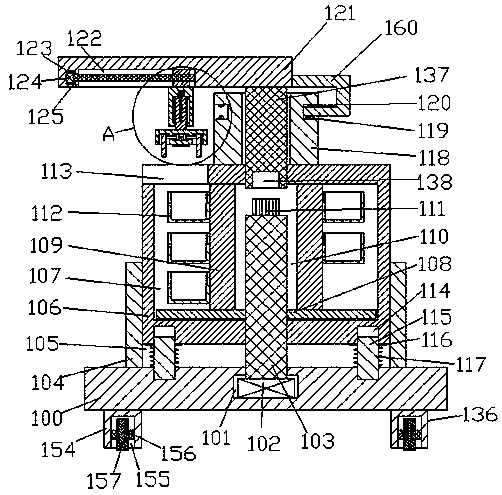

Intelligent office and leisure integrated table

ActiveCN113455820AHigh degree of automationReduce use costOffice tablesFurniture partsGratingControl engineering

The invention relates to an intelligent office and leisure integrated table, and belongs to the technical field of office supplies. The integrated table comprises an office table body, an office suite arranged in the middle of the office table body, a tea drinking suite arranged on the side part of the office table body and an intelligent control system. The office suite comprises a lifting mechanism, an opening and closing mechanism arranged above the lifting mechanism, a computer lifting table in driving connection with the lifting mechanism and a computer suite arranged on the computer lifting table; the tea drinking suite comprises a lifting mechanism, an opening and closing mechanism arranged above the lifting mechanism, and a lifting tea set in driving connection with the lifting mechanism; and an intelligent controller intelligently detects the operation condition through a pressure sensor, an optical grating and the like and controls operation of the whole intelligent office and leisure integrated table. The intelligent control system detects the operation condition through the sensor, the grating and the like, then the operation of the whole intelligent office and leisure integrated table is controlled, the intelligent degree is high, and the use convenience degree is improved.

Owner:广东国景家具集团有限公司

Modern logistics inquiry system application device

The invention discloses a modern logistics inquiry system application device. The device comprises a fixed machine body, wherein a firs conveying space is formed in the fixed machine body; a conveyingwindow which is forwards opened communicates with the front end wall of the conveying space, and rollers which are symmetric in the front and back direction are arranged at the inner lower side of the conveying space; the rollers are rotatably connected to conveyor belts; a sensing device is fixedly arranged at the upper side of the inner left end wall of the conveying space; a driving space is arranged in the right end wall of the conveying space; and a storing chamber is formed in the rear end wall of the driving space. According to the device, the stability of the device in the working process is ensured by gear transmission and hydraulic transmission, and the movement states can be switched by belt transmission, so that the coordination performance of the device is improved; a splinefor supporting and the electromagnetic theory realize the flexibility of the device; a sorting device and a conveying device are driven through different power sources, so that mutual interference isavoided, and the error preventing performance of the device is improved.

Owner:台州瑟知科技有限公司

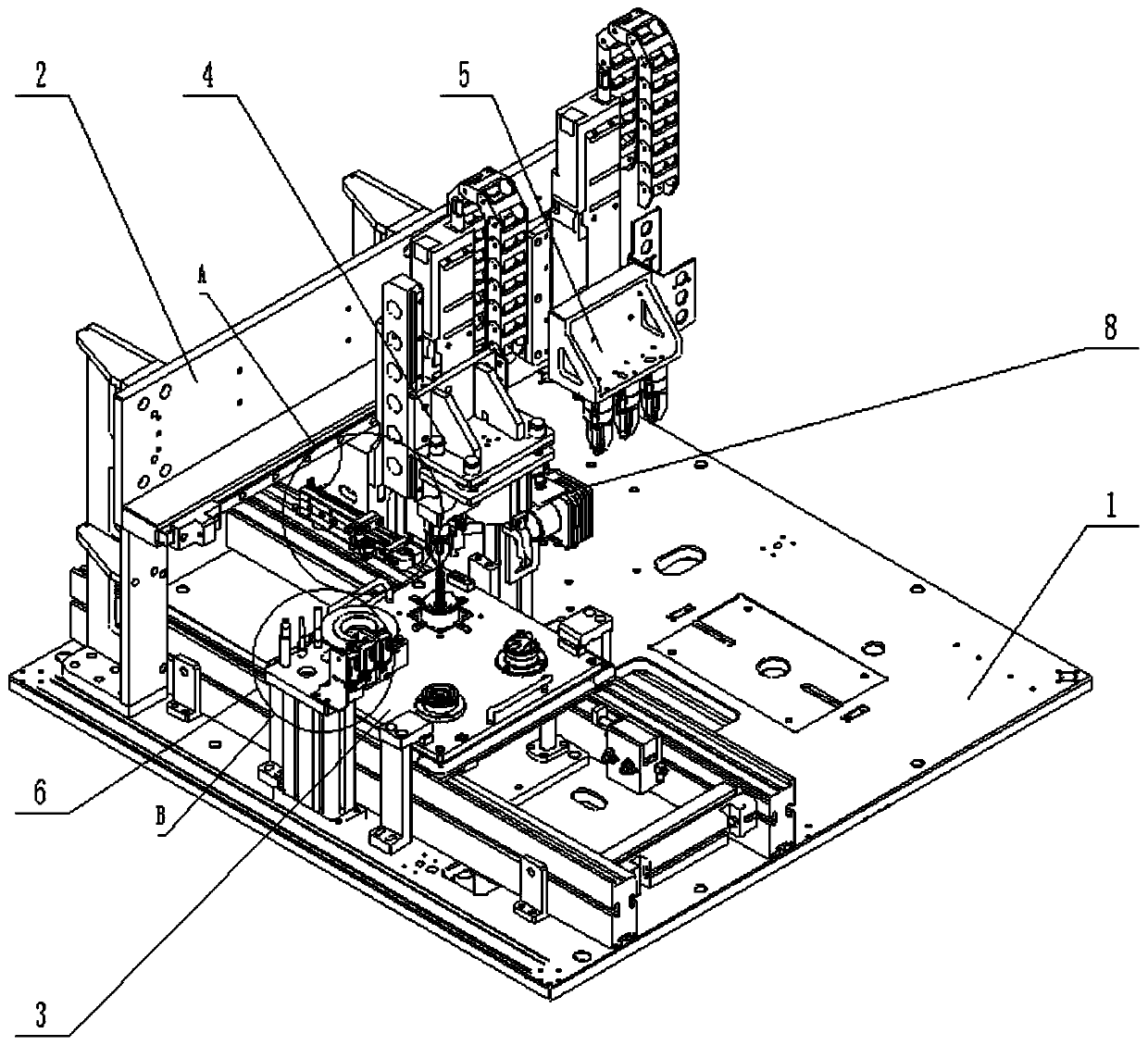

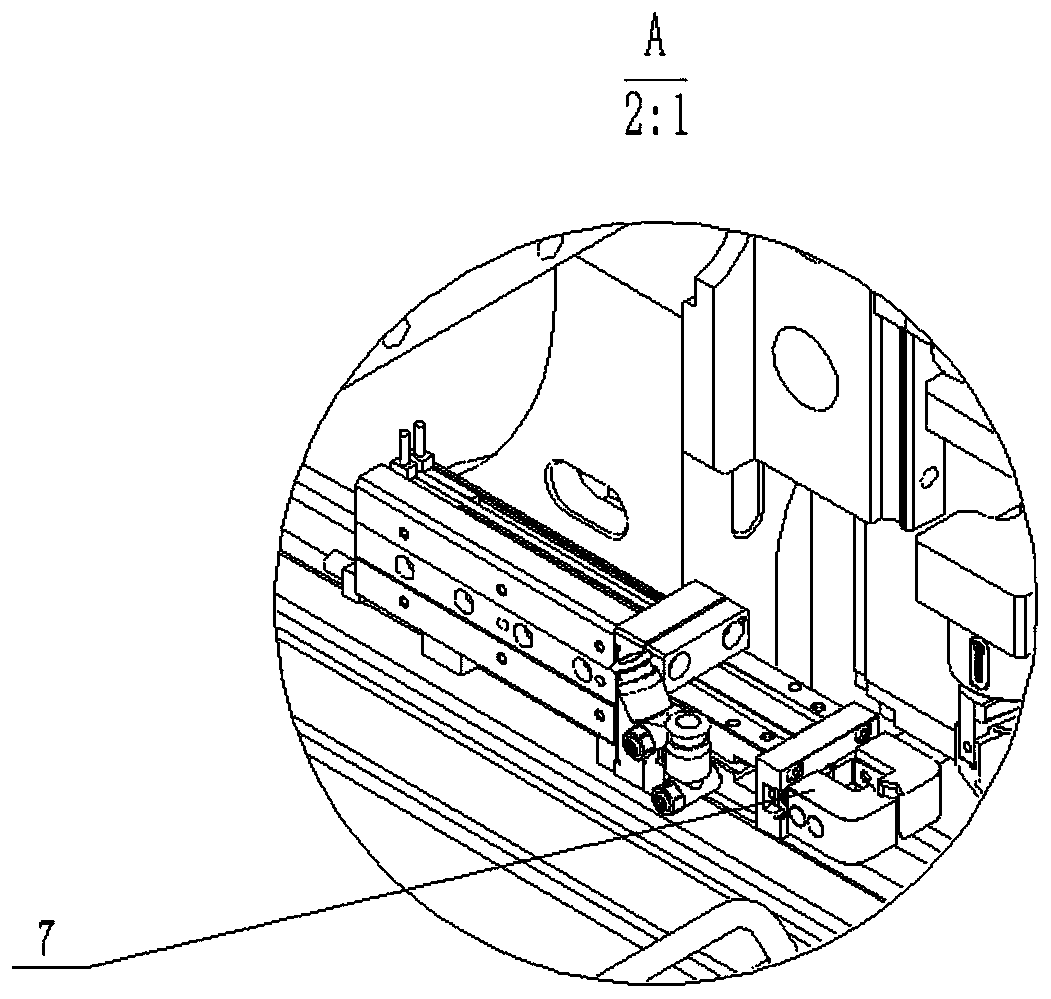

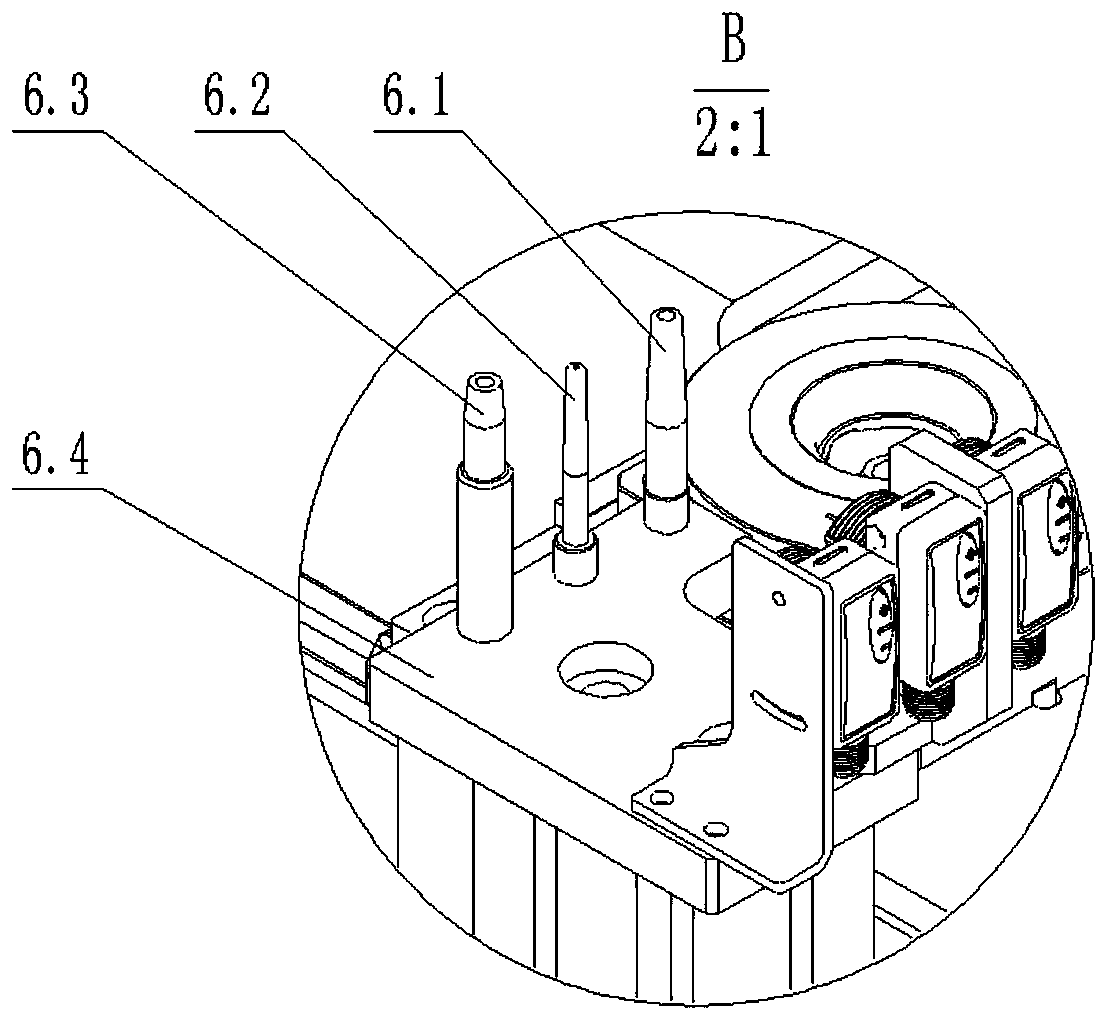

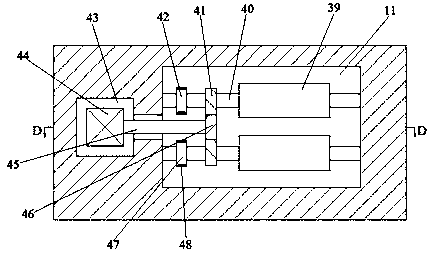

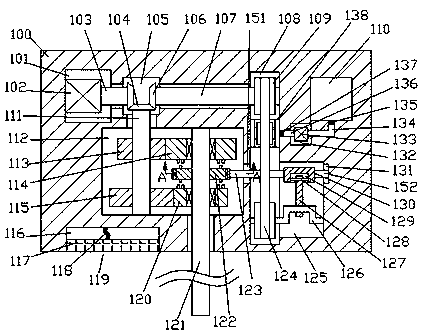

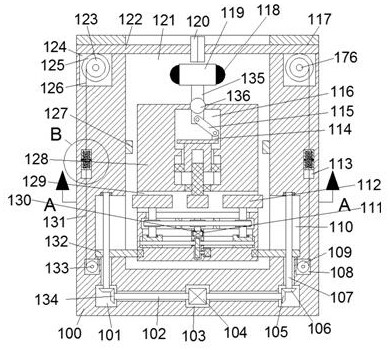

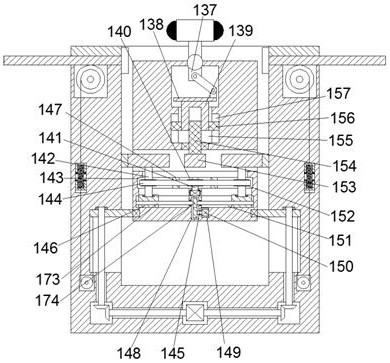

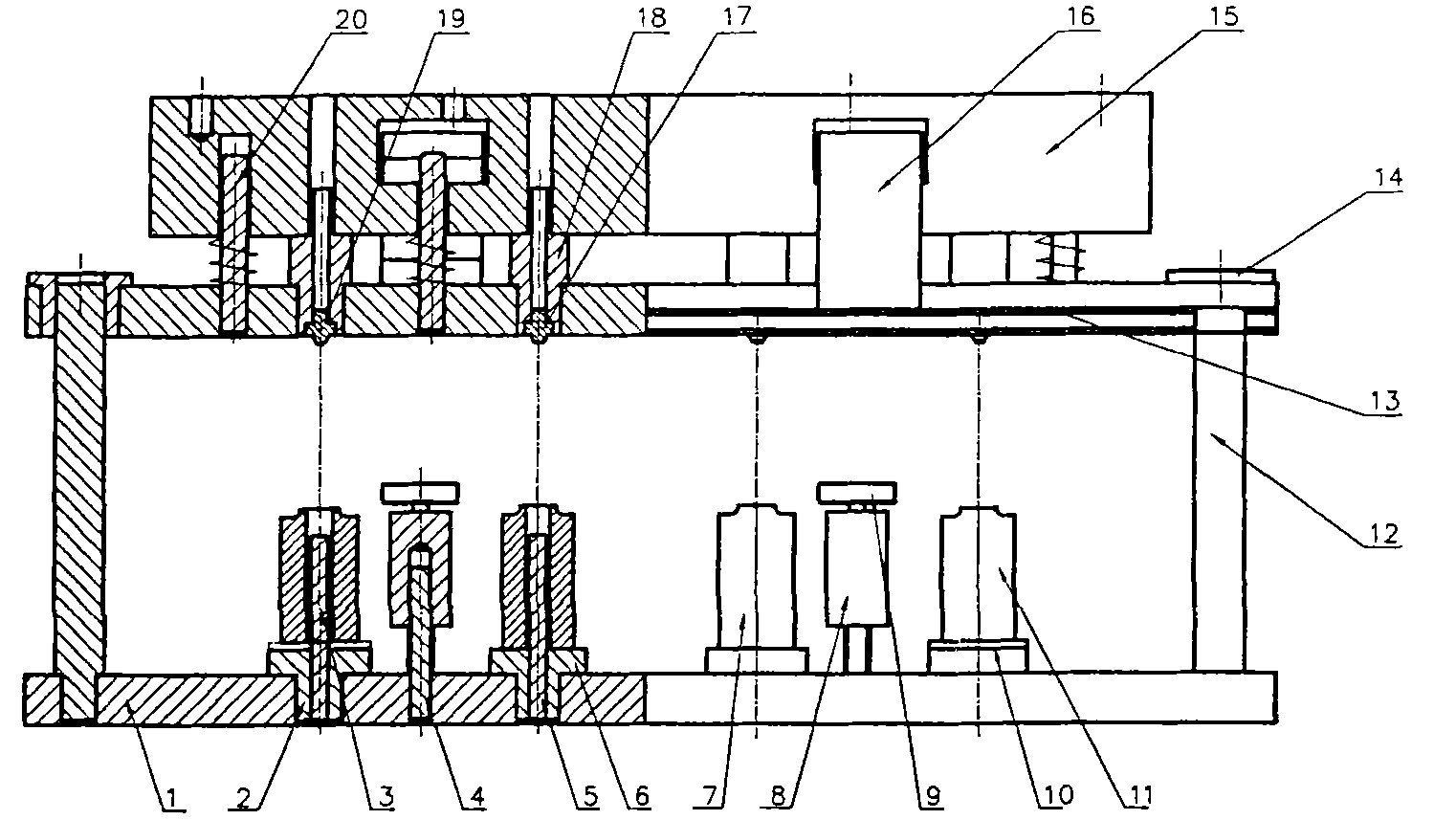

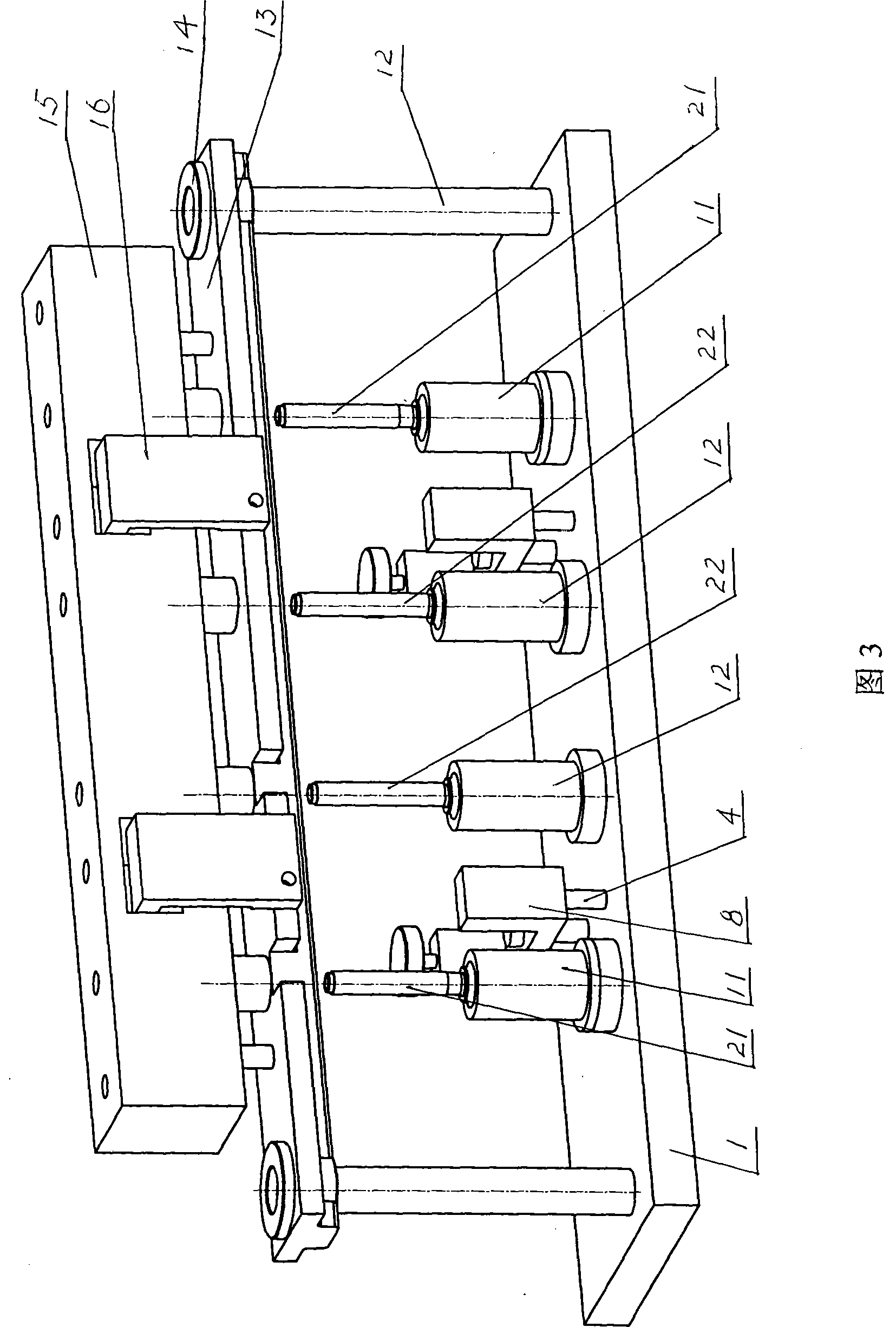

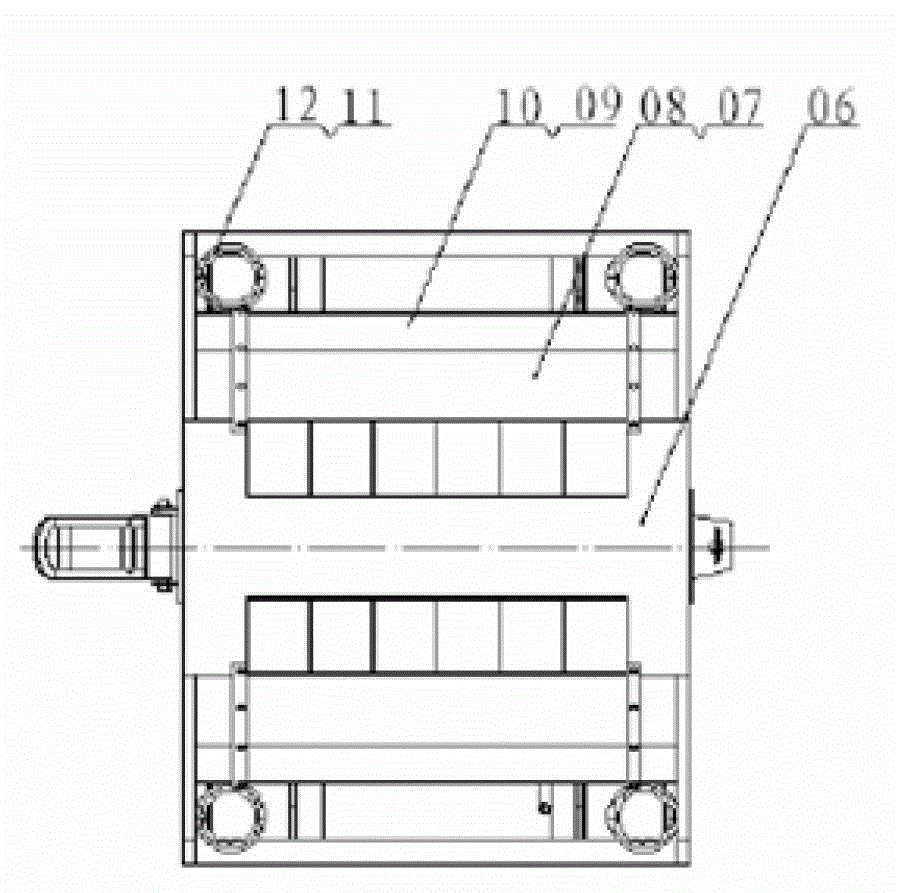

Automatic turbine assembly and intermediate assembling system

PendingCN110303338AImproved error proofingAssembly machinesMetal working apparatusEngineeringTurbine

The invention discloses an automatic turbine assembly and intermediate assembling system comprising an equipment base and an equipment side plate which are fixedly connected. The equipment base is provided with a tray and a guide component. The equipment side plate is provided with a first grabbing device and a second grabbing device. The equipment side plate is movably connected with the first grabbing device and the second grabbing device. Due to arrangement of the two grabbing devices, on the basis of achieving automatic assembling, the waiting time is shortened in the assembling process, the assembling efficiency is improved, and optimization of assembling takt is achieved; the guide component improves assembling precision and reduces errors in the assembling process, parts are protected in the assembling process, and the scratch risk of the parts in the assembling process is lowered. The automatic turbine assembly and intermediate assembling system is further provided with a pressure and displacement monitoring device. The pressure and displacement monitoring device conducts real-time monitoring in the intermediate assembling process, and it is ensured that the assembling process is free of abnormality.

Owner:BORGWARNER AUTOMOTIVE COMPONENTS (NINGBO) CO LTD

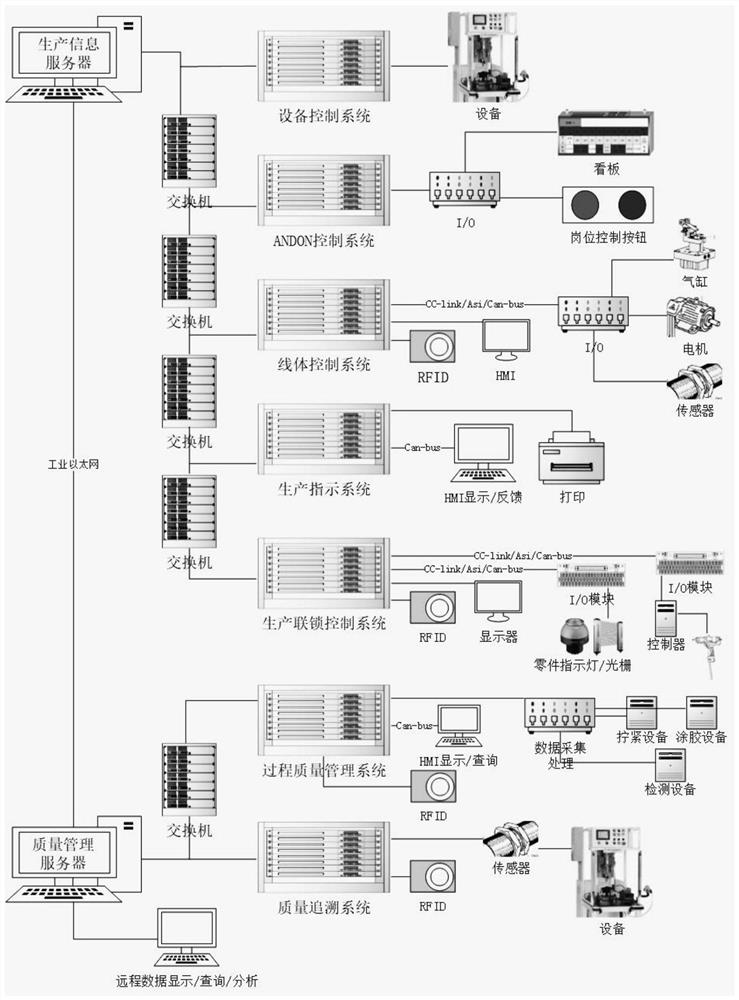

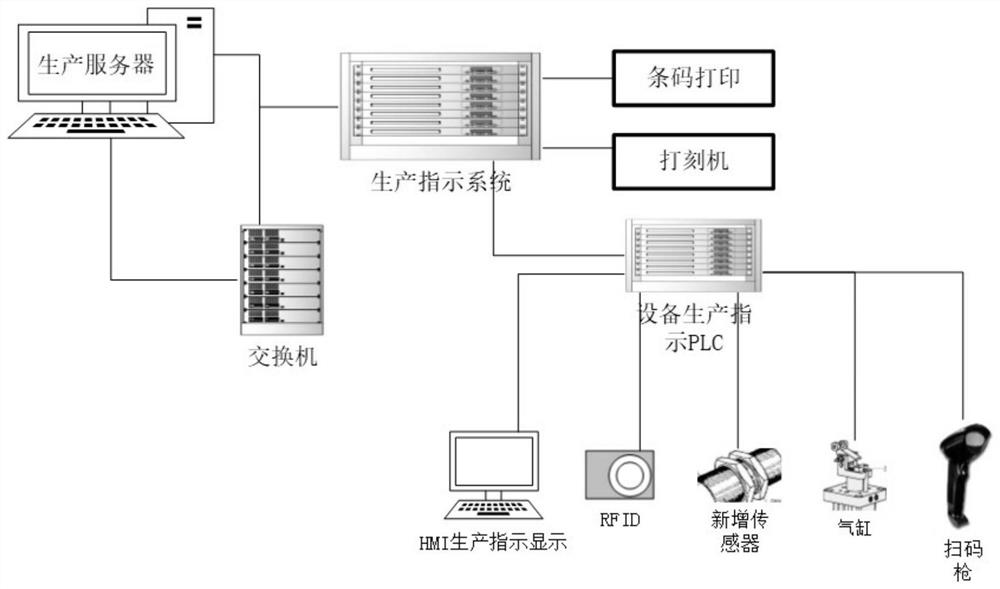

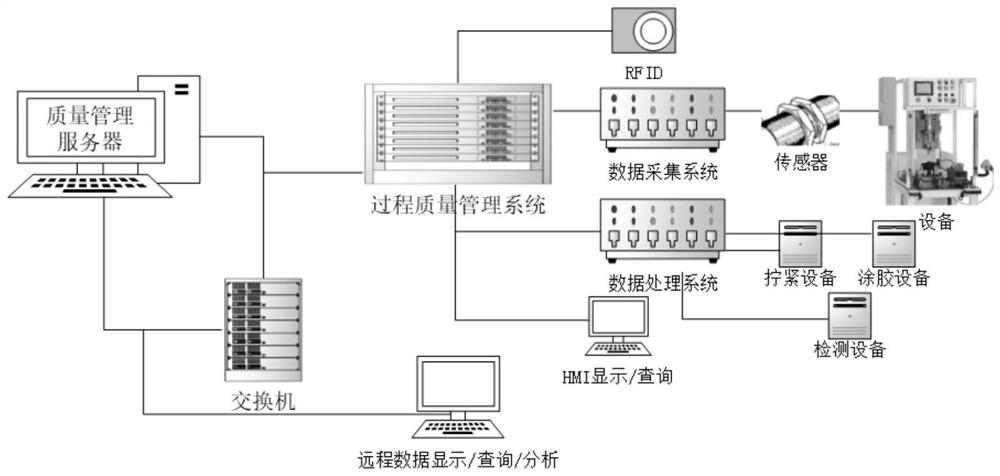

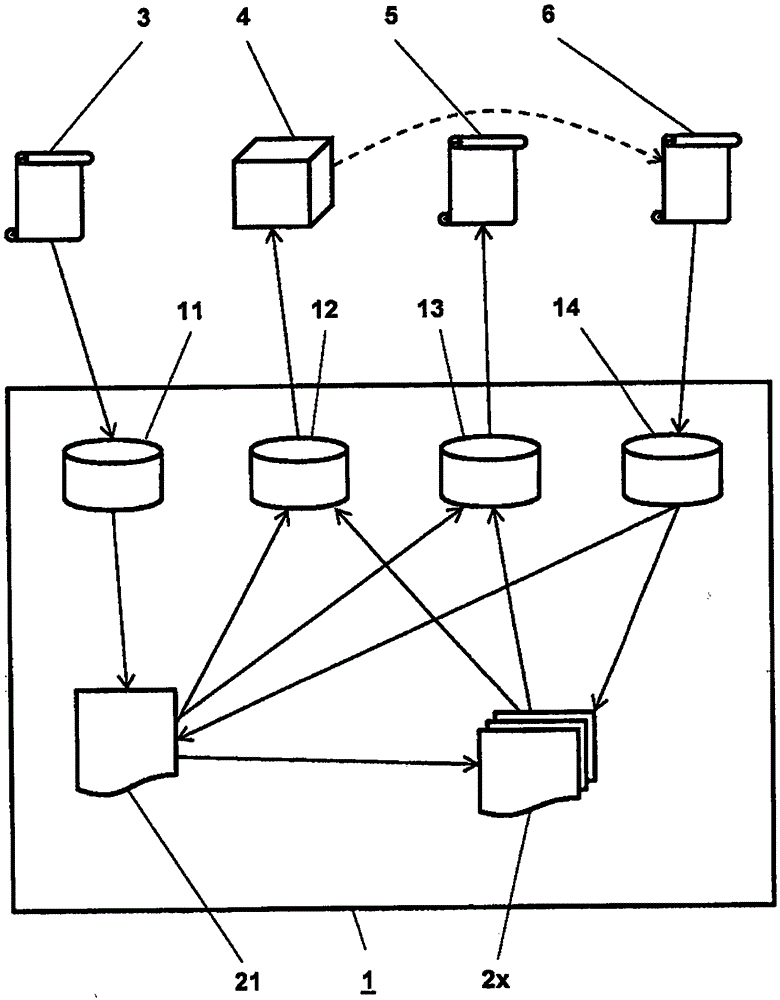

Information management method and system for engine mixed flow assembly line

ActiveCN112130537APrecise managementImprove error proofing abilityResourcesTotal factory controlControl systemServer

The invention discloses an information management method and system for an engine mixed flow assembly line, and belongs to the technical field of production line management. A production information server establishes connection with an equipment control system, an ANDON control system, a line body control system, a production indication system and a production interlocking control system througha switch so as to manage the production process. The method specifically comprises the steps that equipment information collected by the equipment control system in real time, line stopping information collected by the ANDON control system and production line body information and RFID card information collected by the line body control system are acquired; engine information which is issued by anupper-layer system and arranged according to the production sequence is sent to the production indication system; a production plan is issued to the production interlocking control system; and a quality management server interacts with a process quality management system and a quality tracing system through the switch and feeds back information to the production information server. The informatization level of production line operation can be enhanced, the error prevention capacity of a production line can be improved, and operation waste can be reduced.

Owner:DONGFENG MOTOR CORP HUBEI

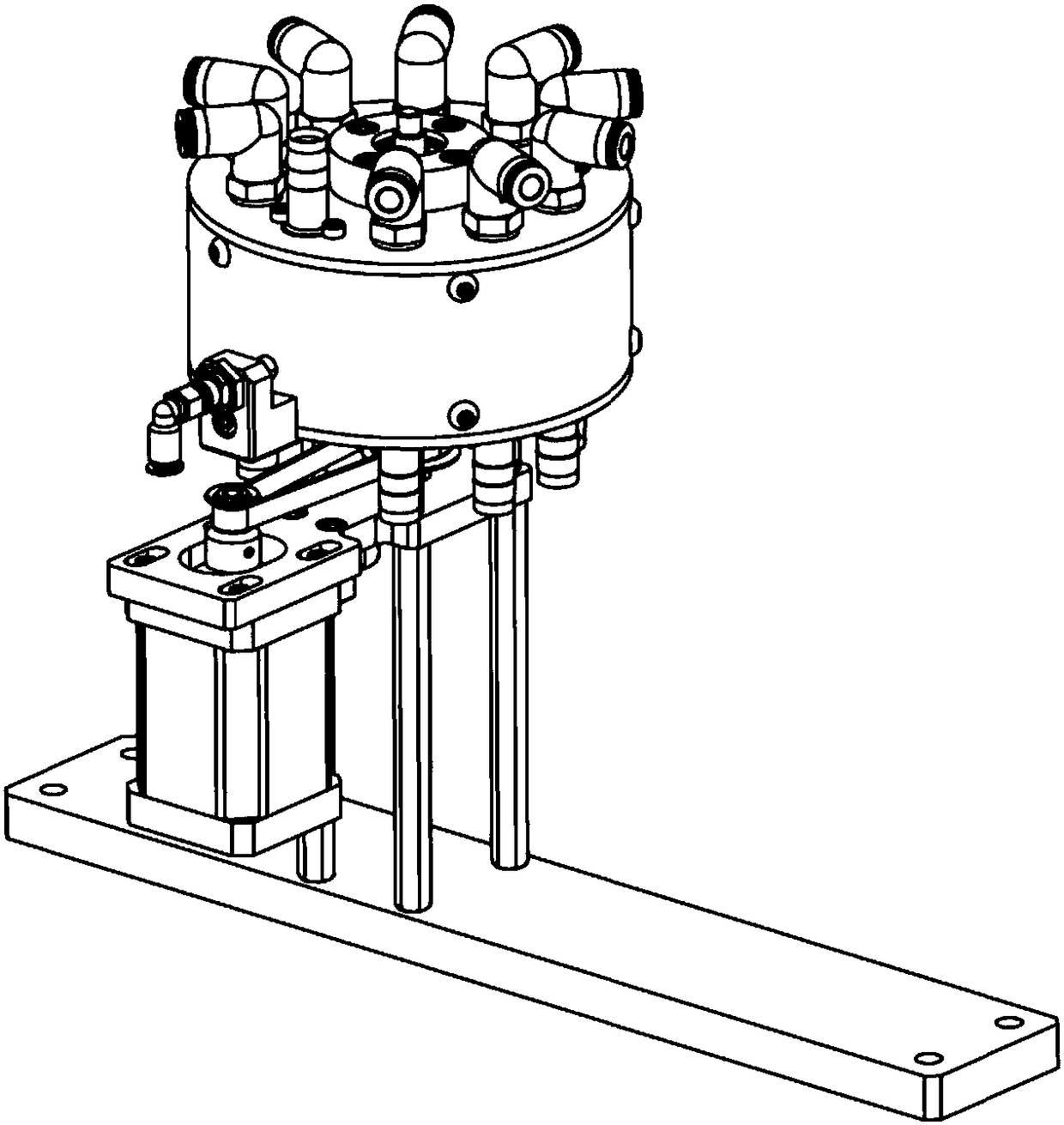

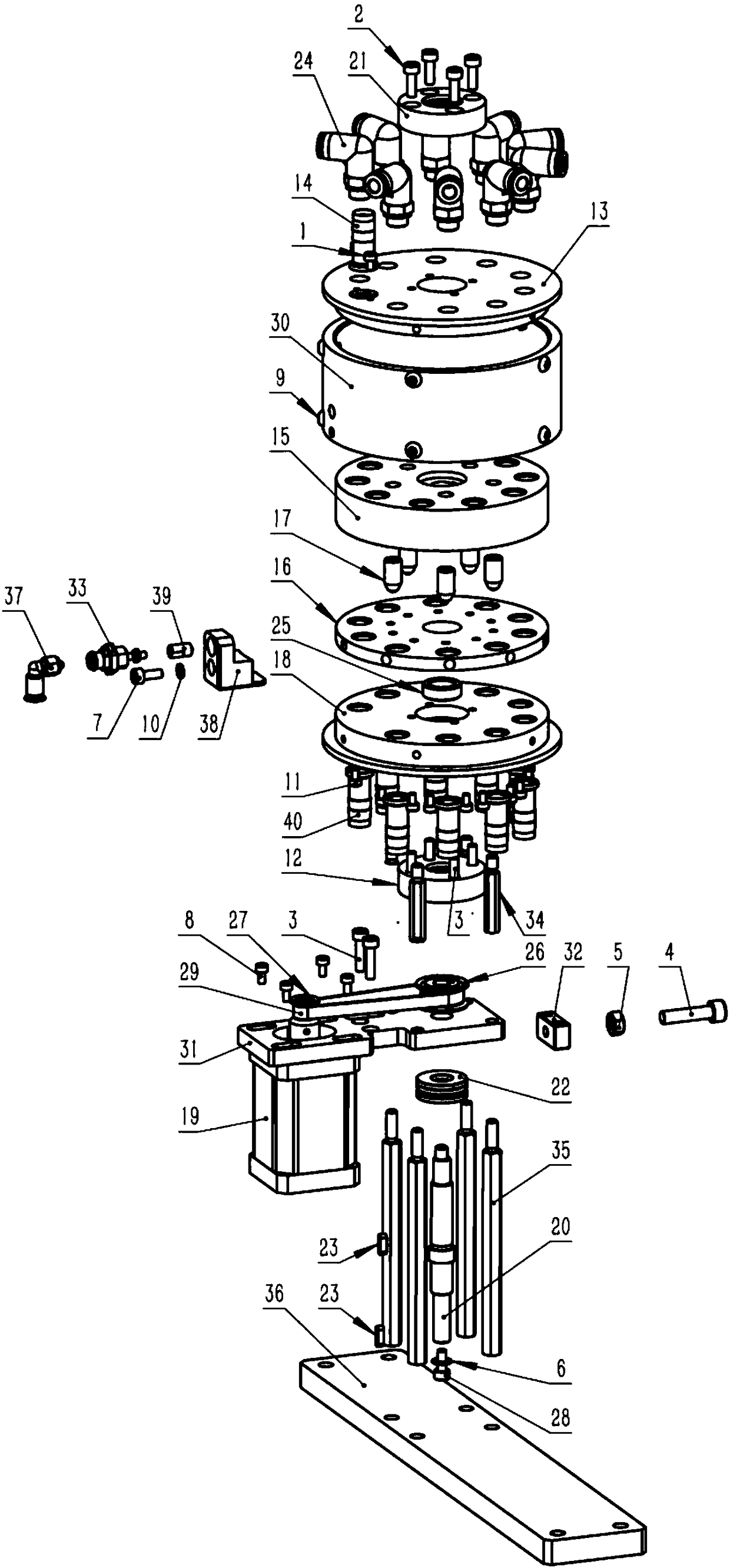

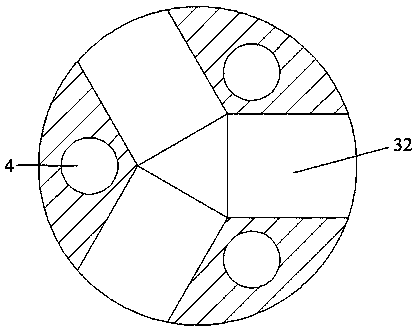

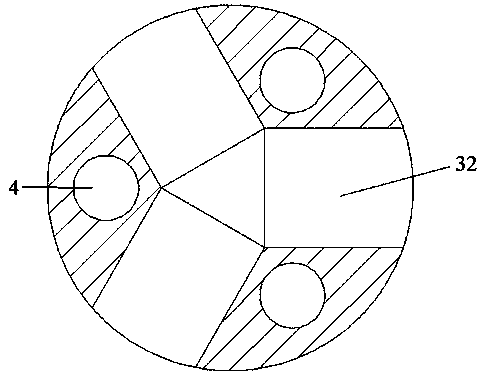

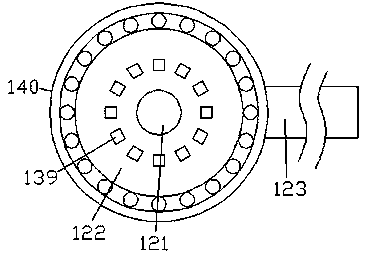

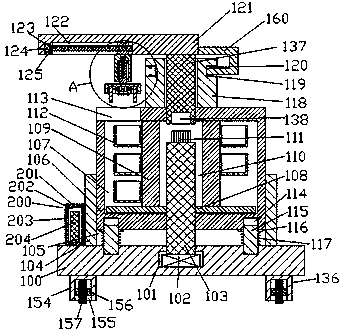

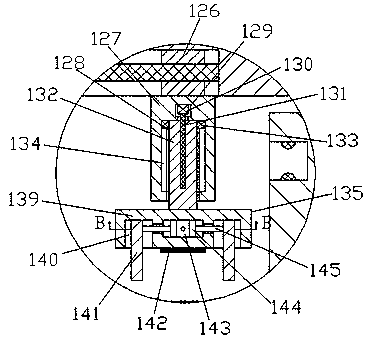

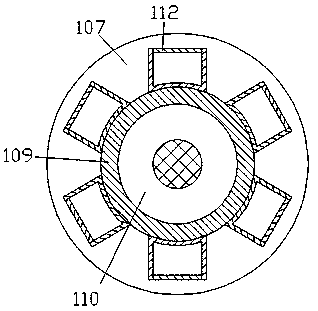

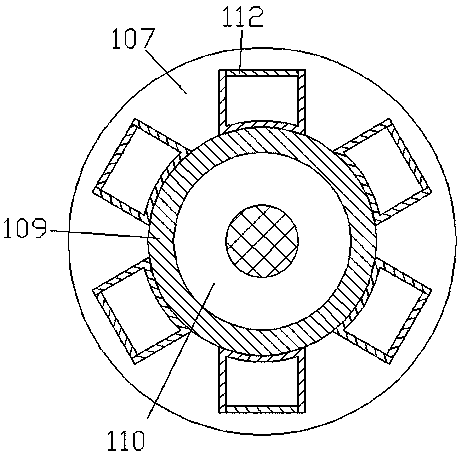

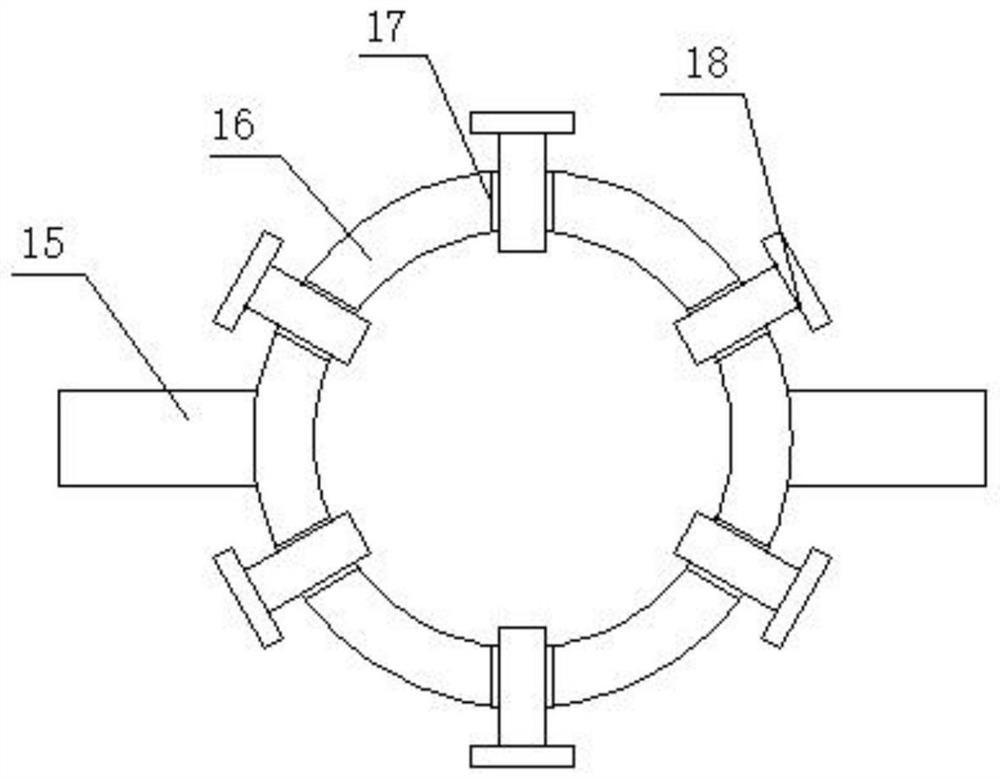

Multi-split material distributor based on motor and belt wheel transmission

ActiveCN108098287AAccurate indexing functionHigh matching precisionMetal working apparatusSteel ballEngineering

The invention discloses a multi-split material distributor based on motor and belt wheel transmission. The multi-split material distributor comprises a feeding inlet, a material distributing assembly,a transmission assembly, discharging outlets and a supporting assembly. The material distributing assembly comprises a shell fixing base. An upper rotating fixing plate and a lower rotating fixing plate are fixed to the two ends of the shell fixing base correspondingly. The shell fixing base is internally provided with a material distributing disc. A separation plate is arranged below the material distributing disc. A plunger is arranged between the material distributing disc and the separation plate. One end of the plunger is fixed to the material distributing disc, and the other end of theplunger is provided with an elastically supported steel ball which is matched with the spherical concave surface of the separation plate. A bolt air cylinder used for fixing the separation plate is further fixedly arranged at the side edge of the shell fixing base. According to the multi-split material distributor based on motor and belt wheel transmission, an internal rotating assembly is driventhrough transmission of a servo motor and a belt wheelk, mutual connection between the feeding inlet and all the discharging outlets is achieved through the precise control of the moving position of the servo motor and the internal positioning plunger of the rotating assembly, and thus the brand new multi-split motor-belt transmission type rotating material distributor can be achieved.

Owner:CHANGZHOU INST OF TECH

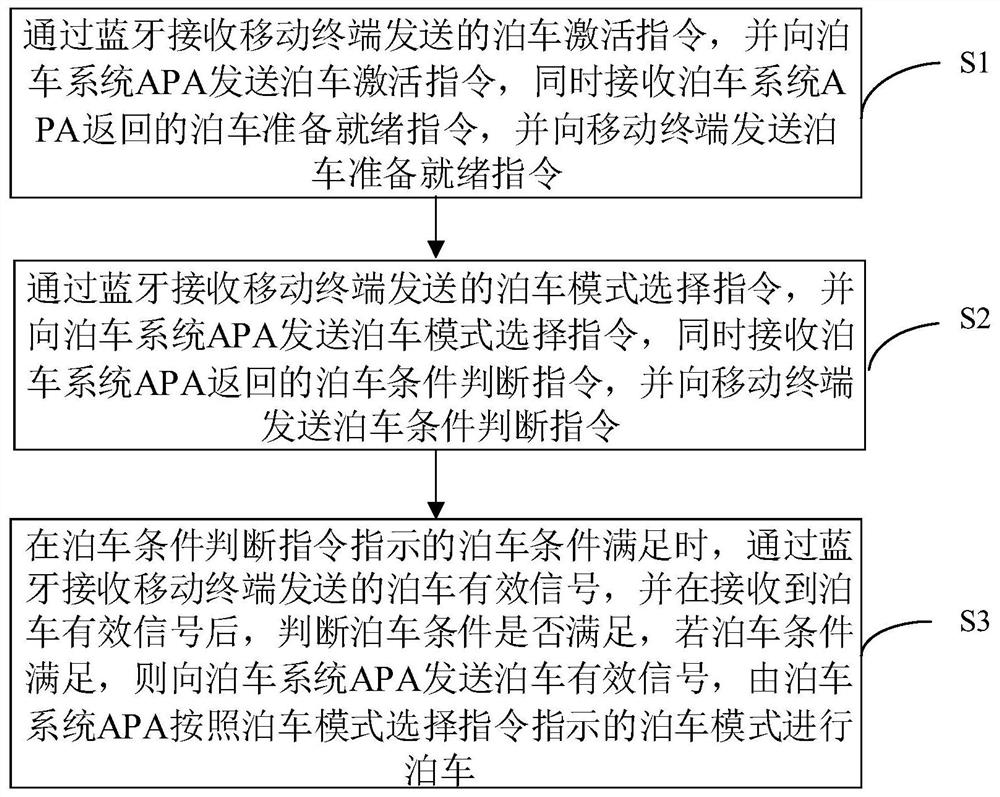

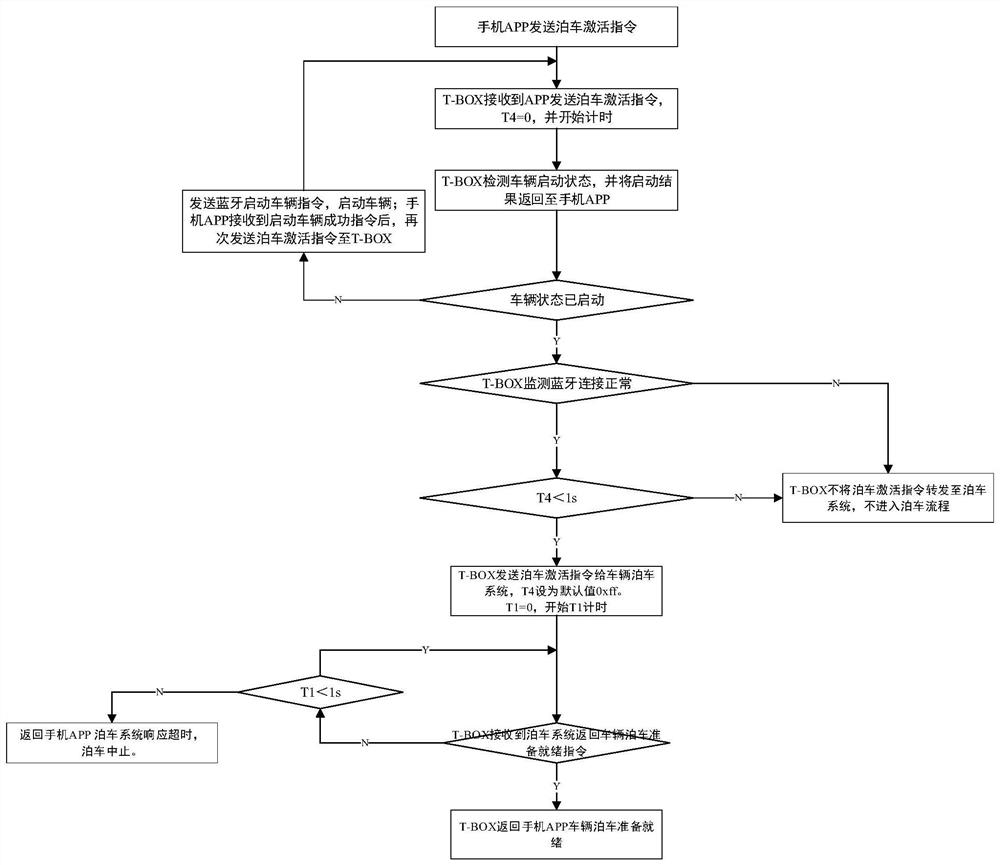

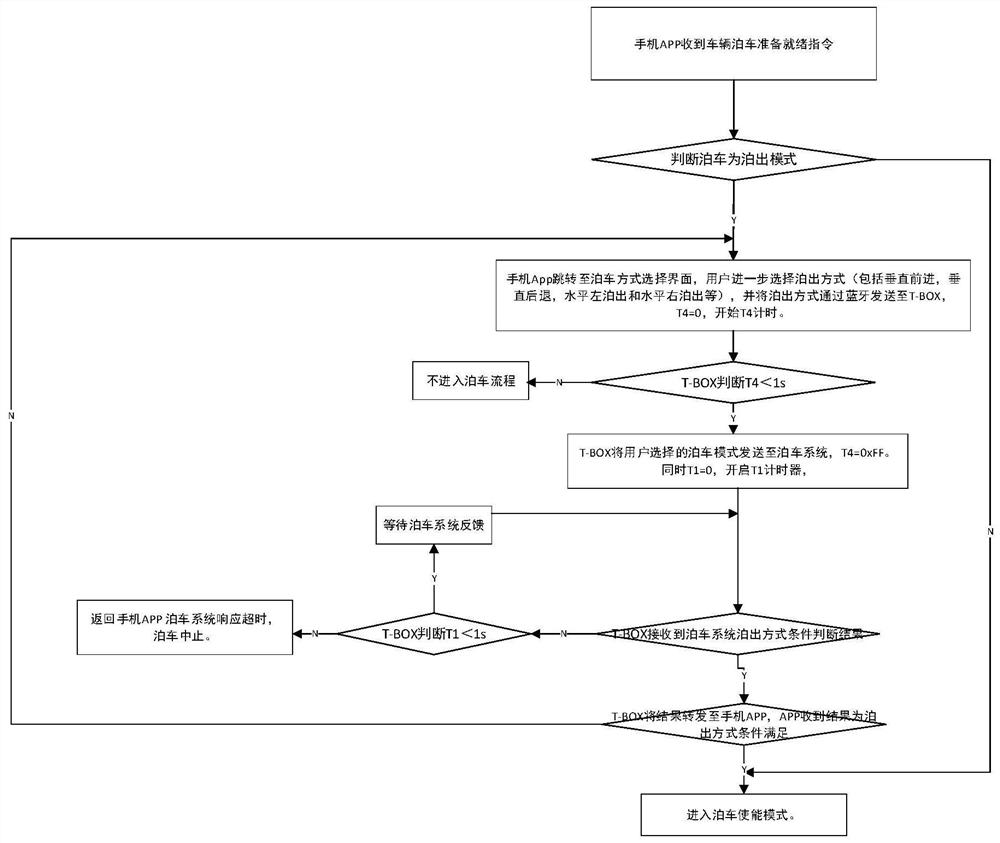

Bluetooth auxiliary parking method of remote monitoring terminal, remote monitoring terminal and system

ActiveCN113525353AImproves assisted parking reliabilityReduce false triggersElectric signal transmission systemsParticular environment based servicesEmbedded systemReliability engineering

The invention discloses a Bluetooth auxiliary parking method of a remote monitoring terminal, the remote monitoring terminal and a system, and belongs to the technical field of automatic vehicle parking, and the method comprises the steps: receiving a parking activation instruction sent by a mobile terminal, sending the parking activation instruction to a parking system, receiving a parking ready instruction returned by the parking system, sending a parking preparation instruction to the mobile terminal; receiving a parking mode selection instruction sent by the mobile terminal, sending the parking mode selection instruction to the parking system, receiving a parking condition judgment instruction returned by the parking system, and sending the parking condition judgment instruction to the mobile terminal; and when the parking condition indicated by the parking condition judgment instruction is met, receiving a parking effective signal sent by the mobile terminal, judging whether the parking condition is met, if the parking condition is met, sending a parking effective signal to a parking system, and performing parking by the parking system according to the parking mode selection instruction. According to the method, the parking reliability can be improved.

Owner:DONGFENG MOTOR GRP

Mailbox equipment fixed to ground

InactiveCN108851915AAvoid errorsEnhanced error proofingKitchen equipmentDomestic articlesDrive motorEngineering

The invention discloses mailbox equipment fixed to the ground. An equipment body is internally provided with a movement space, a fixing body is disposed on the right side of the interior of the movement space and internally provided with a driving space, a driving motor is fixedly disposed in the driving space, a driving shaft is in power connection with the left end of the driving motor, the leftend of the driving shaft penetrates through the left end wall of the driving space to be sleeved with a lifting shaft, the left end of the lifting shaft penetrates through an opening of a lifting slot and is connected with a clamping mechanism, a transmission cavity is formed in the left end wall of the movement space, a scanning device is fixedly connected to the upper end wall of the transmission cavity, a cable is in signal connection with the upper end of the scanning device, and the end, away from the scanning device, of the cable is in signal connection with a display screen. The equipment has a simple structure, letters are sorted and classified, time is saved, the cost is reduced, and the work efficiency is improved.

Owner:潘军权

Mailbox equipment with alarm system

InactiveCN108937500AAvoid clutterAvoid errorsKitchen equipmentDomestic articlesDrive shaftEngineering

The invention discloses mailbox equipment with an alarm system. An activity space is formed in an equipment body, a fixing body is arranged on the right side of the interior of the activity space, a driving space is formed in the fixing body and internally and fixedly provided with a driving motor, a driving shaft is in power connection with the left end of the driving motor, the left end of the driving shaft penetrates through the left end wall of the driving space and is sleeved with a lifting shaft, and the left end of the lifting shaft penetrates through an opening of a lifting groove andis connected with a clamping mechanism; a transmission cavity is formed in the left end wall of the activity space, a scanning device is fixedly connected to the upper end wall of the transmission cavity, a cable is in signal connection with the upper end of the scanning device, and a display screen is in signal connection with the end, away from the scanning device, of the cable. The mailbox equipment is simple in structure, mails are sorted and classified, time is saved, the cost is reduced, and the working efficiency is improved.

Owner:潘军权

Rotating door drive device

InactiveCN109184419ASimple structureEasy to operatePower-operated mechanismElectric machineEngineering

The invention discloses a rotating door drive device. The device comprises a machine body, an output space is arranged in the machine body, the left side of the lower end wall of the output space is rotatably and fixedly connected with a rotation shaft, the lower side of a shaft body of the rotation shaft is fixedly sleeved with a first straight gear, a gear cavity is formed in the upper end wallof the output space, a driving space is arranged in the left end wall of the gear cavity, a driving motor is fixedly arranged on the left end wall of the driving space, a transmission space is arranged in the right end wall of the gear cavity, and a lifting sliding groove communicates between the transmission space and the output space. The rotating door drive device is simple in structure, and convenient to operate, through a single motor, the device is driven to run, the influence factors of the device are reduced, the device mistake proofing property is improved, gear transmission and hydraulic transmission are adopted, stability in the transmission process can be ensured, belt transmission and hydraulic transmission are matched to achieve motion step-by-step operation, and functionality of the device is improved.

Owner:董建月

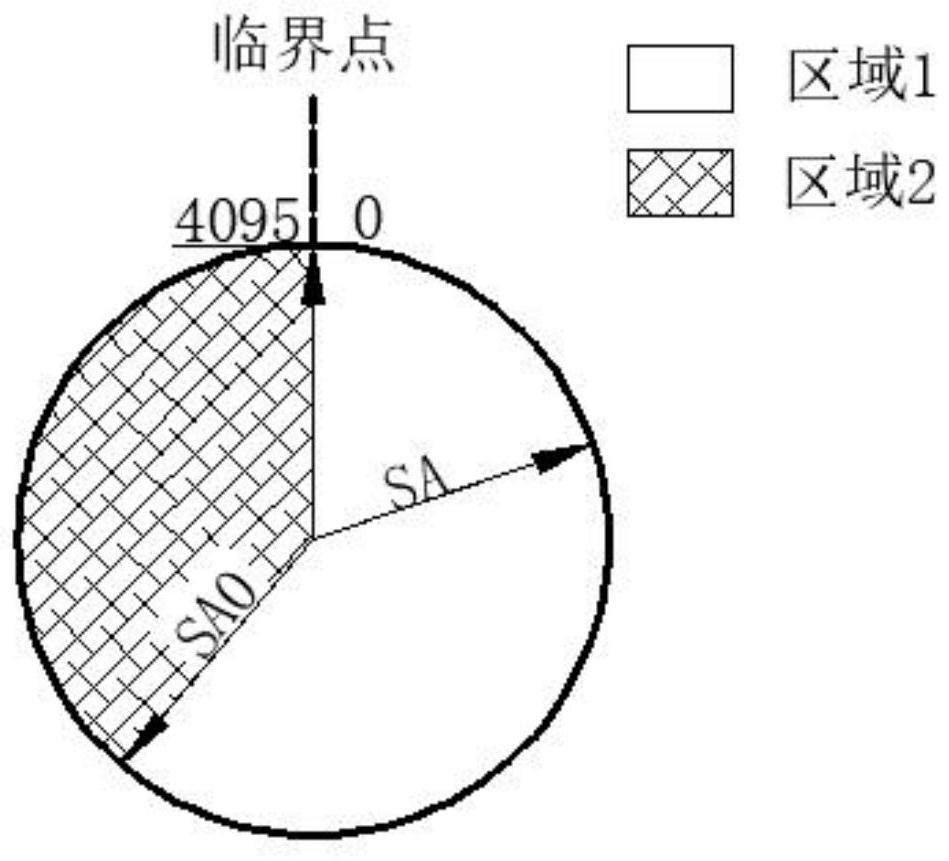

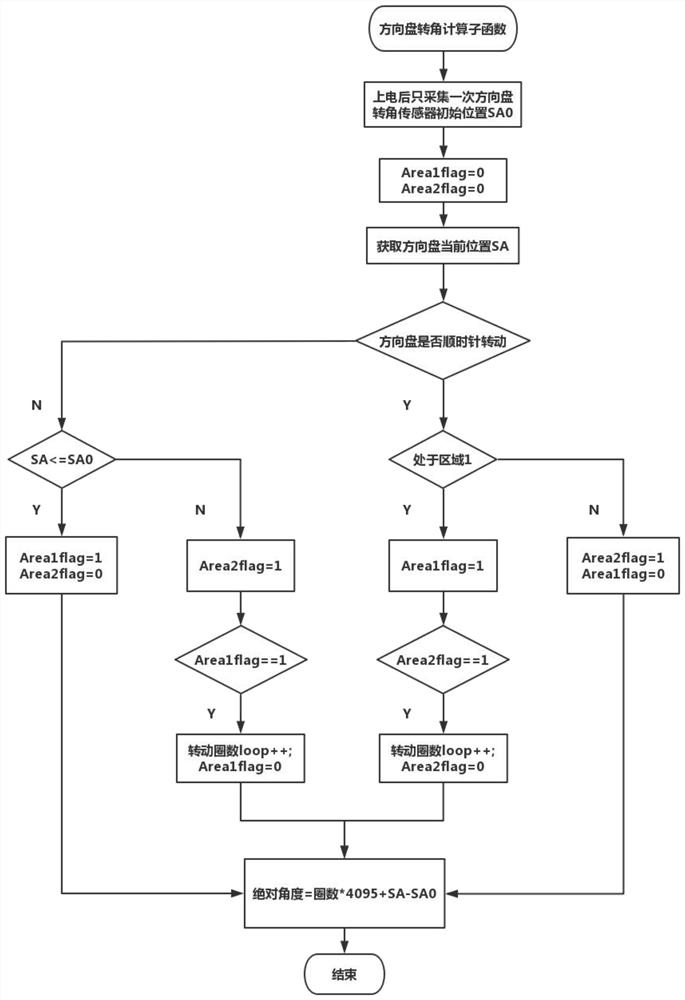

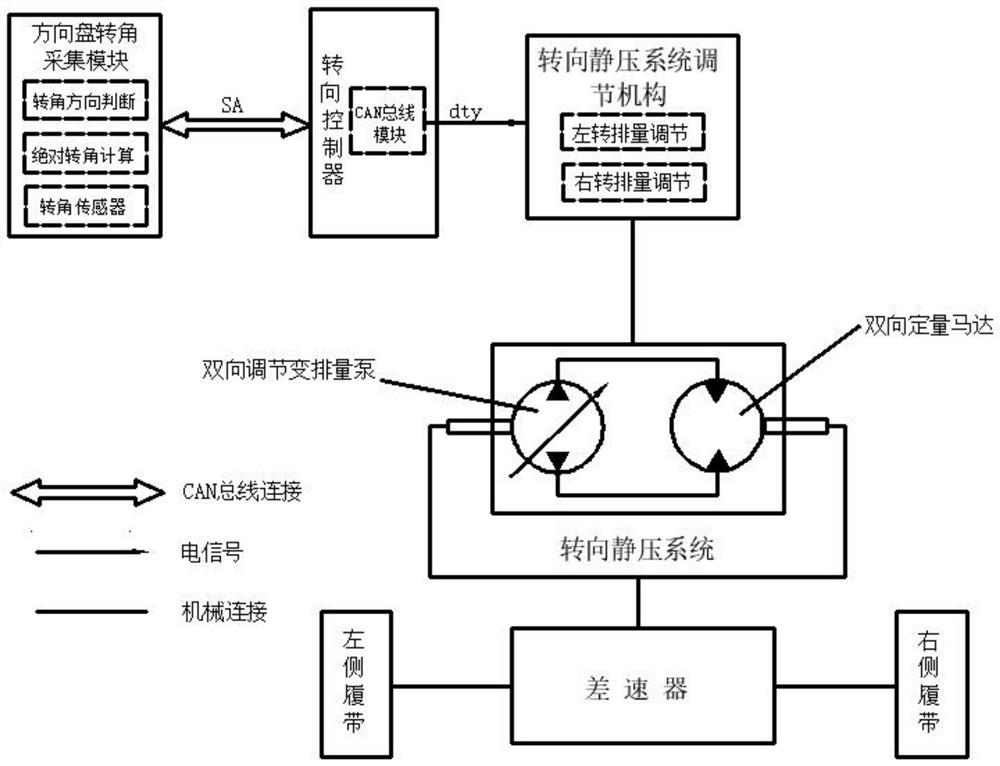

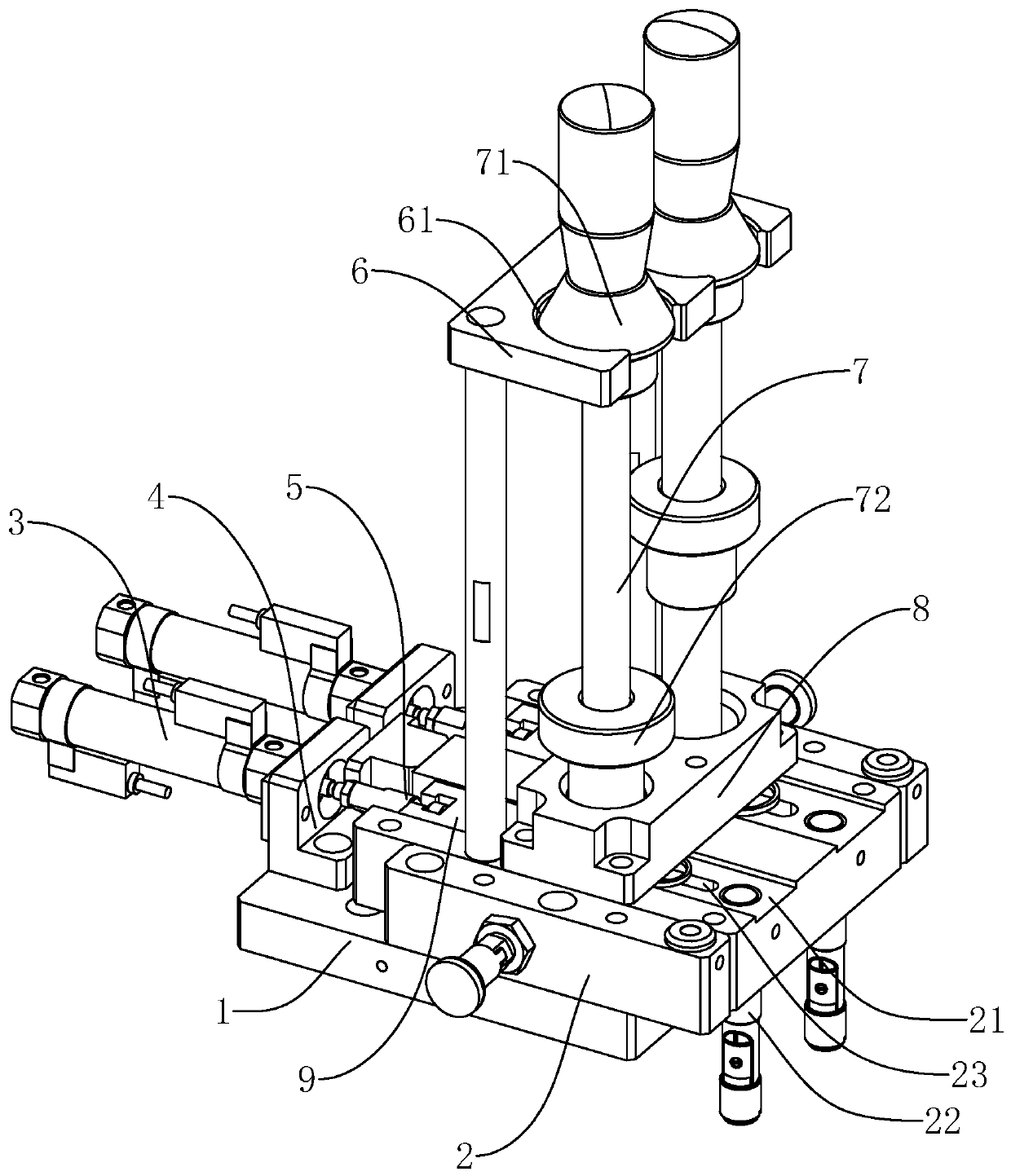

Steering judgment and turning angle calculation method for steering wheel of tracked vehicle

ActiveCN113548111AHigh precisionImprove accuracyNon-deflectable wheel steeringSteering wheelSteering angle

The invention discloses a steering wheel steering judgment and steering angle calculation method for a tracked vehicle. The method comprises the following steps of firstly, reading a steering signal by judging the steering of a steering wheel, then, determining the number of turns of the steering wheel so as to realize the replacement of an initial value of a steering angle, and then, controlling completion of a steering action through a steering pump; It is ensured that a steering angle of the steering wheel is within a certain error range, and accurate steering is achieved. According to the method, safety and the sense of direction of a driver during steering operation can be improved.

Owner:HEFEI UNIV OF TECH

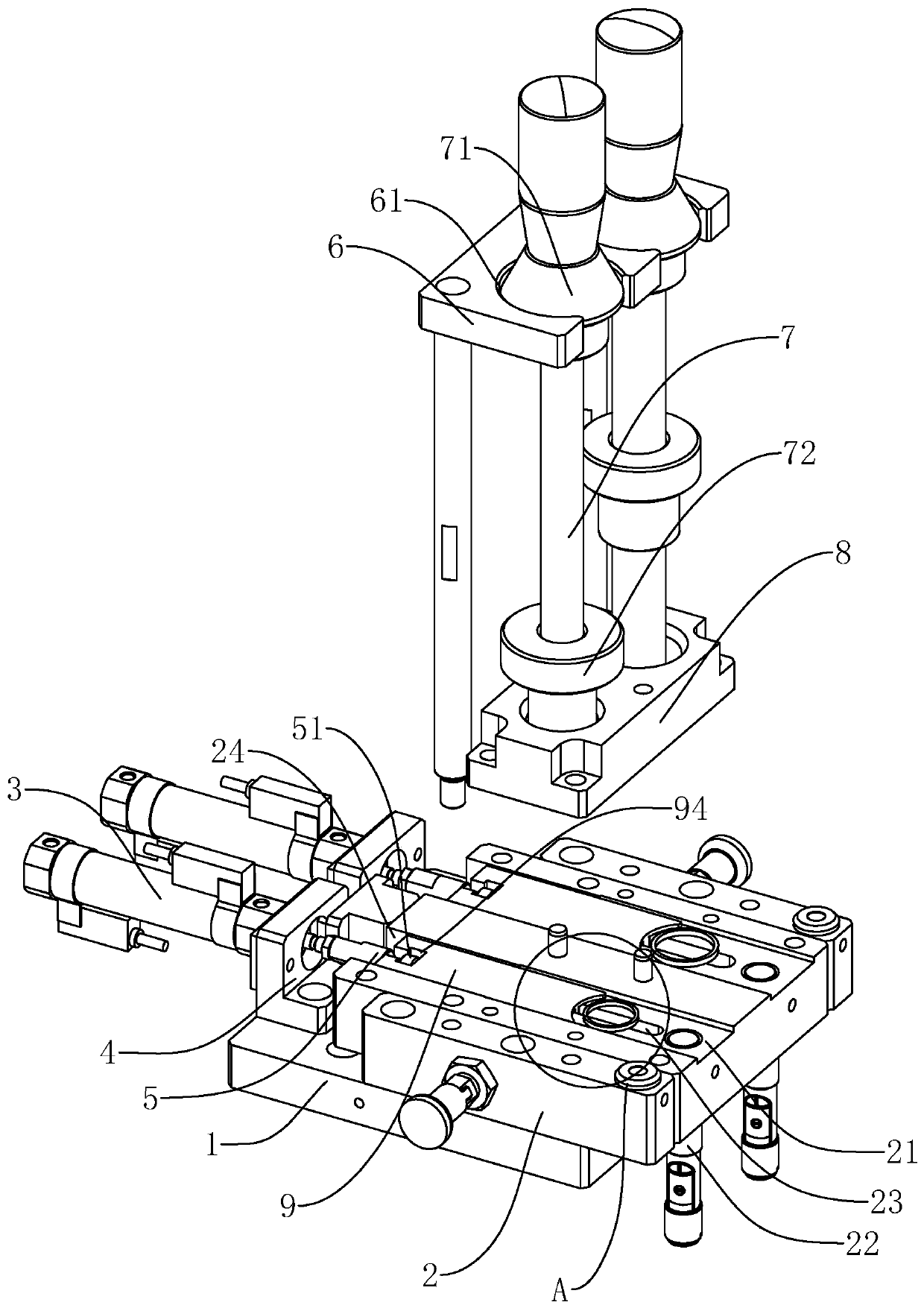

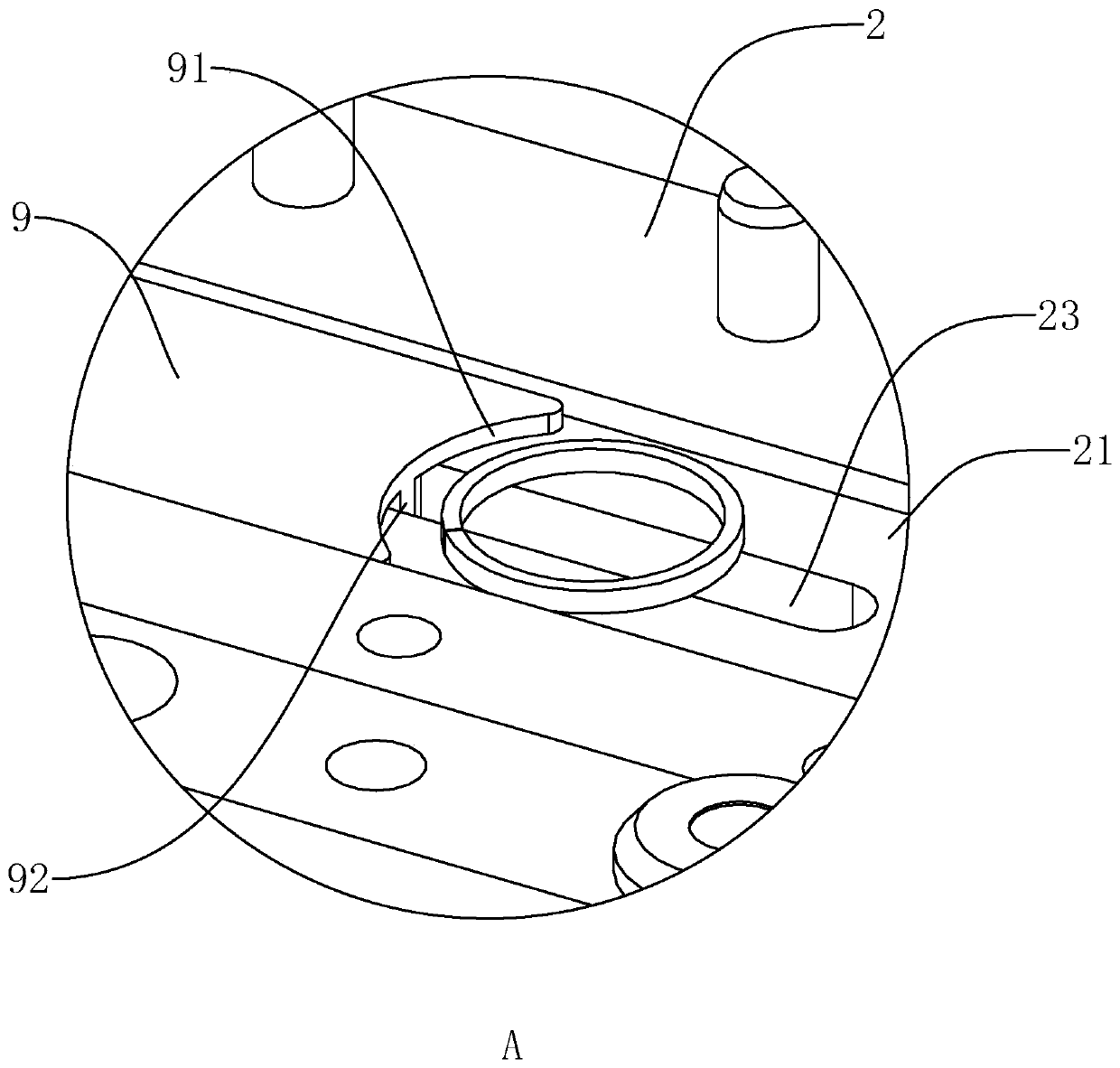

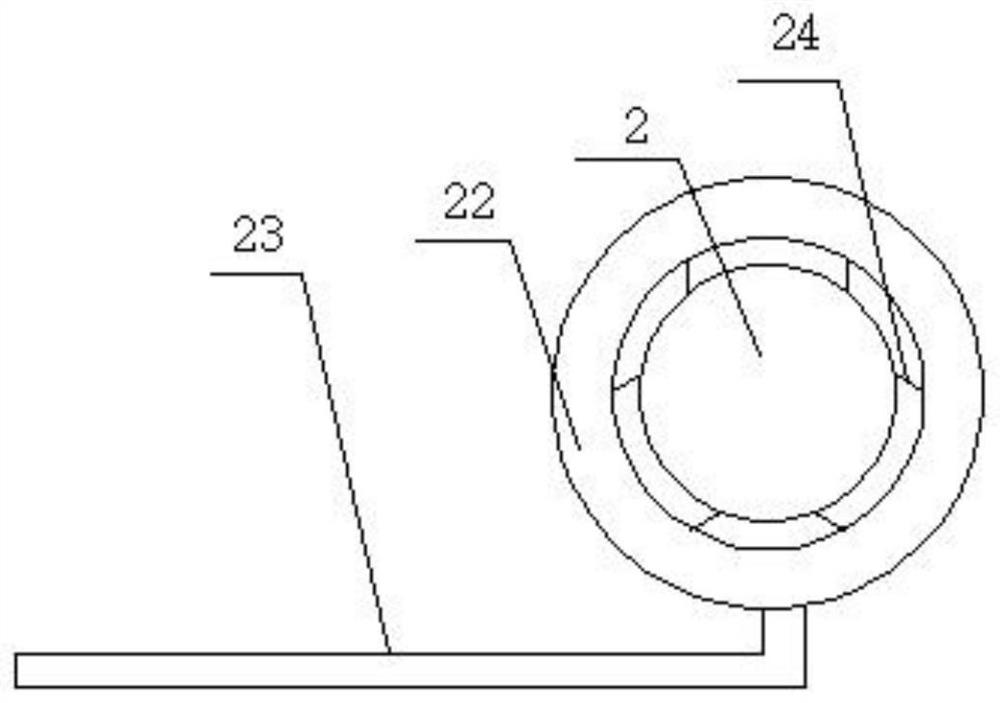

Flexible pushing mechanism for sealing rings

PendingCN110369984AImprove structural strengthImprove mobile stabilityMetal working apparatusProcess errorReciprocating motion

The invention discloses a flexible pushing mechanism for sealing rings. According to the technical scheme, the flexible pushing mechanism comprises a fixed base, a pushing base and a pushing cylinderare arranged on the fixed base, a pushing block is arranged on the upper side of the pushing base, the pushing cylinder is connected with the pushing block and drives the pushing block to do reciprocated motion in the length direction of the pushing base, the pushing base is provided with a storage bracket, the storage bracket is provided with a guiding roller which is inserted into the storage bracket in the vertical direction, and a gap matched with the corresponding sealing ring thickness is formed between the bottom of the guiding roller and the pushing base. By means of the flexible pushing mechanism, the pushing block is driven by the pushing cylinder to push the sealing rings in the gap to the end away from the pushing cylinder, the aim of pushing the sealing rings in different models, types and sizes can be achieved by replacing the corresponding guiding rollers, the product process error proofing capability and the production efficiency are significantly improved, the time ofzero mold replacing between most products with the sealing rings in different sizes is shortened, and the tool cost and the tool management cost are effectively reduced.

Owner:BORGWARNER AUTOMOTIVE COMPONENTS (NINGBO) CO LTD

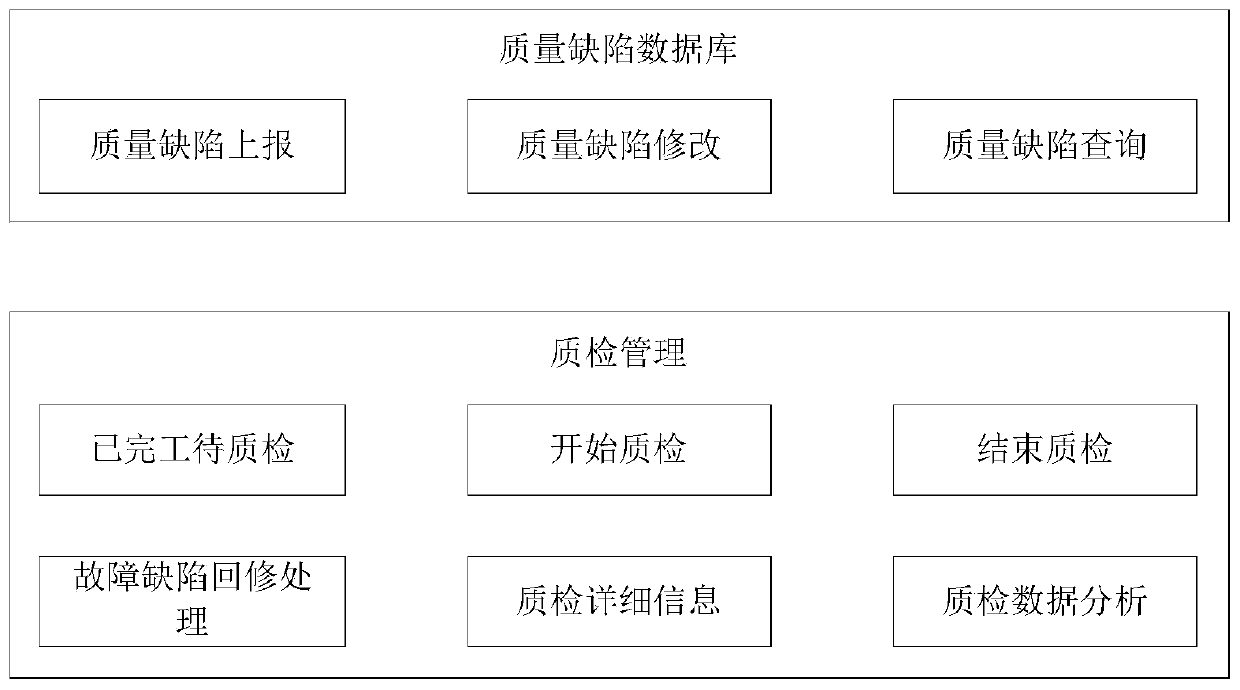

Railway wagon quality inspection information system

PendingCN111311099AEasy to realize systematic managementEasy to achieve qualityResourcesTruckComputer science

The invention provides a rail wagon quality inspection information system. The rail wagon quality inspection information system comprises a quality defect database module and a quality inspection management module, wherein the quality defect database module is used for managing and storing vehicle types, parts, defect types, defect numbers and defect description information, and the quality inspection management module is used for managing quality inspection conditions of finished products; wherein the defect type is selected from one of three types, and the three types are respectively a fatal defect, a heavy defect and a light defect. According to the invention, systematic management and quality tracing of quality inspection information can be realized conveniently, invisible product quality problems are visualized and explicit, enterprises are helped to strengthen supervision and management of the quality problems, the product quality is improved practically, and the mistake-proofing capability and the maintenance efficiency in the operation process are improved.

Owner:CRRC GUIYANG CO LTD

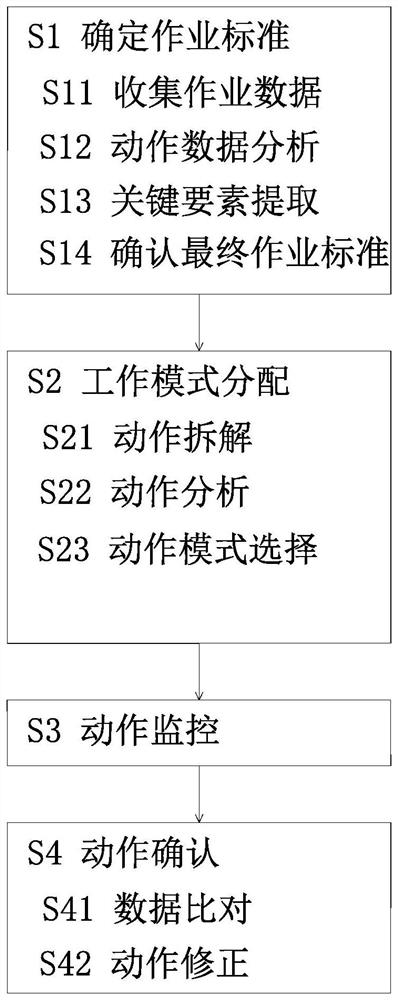

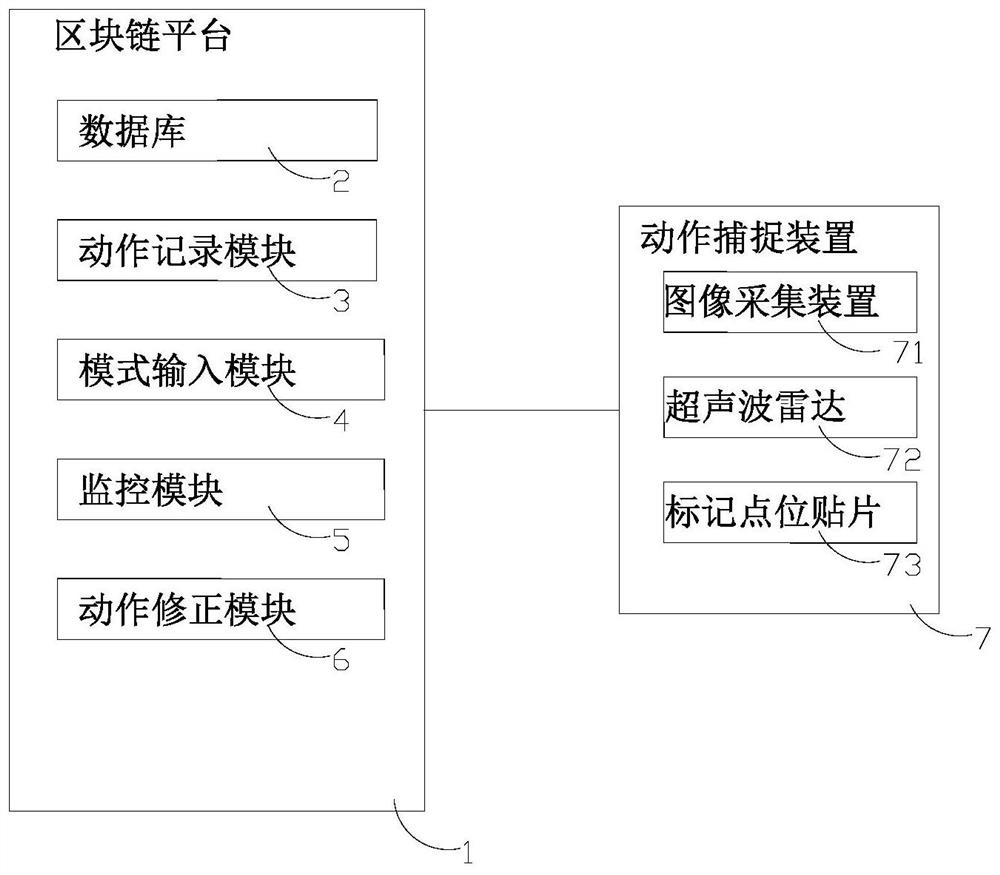

Intelligent manufacturing method and system based on man-machine co-fusion

InactiveCN114367985AImprove accuracyImprove securityProgramme-controlled manipulatorMan machineProcess engineering

The invention relates to an intelligent manufacturing method based on man-machine co-fusion, and the method comprises the steps: collecting manual operation data, and obtaining a final operation standard; according to the characteristics of the different actions, different working modes are distributed to the different actions; the work is monitored in real time, and monitoring data is uploaded; and comparing the action data obtained by real-time monitoring with the action data in the preset mode, and performing action correction. Standard reference data are provided for the machine by collecting the manual action data, so that the accuracy of the machine action is improved; different actions of the operation are decomposed and then working modes are distributed, so that a man-machine co-fusion operation form is formed, meanwhile, the advantages of manual operation and machine operation are reserved, and the working efficiency of the operation is improved; through real-time operation action monitoring and active correction functions, monitoring data of operation actions are reserved and can be used for subsequent checking of historical operation actions, the consistency of actual actions and standard actions is guaranteed, and the mistake proofing capacity of machine operation and manual operation is improved.

Owner:冯玉溪

Warehouse logistics loading and unloading robot designed based on personal and property security consideration

InactiveCN108946505AConsistent state of motionGuaranteed reliabilityLoad-engaging elementsCranesLogistics managementDrive shaft

The invention discloses a warehouse logistics loading and unloading robot designed based on personal and property security consideration. The robot comprises a base, a driving space is arranged insidethe base, a driving motor is fixedly arranged on the lower end wall of the driving space, a driving shaft is in power connection with the upper end of the driving motor, a reinforcing block is fixedly arranged in the center position of the upper end face of the base, the lower end of a lifting barrel penetrates out of an opening of a lifting sliding groove and is connected with a clamping device,a connection shaft is fixedly connected to the right side of the lower end face of a transverse plate, a spline groove with a downward opening is formed inside the lower end wall of the connection shaft, and a moving device is fixedly connected to the lower end face of the base. The structure is simple, thread transmission and hydraulic transmission are adopted and are both stable transmission, equipment stability can be effectively ensured, detection and recording are carried out at the same time, working efficiency is improved, manual errors are avoided, and equipment mistake-proof performance is enhanced.

Owner:朱顺华

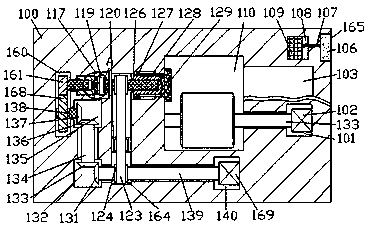

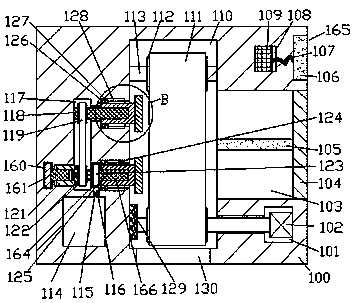

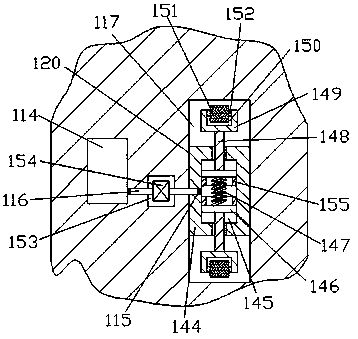

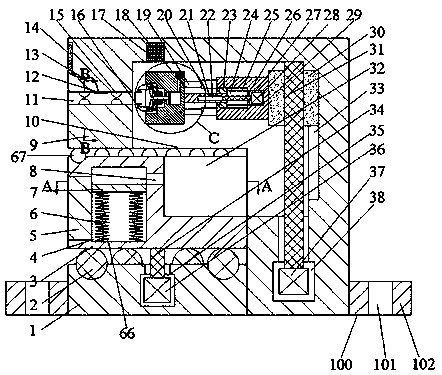

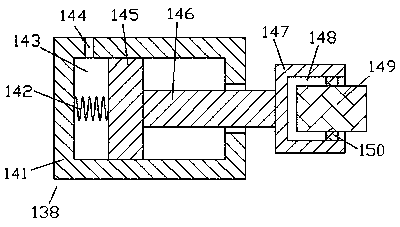

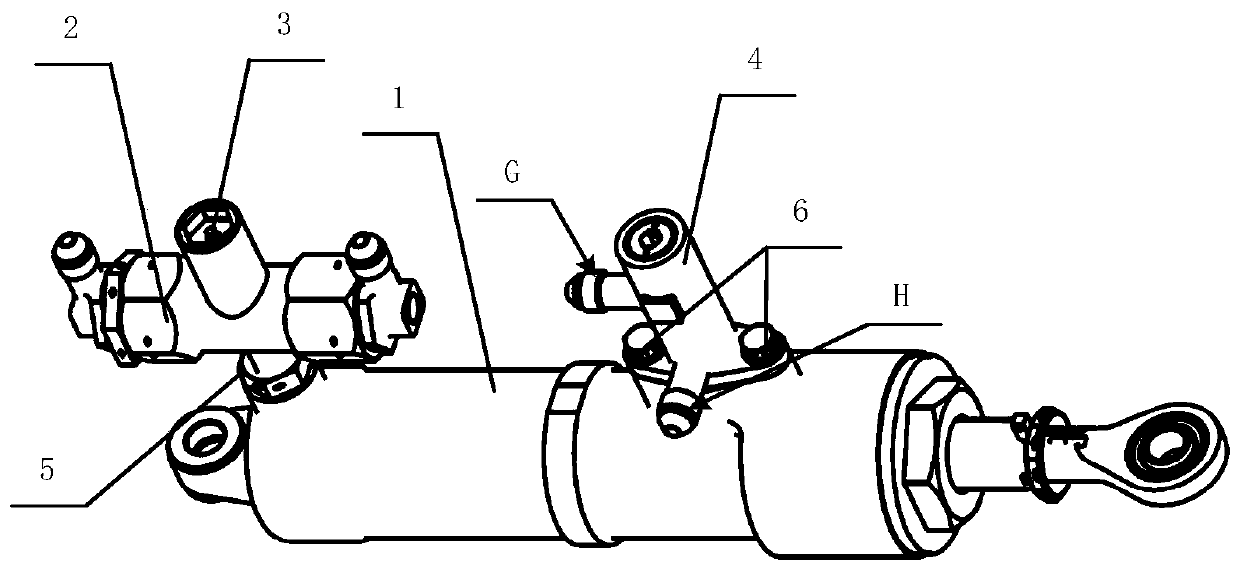

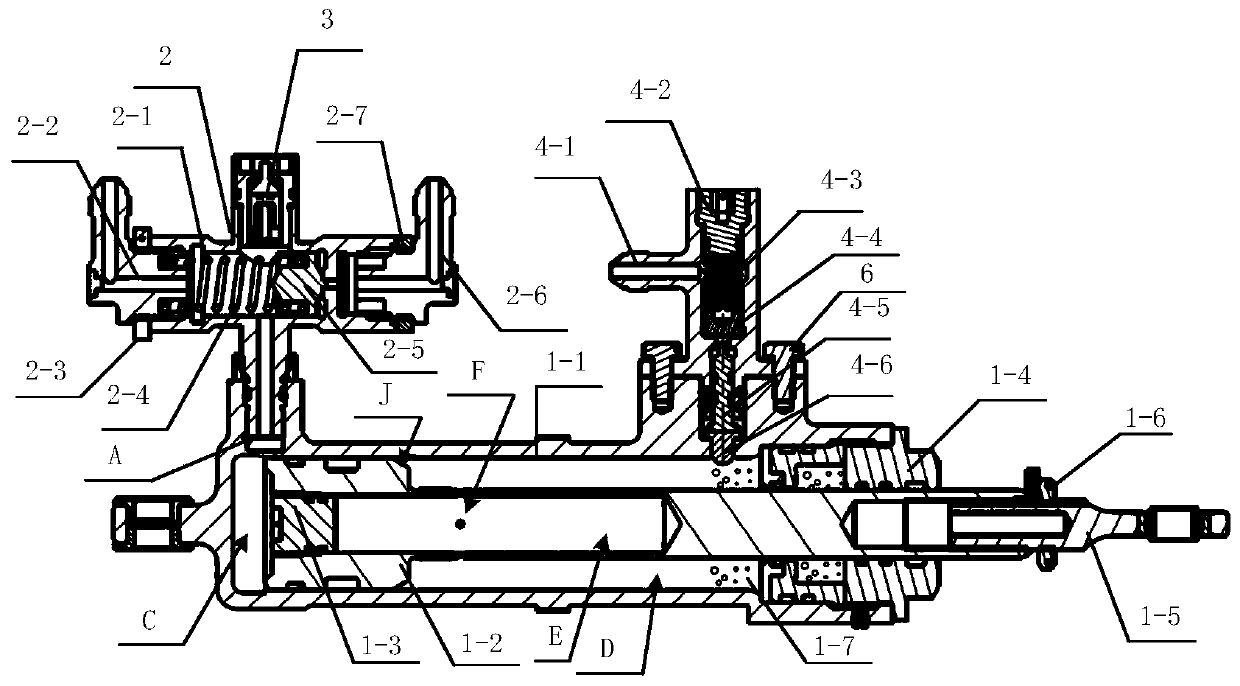

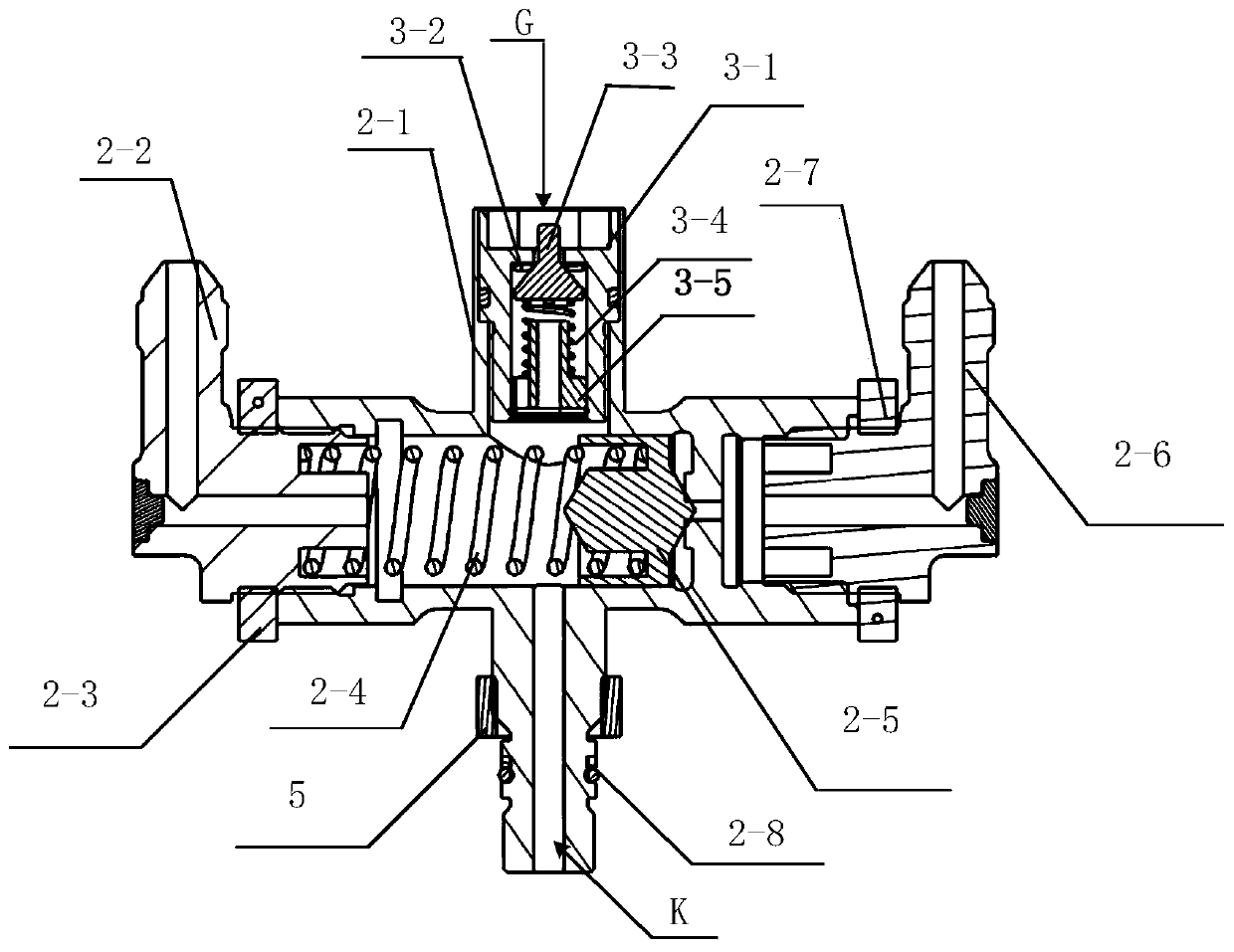

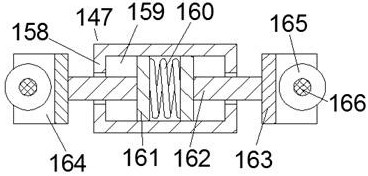

A Highly Reliable Linkage Cylinder

ActiveCN108916152BPrevent backflowDouble redundancy and high reliabilityServomotor componentsExhaust valveEngineering

A high reliability linkage cylinder comprises a cylinder body (1), an intake valve (2), an exhaust valve (3) and a linkage valve (4). The intake valve (2) is connected with an air inlet A of the cylinder body (1), and the exhaust valve (3) is installed at the position of the air inlet A for discharging air in a rodless cavity C when a piston rod (1-2) in the cylinder body (1) is reset. The linkagevalve (4) is mounted at the stroke end of the piston rod. When the linkage valve does not work, a valve element assembly (4-4) is pressed against a linkage valve casing (4-1) and isolates an air inlet G and an air outlet H under the action of the spring force and the air pressure of the air inlet. When the piston rod (1-2) moves to the stroke end, the piston rod ejects an ejection pin (4-6) and apush rod (4-5) under the action of the piston rod (1-2). Under the action of the push rod (4-5), the valve element assembly (4-4) is ejected to communicate the air inlet G and the air outlet H to supply air to a downstream air using unit.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Warehouse logistics loading and unloading robot

InactiveCN108946507AConsistent state of motionGuaranteed reliabilityLoad-engaging elementsCranesLogistics managementDrive shaft

The invention discloses a warehouse logistics loading and unloading robot. The robot comprises a base, a driving space is arranged inside the base, a driving motor is fixedly arranged on the lower endwall of the driving space, a driving shaft is in power connection with the upper end of the driving motor, a reinforcing block is fixedly arranged in the center position of the upper end face of thebase, the lower end of a lifting barrel penetrates out of an opening of a lifting sliding groove and is connected with a clamping device, a connection shaft is fixedly connected to the right side of the lower end face of a transverse plate, a spline groove with a downward opening is formed inside the lower end wall of the connection shaft, and a moving device is fixedly connected to the lower endface of the base. The structure is simple, thread transmission and hydraulic transmission are adopted and are both stable transmission, equipment stability can be effectively ensured, detection and recording are carried out at the same time, working efficiency is improved, manual errors are avoided, and equipment mistake-proof performance is enhanced.

Owner:朱顺华

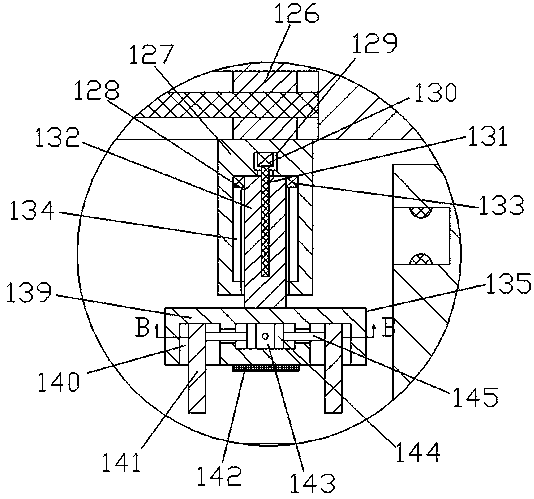

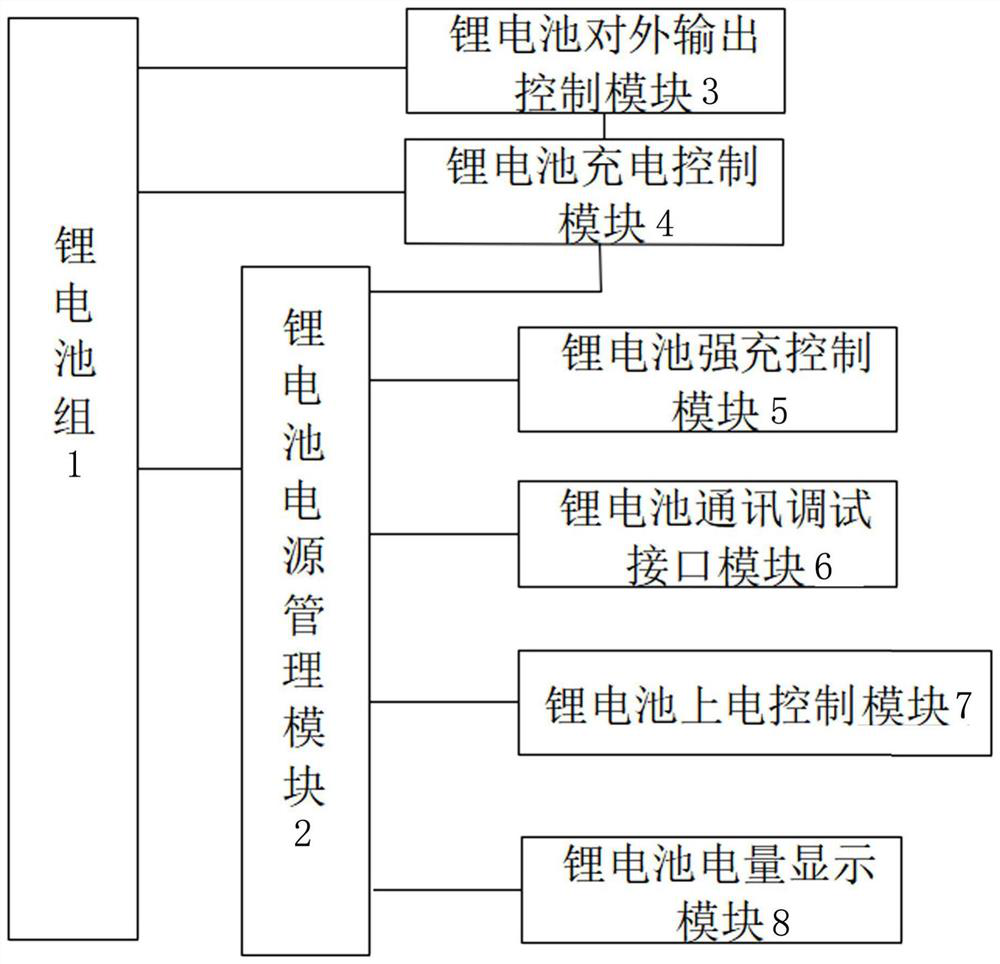

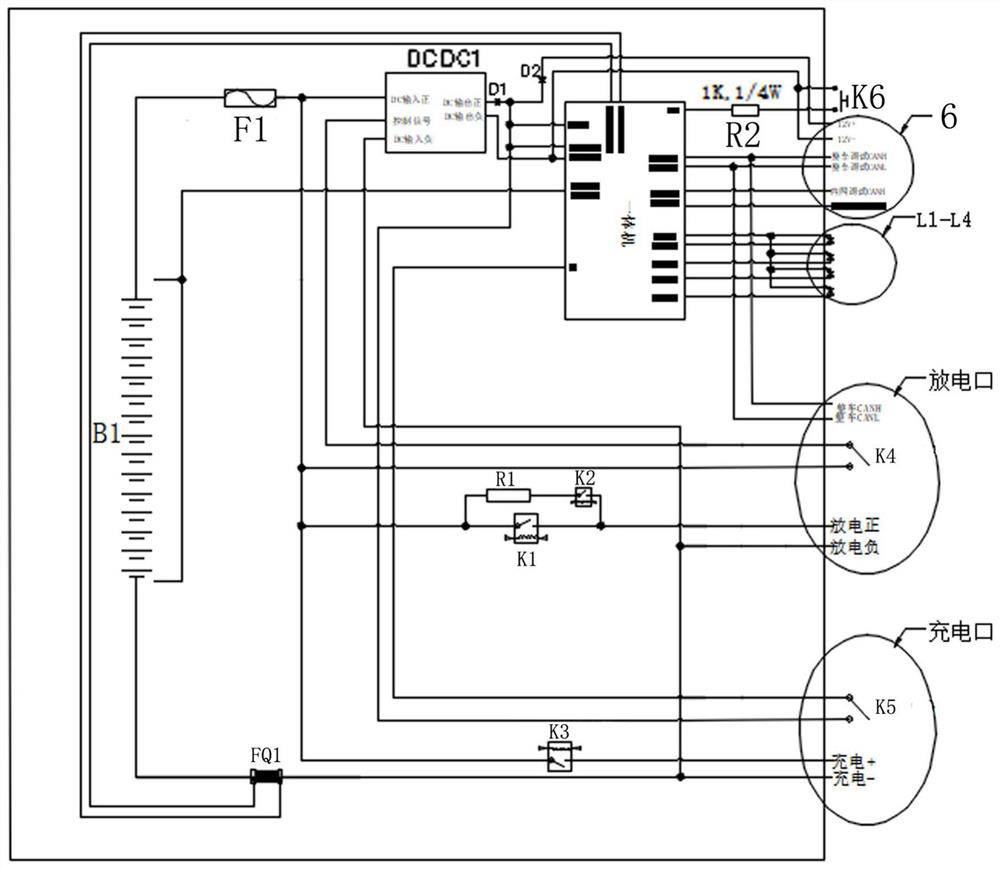

Novel hard switch power battery system for AGV (Automatic Guided Vehicle) and power supply method thereof

PendingCN113183775AImprove charging reliabilityIncreased charging operation diversityCircuit monitoring/indicationDifferent batteries chargingAutomotive engineeringPower battery

The invention belongs to the field of forklift batteries, and particularly relates to a novel hard switch power battery system for an AGV and a power supply method thereof. The system comprises a lithium battery pack, a lithium battery power management module, a lithium battery external output control module, a lithium battery charging control module, a lithium battery forced charging control module, a lithium battery communication debugging interface module, a lithium battery power-on control module and a lithium battery electric quantity display module, the lithium battery pack is electrically connected with the lithium battery power management module, the lithium battery external output control module and the lithium battery charging control module respectively, the lithium battery power management module is electrically connected with the lithium battery charging control module, the lithium battery forced charging control module, the lithium battery communication debugging interface module, the lithium battery power-on control module and the lithium battery electric quantity display module, and the lithium battery external output control module is electrically connected with the lithium battery charging control module. The two-switch design is adopted, and particularly, the charging parts use switches, so that the charging reliability is improved.

Owner:杭州鹏成新能源科技有限公司

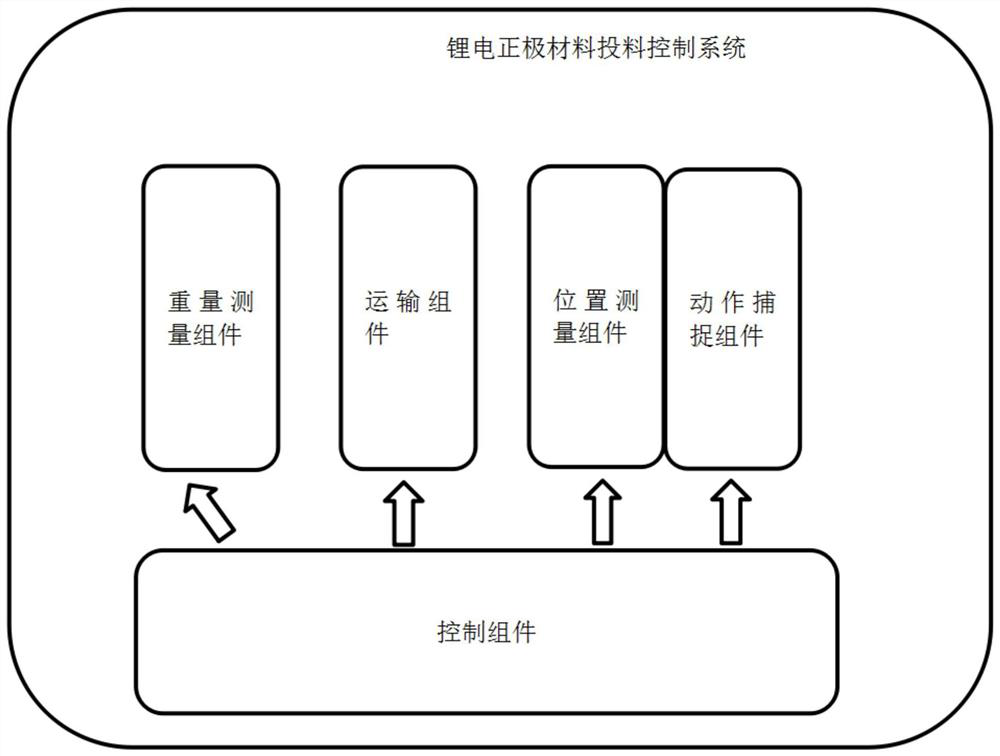

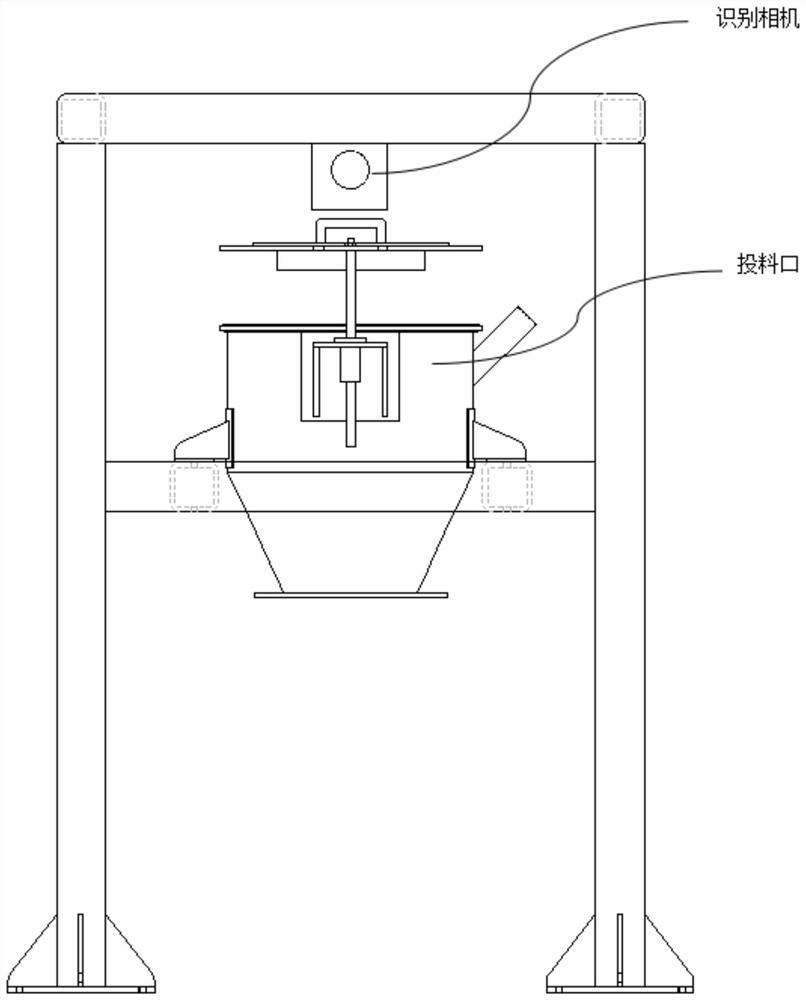

Lithium battery cathode material feeding control system and method

ActiveCN111167370BImproved error proofingQuality improvementTransportation and packagingMixer accessoriesControl systemProcess engineering

The invention discloses a lithium battery cathode material feeding control system and method. By measuring the actual weighing data of the raw materials to be delivered transported by the transport component, and calculating the weighing deviation between the actual weighing data and the preset target weighing data; judging the weighing Whether the deviation is within its corresponding deviation threshold, if so, transport the raw materials to be distributed to the preset feeding point; detect whether the transportation component transports the raw materials to be distributed to the feeding point, if it is detected that the raw materials to be distributed have been transported to At the feeding point, it is judged that the raw materials to be delivered have been delivered into the receiving bin according to whether the action photos of the user when feeding are collected, so as to effectively reduce the risk of errors in the feeding process and improve the error prevention ability in the feeding process of lithium battery cathode materials , and then effectively control the quality of lithium battery cathode material compounding.

Owner:HUNAN JINLU TECH CO LTD

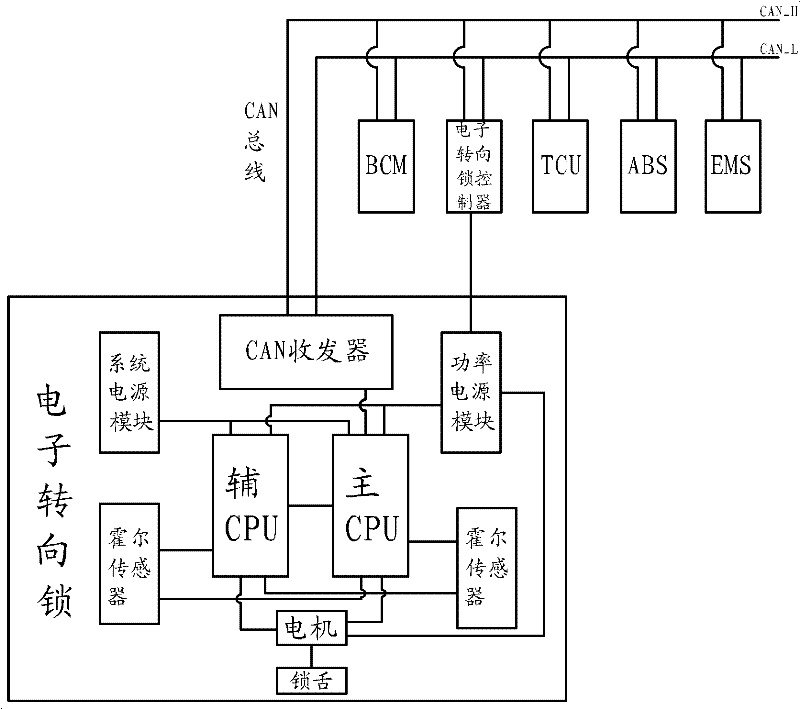

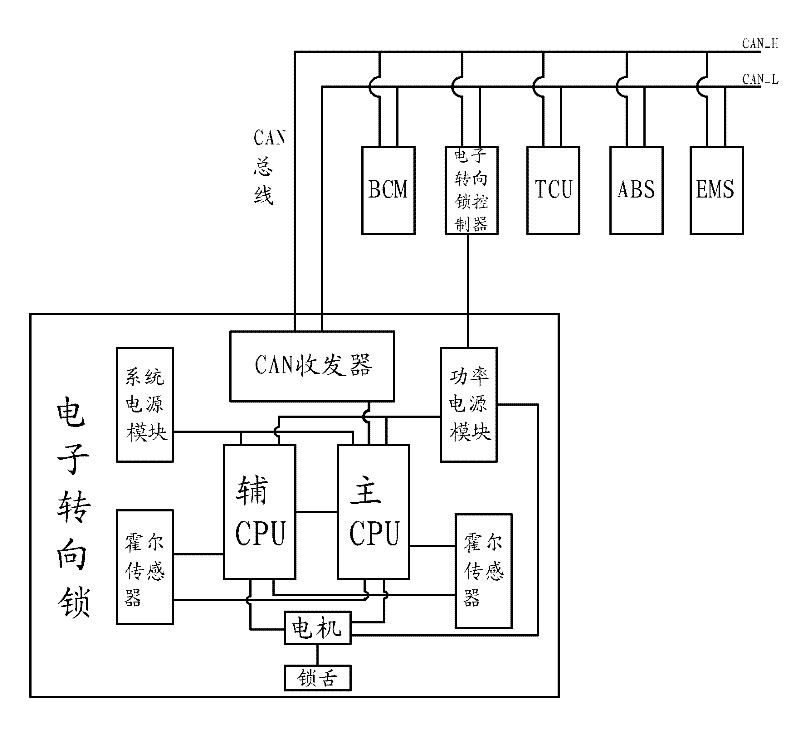

Electronic steering lock with CAN bus

InactiveCN101927753BImproved error detectionImproved error proofingAnti-theft devicesNon-mechanical controlsComputer moduleActuator

The invention provides an electronic steering lock with a CAN bus, which belongs to the technical field of automobiles and solves the problem that a car crash may be caused by the locking operation of a performer even as a result of a locking command given by mistake by a controller in the prior art. The electronic steering lock with the CAN bus is connected with an electronic steering lock controller and comprises a bolt and a bolt driver for driving the bolt to carry out locking / unlocking operation. The electronic steering lock also comprises a CAN transceiver, a system power source module,a limited power source module, two sensors, a main CPU and an auxiliary CPU, wherein the main CPU and the auxiliary CPU can communicate with each other, the main CPU communicates with the CAN bus through the CAN transceiver and can acquire the information of each controller from the CAN bus, the two sensors can acquire the information of the bolt, and the main CPU and the auxiliary CPU can control the electronic steering lock to lock or unlock according to the information. The electronic steering lock with the CAN bus has the advantages of high mistake recognition capability and high locking / unlocking control accuracy.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

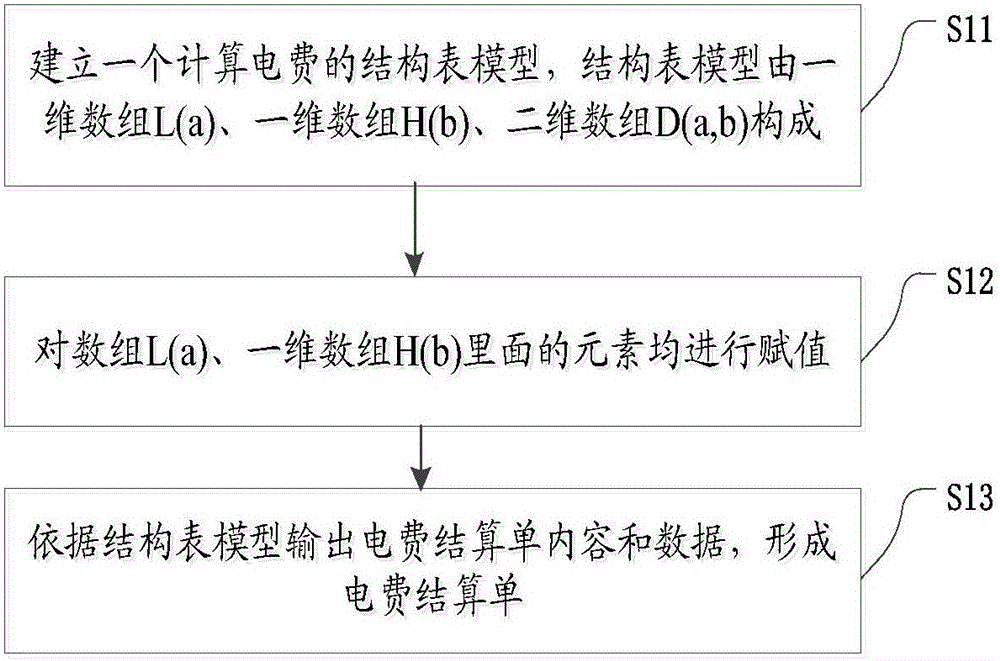

Electricity quantity and electricity charge acquisition method

InactiveCN106227715AImprove efficiencyImproved ease of maintenanceData processing applicationsText processingArray data structureElectricity market

The invention discloses an electricity quantity and electricity charge acquisition method. The method includes the steps that a structural table model for calculating the electricity charge is established, wherein the structural table model is composed of a one-dimensional array L (a), a one-dimensional array H (b) and a two-dimensional array D (a, b), wherein a represents the item name of electricity charge calculation, and b represents the data name of electricity charge calculation; elements in the array L (a) and the one-dimensional array H (b) are assigned with values; electricity charge settlement bill content and data are output according to the structural table model, and an electricity charge settlement bill is formed. By means of the method, the efficiency of acquiring the electricity quantity and the electricity charge is improved, and electricity charge calculation meeting various calculation methods is achieved.

Owner:GUANGDONG POWER GRID CO LTD

an anti-theft tracker

ActiveCN110166750BGuaranteed stabilityAchieve angle adjustmentClosed circuit television systemsControl using feedbackGear driveGear wheel

The invention discloses an anti-theft tracker, which comprises a fixed body. A left-right symmetrical limiting chute is arranged inside the fixed body. A lifting cavity with an upward opening is arranged between the limiting chutes. The cavity is connected with the limit chute, and a slider is slidably arranged inside the limit chute, and the end of the slider away from the limit chute is rotatably fixedly connected with a box body, and a sliding part is arranged inside the box body , the anti-theft tracking device of the present invention adopts gear transmission to ensure the stability during the movement of the equipment, adopts the linkage mechanism to realize the angle adjustment of the equipment simply and effectively, ensures that there are no blind spots in equipment monitoring, and sets tensioning devices and anti-theft devices during the transmission process. The break mechanism enhances the reliability during the working process of the equipment and enhances the error proofing of the equipment, and the device can be placed in a closed cavity to avoid the monitoring effect being affected by external dust and humid gas, and at the same time enhance the service life of the equipment.

Owner:赣州金宁保安服务有限公司

Using method of stapler

The invention discloses a using method of a stapler. The using method of the stapler comprises a base. A binding platform is fixedly arranged on the left side of the upper end surface of the base. A supporting column is fixedly connected with the periphery of the upper end surface of the base. A machine body is fixedly connected to the upper end surface of the supporting column. A driving space isarranged in the machine body. A driving motor is fixedly connected to the right end wall of the driving space, and a driving shaft is dynamically connected to the left end of the driving motor. The lower end of a threaded shaft penetrates through the lower end wall of a power space and is connected and sleeved with a lifting sliding cylinder. The lower end of the lifting sliding cylinder penetrates through the opening of a lifting groove and is fixedly connected with a grabbing device. A magnetic space is arranged in the right end wall of an extrusion cavity. A first electromagnet is fixedlyarranged in the right side of the magnetic space, and a second electromagnet is slidably arranged on the left side of the first electromagnet. The stapler has simple structure, low manufacturing cost,capability of automatic nail feeding, reduction of time waste and enhancement of working efficiency.

Owner:邬时伟

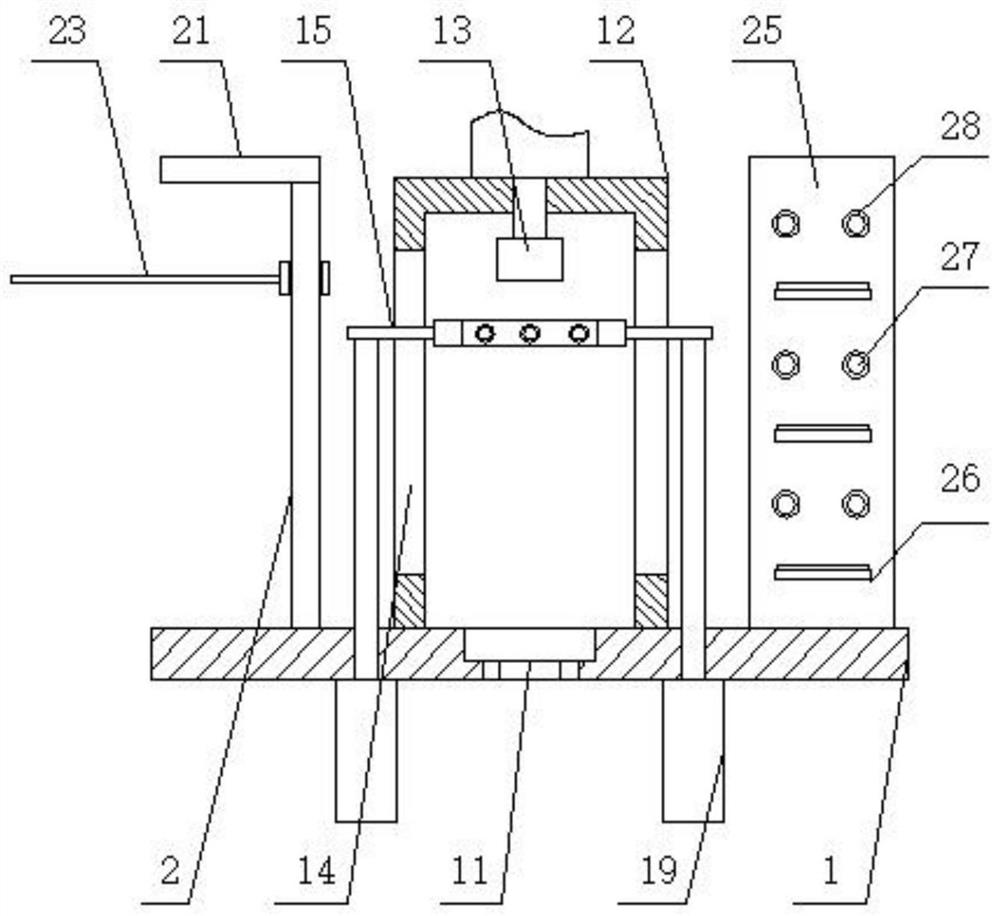

Assembly technique for supporting plate and supporting rod of fuel oil dispensing pipe and clamp thereof

ActiveCN101131139BEasy to adjustShorten adjustment timeFuel injection apparatusMachines/enginesEngineeringFuel oil

The present invention relates to a support plate and support rod assembling fixture for a fuel oil distributing pipe. The fixture includes a pedestal, an A cushion block, a support rod first pin stop, a first pin, a support rod second pin stop, a B cushion block, a Phi 7 height limit column, an adjustable cushion, a fine adjustable bolt, a poka-yoke ring, a Phi 6.4 height limit column, a guide pillar, a movable pressing board, a linear bearing, a pressing block, an auxiliary hook, an A press head, a press head connecting pole, a B press head and a second pin. The assembling process comprises: respectively putting two first support rods with a diameter of 6.4mm and two second support rods with a diameter of 7mm in the height limit column with an internal bore diameter of Phi6.4 at the two sides and the height limit column with an internal bore diameter of Phi 7 at the middle; putting the support plate on the four support rods, aligning assemble holes on the support plate with the four support rods, starting a press for pressing the support plate and the four support rods in place, pressing the four support rods in place by the A press head and the B press head, and riveting, hoisting the movable pressing board by the auxiliary hook and taking out the product. The present invention has high product quality and high production efficiency.

Owner:SHANGHAI WINKELMANN LONGCHUAN (SWL) MOTORCOMPONENTS CO LTD

Automatic mistake-proof external-connected assembling device and assembling method for automobile shock absorber

ActiveCN111890268AAvoid spring interferenceConducive to combined installationWork holdersWrenchSlide plate

The invention discloses an automatic mistake-proof external-connected assembling device and assembling method for an automobile shock absorber. The automatic mistake-proof external-connected assembling device comprises a rack. An installing groove is formed in the surface of one side of the rack. A U-type fixing frame is fixedly connected to the surface of the rack. A torque spanner is rotatably installed at the other end of the U-type fixing frame. Long-strip sliding grooves are formed in surfaces of two sides of the U-type fixing frame correspondingly. Sliding plates are slidingly installedon surfaces of the long-strip sliding grooves. Auxiliary compressing rings are fixedly connected to surfaces of one sides of the sliding plates. Surfaces of the auxiliary compressing rings are slidingly connected to side faces of the U-type fixing frame. Adjustment threaded holes are formed in side faces of the auxiliary compressing rings. Compressing screws are connected to side faces of the adjustment threaded holes in a threaded manner. Compressing cylinders are fixedly installed at two ends of the other side of the rack correspondingly. Piston rod ends of the compressing cylinders are fixedly connected to surfaces of the sliding plates. In this way, using convenience and stability can be improved greatly, and safe and high efficiency are guaranteed.

Owner:温州市坂特车业部件有限公司

Method and device for managing and configuring field devices in an automation installation

ActiveCN105607595AImproved error proofingAvoid typosProgram controlTotal factory controlDevice typePersonalization

A method / device for managing and configuring field devices in an automation installation with a configuration tool designed to physically identify a field device in the automation installation and logically identify its field device type, to logically incorporate and configure it into the automation installation, the tool to this end resorting to a prescribed field-device-type-specific information package at least partially describing functions and data of the field device type. Parameterizing a plurality of field devices of the same type may be achieved by forming a first individual field-device-specific information package for a first field device from the field-device-type-specific information package, and a further individual field-device-specific information package for each further field device of the same type from the first individual field-device-specific information package, by first of all duplicating the first individual field-device-specific information package, then individualizing it for the further field device.

Owner:ABB (SCHWEIZ) AG

Material transfer unit for automobile production lines

ActiveCN103112483BImproved error proofingImprove protectionHand carts with multiple axesProduction lineVertical tube

The invention relates to a material transfer unit for automobile production lines. The material transfer unit comprises a multilayer frame structure formed by at least four vertical tubes fixed together and adjustable universal wheels fixed on a bottom frame. One end of each vertical tube is fixedly connected to the bottom frame. A shelf is disposed between each two adjacent layers of the multilayer frame. The multilayer frame structure is provided with corresponding layered structures according to different weights, sizes and shapes of automobile parts to be transferred. A pull bar and a draw bar are disposed at front and rear ends of the transfer unit respectively. The material transfer unit for automobile production line is applicable to classified storage of various automobile parts, better prevents mistaken placement of materials and better protects the materials. Effective connection between the front pull bar and the rear draw bar enables the material transfer unit to more adapt to material supply and transfer for batch production lines.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Automobile shock absorber automatic error-proof external connection assembly device and assembly method

The invention discloses an automatic anti-error external connection assembling device and an assembling method of an automobile shock absorber. A fixed frame, the other end of the U-shaped fixed frame is rotatably installed with a torque wrench, both sides of the U-shaped fixed frame are provided with a long chute, the surface of the long chute is slidably installed with a sliding plate, One side surface of the sliding plate is fixedly connected with an auxiliary pressing ring, the surface of the auxiliary pressing ring is slidably connected to the side of the U-shaped fixing frame, and the side of the auxiliary pressing ring is provided with an adjustment screw hole. The side of the adjustment threaded hole is threadedly connected with a compression screw, and a compression cylinder is fixedly installed at both ends of the other side of the frame, and the piston rod end of the compression cylinder is fixedly connected to the surface of the sliding plate, which can Greatly improve the convenience and stability of use, and ensure safety and efficiency.

Owner:温州市坂特车业部件有限公司

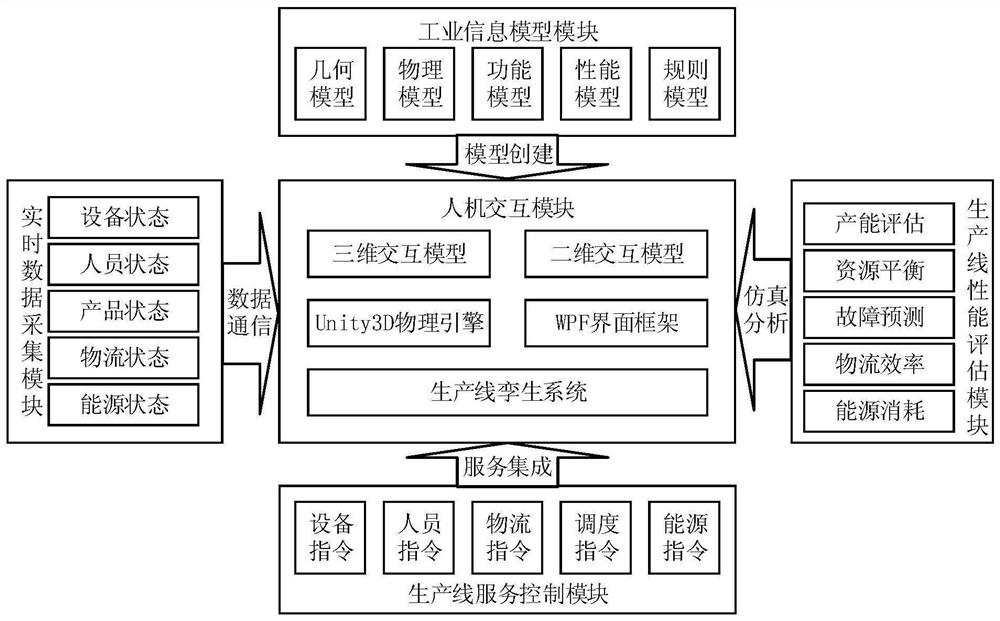

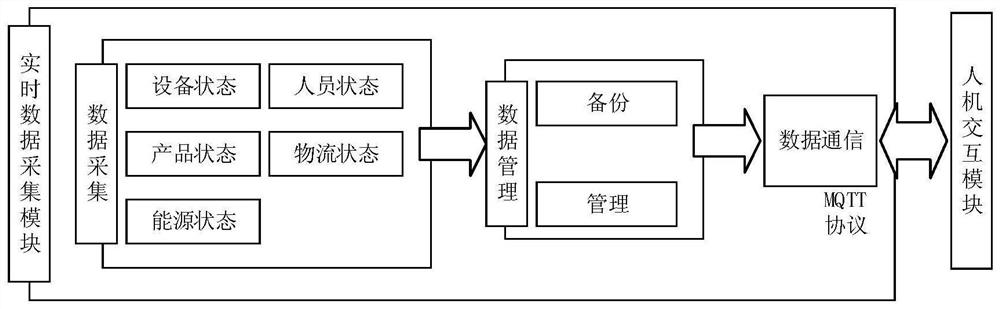

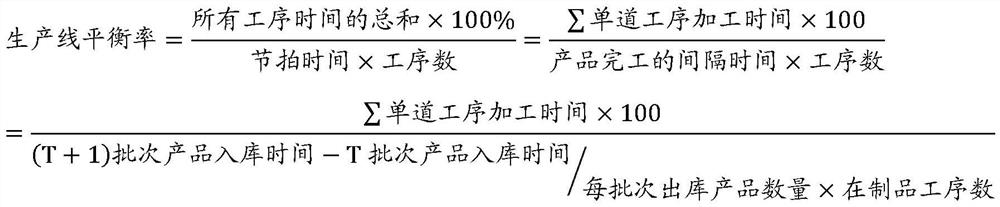

A digital twin system for a production line

ActiveCN111708332BRealize virtual monitoringSimplify the simulation processTotal factory controlProgramme total factory controlNumerical controlData synchronization

The invention discloses a digital twin system of a production line. The system creates a digital twin production line through the instantiation of an industrial information model module, and writes communication and motion control programs based on the Unity3D physics engine to construct a human-computer interaction module of the twin system of the production line; the data acquisition module collects in real time , Analyze the actual state data of the production line, and write a communication program based on the MQTT protocol to realize the data synchronization between the twin system and the physical production line. At the same time, the state data of the production line is managed and forwarded to the production line performance evaluation module; the production line performance evaluation module analyzes the production line operation data, Calculate the performance index of the production line in real time; the production line control service module realizes the control of the production line equipment in the workshop by sending numerical control instructions to the equipment in the system. The invention simplifies the simulation process of the manufacturing execution process of the production line, improves the design efficiency of the simulation system of the production line, and improves the integrated management level of workshop production.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com