Lamina whole life cycle quality traceability system and traceability method

A whole life cycle, traceability system technology, applied in the field of quality traceability system for the whole life cycle of cigarettes. The quality information cannot fully, timely and accurately present the problems of production and management personnel, so as to achieve timely tracking and quality traceability, improve the quality management level of sliced tobacco, and improve the overall management efficiency of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

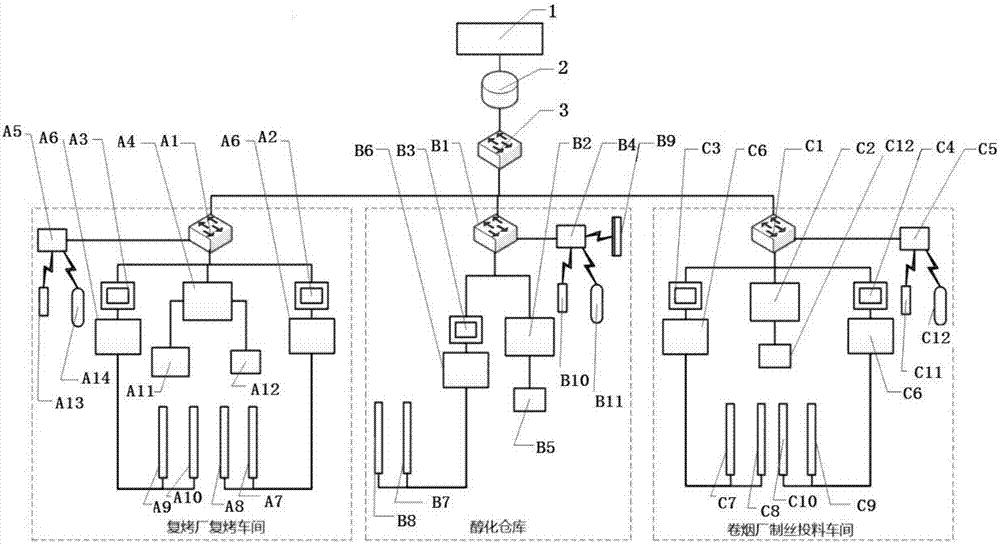

[0040] Such as figure 1 Shown: a quality traceability system for the whole life cycle of cigarettes,

[0041] The system is sequentially connected by the server 1, the database 2, and the main switch 3, and then the main switch 3 is respectively connected to the off-line coding system of the re-baked tobacco production line and the code-scanning system of the re-baked warehouse, and the storage and output of the aging warehouse. Library code scanning and warehouse temperature and humidity collection system, cigarette enterprise formula warehouse silk feeding consumption scanning system; among them:

[0042] The coding system for off-line tobacco production in the rebaking factory and the code scanning system for rebaking out of the warehouse include: the switch A1 is connected to two LED displays A2 and A3, the industrial computer A4, and the wireless access point A5 respectively; two LED displays Each screen is connected to one RFID reader A6, and the two RFID readers A6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com