Quality inspection and supervision method and system

A quality supervision and quality technology, applied in information technology support systems, instruments, data processing applications, etc., can solve problems such as limited detection range and inability to guarantee stable operation of power grids, achieve efficient supervision and management, ensure intrinsic safety and stable operation of power grids , The effect of improving the overall material quality management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

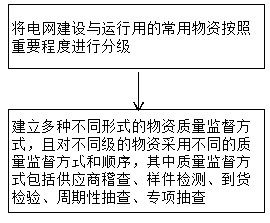

[0019] like figure 1 As shown, this embodiment provides a method for quality inspection and supervision, which includes the following steps: Step S1: Classify the commonly used materials used for power grid construction and operation according to the degree of importance; Step S2: Establish a variety of different forms of material quality supervision methods, And different quality supervision methods and sequences are adopted for different levels of materials, among which quality supervision methods include supplier inspection, sample inspection, arrival inspection, periodic spot check, and special spot check.

[0020] In the quality inspection and supervision method described in this embodiment, in the step S1, the commonly used materials for power grid construction and operation are classified according to their importance, which is conducive to improving the overall material quality management level; in the step S2, a variety of Different forms of material quality supervisi...

Embodiment 2

[0029] This embodiment provides a quality inspection and supervision system, including a grading module and a material quality supervision module, wherein the grading module is used to classify common materials used for power grid construction and operation according to their importance; the material quality supervision module is used for Establish a variety of different forms of material quality supervision methods, and adopt different quality supervision methods and sequences for different levels of materials. The quality supervision methods include supplier audits, sample inspections, arrival inspections, periodic spot checks, and special spot checks.

[0030]The quality inspection and supervision system described in this embodiment includes a grading module and a material quality supervision module, wherein the grading module is used to classify commonly used materials for power grid construction and operation according to their importance, thereby helping to improve the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com