Machine set for spraying number on hot steel billet in real time based on PLC control system

A technology of spraying numbers and steel billets, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc. It can solve problems such as loss of real-time performance, inaccurate numbering, and damage to the surface of steel billets, so as to improve the automation level and labeling The writing is clear and the effect of ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

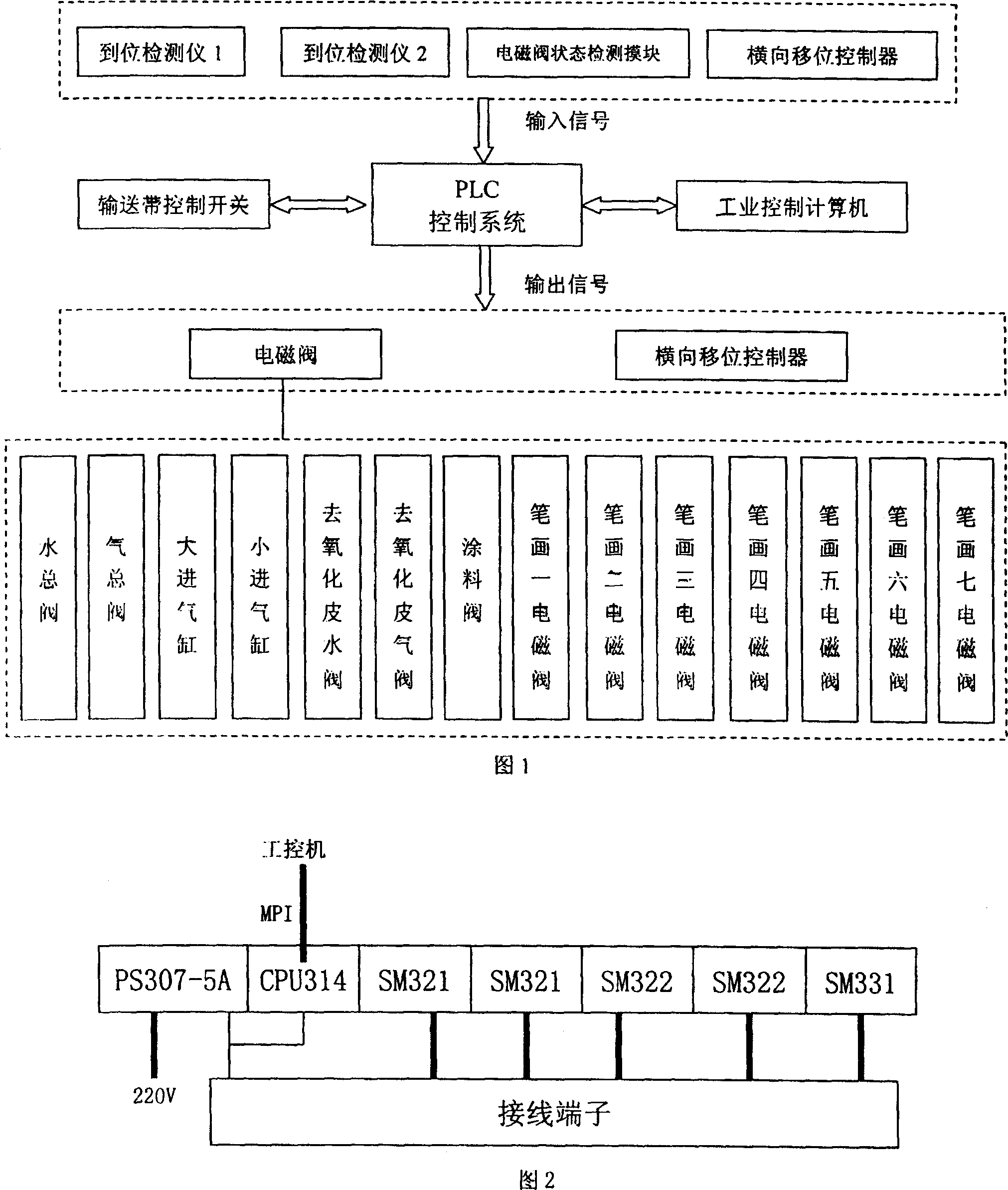

[0025] As shown in Figure 1, the electrical control device is centered on the PLC control system, in which the input module is connected to the mechanical contact in-position detector 1, the infrared heat-collecting hot metal in-position detector 2, the solenoid valve state detection module, and the lateral displacement control The output channel of the device; the output module is connected to the input channel of the solenoid valve and the lateral displacement controller. The PLC control system is connected to the industrial control computer through the MPI network cable, and also connected to the existing start-stop control switch of the conveyor belt through the I / O channel of the PLC. PLC control system and industrial computer are installed in the control room.

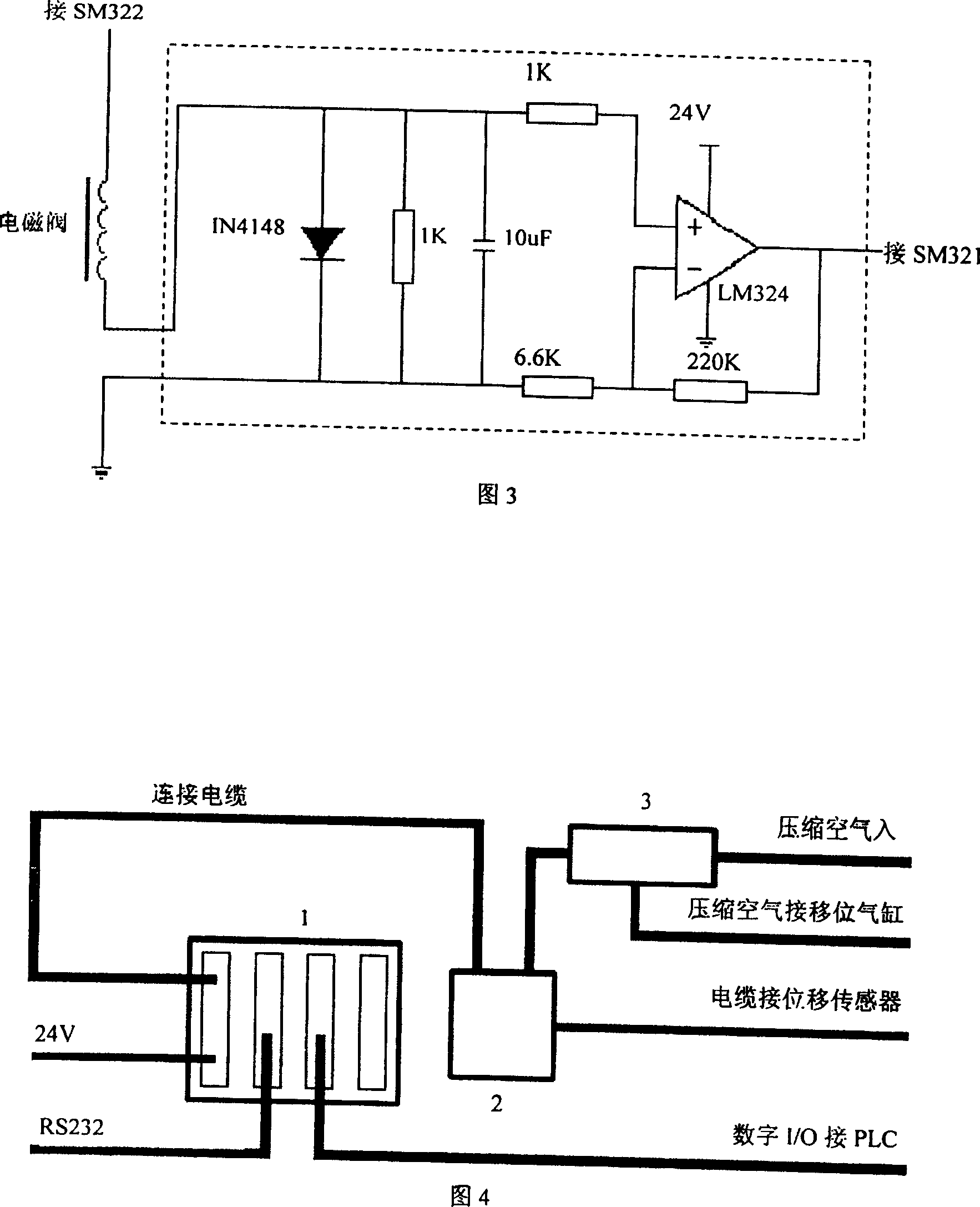

[0026] As shown in Figure 2, the PLC control system takes S7-314 PLC (programmable logic controller) of German Siemens Company as the core, including one power supply module PS307-5A, two 16-point digital input m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com