Central control system for hardfacing production

A central control system, computer technology, applied in manufacturing tools, welding equipment, welding equipment, etc., can solve problems such as inevitable recorded data distortion, and achieve the effect of preventing major quality accidents, making extensive use of value, and avoiding recorded data distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

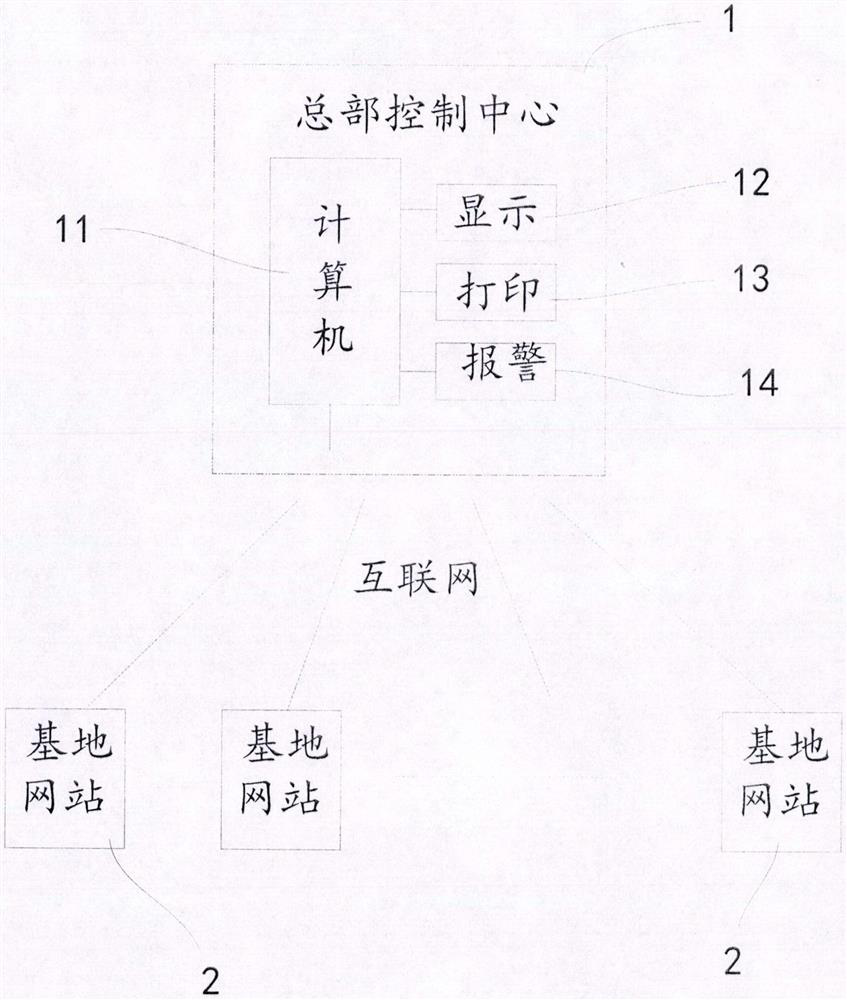

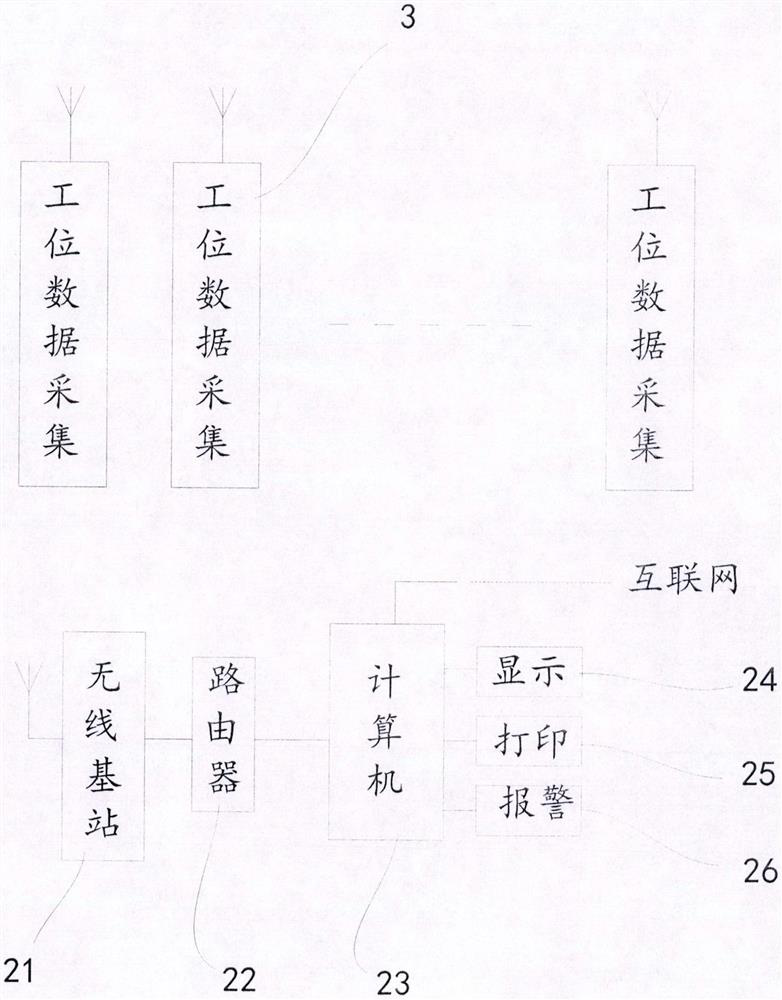

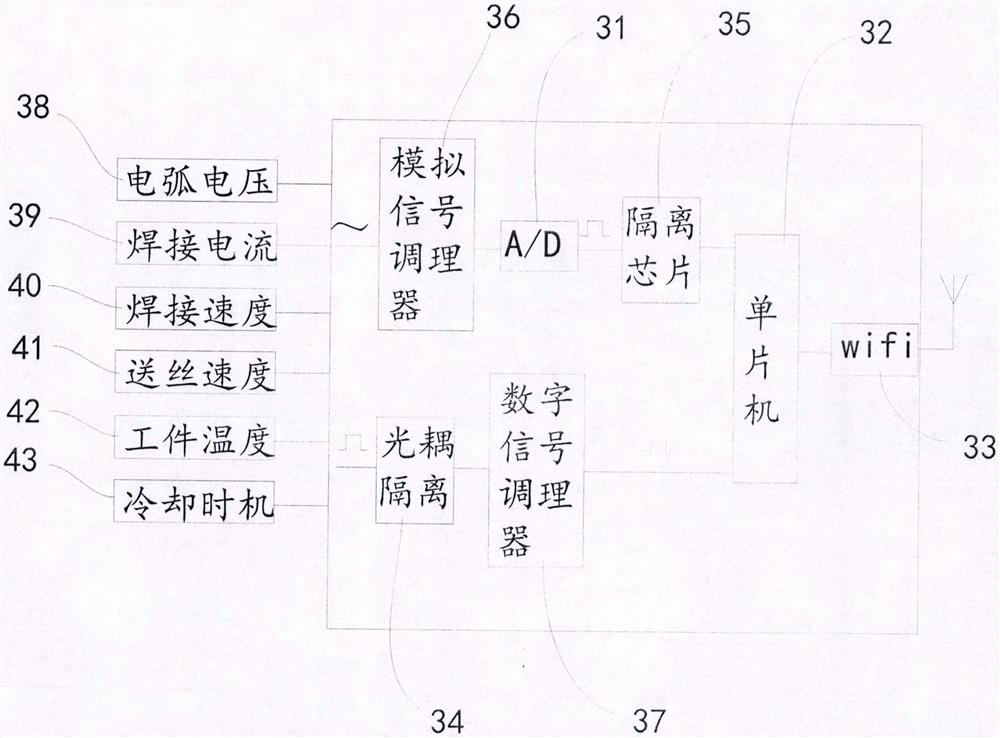

[0026] see figure 1 , figure 2 , image 3 , the central control system for wear-resistant surfacing welding production in a preferred embodiment of the present invention, which includes a headquarters monitoring center 1 and a base website 2, and the headquarters monitoring center 1 is provided with a headquarters computer 11 and an Display 12, printer 13 and alarm device 14, described base website 2 comprises multiple station data acquisition devices 3, wireless base station 21, router 22, base computer 23, display 24, printer 25 and alarm device 26, described multiple The station data acquisition device 3 is connected to the wireless base statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com