Box-shaped object unpacking equipment and unpacking method thereof

A box-shaped object and equipment technology, which is applied to the unsealing, packaging, and packaging protection of objects, and can solve problems such as a large impact on the pick-up rate of defective products, easy scratches, and unsatisfactory results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

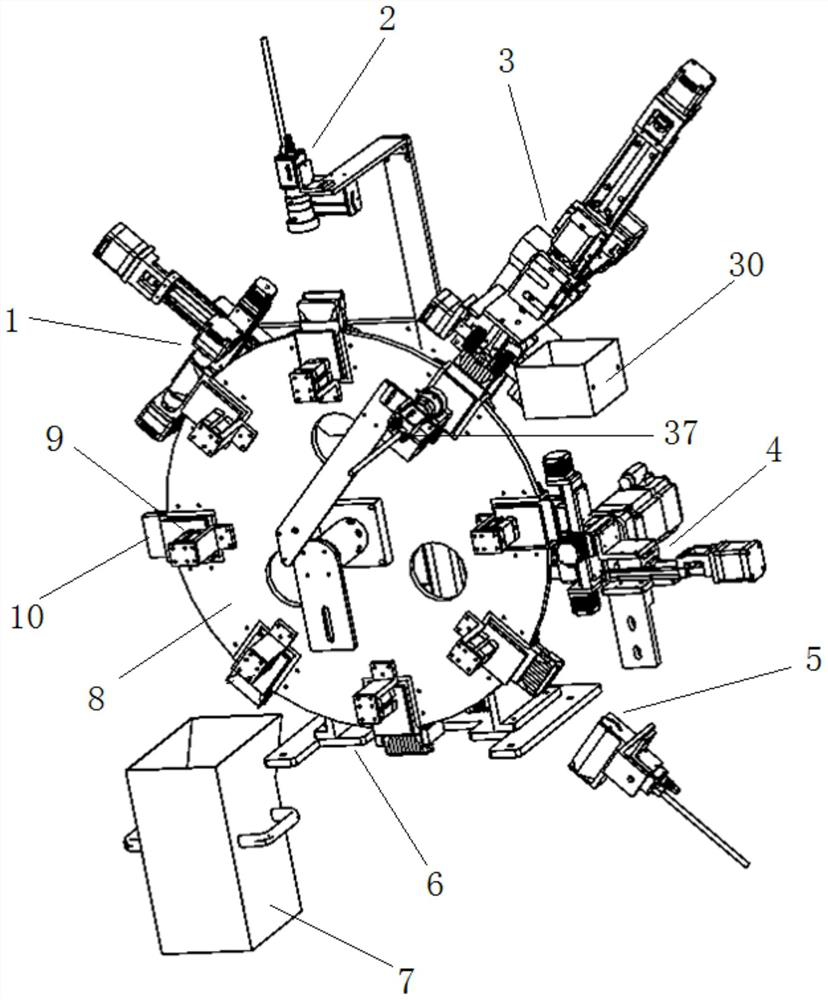

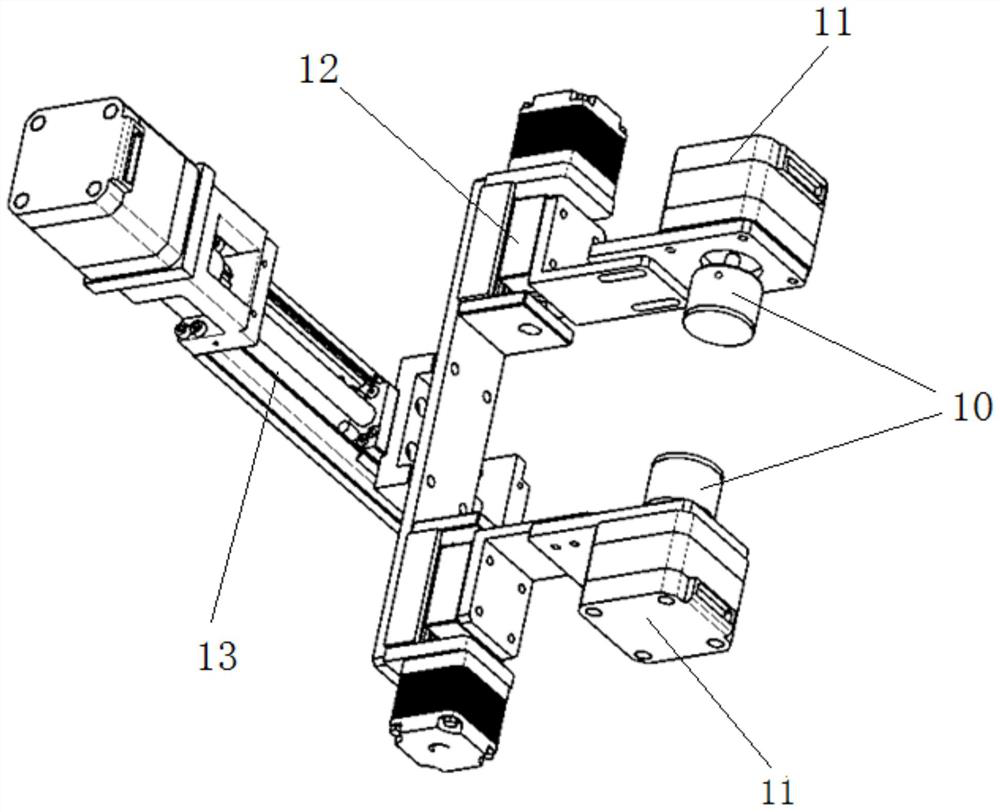

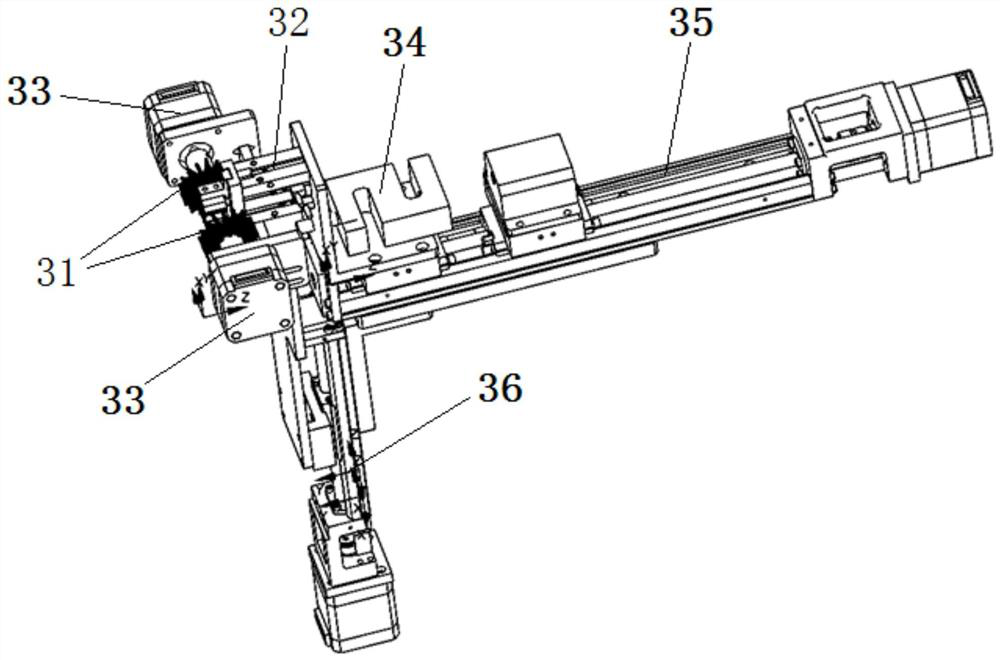

[0044] see figure 1 As shown, the unpacking equipment for a box-shaped object provided by this embodiment includes a rotating wheel 8, a mold box 9, a flip device 1, an aluminum paper tab removal device 3, an aluminum paper stretching device 4 and an extrusion device 6. The mold box 9 is set on the rotating wheel 8, the flip device 1, the aluminum paper pull tab removal device 3, the aluminum paper stretching device 4 and the extrusion device 6 are arranged in sequence along the rotating direction of the rotating wheel 8 and are connected with the mold box 9 correspond. The rotating wheel 8 is arranged on the wheel shaft, and the power device can drive the rotating wheel 8 to rotate. The mold box 9 is used to place the box 14, the cover device 1 is used to clamp the cover of the box 14 and then flipped, the aluminum paper tab removal device 3 is used to remove the aluminum paper tab, and the aluminum paper stretching device 4 is used to Pull apart the aluminum paper, and the...

Embodiment 2

[0069] This embodiment may not be equipped with a rotating wheel structure, that is, a box-shaped object unpacking device provided by this embodiment, including a linear installation platform, a mold box 9, a flip device 1, an aluminum paper pull tab removal device 3, an aluminum paper Stretching device 4 and extrusion device 6, the mold box is set on the linear installation platform, flip device 1, aluminum paper pull piece removal device 3, aluminum paper stretching device 4 and extrusion device 6 are arranged in sequence and move along the linear installation platform The directions are set in sequence and correspond to the mold boxes, and the cigarette packs are disassembled in sequence, and the detection device is also set on the linear installation platform. Other structures are the same or similar to Embodiment 1, and will not be repeated in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com