Traceable QFN bracket structure and design method

A technology of bracket structure and design method, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as difficulty in tracking the position of a single bracket, achieve small size, improve quality management level, and discharge cloth dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

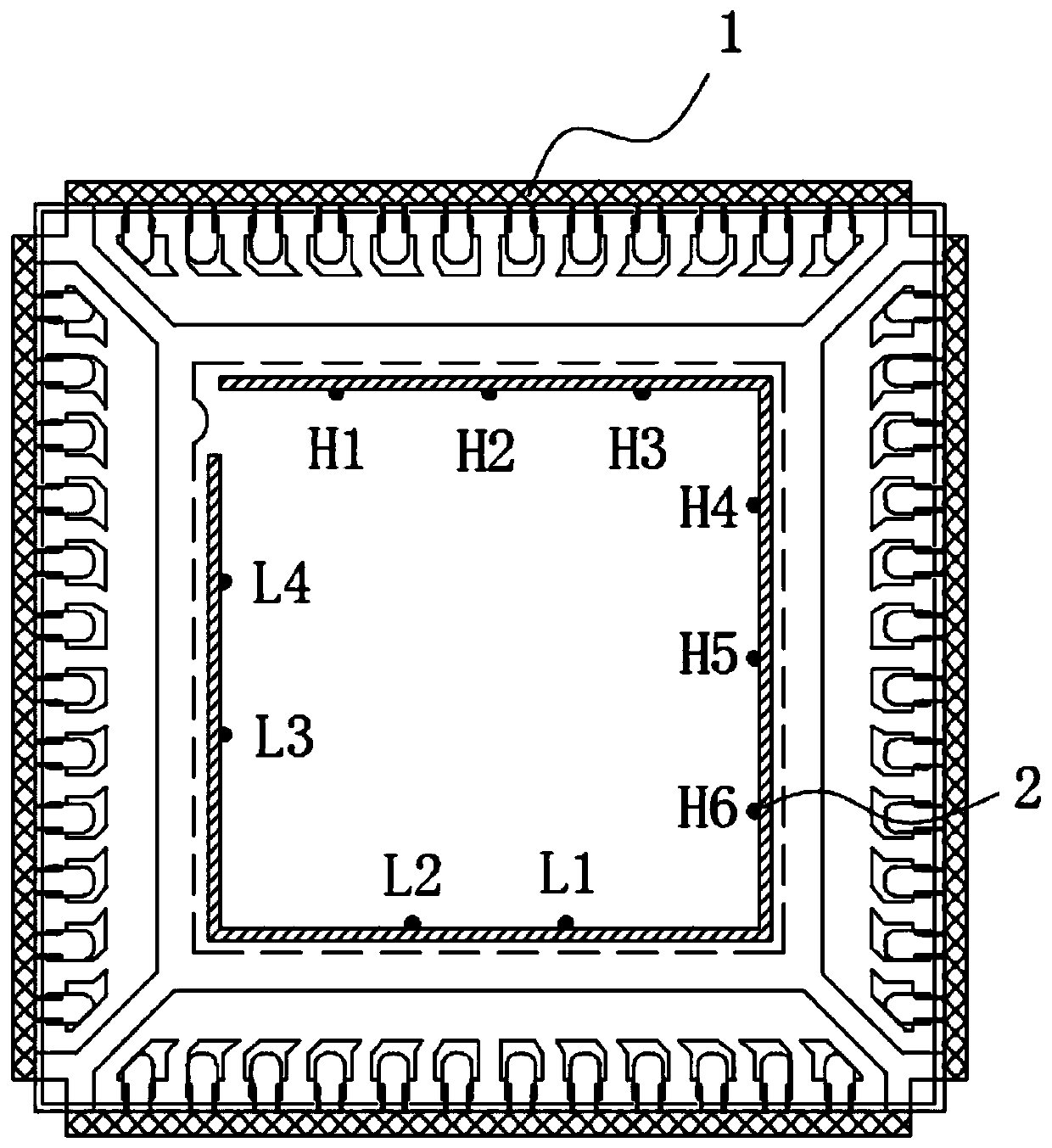

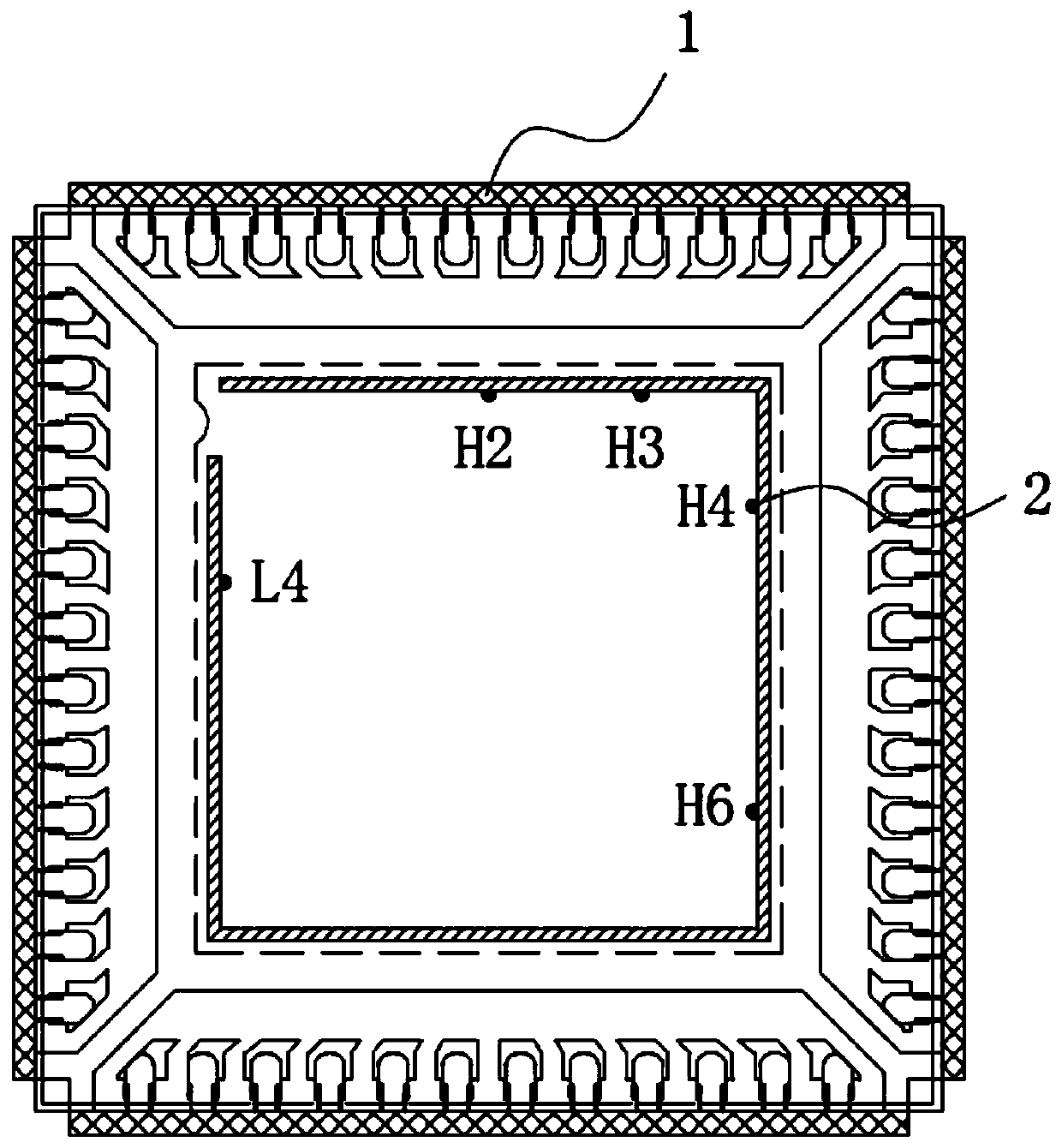

[0031] A traceable QFN scaffold structure, refer to figure 1 , which includes a stent bar (not shown in the accompanying drawings), the stent bar includes several stents 1, the stent 1 is provided with etching marks, and on the stent bars, the etching marks on each support 1 are different; the etching marks include Several etching points 2, and the etching marks are distinguished by the number and position arrangement of etching points 2; in this embodiment, etching points 2 are grooves formed by half etching, wherein the diameter of the groove is greater than 0.08mm and less than 0.12mm, the depth of the groove is greater than 0.08mm and less than 0.12mm, the diameter and depth of the groove in this embodiment are both 0.10mm.

Embodiment 2

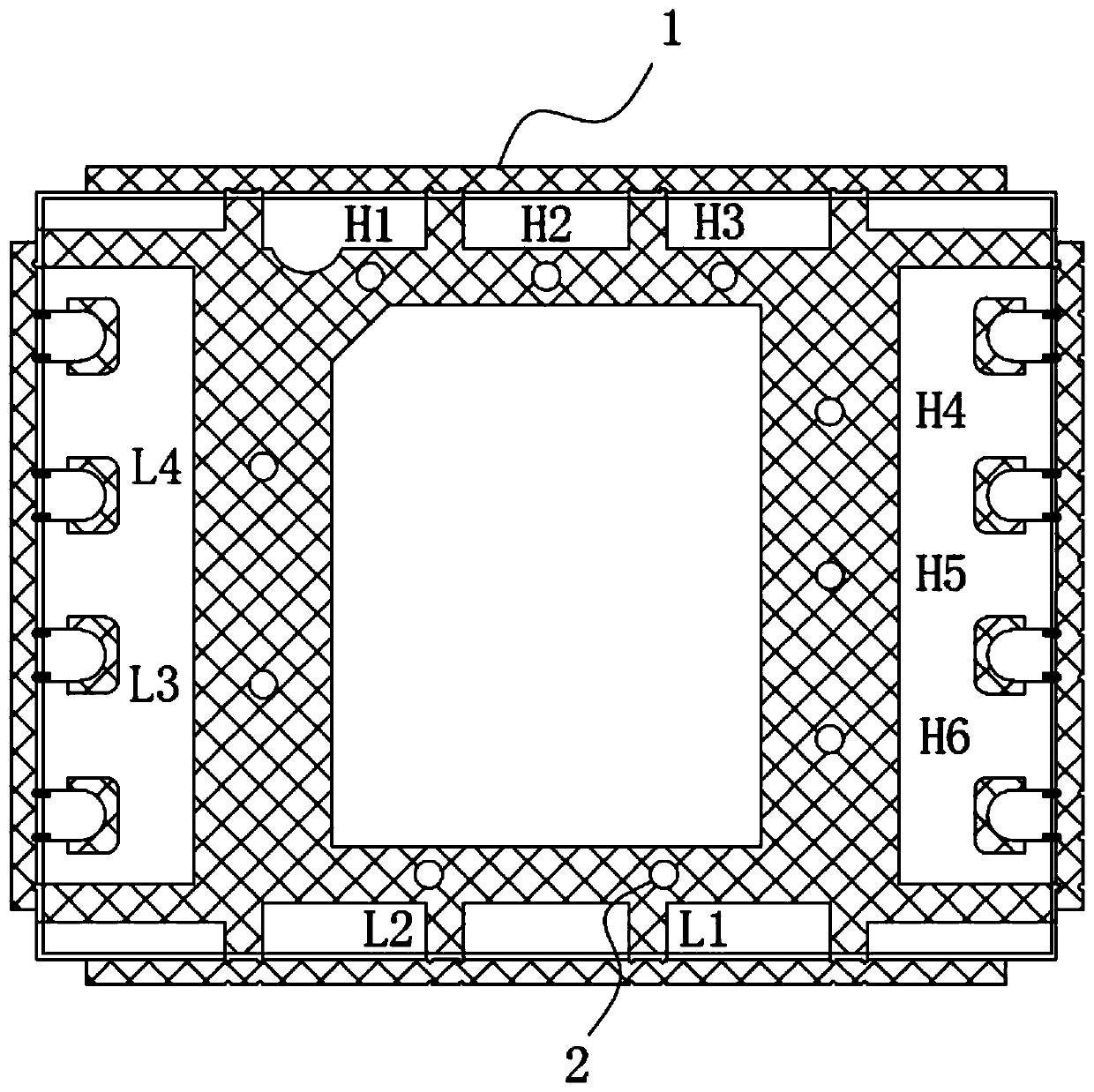

[0033] A traceable QFN scaffold structure, refer to figure 2 , the difference from Example 1 is that the etching point 2 on the bracket 1 in this example is a through hole formed by full etching, wherein the diameter of the through hole is greater than 0.20 mm and less than 0.24 mm, and the diameter of the through hole in this embodiment At the same time, the overall structure of the bracket 1 in the present embodiment is different from that of the bracket 1 in the embodiment 1, but it has no influence, that is, the innovative point of the present invention is applicable to the bracket 1 of various structures.

Embodiment 3

[0035] A traceable QFN stent design method, which includes setting etching marks on a single stent of the stent bar, and making the etching marks on each stent different; the etching marks include several etching points, and define multiple stents on the stent It is used to set the position of etching points, and the etching marks are distinguished by the number and position arrangement of etching points; after the package of the bracket is completed, X-ray irradiation is performed on the package with problems to obtain the X-ray photo of the bracket, and the X-ray photo of the bracket is obtained through X-ray Photophotographs identify the etch marks on the stent and thereby determine the position of the stent on the stent strip.

[0036] refer to figure 1 and figure 2 , the position on the support 1 for setting the etching point 2 includes four single sides arranged in a rectangular shape, each single side defines a plurality of point positions, and the distributed design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com