Cigarette product quality defect prevention and control learning system and method based on big data

A product quality and learning system technology, applied in neural learning methods, electronic digital data processing, digital data information retrieval, etc., can solve problems such as unfavorable enterprise production costs, cigarette product quality defects, cigarette brand influence, etc., to improve skills, The effect of high accuracy and accurate recommendation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

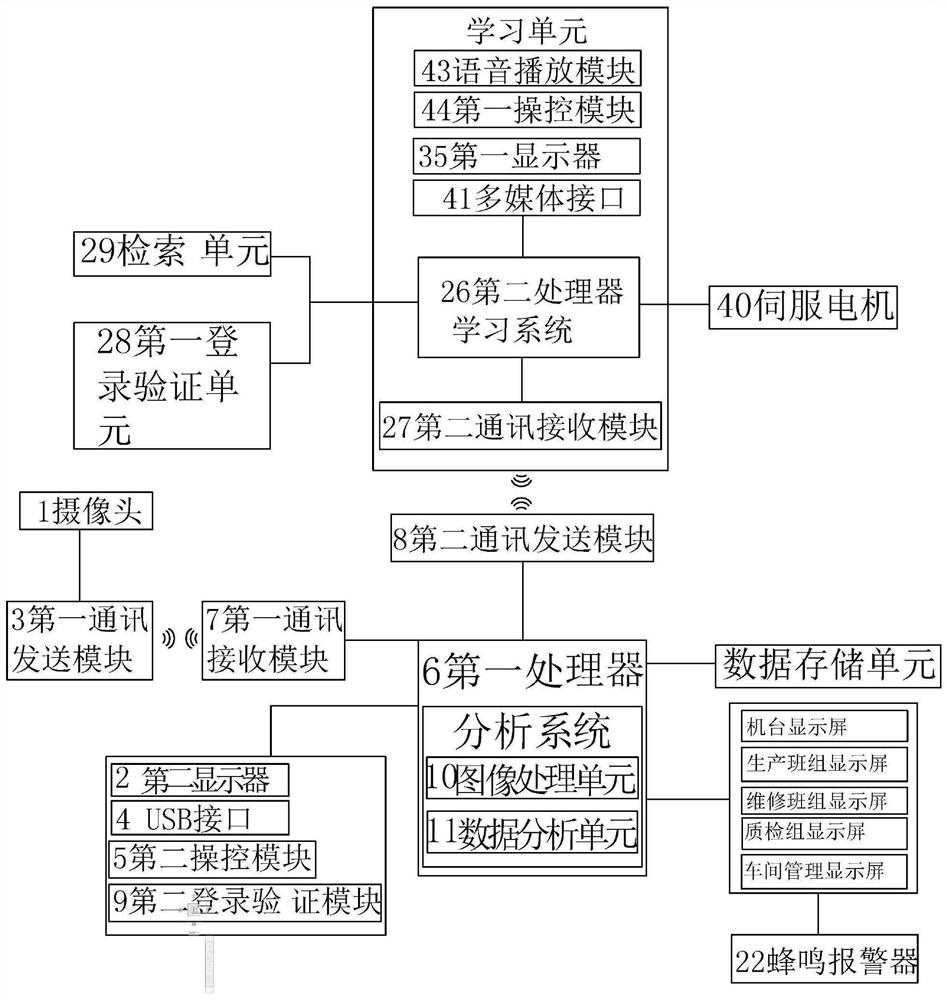

[0047] This embodiment is a big data-based cigarette product quality defect prevention and control learning system, such as Figure 1-6 As shown, it includes a data acquisition unit, a data processing unit, a data storage unit and a learning unit;

[0048] The data acquisition unit includes a camera 1 and a second display 2 installed on the cigarette production line. The camera 1 is electrically connected to a first communication sending module 3 that transmits images captured by the camera 1 , and the second display 2 is electrically connected to the first processor 6 . For connection, the second display 2 is provided with a USB interface 4 and a second control module 5 , and the second control module 5 is electrically connected to the first processor 6 .

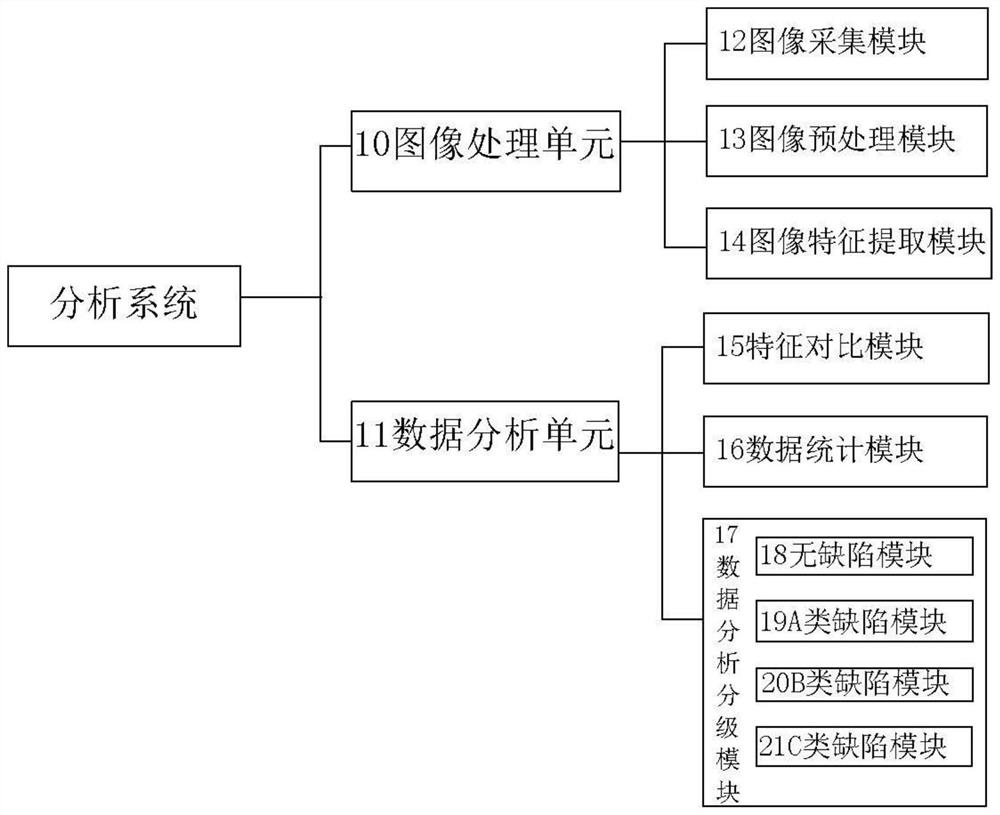

[0049] The data processing unit includes a first processor 6, the first processor 6 is electrically connected with a first communication receiving module 7 and a second communication sending module 8, and the first communi...

Embodiment 2

[0054] This embodiment is a big data-based learning method for prevention and control of cigarette product quality defects, such as Figure 7-8 shown, including the following steps:

[0055] S1, the camera photographs the cigarettes on the production line to form a photographed image, and transmits the image to the image processing unit through the first communication transmission module and the first communication receiving module, and the image acquisition module collects the image;

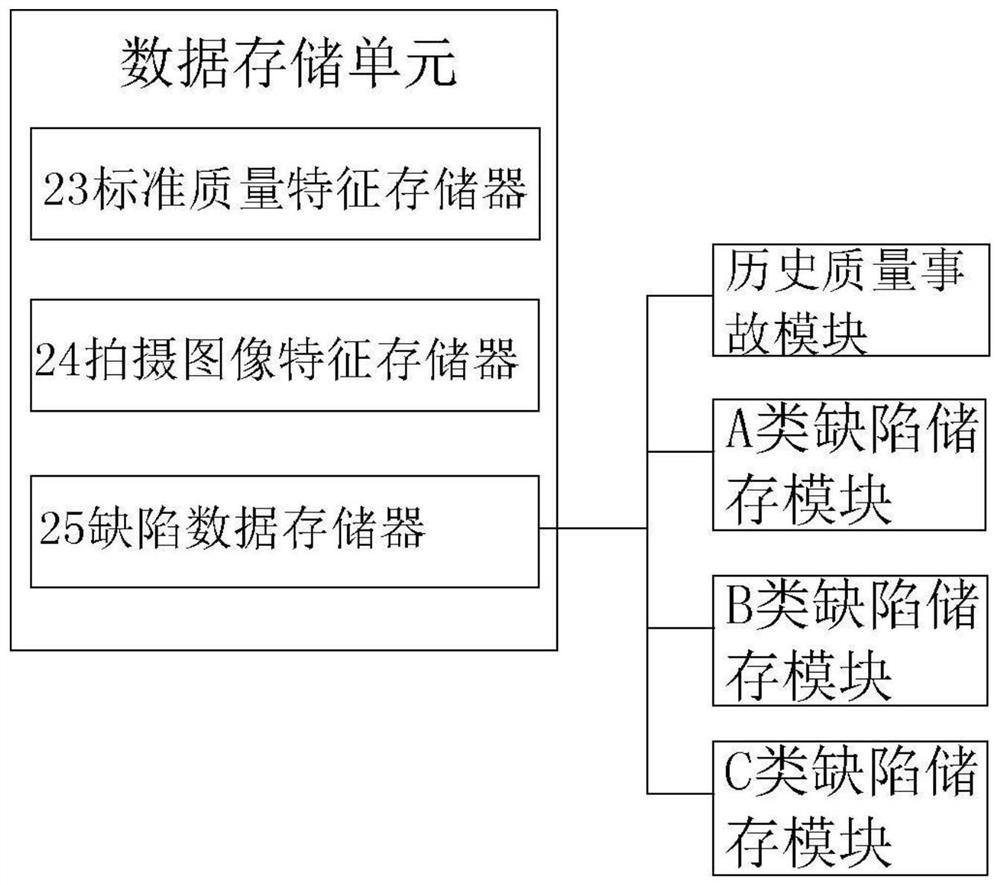

[0056] S2. Manually enter the cigarette defect problem images found in the work into the defect data storage through the USB interface and the second control module, so as to enrich the entire defect storage and analysis database;

[0057] S3. The image preprocessing module performs filtering, enhancement, smoothing and sharpening processing on the collected image electronic signals, so as to make the image clear and ensure the image quality, wherein the method for preprocessing the image inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com