Automobile chassis integrated with hub motor drive device

An in-wheel motor and motor-driven technology, applied in power units, control devices, motion deposition, etc., can solve the problems of poor chassis performance, low degree of freedom of suspension arrangement, and difficulty in generalizing the in-wheel motors of front and rear wheels. pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

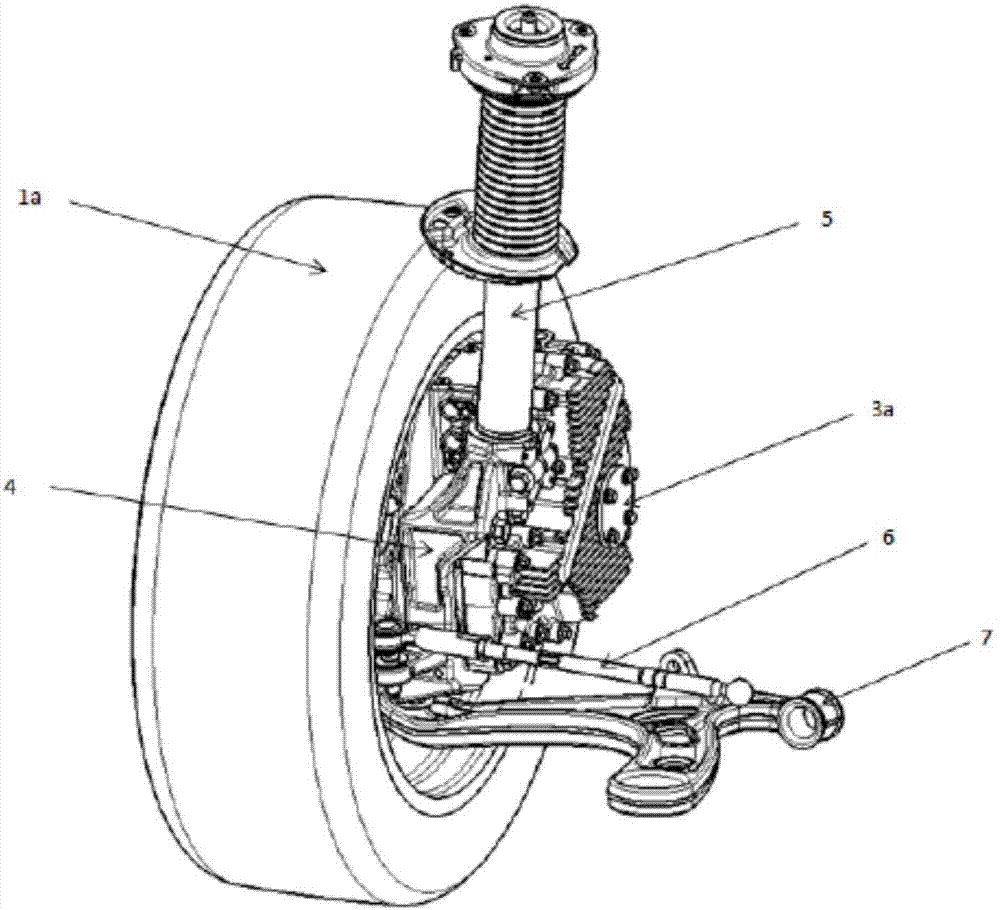

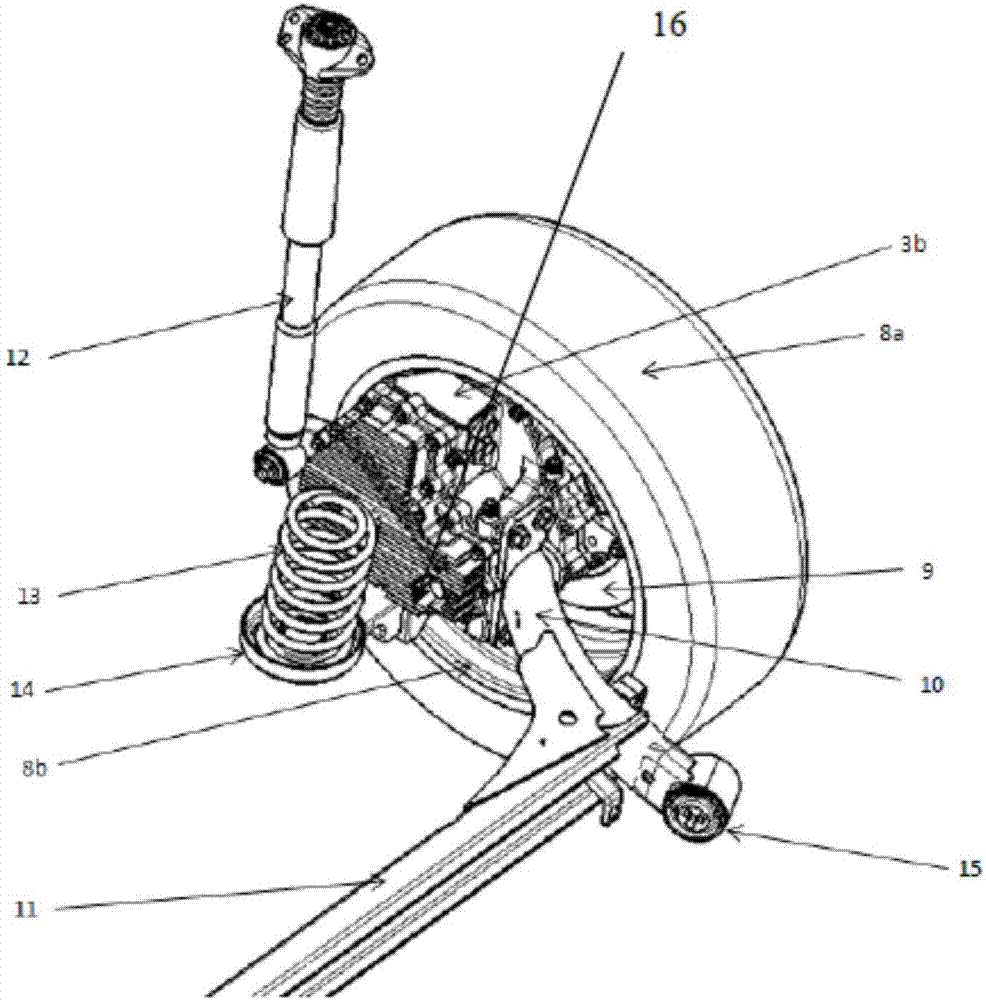

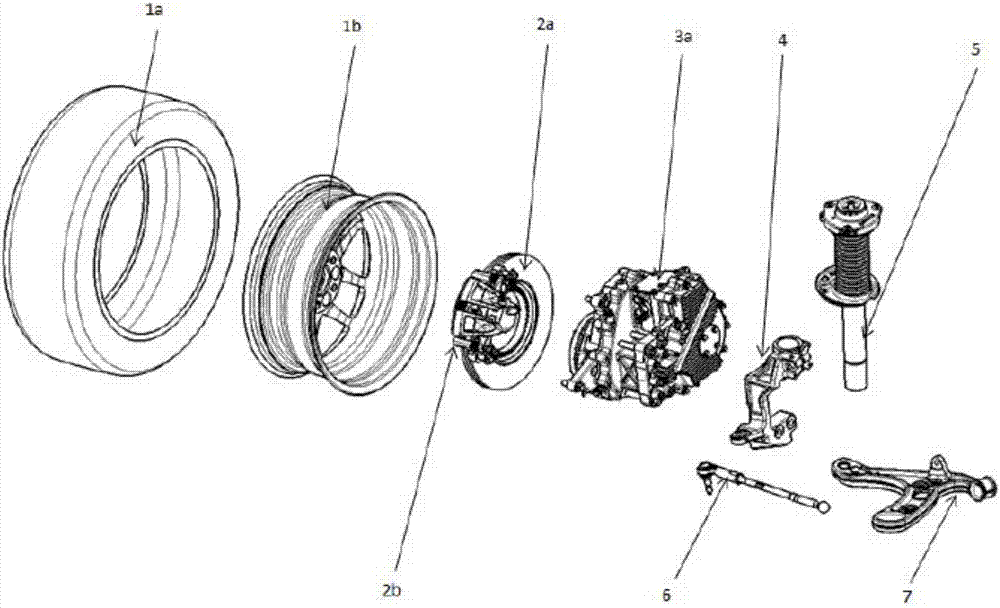

[0024] An embodiment of the present invention provides an automobile chassis integrating a wheel hub motor drive device, the automobile chassis includes a front wheel drive assembly and a rear wheel drive assembly, wherein the front wheel drive assembly is composed of a wheel hub motor with a parallel shaft reducer , McPherson front suspension, braking system and steering system, etc. The rear wheel drive assembly is composed of a hub motor with a parallel shaft reducer, torsion beam non-independent rear suspension, braking system and steering system, etc. .

[0025] Specifically, an embodiment of the present invention provides an automobile chassis integrated with an in-wheel motor drive device, including a front-wheel drive assembly and a rear-wheel dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com