Method and device for detecting vehicle front wheel angle

An angle detection and front wheel technology, applied in the field of machinery, can solve the problems of complex and huge structure, inconvenient testing, inability to accurately reflect the front wheel angle detection device, etc., and achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

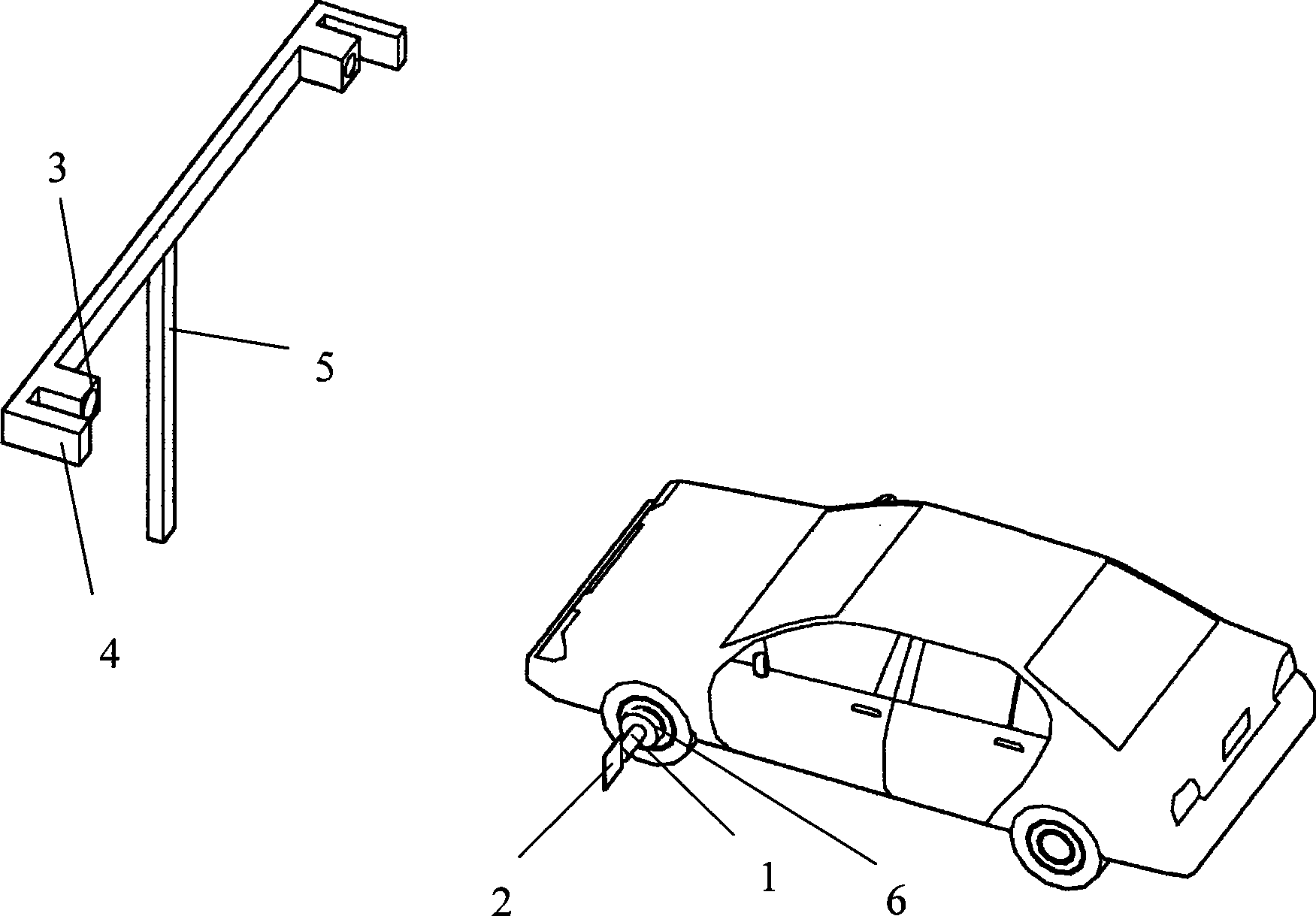

[0013] Such as figure 1 As shown, the automobile front wheel angle detection method of the present invention includes a process of recording the movement state of the front wheels of the automobile, wherein, in the process of recording the movement state of the front wheels of the automobile, the outer end faces of the two front wheels of the automobile are respectively A connecting rod 1 is fixed, and a flat plate 2 is fixedly connected to the outer end of any one of the connecting rods 1, the axial direction of the connecting rod 1 passes through the flat plate 2, and a video camera is respectively fixed in front of the two front wheels 3. A laser pointer 4 is respectively fixed in front of the two front wheels. The radial section of the laser beam of the laser pointer 4 is cross-shaped, and the laser beam of the laser pointer 4 is respectively projected onto one of the Push the car forward or backward on the flat panel 2, and use the camera 3 to record the projected positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com