Method and device for detecting movement track of automotive tire

A technology of automobile tires and motion tracks, which is applied in the field of machinery, can solve the problems of complex structure, inconvenient testing, and inaccurate reflection of wheel alignment detection devices, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

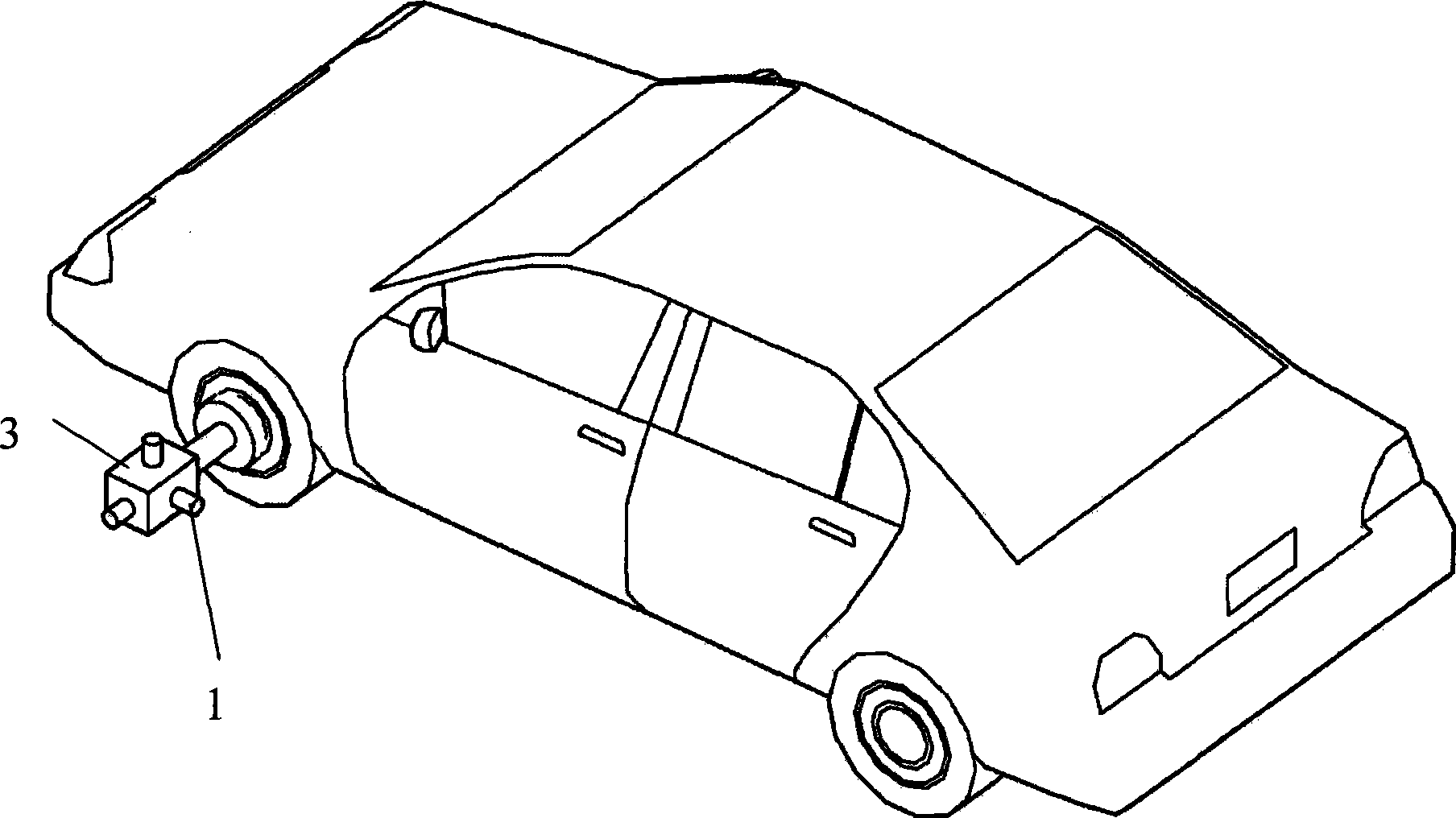

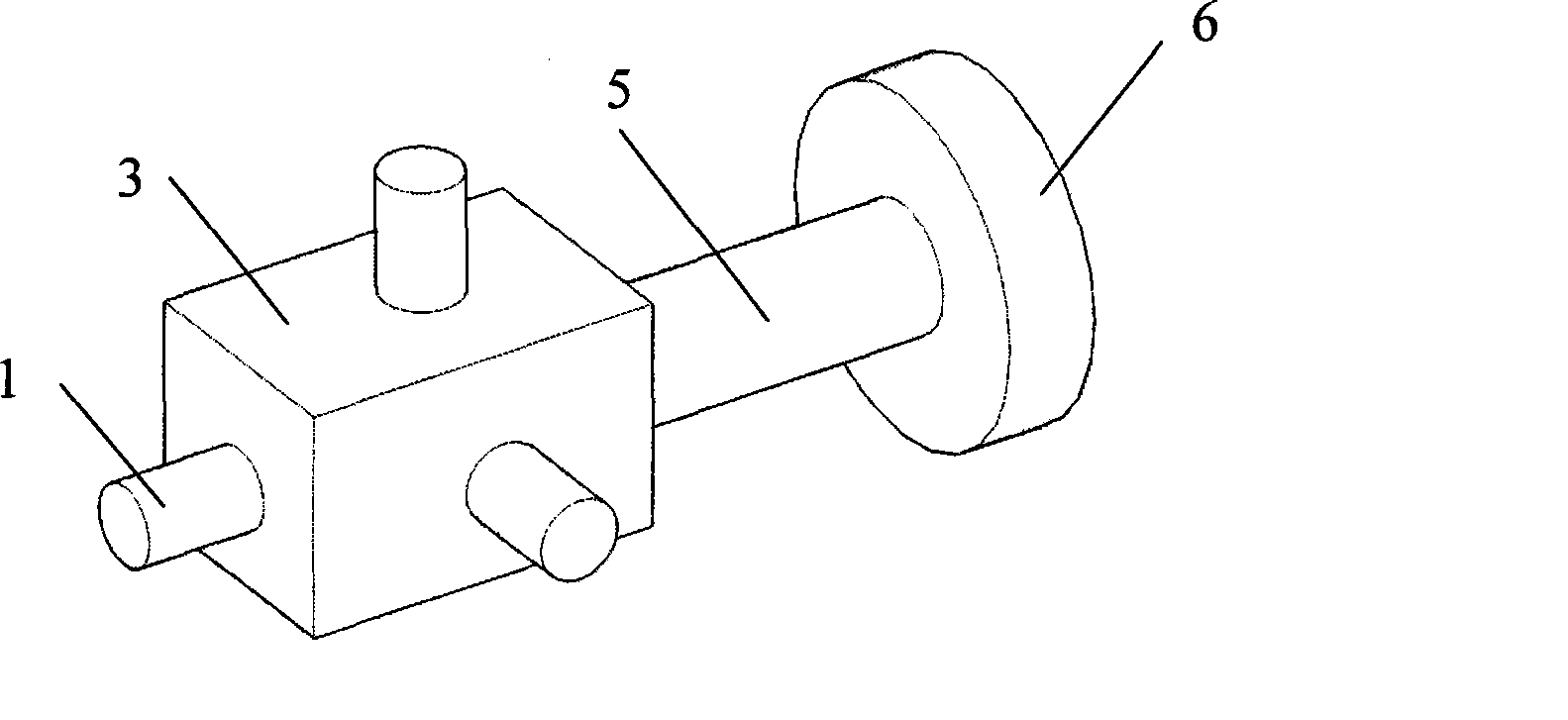

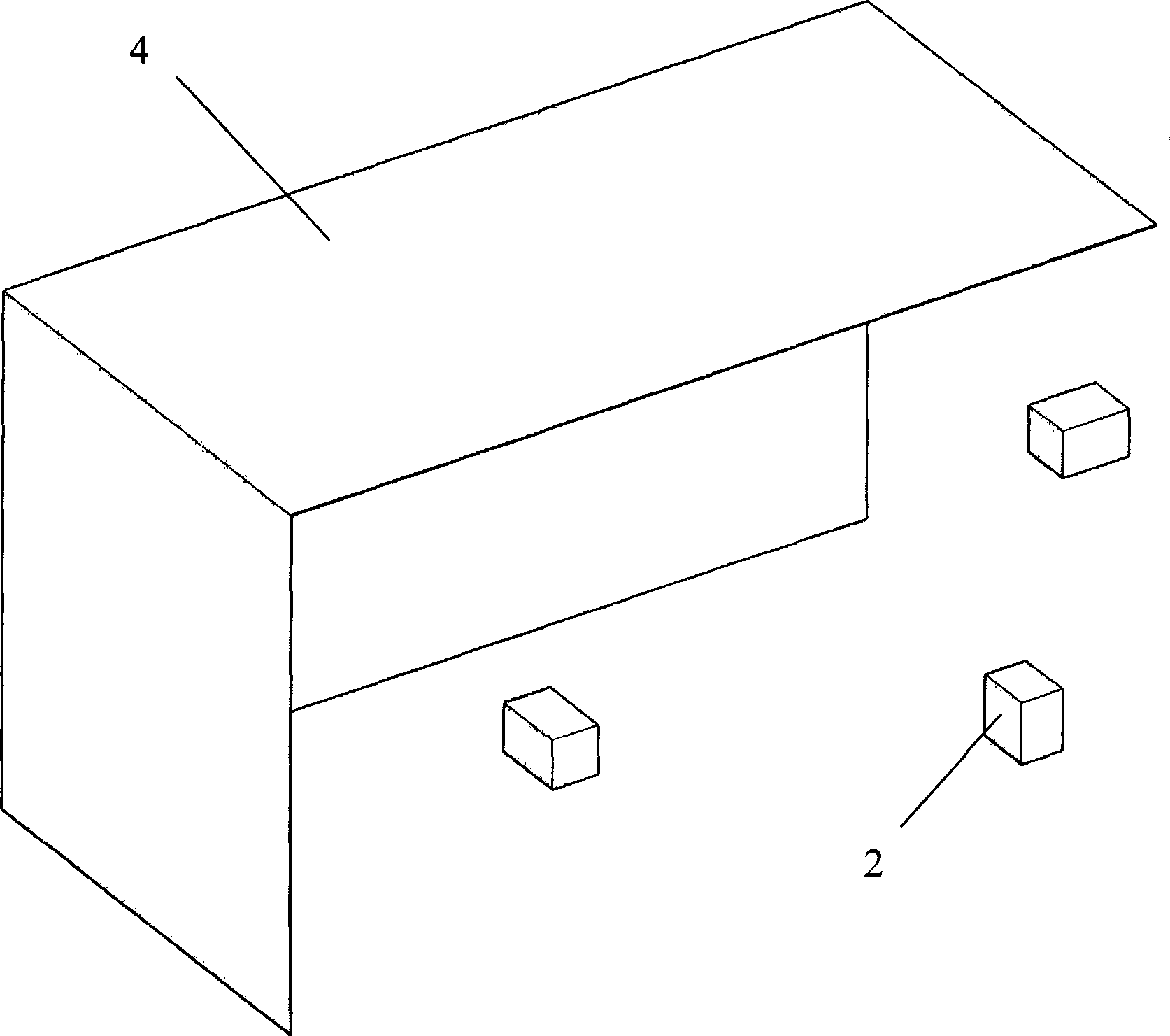

[0015] like figure 1 , figure 2 and image 3 As shown in the figure, the method for detecting the motion track of an automobile tire of the present invention includes a process of recording the motion track of the automobile tire, wherein, in the process of recording the motion track of the automobile tire, three laser indicators are fixedly connected on the outer end face of the automobile tire device 1, adjust the laser projection directions of the three laser pointers 1 to be perpendicular to each other and intersect, and use the three laser pointers 1 to project laser beams on three mutually perpendicular projection screens to push the car forward or Back up, the camera 2 is used to record the positions of the laser beams on the three mutually perpendicular projection screens. Finally, mathematical methods are used to calculate the caster angle of the wheel, the inclination angle of the kingpin, Front camber and front toe.

[0016] Further, after the tire of the car to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com