Automotive disc-type steering joint integrated with steering arm and processing technology of steering joint

A processing technology and steering arm technology, applied in the field of automobile disc steering knuckle and its processing technology, can solve the problems of increased difficulty, heavy overall weight, difficult processing, etc., and achieve the effect of ensuring mechanical performance, scientific structure, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

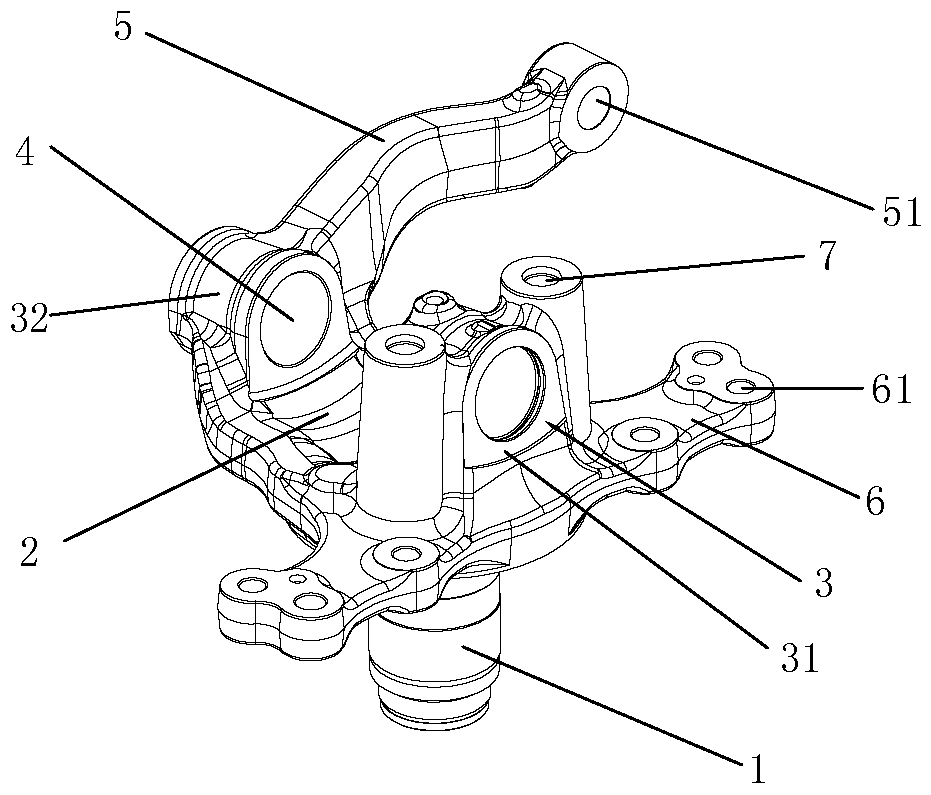

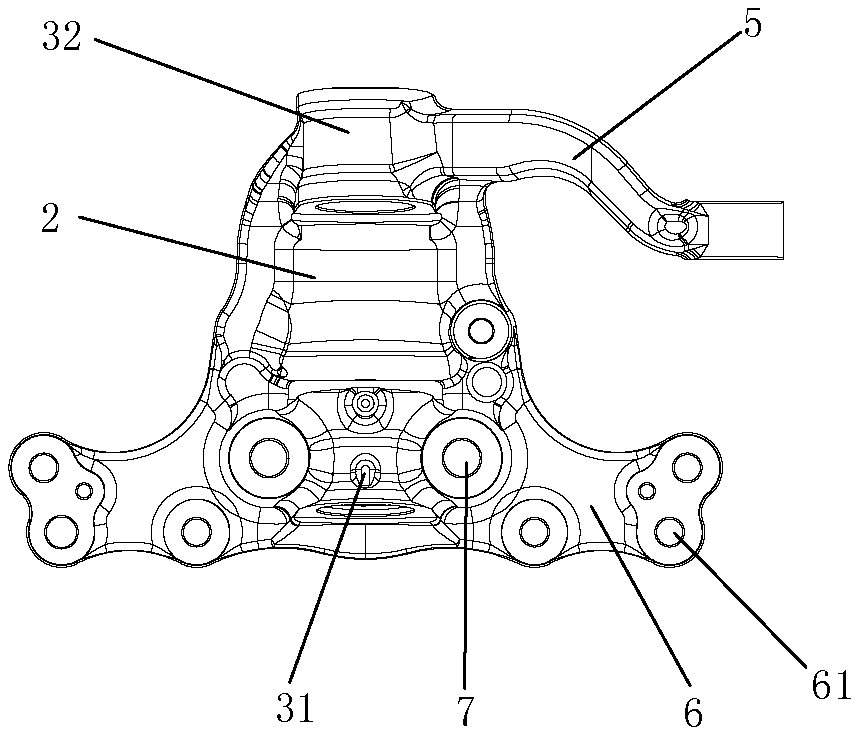

[0024] Such as figure 1 , figure 2 As shown, the automobile disc steering knuckle integrally formed with the steering arm in this embodiment includes a rod part 1, a disc part 2, and an ear part 3, and the ear part 3 includes a long ear 31 and a short ear 32. The ear 31 and the short ear 32 are respectively provided with a kingpin hole 4, and the front end of the short ear 32 protrudes sideways on a plane perpendicular to the kingpin hole 4 to the steering arm 5 for connecting with the steering tie rod. The section is integrally forged and formed, and the long ears 31 on the plane where the disc portion 2 is located extend horizontally to both sides of the connecting arm 6 connected to the brake caliper, and the connecting arm 6 and the kingpin hole 4 form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com