Transmission mechanism

A transmission mechanism and motor vehicle technology, applied in transmission control, transmission parts, movable seats, etc., can solve the problems of enlarged structural space and impact, and achieve the effects of compact structure, reduced manufacturing cost, and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

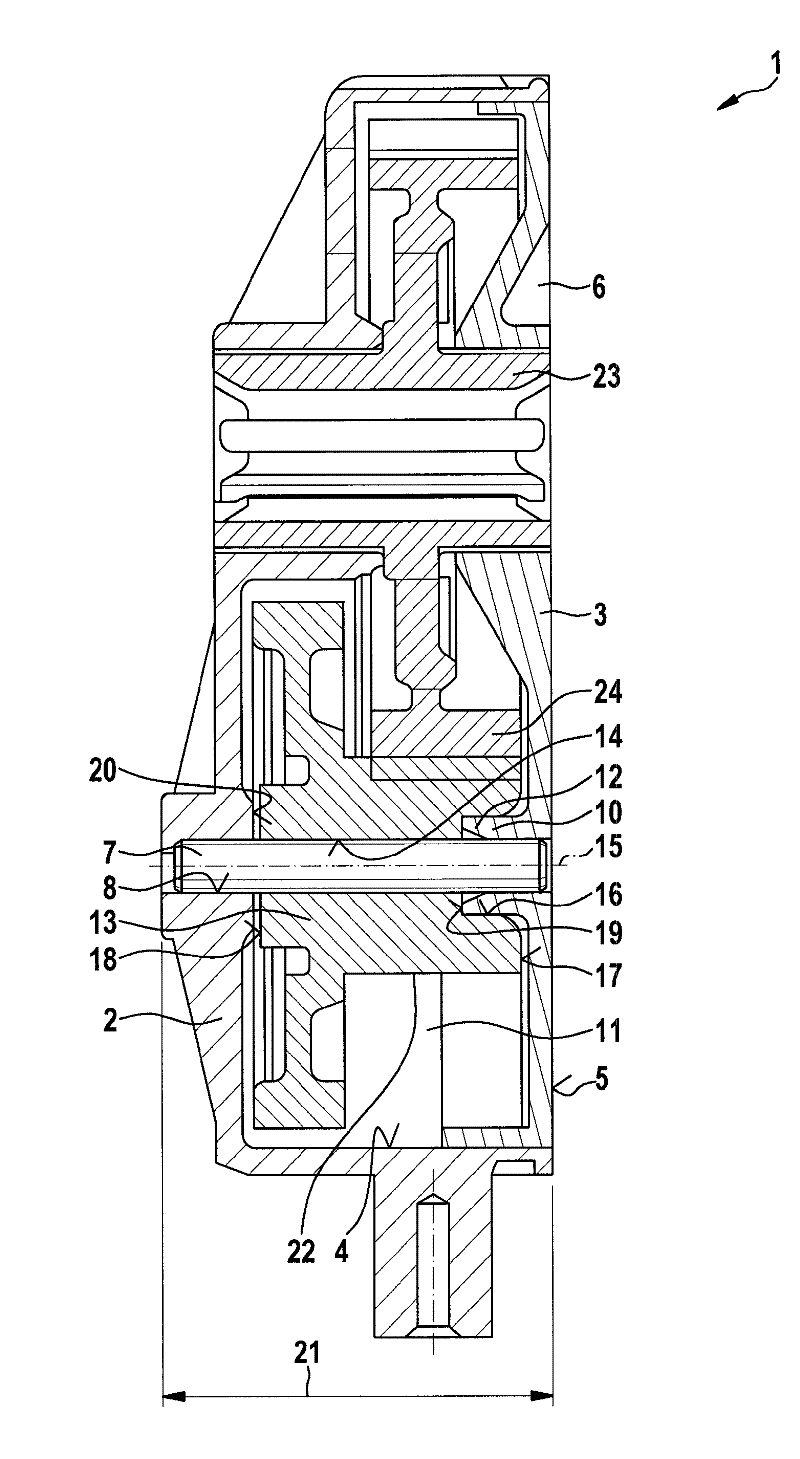

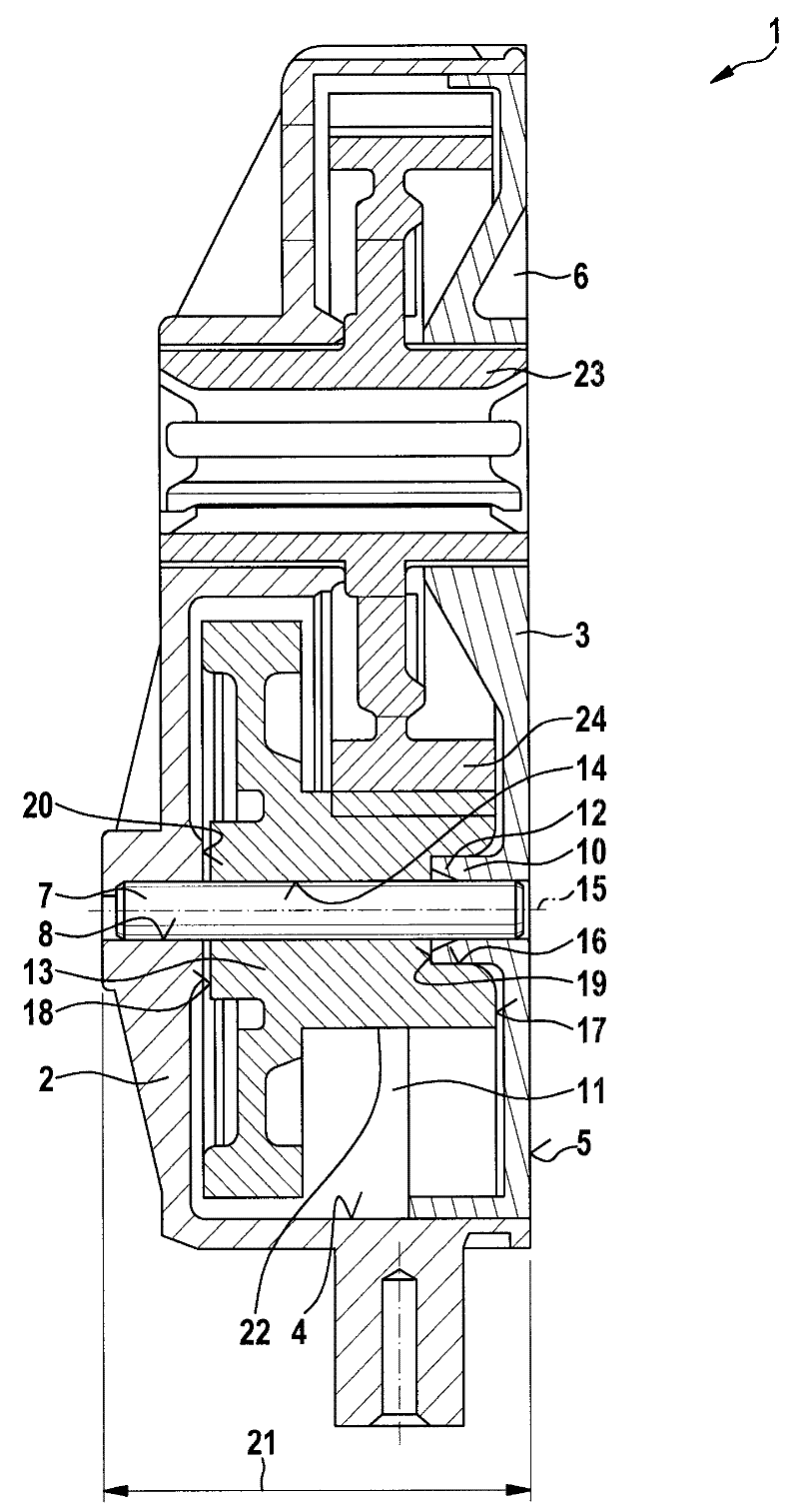

[0014] figure 1 A schematic axial sectional view of a part of a transmission corresponding to an embodiment of the invention is shown. The transmission mechanism 1 is particularly suitable for devices for adjusting motor vehicle seat parts operated by external force. In this case, for example, the adjustment of the seat back can be carried out by means of the transmission 1 via the seat adjustment motor. However, the transmission 1 according to the invention is also suitable for other applications.

[0015] The transmission 1 has a transmission housing part 2 . The housing 2 of the transmission 1 is here formed in the exemplary embodiment by a mechanism housing part 2 . Of course, such a housing can also be composed of a plurality of transmission mechanism housing parts. Furthermore, the gear mechanism 1 has a gear mechanism cover 3 which is inserted into the mechanism housing part 2 at the inner wall 4 of the mechanism housing part 2 . In this case, the gear mechanism co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com