Separating device for removing solid particles from liquid and gas flows for high differential pressures

A separation device and solid particle technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of point pressure load sensitivity, loss of filter function, complex components, etc., and achieve good pressure difference resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0197] Example 1: Calculation of the height of the compensating bush

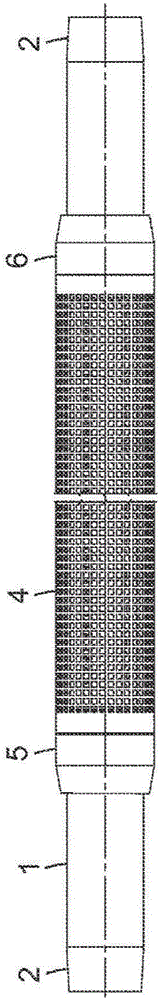

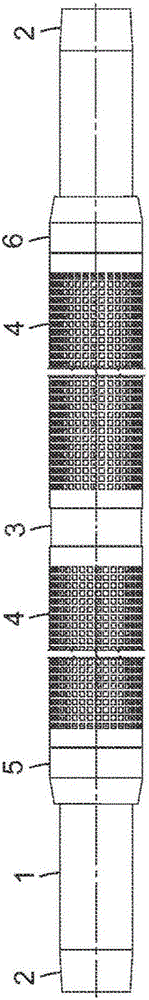

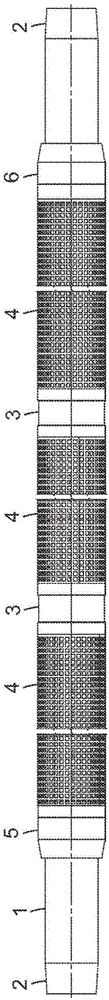

[0198] will be based on the basis of the present invention Figure 3a-Figure 3b The separating device is inserted into the borehole. At the location where the separation device is inserted, a temperature of 150° C. prevails. Steel L80 was used as material for the base pipe. Sintered silicon carbide (SSiC; 3M TM Type F silicon carbide, ESK Ceramics) was used as the material for the annular stack. In order to compensate for the different thermal expansions of the base pipe and the annular stack, compensating bushings of PTFE (polytetrafluoroethylene) are used at one or both ends of the annular stack. The PTFE compensating bushing has the effect of preventing a gap larger than the required filter width from forming between the annular disks at higher temperatures where it is inserted.

[0199] Height H of PTFE compensating bushing K Calculated according to the following formula

[0200] h K =ΔL / (α*ΔT...

Embodiment 2

[0207] Example 2: Calculation of the height of the compensating bush

[0208] According to the basis of the present invention Figure 3a-Figure 3b The separation device is used at a temperature of 200°C. The height of the ring stack is 1500mm. Steel 1.4563 ( Alloy 028) was used as material for the base tube. Sintered silicon carbide (SSiC; 3M TM Type F silicon carbide, ESK Ceramics) was used as the material for the annular stack. Thermal expansion coefficient α of the material used for the base pipe 钢 15.2*10 -6 / K; linear expansion ΔL of the base pipe in the temperature range from 20 to 200 °C 基管 (according to ΔL 基管 = L 基管 *α 钢 *ΔT) is 1500mm*15.2*10 -6 / K*180K, so 4.1mm. Thermal Expansion Coefficient α of SSiC Materials for Annular Stacks SSiC 2.8*10 -6 / K; linear expansion ΔL of an annular stack of silicon carbide in the temperature range from 20 to 200 °C 环形叠堆 (according to ΔL 环形叠堆 = L 环形叠堆 *α SSiC *ΔT) is 1500mm*2.8*10 -6 / K*180K, so 0.76mm. The dif...

Embodiment 9 to 14

[0217] Examples 9 to 14: Testing of Internal and External Voltage Resistance

[0218] In a hyperbaric chamber, tests of internal pressure resistance (burst pressure test), i.e., subjecting the separation device to internal pressure, and tests of external pressure resistance (collapse pressure test), i.e., subjecting the separation device to external pressure, are performed with The separation device according to the invention was carried out as well as with the reference separation device. The test setup and procedure corresponded to ISO 17824, first edition, 2009-08-15, setup and method shown in appendices A (collapse pressure test) and B (burst pressure test).

[0219] The inner diameter of the plenum chamber is 80mm and the usable length is 500mm. Through a pneumatically driven piston pump (GRACO X-treme Model 70, manufactured by Graco Inc., Russell J. Gray Technical Center, 88-11 Northeast Avenue, Minneapolis, MN 55413, USA Technical Center, 88-11th AvenueNortheast, Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com