Rotor pump

A rotor pump and rotor technology, which is applied to rotary piston pumps, pumps, pump components, etc., can solve the problems of cumbersome disassembly and assembly, high use and maintenance costs, and complex wear-resistant plate technology, so as to reduce replacement costs and prolong use. Effect of life and axial load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

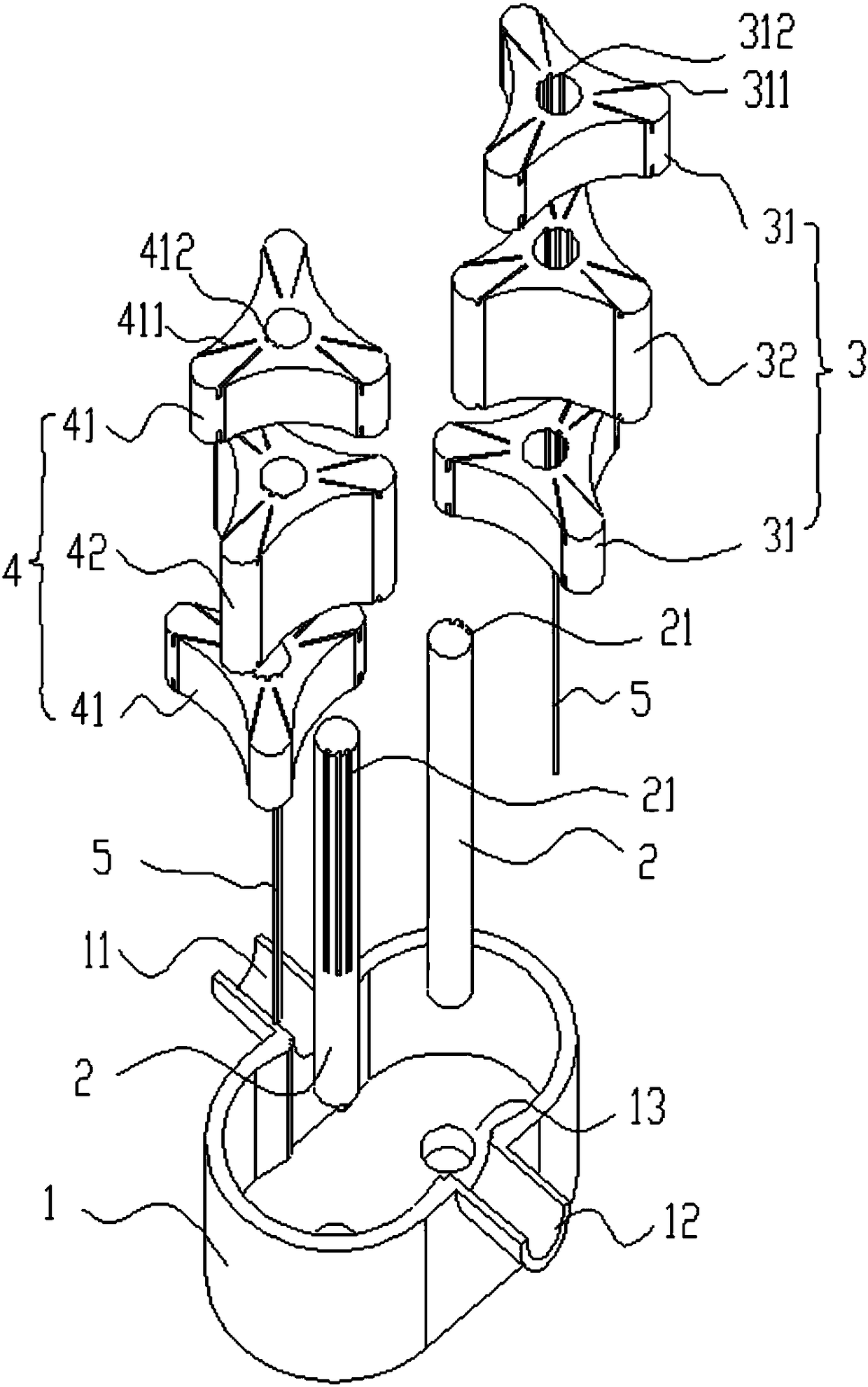

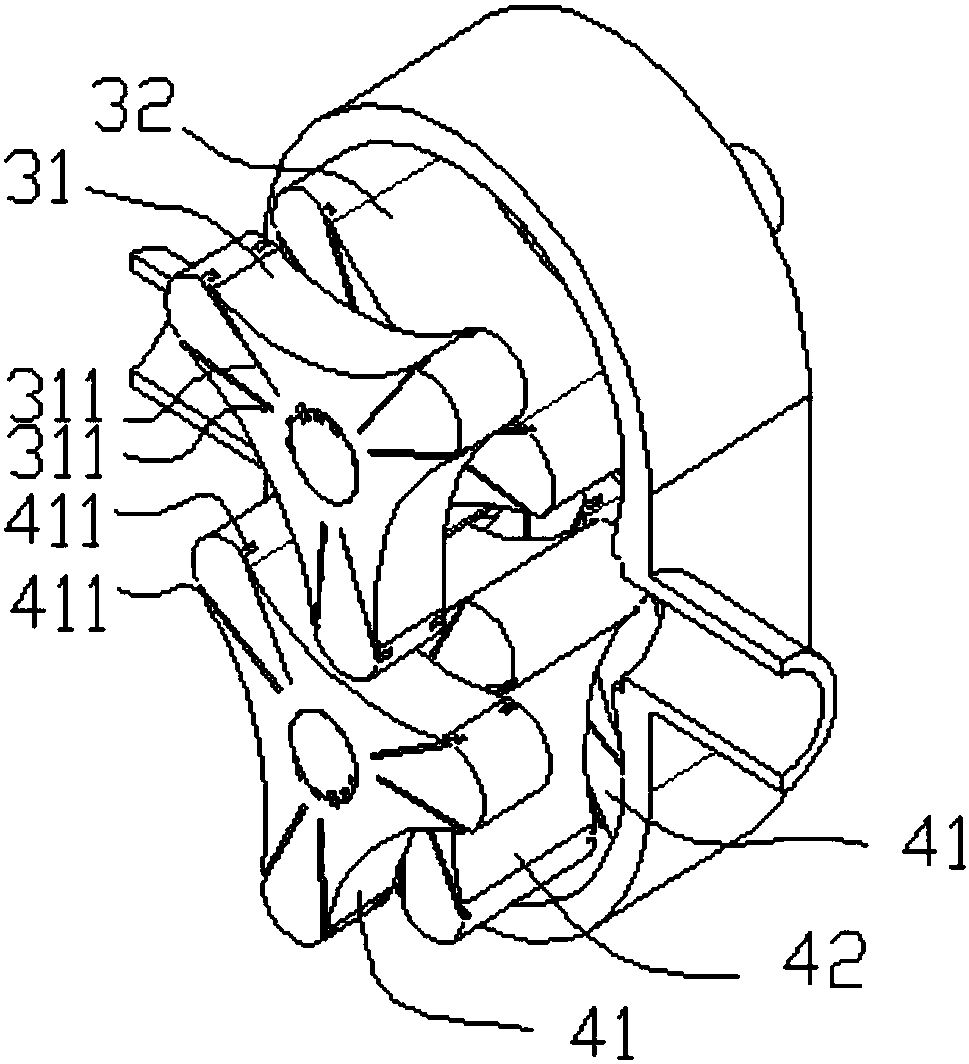

[0033] Such as figure 2 and image 3 As shown, when the rotor pump is applied in the case of high pressure difference and low viscosity fluid medium, multiple linear rotors of the driving rotor 3 and the driven rotor 4 are assembled with interleaving and equal phase difference, and each linear rotor is circumferentially symmetrical and has at least two blades , forming a symmetrical and uniform helical rotor structure.

[0034] The driving rotor 3 and the driven rotor 4 are engaged and installed in the pump body 1 according to the phase difference. When the driving rotor 3 drives the driven rotor 4 to rotate at high speed, the use effect of the helical rotor structure will be similar to that of the helical rotor pump. Compared with linear rotor pumps, screw rotor pumps have stable fluid medium pressure fluctuations.

[0035] In addition, due to the different thicknesses of multiple linear rotors, the relatively thick active linear rotor 2 32 faces the liquid inlet 11 and li...

Embodiment 2

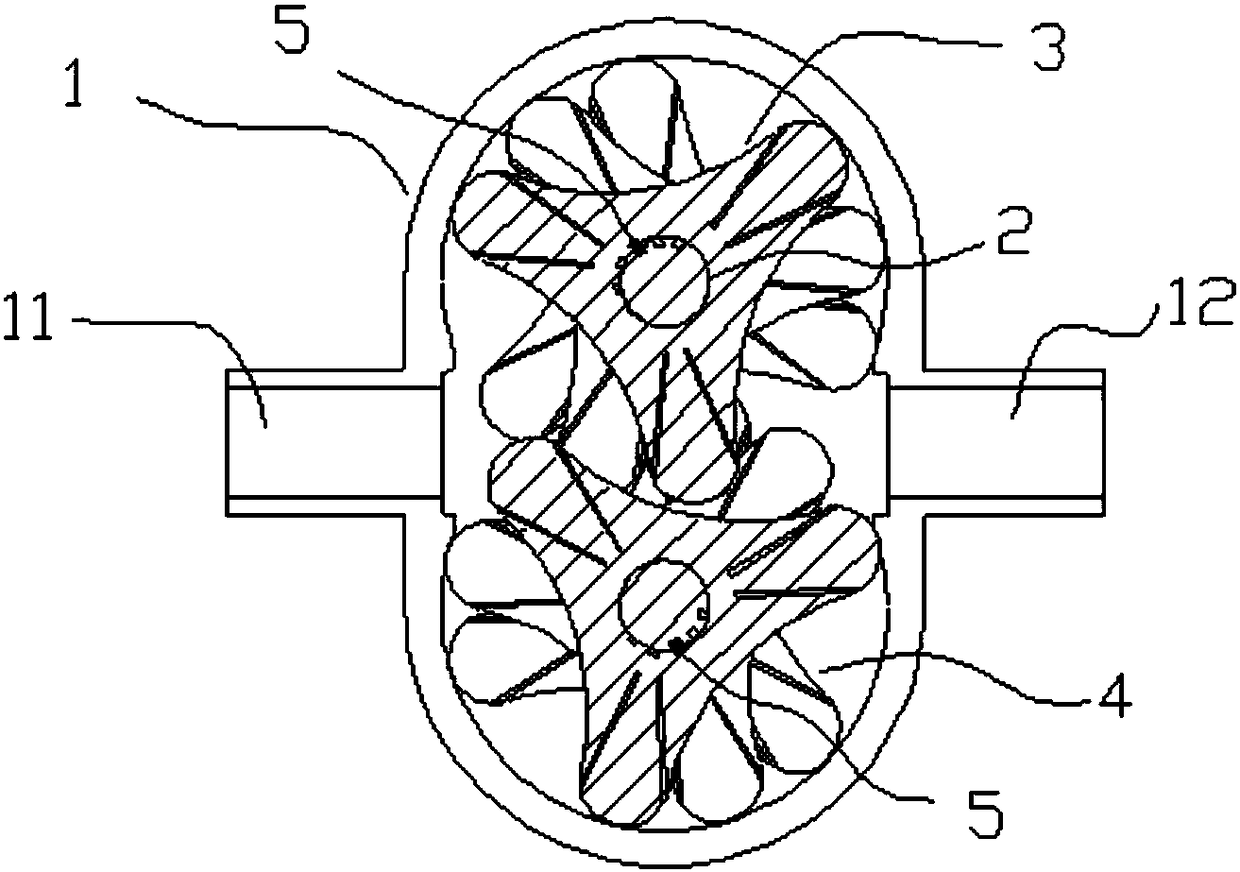

[0038] Such as Figure 4 and Figure 5As shown, when the rotor pump is applied in the case of low pressure difference and high viscosity fluid medium, multiple linear rotors of the driving rotor 3 and the driven rotor 4 are stacked and assembled, and each linear rotor is circumferentially symmetrical and has at least two blades to form a linear rotor. Rotor structure.

[0039] The driving rotor 3 and the driven rotor 4 are installed in the pump body 1 according to the phase difference. When the driving rotor 3 drives the driven rotor 4 to rotate at a low speed, the low-speed high-viscosity fluid is not sensitive to the pressure fluctuation of the fluid medium, and it is difficult to cause cavitation phenomenon without damaging the linear rotor structure.

[0040] In addition, due to the different thicknesses of the multiple linear rotors, the relatively thick active linear rotor 2 32 is facing the liquid inlet 11 and the liquid outlet 12 of the pump body 1, and the relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com