Cylindrical cutter

A cylindrical milling cutter and cutting edge technology, applied in milling cutters, forming cutters, milling machine equipment, etc., can solve problems such as the influence of lateral force on strip running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

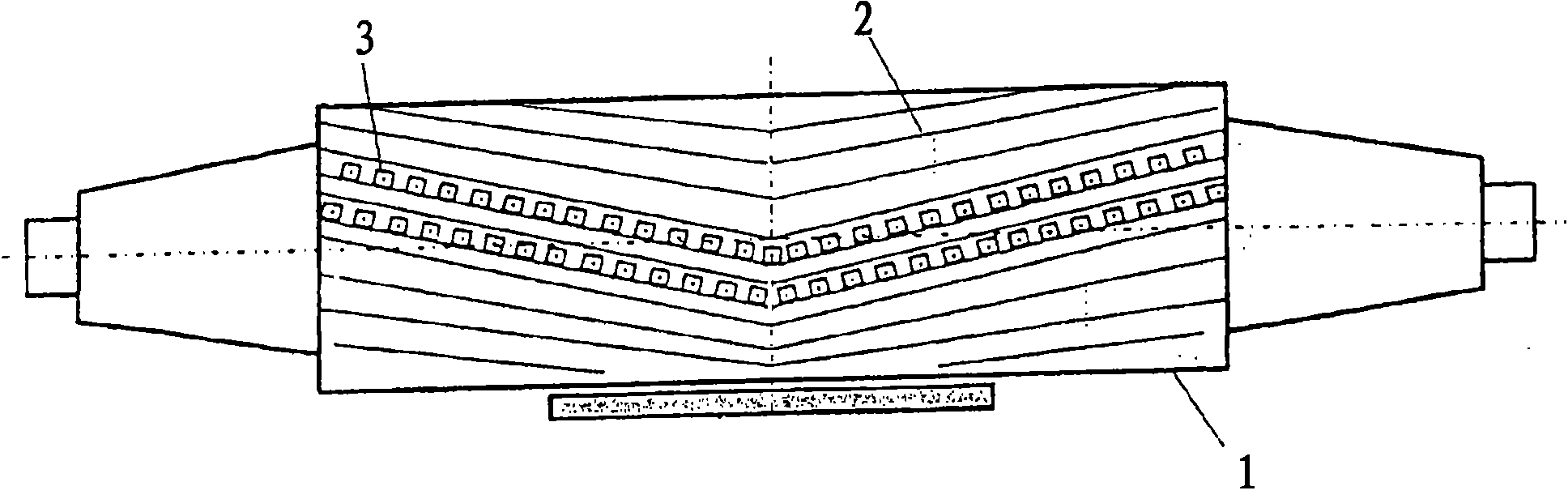

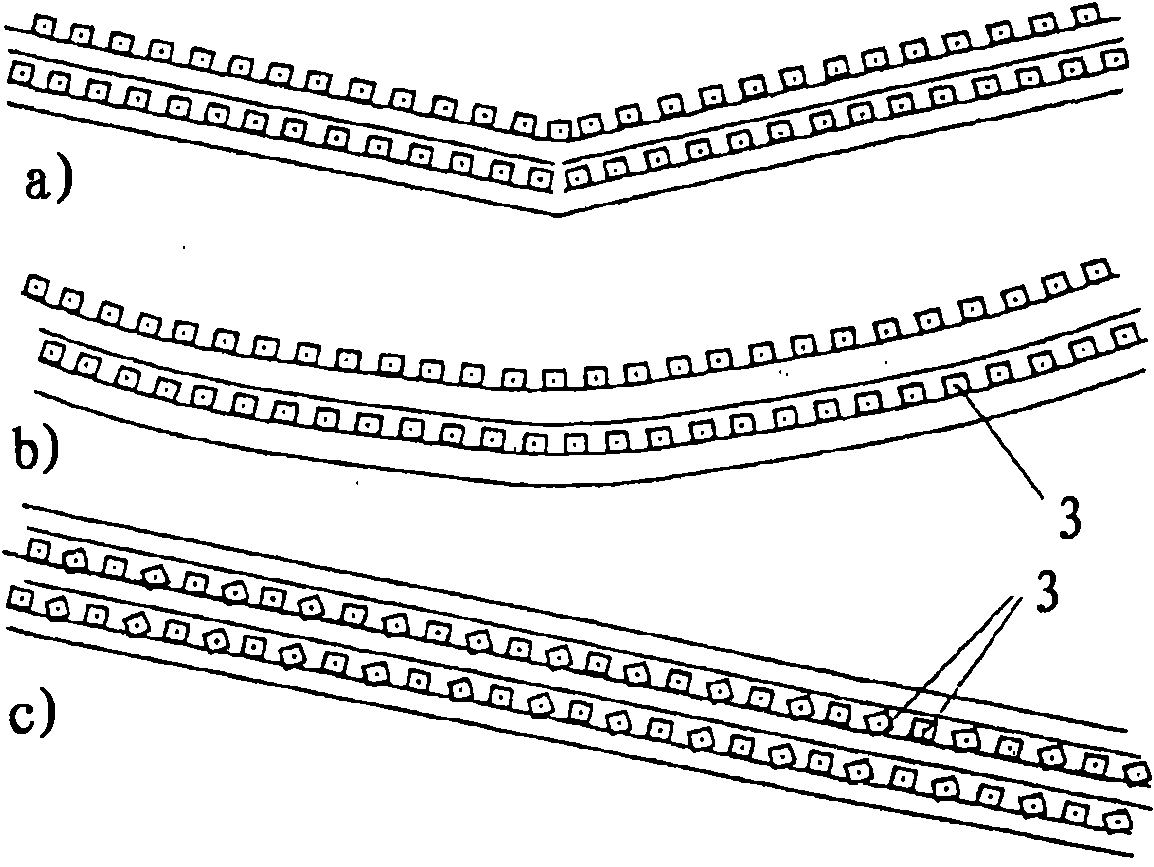

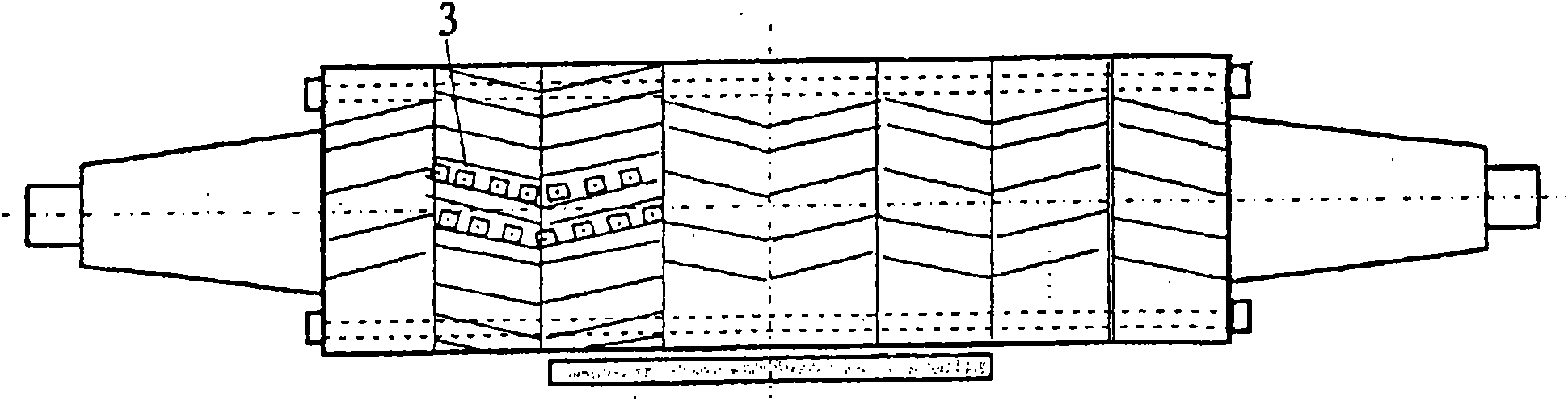

[0030] according to figure 1 In the embodiment shown in , the cylindrical milling cutter comprises a roller body 1, which has a plurality of grooves 2 made in a helical manner on the entire roller circumference for two half-rollers respectively, in which a plurality of indexable inserts are fixed 3. Details which relate neither to fastening nor to roller bearings are not shown, since these are not necessary for understanding here. The cutting edges of the indexable inserts are here arranged or oriented almost in the shape of an arrow. Axial force components are counteracted by a symmetrical arrangement (ie positioning of the cutting edges not only to the left but also to the right), so that the axial forces are minimal (special bead case=0). In the milling machine, the guide for the strip can thus be formed in a simple manner with a small installation space and can be subjected to low loads. Furthermore, in this embodiment the chip splash is directed approximately to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com