Double steel back lining lubricating pump

An oil pump and steel back technology, applied in the direction of pumps, pump components, mechanical equipment, etc., can solve problems such as occlusion and burning, and achieve the effect of improving friction, preventing scratches, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

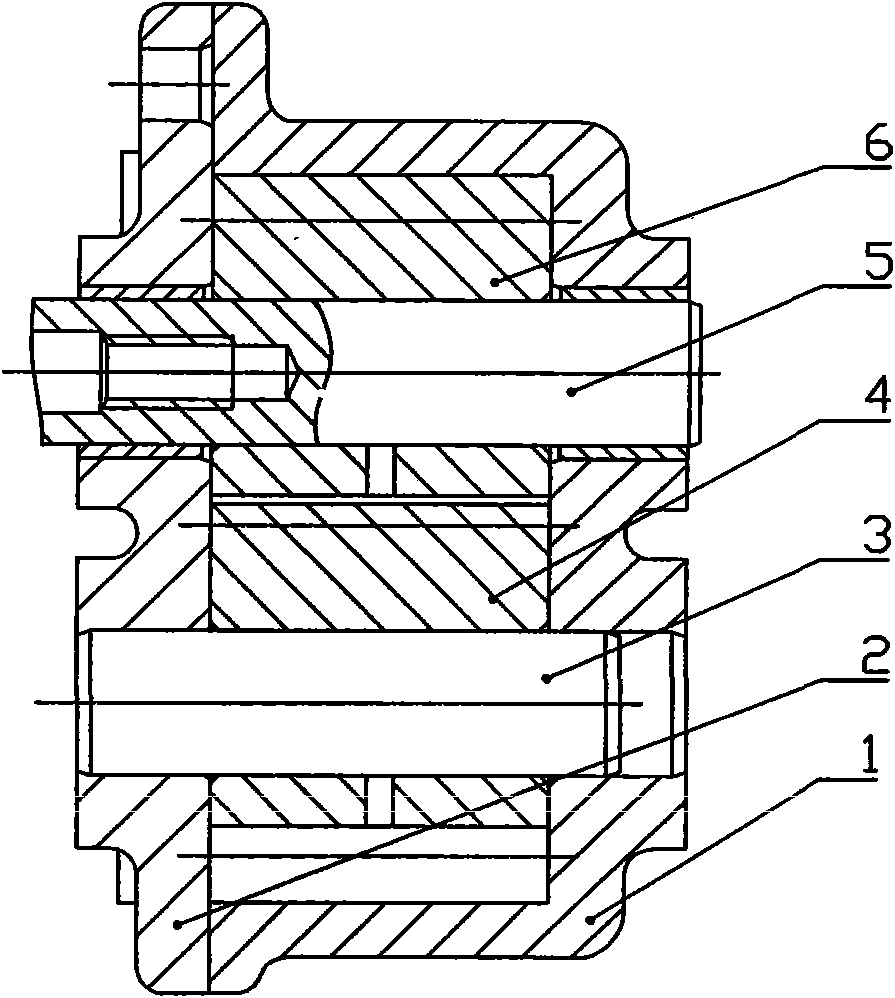

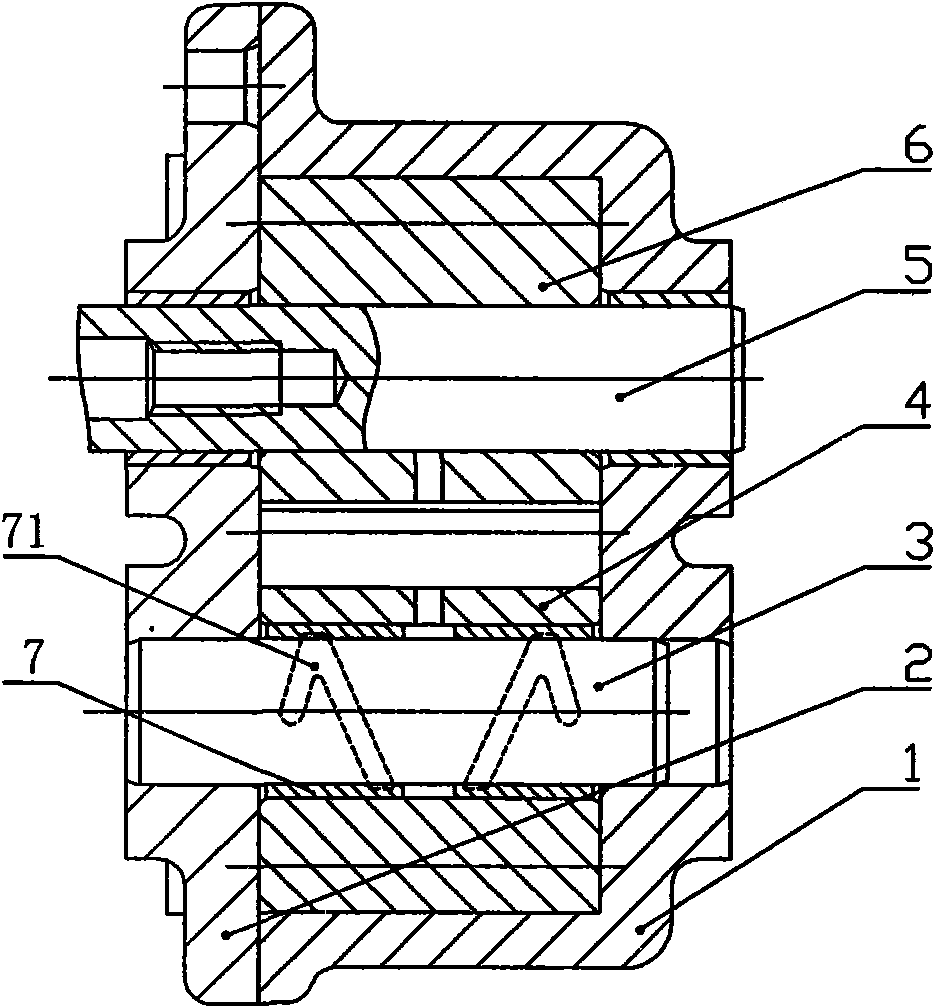

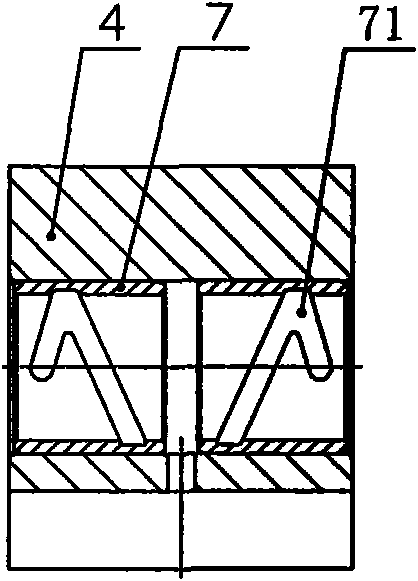

[0013] Such as figure 2 As shown, a double steel back bushing oil pump includes a pump body 1, a pump cover 2, a driven shaft 3, a driven gear 4, a driving shaft 5, a driving gear 6 and a steel back bushing 7; the driven shaft 3 The outer end is in an interference connection with the pump cover 2, and the inner end is installed in the shaft hole of the pump body 1. The driven gear 4 is sleeved on the driven shaft 3 through two steel back bushings 7 with balance oil grooves 71 on the inner surface. The middle part of the driven gear 4, that is, at both ends of the shaft hole of the driven gear 4, is equipped with a steel backing sleeve 7 with a balancing oil groove 71 that can prevent outward movement. The inner surfaces of the two steel backing sleeves 7 are provided The direction of the balance oil groove 71 is opposite (e.g. image 3 (Shown), can make the steel backing sleeve 7 generate inward thrust when rotating, and balance with the outward pushing force of the pressure oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com