Combined position board hammer of reaction crusher capable of rapidly changing wear position and manufacturing method thereof

A technology of impact crusher and combined plate, which is applied in the fields of casting and molding equipment, grain processing, etc., can solve the problems that it is difficult to meet the material requirements of impact crusher blow bar, a lot of time and manpower, complex dynamic balance inspection, etc., to achieve The mating connection is firm and reliable, the cost is reduced, and the effect of overcoming the axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

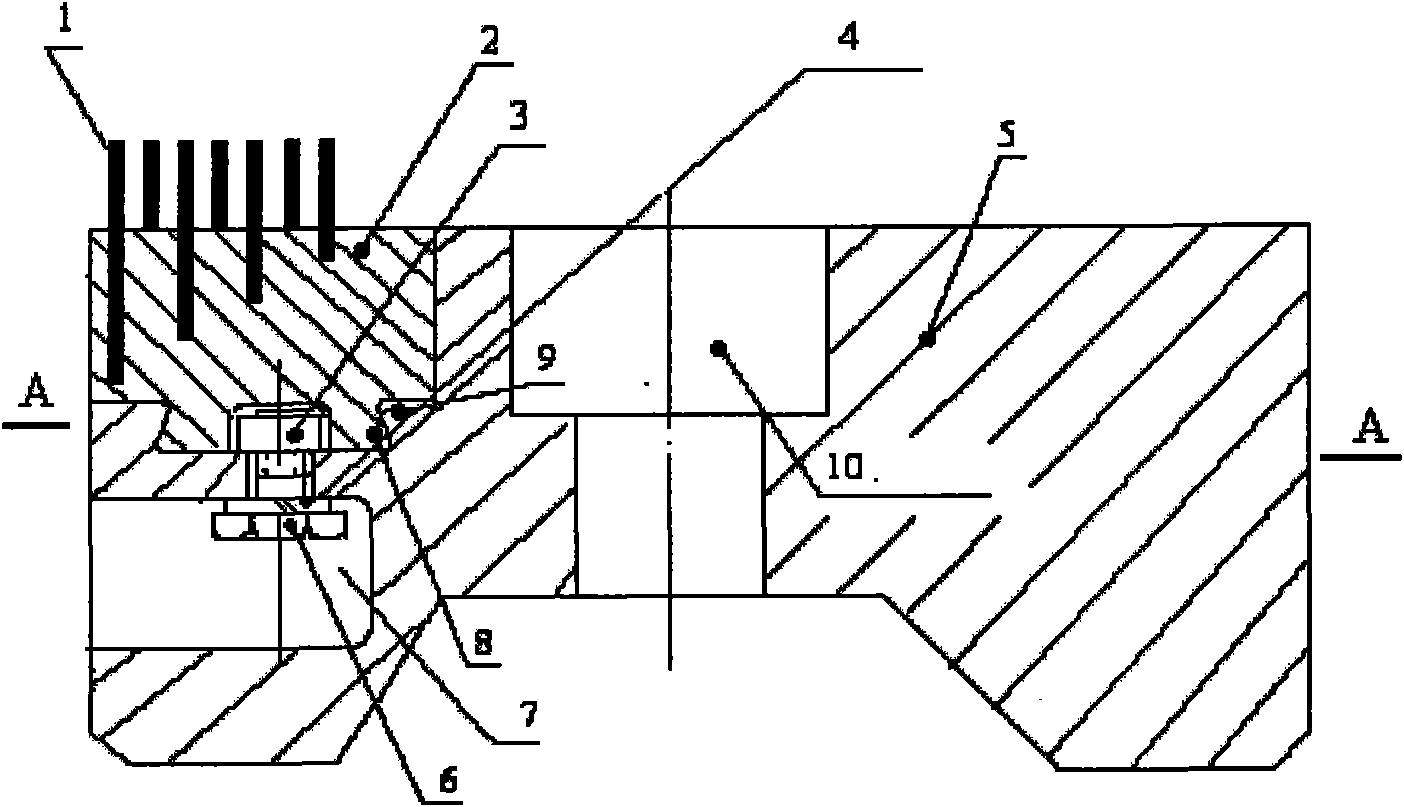

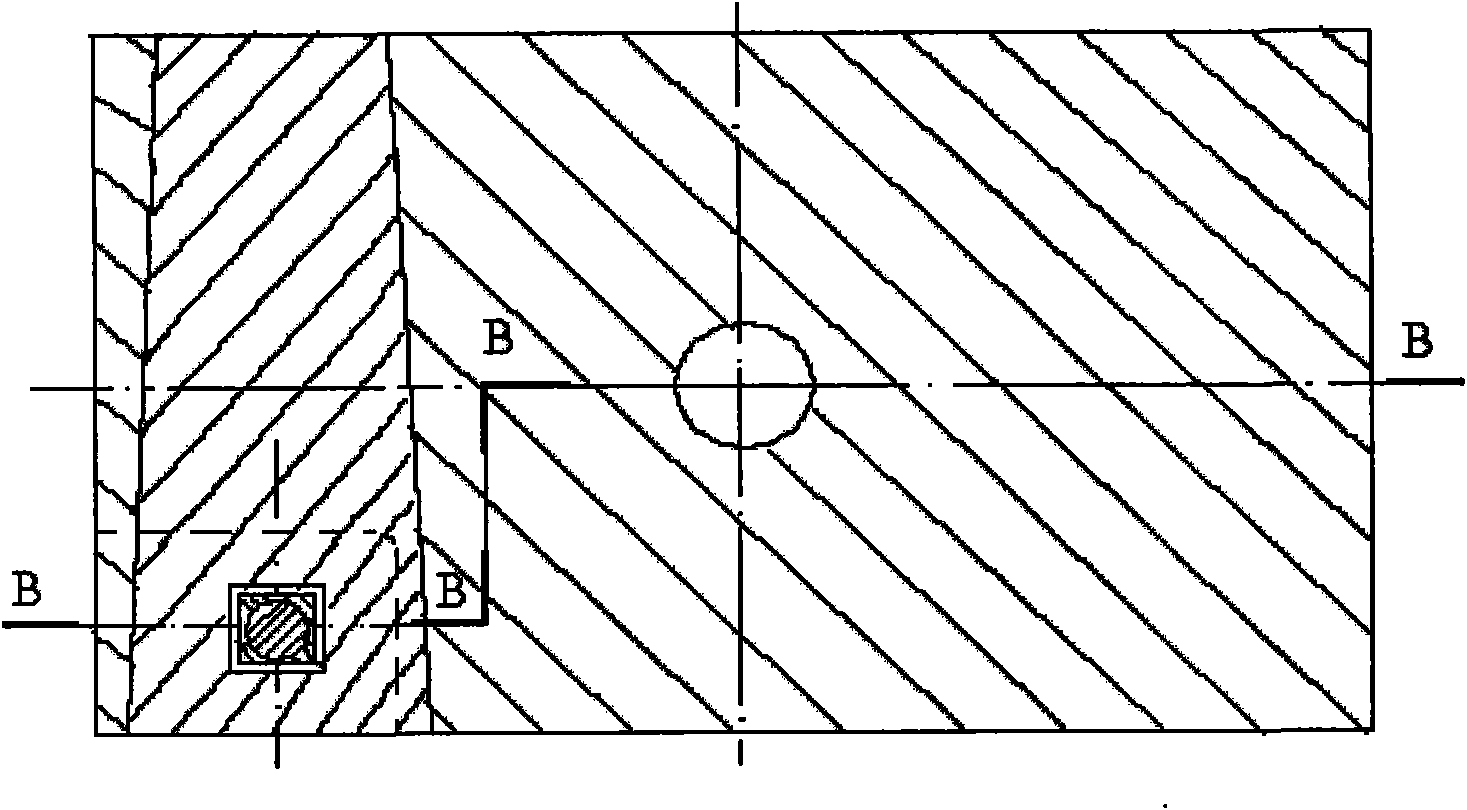

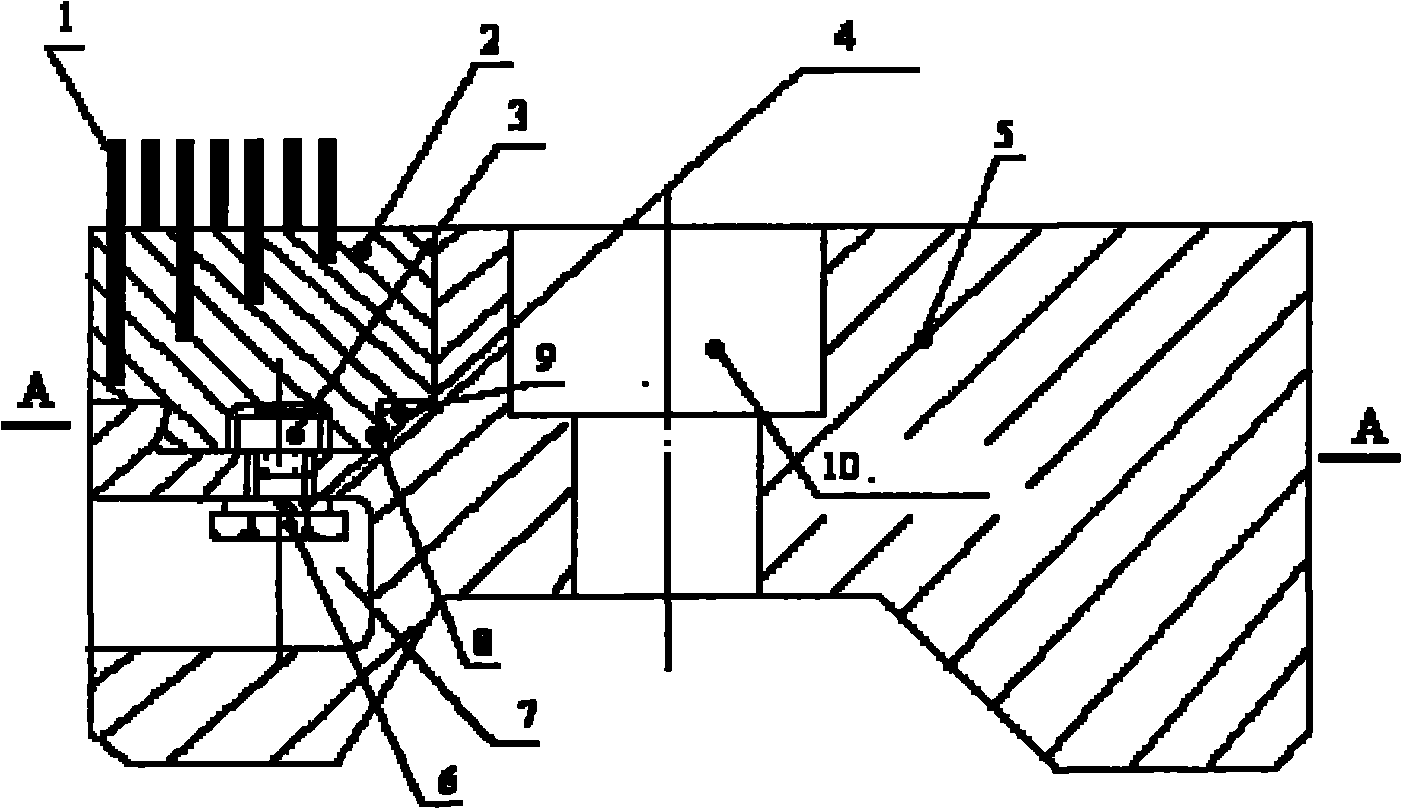

[0022] Example 1: To produce a T-shaped blow bar with a unit weight of 600N. The combined wear-resistant strip and the blow bar body of the blow bar are all cast from high-chromium cast iron, and the mass fraction of the chemical composition of the high-chromium cast iron is: C 2.92% , Si 0.52%, S 0.03%, P0.04%, Mn 0.77%, Cu 0.48%, Cr 25.24%, Ni 0.49%, V 0.12%, RE 0.11%, Fe 69.28%; The worn parts are inlaid with YG20 cemented carbide rods. The alloy rods are purchased parts with a diameter of 5mm. The mass fraction of its chemical composition is: WC 80%, binder 20%, and its performance is: density / t.m -3 13.4~13.8, bending strength / Mpa2400~2480, hardness (HRA)80~83.5.

[0023] The manufacturing method of the blow bar of the present invention, the manufacturing method comprises the production process of the blow bar body and the combined wear-resistant strip high-chromium cast iron, the lost foam casting process, the heat treatment process and the blow bar assembly process; whe...

Embodiment 2

[0024] Example 2: To produce a T-shaped blow bar with a unit weight of 500N. The combined wear-resistant strip and the blow bar body of the blow bar are cast from high-chromium cast iron. The mass fraction of the chemical composition of the high-chromium cast iron is: C 3.16% , Si 0.71%, S 0.03%, P0.05%, Mn 0.87%, Cu 0.57%, Cr 25.95%, Ni 0.55%, V 0.17%, RE 0.13%, Fe 67.81%; The worn parts are inlaid with YG20 cemented carbide rods. The alloy rods are purchased parts with a diameter of 4mm. The mass fraction of its chemical composition is: WC 80%, binder 20%, and its performance is: density / t.m -3 13.4~13.8, bending strength / Mpa2400~2480, hardness (HRA)80~83.5.

[0025] The manufacturing method of the blow bar of the present invention, the manufacturing method comprises the production process of the blow bar body and the combined wear-resistant strip high-chromium cast iron, the lost foam casting process, the heat treatment process and the blow bar assembly process; wherein, th...

Embodiment 3

[0026] Example 3: To produce a T-shaped blow bar with a unit weight of 400N. The combined wear-resistant strip and the blow bar body of the blow bar are cast from high-chromium cast iron, and the mass fraction of the chemical composition of the high-chromium cast iron is: C 3.32% , Si 0.84%, S 0.05%, P0.06%, Mn 0.99%, Cu 0.64%, Cr 26.87%, Ni 0.68%, V 0.24%, RE 0.14%, Fe 66.17%; The worn parts are inlaid with YG20 cemented carbide rods. The alloy rods are purchased parts with a diameter of 3mm. The mass fraction of its chemical composition is: WC 80%, binder 20%, and its performance is: density / t.m -3 13.4~13.8, bending strength / Mpa2400~2480, hardness (HRA)80~83.5.

[0027] The manufacturing method of the blow bar of the present invention, the manufacturing method comprises the production process of the blow bar body and the combined wear-resistant strip high-chromium cast iron, the lost foam casting process, the heat treatment process and the blow bar assembly process; wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com